Table of Contents

Advertisement

Quick Links

Printed in Japan

99610-15130

Pub. No.

OPERATION &

MAINTENANCE MANUAL

The operator and supervisor are requested to read this Oper-

ation and Maintenance Manual carefully before operating the

engine or conducting inspection and maintenance.

Never operate the engine or conduct maintenance work with-

out completely understanding this manual.

November 2007

99610-15130

Pub. No.

Advertisement

Table of Contents

Summary of Contents for Mitsubishi Heavy Industries L2E

- Page 1 OPERATION & MAINTENANCE MANUAL The operator and supervisor are requested to read this Oper- ation and Maintenance Manual carefully before operating the engine or conducting inspection and maintenance. Never operate the engine or conduct maintenance work with- out completely understanding this manual. November 2007 99610-15130 Pub.

- Page 3 FOREWORD This operation and maintenance manual contains detailed operation, inspection and maintenance information for Mitsubishi engines. Please read this manual thoroughly before proceeding with operation, inspection, and maintenance work for correct use and servicing. Failure to follow directions in this manual may result in serious accidents. Pub.

-

Page 4: Limited Warranty

FOREWORD Limited warranty The manufacturer will repair or replace parts returned to the manufacturer when the manufacturer judges after inspection that the parts are defective in material and/or workmanship. The manufacturer's warranty is limited to the repair work or replacement of parts for the defective parts only. The warranty coverage is effective for the original purchaser only. -

Page 5: Warranty Coverage

Protection Agency. Warranty coverage Mitsubishi Heavy Industries warrants to the first owner and each subsequent purchaser of a new L series diesel engine that the emission control system of your engine: • is designed, built and equipped so as to conform at the time of sales with all applicable regulation of the U.S Envi- ronmental Protection Agency. -

Page 6: Important Information

Mitsubishi dealer as soon as possible. formed or must not be performed, it is impossible to • Mitsubishi Heavy Industries recommends the indicate every caution in this manual or on warning engine owner to install an hourmeter on the engine labels. - Page 7 FOREWORD Warning Indication The following two means are used to call the attention of the operators and maintenance personnel to potential dan- gers of the engine. • Warning statements in the manual • Warning labels affixed on the engine Warning statements The warning statements in this manual describe potential danger in operating, inspecting or maintaining the engine, using the following five classifications to indicate the degree of potential hazard.

- Page 8 FOREWORD Units of measurement Measurements are based on the International System of Units (SI), and they are converted to the metric system units in this manual using the following conversion rates. • Pressure: 1 MPa = 10.197 kgf/cm • Torque: 1 N⋅m = 0.10197 kgf⋅m •...

-

Page 9: Table Of Contents

Use only specified fuel, L2E Left view............ 2-1 engine oil and long-life coolant (LLC)....1-4 L2E Right view ..........2-1 Handle LLC (long life coolant) carefully ... 1-4 L3C,L3E Left view ..........2-2 Proper disposal of waste oil and coolant (LLC) 1-4 L3C,L3E Right view.......... - Page 10 CONTENTS Automatic glow type..........2-3 Main properties of engine oil....5-1 Manual glow type............2-3 Dispersibility ............. 5-1 Water temperature meter and thermo unit ..2-3 Acid neutralization ability........5-1 Ammeter............2-4 Viscosity ............5-1 Hour meter ............2-4 Recommended engine oil ....5-2 Stop solenoid ...........

- Page 11 CONTENTS Chapter 8 Chapter 9 PERIODIC INSPECTION AND LONG-TERM STORAGE MAINTENANCE PROCEDURES Long-term storage....... 9-1 Storing the engine in a non-operable Every 50 service hours ......8-1 condition for 3 months or more ... 9-1 Draining water from the fuel tank ..... 8-1 Preparation for storage ........

