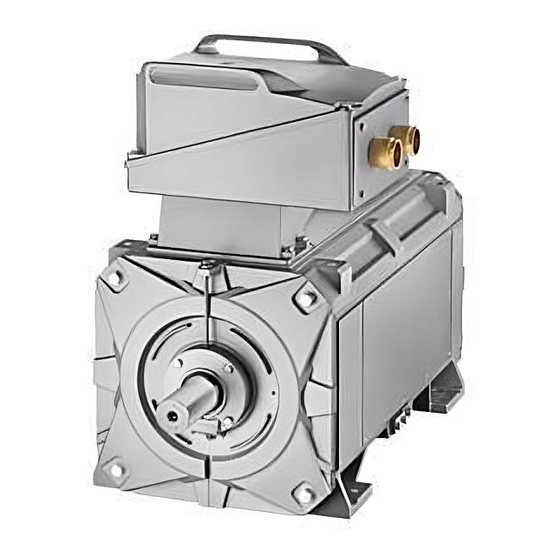

Siemens SIMOTICS FD 1LH1 Operating Instructions & Installation Instructions

Low-voltage motor

Hide thumbs

Also See for SIMOTICS FD 1LH1:

Summary of Contents for Siemens SIMOTICS FD 1LH1

- Page 1 Operating Instructions Installation Instructions Low-voltage motor SIMOTICS FD Type 1LH1 Edition 01/2019 www.siemens.com/drives...

- Page 2 23.01.2019 19:26 V11.01...

- Page 3 Introduction Safety information Description Low-voltage motor Preparations for use SIMOTICS FD Type 1LH1 Assembly Electrical connection Operating Instructions Installation Instructions Start-up Operation Maintenance Spare parts Disposal Service and Support Technical data and drawings Quality documents Edition 01/2019...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Table Of Contents

Thermal motor protection .......................37 Thermal motor protection using PTC thermistors (option) .............37 Interlock circuit for the automatic regreasing system (option)..........37 Interlock circuit for anti-condensation heating................37 4.10 IM B5 type of construction with support foot ................37 SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 6 Preconditions for smooth, vibration-free operation ..............66 5.4.2 Aligning the machine to the driven machine and mounting (IM B3 / IM B35) ......66 5.4.3 Aligning the machine to the driven machine and attaching it to it (IM B5) ......68 SIMOTICS FD 1LH1 Operating Instructions 01/2019...

- Page 7 6.6.4 Terminating the connection work (auxiliary circuit) ..............96 Start-up...............................97 Checks to be carried out prior to commissioning ..............97 Converter operation .......................99 Measuring the insulation resistance before commissioning...........99 Greasing the roller bearings prior to commissioning............100 SIMOTICS FD 1LH1 Operating Instructions 01/2019...

- Page 8 Regreasing intervals and types of grease for operating roller bearings.......127 9.1.10 Sealing the rolling-contact bearings ("Increased degree of protection" option) ....131 9.1.11 Cleaning the cooling water ducts ..................131 9.1.12 Touch up any damaged paintwork ..................131 SIMOTICS FD 1LH1 Operating Instructions 01/2019...

- Page 9 11.1 RoHS - restricting the use of certain hazardous substances ..........159 11.2 Information according to Article 33 of the REACH regulation ..........159 11.3 Preparing for disassembly....................160 11.4 Dismantling the machine......................160 11.5 Disposal of components.......................160 SIMOTICS FD 1LH1 Operating Instructions 01/2019...

- Page 10 Spare parts for the bearing cartridge at the drive end and non-drive end.........145 Table 10-3 Spare parts for the bearing cartridge at the drive end and non-drive end.........146 Table 10-4 Terminal box GT640........................147 Table 10-5 Terminal box 1XB1621 spare parts...................148 Table 10-6 Additional spare parts........................149 SIMOTICS FD 1LH1 Operating Instructions 01/2019...

- Page 11 Disassembling the labyrinth sealing ring (schematic diagram) ..........135 Figure 9-3 Install the V ring.........................137 Figure 9-4 Roller-contact bearing with grease chamber (schematic diagram) ...........138 Figure 9-5 Position the set screws for the labyrinth sealing ring on the outer bearing cover .....139 SIMOTICS FD 1LH1 Operating Instructions 01/2019...

