Summary of Contents for Endress+Hauser Cleanfit CPA450 A Series

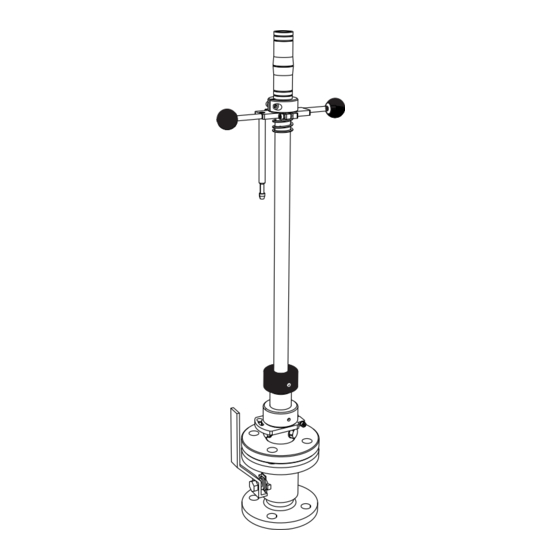

- Page 1 Products Solutions Services BA00183C/07/EN/14.18 71439248 2018-10-31 Operating Instructions Cleanfit CPA450 Retractable assembly for 12mm sensors for pH/ORP and oxygen measurement...

-

Page 3: Table Of Contents

Environment ......36 Process ......36 Endress+Hauser... -

Page 4: About This Document

Symbols used Symbol Meaning Additional information, tips Permitted or recommended Not permitted or not recommended Reference to device documentation Reference to page Reference to graphic Result of a step Symbols on the device Symbol Meaning Reference to device documentation Endress+Hauser... -

Page 5: Basic Safety Instructions

The manufacturer is not liable for damage caused by improper or non-designated use. Occupational safety As the user, you are responsible for complying with the following safety conditions: • Installation guidelines • Local standards and regulations Endress+Hauser... -

Page 6: Operational Safety

State of the art The product is designed to meet state-of-the-art safety requirements, has been tested, and left the factory in a condition in which it is safe to operate. The relevant regulations and European standards have been observed. Endress+Hauser... -

Page 7: Incoming Acceptance And Product

4. Pack the product for storage and transportation in such a way that it is protected against impact and moisture. The original packaging offers the best protection. Make sure to comply with the permitted ambient conditions. If you have any questions, please contact your supplier or your local Sales Center. Endress+Hauser... -

Page 8: Product Identification

A new window (Device Viewer) opens. All of the information relating to your device is displayed in this window as well as the product documentation. 3.2.3 Manufacturer's address Endress+Hauser Conducta GmbH+Co. KG Dieselstraße 24 D-70839 Gerlingen Scope of delivery The scope of delivery comprises: •... -

Page 9: Certificates And Approvals

Incoming acceptance and product identification Certificates and approvals 3.4.1 CE/PED The assembly has been manufactured according to good engineering practice as per Article 4, Paragraph 3 of the Pressure Equipment Directive 2014/68/EU and is therefore not required to bear the CE label. Endress+Hauser... -

Page 10: Installation

Ø 25 (0.98) Ø 21.2 (0.83) M23 + 1.5 Ø 27 (1.06) (3.5) (3.5) A0037726 1 Dimensions (see the following table). Engineering unit in mm (inch) 130 mm (5.12 in) (flange DN32) 140 mm (5.51 in) (flange ANSI 1¼") Endress+Hauser... - Page 11 Install the assembly at an angle of at least 15° to the horizontal → 2, 12. • ISFET sensors: For ISFET sensors, there are basically no restrictions regarding orientation. The installation angle should be from 0 to 180°. • All other sensors: Pay attention to the information in the relevant TI. Endress+Hauser...

- Page 12 Top edge of adapter Depending on the assembly version, a mounting clearance of at least 700 or 1150 mm (27.6" or 45.3") is required from the top edge of the adapter. Endress+Hauser...