- Page 12 CONTENTS Chapter 12 List of Illustrations MAIN SPECIFICATIONS Fig. 2-1 Engine left view(L2E).........2-1 Main specifications ......12-1 Fig. 2-2 Engine right view(L2E).......2-1 Fig. 2-3 Engine left view(L3C,L3E) ......2-2 Fig. 2-4 Engine right view(L3C,L3E) .......2-2 Fig. 2-5 Starter switch ..........2-3 Fig. 2-6 Preheat indicator........2-3 Fig.

- Page 13 CONTENTS Fig. 8-12 Changing solenoid fuel pump filter.... 8-8 List of Tables Fig. 8-13 Checking starter........8-9 Table 3-1 Pre-heating duration Fig. 8-14 Inspecting alternator ......... 8-9 (automatic grow plug)......3-4 Fig. 8-15 Radiator cap..........8-10 Table 3-2 Pre-heating duration Fig. 8-16 Draining coolant (radiator) ...... 8-10 (manual grow plug).........3-4 Fig.

-

Page 15: Basic Safety Precautions

Chapter 1 BASIC SAFETY PRECAUTIONS Fire and explosion Keep flames away Prevent electrical wires from short-circuiting Store fuel and engine oil in a well ventilated designated area. Avoid inspecting or servicing the electrical system with Make sure that the caps of fuel and the ground cable connected to the battery. -

Page 16: Stay Clear Of All Rotating And Moving Parts

Chapter 1 BASIC SAFETY PRECAUTIONS Stay clear of all rotating and moving parts Install protective covers around Lockout and Tagout rotating parts Be sure to lockout and tagout before starting inspec- Make sure the protective covers of tion and maintenance. the engine are correctly installed. -

Page 17: Be Careful Of Exhaust Fume Poisoning

Chapter 1 BASIC SAFETY PRECAUTIONS Be careful of exhaust Be careful of falling down fume poisoning Lift engine carefully To lift the engine, always use a Operate the engine in a well- correct wire rope capable of with- ventilated area standing the engine weight. -

Page 18: Be Careful Of Burns

Chapter 1 BASIC SAFETY PRECAUTIONS Be careful of burns Be careful of handling fuel, engine oil and LLC Do not touch engine during or immediately after operation Use only specified fuel, engine To avoid burns, do not touch the oil and long-life coolant (LLC) engine during or immediately after Use fuel, oil and LLC specified in this manual, and operation. -

Page 19: Service Battery

Chapter 1 BASIC SAFETY PRECAUTIONS Service battery When abnormality occurs Handle the battery correctly Do not add coolant immediately • Never use flames or allow after a sudden stop due to over- sparks to generate near the bat- heating tery. The battery releases flam- If the engine stops suddenly or if you have no choice mable hydrogen gas and but to stop the engine suddenly due to overheating, do... -

Page 20: Other Cautions

Chapter 1 BASIC SAFETY PRECAUTIONS Other cautions Never modify engine Warm up the engine before use Unauthorized modification of the engine will void the When starting auxiliary devices, such as a water manufacturer's warranty. heater and an engine oil priming pump, are not Modification of the engine may not only cause engine installed, let the engine idle for 5 to 10 minutes before damage but also produce personal injuries. -

Page 21: Properly Maintain The Air Cleaner And Pre-Cleaner

Chapter 1 BASIC SAFETY PRECAUTIONS Properly maintain the air Use of tools optimum for each cleaner and pre-cleaner work The major cause of abnormal wear on engine parts is Always keep in mind to select most appropriate tools dust from intake air. Worn parts produce many prob- for the work to be performed and use them correctly. -