- Page 12 Terminal box 1XB7750 with standard cable entry..............154 Figure 10-12 Auxiliary terminal box 1XB9014 .....................155 Figure 10-13 Auxiliary terminal box 1XB9015 .....................156 Figure 10-14 1XB9016 auxiliary terminal box ....................157 Figure 10-15 Auxiliary terminal box 1XB302....................158 SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 13: Introduction

Using the "Documentation" function, from Product Support manuals, you can compile your own "Documentation". However, you can also include other Product Support content such as FAQs or characteristics in the documentation that you compile. SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 14 Using the "Documentation" function, you can efficiently compile your own plant or system documentation. The "Documentation" compiled in a specific language can also be automatically exported in one of the other available languages. The full functionality is only available for registered users. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 15: Safety Information

Also disconnect the auxiliary circuits, for example, anti-condensation heating. 2. Secure against reconnection. 3. Verify absence of operating voltage. 4. Ground and short-circuit. 5. Provide protection against adjacent live parts. To energize the system, apply the measures in reverse order. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 16: Qualified Personnel

● Ensure that all rotating parts are reliably covered. ● Switch off and disconnect the machine first if you want to remove covers. Observe the "5 safety rules". ● Only remove covers when the rotating parts have come to a complete standstill. SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 17 ● Take steps to reduce noise so that the machine can be operated safely within your system. The following measures may help to reduce noise. – Covers – Noise insulation – Hearing protection measures SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 18: Electrostatic Sensitive Devices

= ESD overall e = ESD wristband f = cabinet ground connection Interference immunity By selecting suitable signal cables and evaluation units, ensure that the interference immunity of the machine is not diminished. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 19: Influence On The Line Power Supply Through A Strongly Irregular Torque

● Observe the nationally applicable health and safety regulations. ● It is forbidden for people with pacemakers to be close to the machine. ● Do not carry any magnetic or electronic data media. SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 20 Safety information 2.9 Electromagnetic fields when operating electrical power engineering installations SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 21: Description

Cooling IEC/EN 60034‑6 Type of construction IEC/EN 60034‑7 Terminal markings and direction of rotation IEC/EN 60034‑8 Noise emission IEC/EN 60034‑9 Starting characteristics of rotating electrical machines * IEC/EN 60034‑12 Vibration severity grades IEC/EN 60034‑14 SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 22 GOST R IEC 60034-14 Rating plate The rating plate shows the identification data and the most important technical data. The data on the rating plate and the contractual agreements define the limits of proper usage. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 23: Table 3-2 Data On The Rating Plate

Thermal class of the utilization (24) Country of manufacture and location (11) Maximum speed [rpm] (25) Certification mark for UL/CSA + file number (optional) (12) Standards (26) Certificate number(s) for Ex motors for Zone 2 (optional) SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 24 Carefully observe the content of the quotation, and that there is a cUL-marking on the rating plate. Quality management system Siemens AG employs a quality management system that meets the requirements of ISO 9001 and ISO 14001. Certificates that can be downloaded You can download certificates for the SIMOTICS motor series at the following link: Certificates (https://support.industry.siemens.com/cs/ww/en/ps/13358/cert)

- Page 25 A shaft-mounted fan ensures circulation of the cooling air. Degree of protection The machine is available with degree of protection IP55. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 26: Table 3-3 Rolling-Contact Bearing Variants

The chamber is sealed off from the space where the lubricating grease collects by a V-ring or a V-ring and felt ring combination which prevents the sealing grease in the chamber from penetrating into the lubricating grease collecting space. SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 27 Depending on the order, various supplementary devices can be installed or mounted. These include sensors for bearing temperature monitoring or winding monitoring, for example. Anti-condensation heating (option) The machine is fitted with anti-condensation heating. The connection data is listed on an additional plate on the machine. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

- Page 28 Description SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 29: Preparations For Use

Configuration of the cooling circuit and coolant supply 4.4.1 Material selection for the cooling circuit For optimum durability of the cooling system, use a closed or half open cooling circuit in stainless steel or acrylic butadiene styrene (ABS). SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 30: Pressures And Differential Pressures In The Cooling Circuit

● If there is a risk of frost, use cooling water with antifreeze suitable for this temperature. The pressure drop increases when antifreeze is added. See also Connecting the cooling water supply (Page 70) SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 31: Components And Materials Of The Cooling Circuit