-

Page 13: Installation

• Hook wrench AF 55 (included in scope of delivery) • Combination wrench AF 20 (20 mm (0.79")) or adjustable open-ended wrench • Adjustable open-ended wrench (up to 45 mm (1.8")) • Open-ended wrench set (only for flange connection) Endress+Hauser... - Page 14 Install the safety equipment only if the assembly has been removed. The safety equipment is not a substitute for the standard retainer of the assembly. A0014680 6 Assembly with safety kit Preparation A0014681 7 Installing the safety kit Service chamber Setting collar Endress+Hauser...

- Page 15 9. Mount the lower part of the safety kit (item 2) on the service chamber. The side with the chamfered edge points towards the ball valve. Secure the lower part with a torque of 3.5 Nm (2.6 lbf ft). 10. Assemble the assembly. Endress+Hauser...

- Page 16 In addition to water, other or additional cleaning solutions can be used as rinse liquids. The specifications regarding the material resistance of the assembly and the permitted temperatures or pressures must be complied with. You can also connect a drain valve or a manometer. These are available along with other accessories. Endress+Hauser...

- Page 17 Clean or rinse the rinse chamber. ‣ Mount the assembly only if vessels or pipes are empty and unpressurized. ‣ Before subjecting the assembly to the process pressure, verify that all connections are sealed. A0010212 9 Cable entry and sensor installation Endress+Hauser...

-

Page 18: Post-Installation Check

1. After mounting, check all the connections to ensure they are secure and leak-tight. 2. Ensure that the hose of the (optional) rinse water connections cannot be removed without force. This pipe is in open contact with the medium and must be secured accordingly. 3. Check the hoses for damage. Endress+Hauser... -

Page 19: Operation Options

For setting the desired immersion depth of the assembly. Alternatively, the safety kit can be used. • Coupling nut (black) (item 10). For locking the assembly in the desired position. • Locking ring (metal) (item 9) For securing the assembly on the ball valve. Endress+Hauser... -

Page 20: Operating The Assembly

1. Use the hook wrench to carefully open the coupling nut (black) by ¼ to ½ turn. 2. Pull the immersion tube out as far as the stop (service position). 3. Close the ball valve. The lever is horizontal. Endress+Hauser... - Page 21 1. Release the coupling nut (black) using the hook wrench. 2. Push the handles towards the ball valve, turning them clockwise. The locking pin is unlocked. 3. Move the assembly to the service position. 4. Close the ball valve. Endress+Hauser...

-

Page 22: Maintenance

4. For very persistent dirt, soak the parts in a cleaning solution. Then clean the parts with a brush. A typical example of a cleaning interval would be 6 months in the case of drinking water. Apply grease to dry O-rings to ensure that the assembly is properly sealed, particularly the sensor holder O-rings. Endress+Hauser... -

Page 23: Cleaning Agent

(commercially available) Protein buildup Mixture of 3% hydrochloric acid and pepsin (commercially available) Fibers, suspended substances Pressurized water, possibly surface-active agents Light biological buildup Pressurized water ‣ Choose a cleaning agent to suit the degree and type of soiling. Endress+Hauser... -

Page 24: Replacing Seals

1. Move the assembly to the service position. 2. Close the ball valve. 3. Open the locking ring (metal) using the hook wrench. 4. Remove the assembly from the ball valve and the adapter. Ordering information for O-ring kits → 28 Endress+Hauser... - Page 25 2. Slide the flanged sleeve including the locking ring (item 1) off the immersion tube. 3. Replace the inner O-ring (item 2, 24.99 x 3.53) and the outer O-ring (item 3, 32.92 x 3.53). 4. Slide the flanged sleeve with the locking ring (metal) back onto the immersion tube. Endress+Hauser...