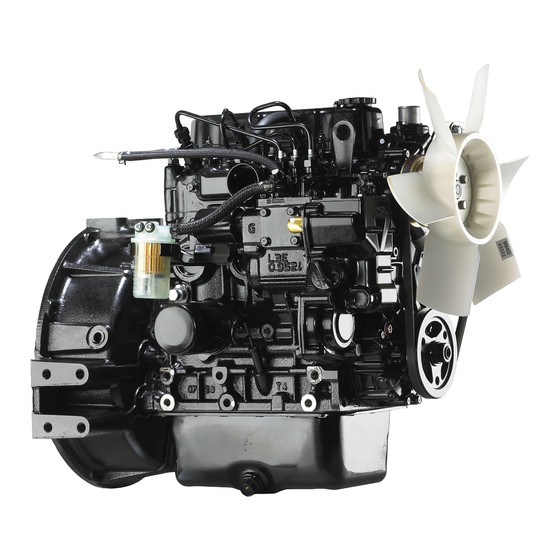

Page 23: Names Of Parts

Engine external diagrams The external diagram is for the standard type of the engine.The installed equipment and shapes differ according to the engine type. L2E Left view Fig. 2-1 Engine left view(L2E) L2E Right view Fig. 2-2 Engine right view(L2E) -

Page 24: L3C,L3E Left View

Chapter 2 NAME OF PARTS L3C,L3E Left view Fig. 2-3 Engine left view(L3C,L3E) L3C,L3E Right view Fig. 2-4 Engine right view(L3C,L3E) -

Page 25: Equipment And Instrument

Chapter 2 NAMES OF PARTS Equipment and instrument Described below is for standard equipment of this engine. The installed equipment and shapes differ on the engine type. Starter switch The starter switch is used to start the engine. HEAT When the key is turned to this position, the glow plugs become hot and allow easy startup of a cold engine. -

Page 26: Ammeter

Chapter 2 NAMES OF PARTS Ammeter The ammeter shows the charging condition of battery when the engine is running. The indicator needle swings to the positive ( + ) side when battery is charged and to the negative (-) side when the battery is discharged. -

Page 27: Engine Protection Devices

Chapter 2 NAMES OF PARTS Engine protection devices Oil pressure switch The oil pressure switch activates the alarm system when the engine oil pressure becomes abnormally low. Fig. 2-11 Oil pressure switch Thermo switch The thermo switch is equipped to prevent the engine from overheating when the coolant temperature rises high. -

Page 29: Preparations For Operation

Chapter 3 OPERATION Preparations for operation Should an engine abnormality be observed during operation, stop the engine and correct the problem, or contact a Mitsubishi dealer. Always conduct the following inspection before starting the engine. External inspection Be sure to keep combustible materials away from the engine, especially from the hot engine parts such as exhaust manifolds, or the battery. -

Page 30: Checking The Fuel Tank Oil Level

Chapter 3 OPERATION Checking the fuel tank oil level When working around fuel, make sure there are no open flames, heaters or other fire hazards. Wipe off any spilled fuel completely. Spilled fuel can ignite and cause a fire. Do not remove the strainer when filling the fuel tank. For fuel to be used, refer to "FUEL"... -

Page 31: Checking The Coolant Level

Chapter 3 OPERATION Checking the coolant level Remove the radiator cap only after the engine has cooled to room temperature. Place a cloth over the cap, and loosen the cap about a half-turn or stand the lever to the upright position to release internal pres- sure. -

Page 32: Starting

Chapter 3 OPERATION Starting Automatic grow plug The starting method changes based on the application 1. Turn the starter key to "ON" position. and specifications. Start the engine according to the And make sure that oil pressure, water tempera- specified procedure. ture and pre-heating lamps are lit. -

Page 33: Warming-Up Operation

Chapter 3 OPERATION Warming-up operation Do not approach rotating parts during operation. Entanglement by rotating parts can cause serious injury. Do not conduct warm-up operation for a prolonged period of time. Prolonged warm-up operation causes carbon buildup in the cylinders that leads to incomplete combustion. Do not turn the battery switch to OFF. -

Page 34: Operation

Chapter 3 OPERATION Operation Inspection during operation Carefully check the exterior of engine such as piping joints for leaks. Do not approach rotating parts during operation. Check for abnormal engine noises or vibrations such Entanglement by rotating parts can cause serious as knocking. -

Page 35: Stopping

Chapter 3 OPERATION Stopping Stopping the engine suddenly during high speed operation creates a local abnormal high temperature rise, and shortens the service life of engine. Except in an emergency, be sure to conduct the cooling operation for 5 to 6 min- utes at low idling speed before stopping the engine. -