● Connect an equipotential bonding conductor to all of the components in the cooling system (motor, converter, piping system, etc.). ● Implement the equipotential bonding using a copper rail or finely stranded copper cable with the appropriate cable cross-sections. In this way, you suppress electrochemical processes. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 32: Power Loss

Use inhibitors if the drinking water has an excessively high chloride percentage. To better explain the coolant recommendations in this document, some of the problems that can be encountered if the recommendations are ignored are listed in the table below. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 33: Table 4-2 Substances That Can Destroy The Cooling System

5 K, this may result in condensation forming in the machine. This results in material damage. ● Make sure that the condensation can drain away freely. ● Adopt appropriate measures to achieve the required intake temperature of the cooling water. ● Alternatively, dry the ambient air. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 34: Coolant Specification (M85 "Stainless Steel Version" Option)

Sulfate ions SO < 240 mg/l Nitrate ions NO < 50 mg/l Dissolved solids < 340 mg/l Total hardness < 1.7 mmol/l Electrical conductivity < 2000 μS/cm Maximum size of dissolved substances < 0.1 mm SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 35: Inhibitors, Anti-Freeze, Biocides

Corrosive mixture Top up with antifreeze to comply with the minimum concentration, otherwise a mixture is obtained that has a corrosive effect. The cooling system can be damaged. ● Never mix inhibitors and anti-freeze. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 36: Cooling Capacity Derating

Varidos FSK Antifrogen L Antifrogen N / Varidos FSK ≙ ethylene glycol Antifrogen L ≙ propylene glycol Note Order-specific agreements Order-specific agreements regarding the cooling water specification can deviate from the cooling water specification mentioned. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 37: Thermal Motor Protection

The weight of the machine is stated on the rating plate, data on geometry is shown in the dimension drawing. ● There is a threaded hole M36 at the bottom of the machine where you can attach the support foot. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 38: Noise Emissions

Voltage and frequency fluctuations during line operation Unless otherwise stated on the rating plate, the permissible voltage/frequency fluctuation is corresponds to Zone B in IEC / EN 60034‑1. Permissible fluctuations that go beyond this are indicated on the rating plate. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 39: Phase Synchronization During Supply System Switching

If the configuration does not correctly recognize the mechanical torsional loadings of the shaft assembly, this can lead to serious damage to the machine. This can result in death, serious injury or material damage. When planning the system, consider the configuration data. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 40: Transport

Danger due to incorrect attachment and lifting ● Ensure that suitable lifting equipment is available. ● Only hoist the goods using the designated hoisting points and/or at marked positions. The attachment points are not dimensioned for additional loads. SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 41 Note the maximum capacity of the lifting lug. Danger when attachment points fracture At low temperatures, the material of the attachment points can become brittle. When lifting and transporting, the attachment points can shear off and the motor can fall. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 42: Checking The Delivery

– If a machine has to be transported in a horizontal position, the rotor must be fixed in position before the machine is turned onto its side. Vertical machines can be supplied in the horizontal position from the manufacturing plant. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 43: Figure 4-1 Axial Fastening Of The Rotor

40 kN Axial preload force for other rotor shipping brace types Note Store the rotor locking device Be sure to store the rotor locking device. It must be remounted for possible disassembly and transport. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 44: Lifting And Transporting The Machine

You must correctly store the machine if you do not install and use it after it has been delivered. NOTICE Bearing seizure damage if incorrectly stored If storage conditions are inappropriate there is a risk of bearing seizure damage. Resulting damage can include scoring (brinelling) and corrosion. ● Follow the storage guidelines. SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 45 ● The ground must be sufficiently strong. Prevent the machine from sinking into the ground. ● Covers or tarpaulins used to protect the equipment against the weather must not make contact with the surfaces of the equipment. Otherwise air circulation under the stored items will be prevented. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

- Page 46 (if available), and ensure that the air circulates in the storage room. Storage for longer than three months Lubricate the machine after every two years of storage. 1. Unpack the machine. 2. Remove the rotor shipping brace, if one is being used. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 47: Protecting The Cooling Water Circuit During Storage

● Inspect the machine regularly and if necessary, apply an additional coating of corrosion protection. Document all preservation measures taken so that they can be reversed before the machines are put back into service. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 48: Converter Operation

C (IVIC C = high stress). If voltage peaks higher than those specified according to IVIC C can occur, then please contact your Siemens partner: ● For a line supply voltage (converter input voltage) up to max. 480 V, and when controlled from a SINAMICS G/SINAMICS S converter with uncontrolled/controlled infeed: Comply with the guidelines for configuring motor and converter. -

