Table of Contents

Advertisement

Quick Links

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thought-

ful operation on your part. DO

NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT

READING

THIS

MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED

THROUGHOUT. And, most

importantly, think before you act

and be careful.

This manual covers equipment which is no

longer in production by The Lincoln Electric Co.

Speci cations and availability of optional

features may have changed.

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

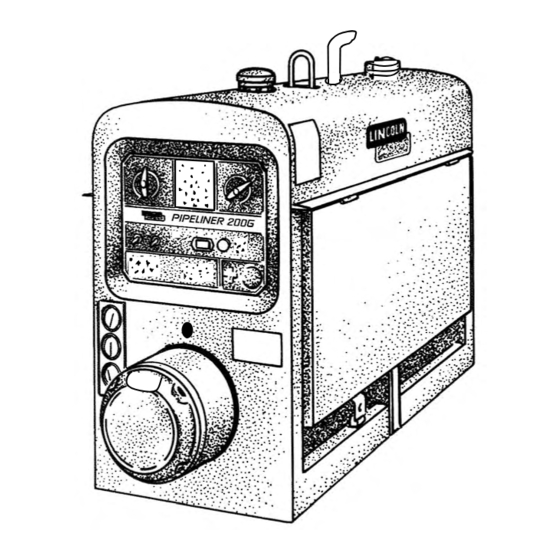

PIPELINER 200G

For use with machines having Code Numbers 10660; 10913; 11136

OPERATOR'S MANUAL

• World's Leader in Welding and Cutting Products •

Copyright © 2004 Lincoln Global Inc.

IM698-B

December, 2004

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln Electric PIPELINER 200G

- Page 1 THROUGHOUT. And, most importantly, think before you act and be careful. This manual covers equipment which is no longer in production by The Lincoln Electric Co. Speci cations and availability of optional features may have changed. OPERATOR’S MANUAL Copyright © 2004 Lincoln Global Inc.

-

Page 2: California Proposition 65 Warnings

351040, Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS. -

Page 3: Electric Shock Can Kill

MSDS forms are available from your welding distributor or from the manufacturer. 3.j. Also see Items 6.c. and 8. 5.e. Also see item 1.b. Mar ‘95 PIPELINER 200G... - Page 4 This can create fire hazards or overheat lifting chains Electrical Code, all local codes and the manufacturer’s or cables until they fail. recommendations. 6.h. Also see item 1.c. 8.c. Ground the equipment in accordance with the U.S. National Electrical Code and the manufacturer’s recommendations. Mar ‘95 PIPELINER 200G...

- Page 5 Se protéger avec des vêtements de protection libres de l’huile, tels que les gants en cuir, chemise épaisse, 4. Garder tous les couvercles et dispositifs de sûreté à leur pantalons sans revers, et chaussures montantes. place. Mar. ‘93 PIPELINER 200G...

- Page 6 The code number is especially important when identifying the correct replacement parts. On-Line Product Registration - Register your machine with Lincoln Electric either via fax or over the Internet. • For faxing: Complete the form on the back of the warranty statement included in the literature packet accompanying this machine and fax the form per the instructions printed on it.

-

Page 7: Table Of Contents

TABLE OF CONTENTS Page Installation ......................Section A Technical Specifications ..................A-1 Safety Precautions....................A-1 Exhaust Spark Arrester..................A-2 Location / Ventilation.....................A-2 Machine Grounding ....................A-2 Angle of Operation....................A-3 Lift Bail ........................A-3 Trailers........................A-3 Vehicle Mounting ....................A-3 Polarity Control and Cable Sizes ................A-3 Pre-Operation Service ...................A-4 Oil... -

Page 8: Installation

INSTALLATION TECHNICAL SPECIFICATIONS - Pipeliner 200G (K6090-7) INPUT - GASOLINE ENGINE Make/Model Description Speed (RPM) Displacement Ignition Capacities cu. in. (Ltrs.) System High Idle 1600 Delco Voyager Fuel: 15 gal. 4 Cylinder High Energy 57 Ltrs. 4 Cycle 3.0 Liter... -

Page 9: Safety Precautions

The U.S. ---------------------------------------------------------------------- National Electrical Code lists a number of alternate means of grounding electrical equipment. A machine grounding stud marked with the symbol is provid- ed on the front of the welder. PIPELINER 200G... -