Page 37: Recommended Fuel

Chapter 4 FUEL Recommended fuel Use the recommended fuel specified in this manual. Do not refill the fuel tank more than the specified level, as it could result in a fire. Use a diesel oil that meets “JIS K2204, Diesel Oil” or its equivalent (ASTM D975,etc.). -

Page 39: Engine Oil

Chapter 5 ENGINE OIL Properties of engine oil Acid neutralization ability Compared to gasoline fuel, diesel oil produces more and its influence on sulfuric acid due to the high sulfur content in the fuel engine performance during combustion, and the sulfuric acid contaminates Engine oil lubricates the engine and greatly influences the oil. -

Page 40: Recommended Engine Oil

Chapter 5 ENGINE OIL Recommended engine oil Use only the engine oils recommended in this manual. Never use other oils. The use of inappropriate or inferior oils will result in sticking of piston rings, seizure between piston and cylinder, or premature wear of bearings and moving parts, and significantly shortens the service life of the engine. -

Page 41: Other Brands Of Engine Oil

Chapter 5 ENGINE OIL Other brands of engine oil The quality and performance of commercially available oils as well as their components variations are the responsi- bility of engine oil suppliers. Before purchasing commercial oils, be sure to discuss the suitability of the engine oil with the oil supplier. -

Page 42: Service Limits Of Engine Oil

Chapter 5 ENGINE OIL Service limits of engine oil Engine oil degrades through the use and by lapse of time. Be sure to renew the engine oil if any of the properties below exceeds the limit. Table 5-1 Service limit for engine oil properties Property Service limit Test Method... -

Page 43: Recommended Water For Coolant

GLASSY long life coolant (Non-amine type)” as coolant. When using other brand LLCs by necessity, be sure to use the LLC that meets the Mitsubishi specification. Mitsubishi heavy industries, Ltd. disclaim the warranty calim con- cerning mulfunctions caused by the use of LLC that does not meet the Mitsubishi specification. -

Page 44: Other Brand Llcs

Chapter 6 COOLANT Other brand LLCs Standard for other brand Never mix genuine Mitsubishi LLC with other brand When using other brand LLCs by necessity, be sure to LLCs. Mixing with other brand LLCs degrades the per- use the LLC that meets following specification. Mit- formance of the genuine Mitsubishi LLC. -

Page 45: Llc Specification

Chapter 6 COOLANT LLC specification LLC shall examine according to JIS K2234 section 7 (examination methods), and satisfy this specification. General matters and the sample to the examination is shown in JIS K2234. Table 6-2 LLC specification Property Limit External Not precipitation Minimum 1.112 g/cm (20/20°C)[68/68°F]... - Page 46 Chapter 6 COOLANT Table 6-2 LLC specification Property Limit Aluminum, Cast Mass change iron, Steel, Brass, ±0.30 mg/cm Solder, Copper Test piece Not corrosion on surface excluding External of test piece after the between test piece and spacer. Discolora- examination tion is OK.

- Page 47 Chapter 6 COOLANT Table 6-2 LLC specification Property Limit -60 to 0 % Tensile strength change -40 to +20 % Elongation change silicon 0 to +40 % Volume change -20 to +10 % Hardness change 0 to +10 % Tensile strength change Rubber adaptabil- Acrylonitrile -15 to +15 %...

-

Page 48: Maintenance Of Llc

Chapter 6 COOLANT Maintenance of LLC Should coolant or LLC be accidentally swallowed, induce vomiting immediately and seek medical atten- tion. If LLC should enter eyes, flush immediately with plenty of water and seek medical attention. LLC is toxic. Never dispose of coolant containing LLC drained from engine into regular sewage. -

Page 49: Importance Of Llc

Chapter 6 COOLANT Importance of LLC Examples of abnormali- Today's trend is toward smaller and lighter engines ties caused by LLC offering greater output, lower fuel consumption and lower exhaust emission levels. Pitting of iron parts Conditions to which engine coolant is subjected, Amines are generally effective in suppressing the rust- therefore, are becoming severer due to longer operat- ing of ferrous metals, but they are said to cause prob-... -