Page 49: Reducing Bearing Currents

● To ensure good discharging of high-frequency currents, provide contacting over a large surface area: – as contact established through 360° at the converter – at the motor, for instance with EMC glands at the cable entries SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 50: Insulated Bearings When Operating The Converter

● In the overall system, set up a properly meshed grounding system with low impedance. ● Use the common-mode filter (damping cores) at the converter output. The Siemens sales representative is responsible for selection and dimensioning. -

Page 51: Figure 4-2 Schematic Representation Of A Single Drive

Bearing currents can flow if the coupling between the motors of the tandem drive is not insulated. This can damage the DE bearings of both motors. ● Use an insulated coupling to link the motors. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 52: Converter Operation On A Grounded Network

PE connecting points of standard terminal boxes is suitable for this purpose. Material damage can result. ● Use an appropriately sized PE conductor. ● Connect the PE conductor to the grounding terminal on the motor enclosure. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 53: Assembly

● Where necessary, use suitable steps when performing installation work on the machine. ● Do not stand on cables or attachments during installation. Do not use attachments as steps. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 54: Preparations For Installation

● Within the scope of maintenance work The following information is provided regarding the state of the winding insulation: ● Is the winding head insulation conductively contaminated? ● Has the winding insulation absorbed moisture? SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 55: Testing The Insulation Resistance And Polarization Index

Convert the measured insulation resistances in accordance with the formula to the reference temperature of 40° C. This thereby ensures that the minimum values specified can be compared. 5. Read out the insulation resistance one minute after applying the measuring voltage. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 56: Table 5-1 Stator Winding Insulation Resistance At 40° C

In this case, doubling or halving the insulation resistance at a temperature change of 10 K is used as the basis. ● The insulation resistance halves every time the temperature rises by 10 K. ● The resistance doubles every time the temperature falls by 10 K. SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 57 Limit values of the anti-condensation heating insulation resistance The insulation resistance of the anti-condensation heating with respect to the machine housing should not be lower than 1 MΩ when measured at 500 V DC. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 58: Prepare The Mating Faces (Im B3)

● Measuring the concentricity and axial eccentricity tolerances ● Positioning the machine If you are not familiar with the prescribed measures and procedures, then you can make use of the services offered by the local Service Center (Page 163). SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 59: Checking The Load Handling Attachments

Failure to fit the rotor shipping brace can result in damage to the bearings while the machine is being turned onto its side. ● Fix the rotor in place before you turn the machine into a horizontal position. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 60: Removing Anti-Corrosion Protection

● "H" means balancing with a half feather key ● "F" means balancing with a whole feather key Figure 5-1 Balancing type on the drive-end side SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 61 ● Only operate the motor with the transmission element pulled on. ● For test operation or when commissioning without transmission element, carefully secure the feather key using a suitable locking element. When doing this, take into account the type of machine balancing. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 62: Lifting And Transportation

● Always take account of the center of gravity when transporting or lifting the machine. If the center of gravity is not located centrally between the attachment points, then position the hoisting hook above the center of gravity. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 63: Putting The Machine Down

There is no condensation present within the machine. Setting down the machine ● Set down the machine slowly and carefully at the installation location to avoid any impact. See also Draining condensation (Page 64) SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 64: Draining Condensation

In the DE bearing shield, water drain holes are located in the area of the mounting feet or opposite the regreasing system. They are sealed with screw plugs. Figure 5-2 Condensation water drain for vertical mounting SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 65: Roughly Aligning The Machine

The transmission element such as a coupling half has already been pulled on. Roughly aligning the machine ● For horizontal positioning, push the motor sideways across the foundation. When doing so, ensure that the axial position is maintained. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 66: Installing The Machine

The balance state of the shaft (full-key or half-key balancing) and alignment errors primarily influence the service life of the bearing, especially for high motor speeds or when using rigid couplings. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 67: Table 5-2 Permissible Deviations For Aligning The Machine With Flexible Coupling

= 0.05 mm / 100 mm ∅ D Note Machine expansion When performing alignment, make allowance for the thermal expansion of the machine due to rising temperature. See also Tightening torques for screw and bolt connections (Page 165) SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 68: Aligning The Machine To The Driven Machine And Attaching It To It (Im B5)