- Page 26 3. Place the assembly back onto the adapter, and tighten the locking ring (metal) using the hook wrench. 4. For assemblies with a ball valve, open the ball valve. 5. Move the assembly to the measuring position. 6. Check the assembly for leaks. Endress+Hauser...

-

Page 27: Repair

‣ Following each repair and maintenance task, check the assembly for leaks using appropriate procedures. Following this, the assembly must again comply with the specifications in the technical data. ‣ Replace all other damaged components immediately. Endress+Hauser... -

Page 28: Spare Parts

Repair Cleanfit CPA450 Spare parts A0037952 11 Spare parts Item No. Description and contents Order number of spare parts Seal set, EPDM 50090489 Seal set, FPM, Viton 50090490 Endress+Hauser... - Page 29 Adapter with 3 x rinse connection G 1¼, connection G 1¼ 51501538 For assembly version: • CPA450-xBxxx • CPA450-xFxxx • CPA450-xGxxx Adapter with 3 x rinse connection G 1¼, connection NPT 1¼" 51501539 For assembly version: • CPA450-xCxxx • CPA450-xHxxx Endress+Hauser...

- Page 30 51501548 For assembly version: CPA450-xIxxx Ball valve ANSI 1¼" flange 51501549 For assembly version: CPA450-xKxxx Flange DN32 51501544 For assembly version: • CPA450-xDxxx • CPA450-xIxxx Flange ANSI 1¼" 51501545 For assembly version: • CPA450-xExxx • CPA450-xKxxx Safety kit 71098681 Endress+Hauser...

-

Page 31: Return

The product must be returned if repairs or a factory calibration are required, or if the wrong product was ordered or delivered. As an ISO-certified company and also due to legal regulations, Endress+Hauser is obliged to follow certain procedures when handling any returned products that have been in contact with medium. -

Page 32: Accessories

• Material: stainless steel 1.4571 (AISI 316 Ti) • Order number: 51502284 Safety kit • Mechanical device for securing the measuring position • For applications in dusty or sooty environments • For applications involving vibrations or pressure surges • Order number: 71098681 Endress+Hauser... -

Page 33: Sensors

• Sterilizable and autoclavable ISFET sensor for pH measurement • Refillable KCI liquid electrolyte • Product Configurator on the product page: www.endress.com/cps47d Technical Information TI01412C Memosens CPS77D • Sterilizable and autoclavable ISFET sensor for pH measurement • Product Configurator on the product page: www.endress.com/cps77d Technical Information TI01396 Endress+Hauser... -

Page 34: Connection Accessories

• Terminated measuring cable for connecting analog sensors with TOP68 plug-in head • Selection in accordance with product structure • Ordering information: Endress+Hauser sales office or www.endress.com. Measuring cable CPK12 • Terminated measuring cable for connecting analog ISFET sensors with TOP68 plug-in head •... - Page 35 • Cable extension: Memosens sensors, Liquiline • Order No.: 71145498 • Junction box for cable extension • 10 terminal strips • Cable entries: 2 x Pg 13.5, 2 x Pg 16 • Material: polycarbonate • Degree of protection: IP 65 • Order number: 50005276 Endress+Hauser...

-

Page 36: Technical Data

[bar] ratings T [°C] T [°F] A0038118-EN 12 Pressure/temperature ratings Maximum process pressure (static), only for fully installed assembly Maximum pressure for moving the assembly (functional) Observe the maximum permitted process temperature and process pressure of the sensor. Endress+Hauser... -

Page 37: Mechanical Construction

Not in contact with medium Screws: stainless steel 1.4401 (AISI 316) Coupling nut (black): PA66GF Clamping ring: PEEK Handle: Cable protector: thermoplastic elastomer (TPE) Rinse connection nozzles For material 316L: 3 x G ¼ For titanium or Alloy C22: 3 x NPT ¼" Endress+Hauser... -

Page 38: Index

Damaged parts ......27 Seals ........24 Endress+Hauser... - Page 40 *71439248* 71439248 www.addresses.endress.com...