Page 51: Maintenance Schedule

Chapter 7 MAINTENANCE SCHEDULE How to use the maintenance schedule Periodic inspection not only extends the service life of the engine but also serves to ensure safe operation. Be sure to conduct inspections and maintenance according to the maintenance schedule. The maintenance schedule shows the standard service intervals. -

Page 53: Periodic Inspection And Maintenance Procedures

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Every 50 service hours Draining water from the fuel tank When handling fuel, make sure there are no open flames or other fire hazards near the engine. Wipe off any spilled fuel completely. Spilled fuel can ignite and cause fire. Do not remove the strainer when filling the fuel tank. -

Page 54: Every 100 Service Hours

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Every 100 service hours Checking and cleaning solenoid fuel pump filter Make sure that any fire hazard is not around the work area when handling fuel. Wipe off spilled fuel thoroughly. It can cause a fire. 1. -

Page 55: Every 250 Service Hours

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Every 250 service hours Changing the engine oil and oil filter When draining oil or changing the oil filter, wear gloves. Hot engine oil and parts may cause burns. Do not dump waste oil. It is forbidden by law. Consult your Mitsubishi dealer for disposal of waste oil. Change engine oil and the oil filter at the same time. -

Page 56: Changing The Oil Filter

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Changing the oil filter Do not use any oil filter that has dents, as the filter may be damaged during operation, resulting in a fuel leakage and possible fire. To avoid damage to the filter, do not use a filter wrench. Tighten the filter by hand. 1. -

Page 57: Refilling Engine Oil

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Refilling engine oil 1. Make sure that the engine oil drain plug is closed. 2. Remove the oil filler cap. 3. Fill the engine oil pan with specified engine oil to the specified level. Note: For engine oil, refer to "ENGINE OIL"... -

Page 58: Inspecting V-Belt And Adjusting Belt Tension

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Inspecting V-belt and adjusting belt tension If defects such as cuts or surface separations are found on V-belt during inspection, replace V-belt. Keep oil and grease away from the belt, since they may cause the belt to slip and shorten the service life. Excessive V-belt tension can cause rapid wear of the alternator bearing and shorten the service life of the belt. -

Page 59: Every 400 Service Hours

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Every 400 service hours Changing fuel filter (Cartridge type) Make sure that any fire hazard is not around the work area when handling fuel. Wipe off spilled fuel thoroughly. It can cause a fire. 1. -

Page 60: Every 500 Service Hours

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Every 500 service hours Changing fuel filter element (Cock type) Make sure that any fire hazard is not around the work area when handling fuel. Wipe off spilled fuel thoroughly. It can cause a fire. 1. -

Page 61: Every 1000 Service Hours

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Every 1000 service hours Inspecting starters Check the exterior of the starters for damage. If the starters are dusty, blow dirt using compressed air. Note: If the starters are defective, consult a Mitsubishi dealer. -

Page 62: Every 2 Years

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Every 2 years Changing the coolant Do not remove the radiator cap until the engine has cooled to the room temperature. When removing the radiator cap, place a cloth over the cap, and loosen the cap about a half-turn or place the lever in the upright position to release internal pressure. -

Page 63: Refilling The Coolant

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Refilling the coolant 1. Make sure drain cocks and plugs are closed tightly. 2. Remove the radiator cap, and pour in undiluted LLC. Note: Determine the amounts of LLC and water to be added by using the LLC concentration chart. -

Page 64: When Required

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES When required Cleaning, inspecting, and replacing the air cleaner ele- ment Never service the air cleaner while the engine is run- ning. Servicing the air cleaner while the engine is in operation can cause particles of foreign matter to enter the engine and result in rapid wear of parts, leading to a shorter service life of the engine. -

Page 65: Bleeding The Fuel System

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Bleeding the fuel system Make sure that any fire hazard is not around the work area when handling fuel. Wipe off spilled fuel thoroughly. It can cause a fire. After cleaning or replacing fuel system components, bleed the components. Note: Air trapped in the fuel injection pipe and nozzle is automatically exhausted when cranking the engine. -