The machine or machine parts may loosen during operation. This can result in death, serious injury or material damage. ● Mount the support base so that no additional mechanical tensions can occur in the housing. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 69: Aligning The Machine To The Driven Machine And Attaching It To It (Im V1, Im V10)

0.05 mm in diameter. 5.4.5 Axial and radial forces You can obtain the permissible values for axial and radial forces by contacting the Siemens Service Center (Page 163) or referring to the machine catalog. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 70: Connecting The Cooling Water Supply

There are three couplings on the bearing shield for the coolant connection. The ② lower coupling is used to drain the coolant for type of construction IM B3. Figure 5-5 Standard coolant connections and coolant drain hole SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 71 Adequate machine cooling cannot be guaranteed if the cooling ducts are not completely filled with water. The machine can overheat. ● Vent the cooling ducts when filling. Completely fill the cooling ducts with water. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

- Page 72 Assembly 5.5 Connecting the cooling water supply SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 73: Electrical Connection

● The connecting cables can be sealed and secured at every cable entry point into the terminal box. ● Lay the connecting cables and in particular the PE conductor in the terminal box in an open arrangement so that chafing of the cable insulation is prevented. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 74: Terminal Box

You can identify the terminal box installed on the machine via the illustrations in the following chapters. 6.3.1 Terminal box GT640 The GT640 terminal box is used only for machines on the power supply with shaft height 315. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 75: Terminal Box 1Xb1621

● Bringing cables into the terminal box 1XB... with cable gland (Page 88) ● Connecting cables without cable lugs (Page 90) ● Connecting cables with cable lugs (Page 89) See also Bringing cables into the terminal box 1XB... with sealing insert with break-off ring (Page 87) SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 76: Terminal Box 1Xb1631

● Bringing cables into the terminal box 1XB... with cable gland (Page 88) ● Connecting cables without cable lugs (Page 90) ● Connecting cables with cable lugs (Page 89) See also Bringing cables into the terminal box 1XB... with sealing insert with break-off ring (Page 87) SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 77: Terminal Box 1Xb7730

● Bringing cables into the terminal box 1XB... with cable gland (Page 88) ● Connecting cables with cable lugs (Page 89) ● Connecting cables without cable lugs (Page 90) 6.3.5 Terminal box 1XB7731 Figure 6-6 Terminal box 1XB7731 SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 78: Terminal Box 1Xb7740

You can find additional information here: ● Bringing cables into the terminal box 1XB... with cable gland (Page 88) ● Connecting cables with cable lugs (Page 89) ● Connecting cables without cable lugs (Page 90) SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 79: Terminal Box 1Xb7750

● 1XB7731 – For six or fewer cables, you can rotate the terminal box with installed stator cables through ±90°. – For more than six cables, you must remove the internal stator cables before rotation. SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 80 – Connecting cables ... 11.Screw in the two diagonally arranged threaded bars and slide the cover onto these bars. Take care not to damage the seal. 12.Fix the two free screw connections and tighten by hand. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

- Page 81 – Connecting the grounding conductor (Page 83) – Introducing and routing the cables ... – Connecting cables ... 13.Screw in the two diagonally arranged threaded bars and slide the cover onto these bars. Take care not to damage the seal. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 82: Mounting/Removing The Terminal Box

2. Slide the terminal box cover over the threaded bars onto the lower section of the terminal box. 3. Screw the screws into the free holes and tighten by hand. 4. Release the threaded bars. 5. Tighten all four M10 screws, tightening torque 40 Nm. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 83: Preparation

Connecting the grounding conductor The grounding conductor cross-section of the motor must be in full conformance with the installation specifications, e.g. in accordance with IEC 60034-1. External conductor cross-section S Grounding conductor cross-section mm² mm² SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 84 > 9 mm 8 Nm When using grounding > 12 mm 20 Nm terminals > 15 mm 40 Nm > 18 mm 70 Nm > 20 mm 170 Nm See also Converter operation (Page 99) SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 85: Connection Without Terminal Box

The machine will not be adequately cooled if it is operated other than how it was originally ordered or with the incorrect direction of rotation. This can result in machine damage. Observe the direction of rotation data on the nameplate. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 86: Undrilled Entry Plate

