Summary of Contents for Endress+Hauser UniFit CPA 441

- Page 1 UniFit H BA 026C/07/en/06.99 No. 51500738 CPA 441 Process Assembly for pH/Redox Measurement Operating Instructions Quality made by Endress+Hauser Endress Hauser Nothing beats know-how ISO 9001...

- Page 2 Index ............. . . Endress+Hauser...

- Page 3 If you have any questions, consult your matter has been settled. supplier or the Endress+Hauser sales agency in your area (see back cover of Check that the delivery is complete and agrees these operating instructions for addresses).

- Page 4 Adapter 1.4571 (SS 316Ti) / DN 25, G 1¼ / oblique Adapter 1.4571 (SS 316Ti) / dairy fitting DN 40 Adapter 1.4571 (SS 316Ti) / Tri-Clamp 2" Adapter 1.4571 (SS 316Ti) / Varivent for DN 40 ... 125 (only version 14) CPA 441- complete order code Endress+Hauser...

- Page 5 • Repairs not described in these operating instructions may only • Check that all connections have be performed directly at the been properly made before manufacturer’s works or by powering up the system. the Endress+Hauser service organisation. Endress+Hauser...

- Page 6 The maximum operating pressure of the assembly must not be exceeded. • The system must be depressurised before installation or removal of the assembly. • Couplings, cocks and lines must be checked for leakage and damage at regular intervals. Endress+Hauser...

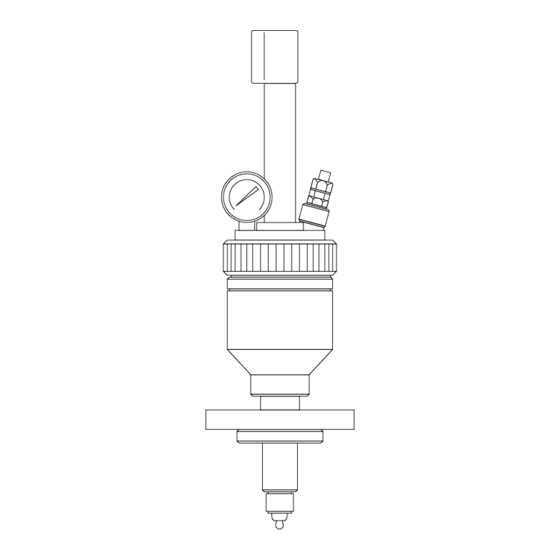

- Page 7 1 Taper fitting ∅ 75 2 Coupling nut F 40, ∅ 84 DIN 11851 ∅ 71 3 Electrode ∅ 42 ∅ 25 4 Protection guard ∅ 24 Â Mounting version: Varivent adapter 1 Clamp fitting 2 Electrode PA441-03.CDR AD-VV.CDR Endress+Hauser...

- Page 8 O-ring is properly seated and clean. The sealing surface of the built-in adapter must be protected against mechanical damage. To permit use in food applications, an Endress+Hauser built-in adapter should be used (see Fig. 3.4 and Fig. 3.5). ∅ 42 However, adapters from other manufacturers are basically usable as well.

- Page 9 Shake the electrode several times if required. • Should the assembly remain dry for an extended period after electrode installation, then the electrode tip must be kept moist, e.g. in KCl solution (3 mol/l). Endress+Hauser...

- Page 10 Screw the electrode connector into Screw the protection sleeve back on. Bend the measuring cable and the threaded plug-in head on the plug in the splash protection cap. electrode. Fig. 3.6 Electrode installation and mounting of measuring cable MOUNT04.CDR MOUNT05.CDR MOUNT06.CDR Endress+Hauser...

- Page 11 • Ensure by all means that no electrolyte penetrates the electrode head or the cable plug. • The compressed-air and manometer connections must not be flooded with electrolyte Fig. 3.8 Electrolyte filling level EL_LEVEL.CDR (see Fig. 3.8). Endress+Hauser...

- Page 12 To prevent a penetration of medium into the electrode, the electrolyte pressure must always exceed the medium pressure. Fig. 3.10 shows the electrolyte flow for various diaphragm types. Fig. 3.10 Dependance of the Ceramics Triple Fibre electrolyte flow on the ceramics diaphragm diaphragm type Endress+Hauser...

- Page 13 3% in the injector Sulfide deposits Mixture of hydrochloric acid (3%) and thiourea (saturated) Protein coatings Mixture of hydrochloric acid (3%) and pepsin (saturated) Fibres, suspended substances Pressure water, possibly containing wetting agents Light biological coatings Pressure water Endress+Hauser...

- Page 14 Check the electrode for mechanical damage. MEAS DIAG PARAM Immerse the electrode Perform the calibration Rinse the electrode with in buffer 2 (e.g. pH 4). on the measuring distilled water. instrument. MEAS DIAG PARAM Fig. 4.1 Calibration CAL.CDR Endress+Hauser...

- Page 15 Example of a suitable lubricant: ISOFLEX Topas AK 50 (art. no. 004151) Manufacturer: Klüber Lubrication KG, Munich • Any other interventions in and modifications of the assembly are impermissible and will void the warranty. Fig. 4.2 O-rings in the CPA 441 O_RINGS.CDR Endress+Hauser...

- Page 16 O-ring set Concentration, Volume Order code temp. range EPDM 50029766 100 ml CPY 4-1 3.0 mol, Viton 50043956 –10 ... 100 °C 1000 ml CPY 4-2 100 ml CPY 4-3 1.5 mol, –30 ... 100 °C 1000 ml CPY 4-4 Endress+Hauser...

- Page 17 Technical data UniFit H CPA 441 Technical data General data Manufacturer Endress+Hauser Product designation UniFit H CPA 441 Materials in contact with medium Electrode holder stainless steel 1.4571 (SS 316Ti) O-rings EPDM, Viton Materials not in contact with medium O-rings...

- Page 18 Junction box......15 Lubricants ......14 Endress+Hauser...

- Page 19 Philippines Poland Wien Samson Endress+Hauser Ltda. Brenton Industries Inc. Endress+Hauser Polska Sp. z o.o. Tel. (01) 8 80 56-0, Fax (01) 8 80 56-35 Sao Paulo Makati Metro Manila Warszawy Tel. (0 11) 5 36 34 55, Fax (0 11) 5 36 30 67 Belarus Tel.