Page 66: Draining Water Sedimenter

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Draining water sedimenter Make sure that any fire hazard is not around the work area when handling fuel. Wipe off spilled fuel thoroughly. It can cause a fire. 1. Clean around the water sedimenter. 2. -

Page 67: Long-Term Storage

Chapter 9 LONG-TERM STORAGE Long-term storage The following describes how to store the engine in a Note :(a) Store the engine in a well-ventilated indoor non-operable condition for three months or more and area. in an operable condition for three months or more. (b) It is not necessary to drain coolant since it If the engine has been left unattended for three contains LLC. -

Page 68: Using The Engine After Storage

Chapter 9 LONG-TERM STORAGE Using the engine after storage Storing the engine in an 1. Remove the cover from the engine. operable condition for 3 2. Connect a fully charged battery. months or more 3. Remove the covers from the starters and alterna- tor. -

Page 69: Lift The Engine Carefully

Chapter 10 TRANSPORTATION Lift the engine carefully To lift the engine, use wire ropes, shackles and slings capable of supporting the weight of the engine. Attach slings to the hangers provided on the engine to lift the engine. Keep the engine balanced during lifting by considering the engine's center of gravity. -

Page 71: Troubleshooting

Chapter 11 TROUBLESHOOTING General precautions Contact your Mitsubishi dealer Cautions regarding parts han- for repair service dling Repairing a malfunctioning engine may require special Handle parts carefully. equipment or involve potentially dangerous work, When replacing parts, use only genuine parts by refer- except for relatively simple procedures such as the ring to the parts catalog. -

Page 72: How To Troubleshoot

Chapter 11 TROUBLESHOOTING How to troubleshoot The starter does not crank or cranks slowly, resulting in start failure Table 11-1 The starter does not crank or cranks slowly, resulting in start failure Cause Remedy Blown fuse Change fuse Faulty wiring connection between Connect wire correctly battery and starter switch Faulty wiring connection between... -

Page 73: Other Problems And Countermeasures11-3

Chapter 11 TROUBLESHOOTING Other problems and countermeasures Engine output is low Table 11-3 Engine output is low Cause Remedy Use engine oil of appropriate viscosity according to ambient temper- Engine oil viscosity too high ature. Refer to "ENGINE OIL" (5-1). Improper fuel Use proper fuel. -

Page 74: Exhaust Smoke Is Black Or Dark Gray

Chapter 11 TROUBLESHOOTING Exhaust smoke is black or dark gray Table 11-5 Exhaust smoke is black or dark gray Cause Remedy Improper fuel Use proper fuel. Refer to "FUEL" (4-1). Incorrect valve clearance Contact your local Mitsubishi dealer Faulty fuel feed pump Contact your local Mitsubishi dealer Low compression pressure Contact your local Mitsubishi dealer... -

Page 75: Engine Overheats

Chapter 11 TROUBLESHOOTING Engine overheats Table 11-8 Engine overheats Cause Remedy Radiator, heat exchanger leakage Contact your local Mitsubishi dealer Low coolant level Add coolant. Refer to "Checking the coolant level" (3-3). Faulty water pump Contact your local Mitsubishi dealer Faulty thermostat Contact your local Mitsubishi dealer Engine oil pressure is faulty... -

Page 77: Main Specifications

Chapter 12 MAIN SPECIFICATIONS Main specifications Table 12-1 Main specifications Engine model Type 4-cycle, water-cooled, vertical, diesel Number of cylinders, arrange- 2-in-line 3-in-line ment Bore×Stroke (mm [in.]) 76 × 70 [2.99 × 2.76] 70 × 70 [2.76 × 2.76] 76 × 70 [2.99 × 2.76] Total displacement (Liter [cu.in.]) 0.635 [38.7] 0.808 [49.3]...

Need help?

Do you have a question about the L2E and is the answer not in the manual?

Questions and answers