Page 10: Angle Of Operation

4. Typical conditions of use, i.e., travel speed; rough- ness of surface on which the trailer will be operat- ed; environmental conditions; likely maintenance. PIPELINER 200G... -

Page 11: Pre-Operation Service

Engine Operator’s Manual. Make sure fuel valve on the sediment bowl is in the open position. The Pipeliner 200G is equipped with a wet charged battery. The charging current is automatically regulat- ed when the battery is low (after starting the engine) to a trickle current when the battery is fully charged. -

Page 12: Operation

ENGINE EXHAUST can kill. • Use in open, well ventilated areas or Welding Generator vent exhaust outside. The Pipeliner 200G uses the old style, round, all cop- ------------------------------------------------------------------------ per FJW Generator frame which provides the cus- MOVING PARTS can injure. -

Page 13: Engine Operation

DUTY CYCLE “Auto” position , engine will run at 1600 RPM until engine coolant temperature reaches 130°F. The NEMA output rating of the Pipeliner 200G is 200 amperes at 28 arc volts on a 60% duty cycle. Duty cycle is based on a ten minute period; thus, the welder can be loaded at rated output for six minutes out of every ten minute period. -

Page 14: Control Of Welding Current

(to a maxi- mum of 2000 RPM) for up to 10 seconds after throttle body icing conditions have occurred. The electronic governor will correct itself for the new operating condi- tions and normal operation will resume. PIPELINER 200G... -

Page 15: Accessories

100 ft (30.5m) cable. Easy Installation. REMOTE CONTROL (K2464-1) - Contains remote control rheostst (for adjusting the CC “STICK” OCV), remote control potentiometer (for adjusting the CV “WIRE” OCV), and 100 ft. (30.5m) cable. Easy Installation> PIPELINER 200G... -

Page 16: Maintenance

COOLING SYSTEM MOVING PARTS can injure. • Do not operate with doors open or The Pipeliner 200G is equipped with a pressure radia- guards off. tor. Keep the radiator cap tight to prevent loss of • Stop engine before servicing. -

Page 17: Bearings

After stoning, blow out the dust with low pressure air. PIPELINER 200G... -

Page 18: Engine Service Chart

(4) Clean the air filter if the engine is operating in very dusty conditions. Above operations to be carried out by trained personnel with reference to the workshop manual where necessary. These preventive maintenance periods apply to average conditions of operation. S20919-3 If necessary use shorter periods. PIPELINER 200G... -

Page 19: Troubleshooting

• Only qualified personnel should install, use or service this equipment. Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. - Page 20 2. Polarity may be wrong. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. PIPELINER 200G...

- Page 21 CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. JULY97 PIPELINER 200G...

- Page 22 11. Faulty function of the engine. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. PIPELINER 200G...

- Page 23 2. Incorrect timing. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. PIPELINER 200G...

- Page 24 Authorized Field Service Facility. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. PIPELINER 200G...

-

Page 25: Troubleshooting Guide

Not O.K. Correct wiring CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. PIPELINER 200G... - Page 26 DIAGRAMS PIPELINER 200G...

- Page 27 DIAGRAMS PIPELINER 200G...

- Page 28 DIAGRAMS K2464-1 REMOTE CONTROL WIRING / CONNECTION DIAGRAM CV "WIRE" CONTROL POT RESISTORS CC "STICK CONTROL BLUE ORANGE CABLE CONNEC TION TABLE LEAD COLOR ORANGE BLUE REMOTE CONTROL BOX WHITE JUMPER CONNECT TO CASE WHITE JUMPER S26097 PIPELINER 200G...

-

Page 29: Diagrams

DIAGRAMS PIPELINER 200G... - Page 30 NOTES PIPELINER 200G...

- Page 31 NOTES PIPELINER 200G...

- Page 32 Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. WARNING electrode with skin or wet clothing. Insulate yourself from work and ground. Spanish No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el AVISO DE bajo carga con la piel o ropa moja-...

- Page 33 Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or Use ventilation or exhaust to guards off. WARNING remove fumes from breathing zone. Spanish Los humos fuera de la zona de res- Desconectar el cable de ali- No operar con panel abierto o AVISO DE...

- Page 34 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...

Need help?

Do you have a question about the PIPELINER 200G and is the answer not in the manual?

Questions and answers