The circuit diagram is located in the cover of the terminal box. Refer to the "Connecting cables..." section for more information. See also Connecting cables with cable lugs (Page 89) Connecting cables without cable lugs (Page 90) SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 87: Bringing Cables Into The Terminal Box 1Xb

7. Insert the cable with the seal insert in position into the gland opening. Screw the strain relief device together once the cable is in a concentric position in the gland opening. 8. Secure the strain relief device. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 88: Bringing Cables Into The Terminal Box 1Xb

5. Fit the cable entry plate to the terminal box with the assembled cables. 6. Connect the ends of the cables to the terminals in accordance with the circuit diagram. The circuit diagram is located in the cover of the terminal box. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 89: Laying Cables

3. Fasten the cable lug to the end of the conductor correctly, e.g. by squeezing. Figure 6-10 Connection with cable lug and fixing screw (schematic diagram) 4. Insulate the cable lug sleeves where necessary to ensure minimum air clearances and the creepage distance are maintained. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 90: Connecting Cables Without Cable Lugs

2. Prepare the end of the cable depending on the cable and its use. It is not permissible that the cable connection is subject to external forces. 3. Insulate the conductor ends in such a way that the remaining insulation reaches almost up to the cable lug. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 91: Figure 6-11 Connection Using Terminal Clamps (Schematic Diagram)

GT640 / 1XB7730 / 1XB7731 / 1XB7740 / 1XB7750 20 Nm ① For terminal boxes GT640, 1XB7730 and 1XB7731, fasten the terminal element using a clamping nut M12 on the threaded stud of the terminal support with a torque of 20 Nm. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 92: Use Of Aluminum Conductors

● Use a cable entry plate made of non-ferrous metal. 6.5.9 Internal equipotential bonding Between the ground terminal in the terminal box enclosure and the machine enclosure, the fixing screws of the terminal box serve as PE conductor connection. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 93: Stepless Mating Face For The Seal In The Terminal Box Cover

When determining the required minimum air clearance, the voltage value in the table may be increased by a factor of 1.1, so that the rated input voltage range is taken into account during general use. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 94: Finishing Connection Work

Take the following criteria into account when selecting the connecting cables for the auxiliary circuits: ● Rated current ● Rated voltage ● System-dependent conditions, such as ambient temperature, routing type, cable cross- section as defined by required length of cable, etc. ● Requirements according to IEC/EN 60204‑1 SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 95: Bringing Cables Into The Auxiliary Terminal Box And Routing Them

6. Make sure that the seal on the screwed sockets for the cable glands satisfies the degree of protection. 6.6.3 Connecting temperature monitoring for the stator winding The stator winding is monitored for thermal loading by temperature sensors embedded in the stator winding. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 96: Terminating The Connection Work (Auxiliary Circuit)

2. Close the auxiliary terminal box using the cover supplied for this purpose. See section "Tightening torques for screw and bolt connections (Page 165)" for the tightening torque of the fixing bolts for the cover. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 97: Start-Up

● All touch protection measures for moving and live parts have been taken. ● For test operation or when commissioning without output element, carefully secure the feather key using a suitable security element. When doing this, take into account the balancing type of the motor. SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 98 ● Any supplementary motor monitoring devices and equipment have been correctly connected and are functioning correctly. ● All brakes and backstops are operating correctly. ● At the monitoring devices, the values for "Warning" and "Shutdown" are set. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 99: Converter Operation

● Within the scope of maintenance work The following information is provided regarding the state of the winding insulation: ● Is the winding head insulation conductively contaminated? ● Has the winding insulation absorbed moisture? SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 100: Greasing The Roller Bearings Prior To Commissioning

1. Remove the bearing, regreasing pipes, grease nipples and the bearing cap. 2. Flush out the old grease. 3. Check the bearings before regreasing. If necessary, install new bearings. 4. Lubricate the bearings and reinstall the bearing components. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 101: Setting The Automatic Regreasing System

T Table 7-2 Set values for monitoring the bearing temperatures Set value Temperature Alarm + 5 K ≤ 115 °C operation Shutting down + 10 K ≤ 120 °C operation SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 102: Set Values For Monitoring The Winding Temperature

Allow the machine to run down before switching it on again. 2. If the machine is running smoothly and evenly, switch on the cooling equipment. Continue to observe the machine for a while in no-load operation. SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 103 If the vibration values in operation are not maintained in accordance with DIN ISO 10816-3, then the machine can be mechanically destroyed. ● During operation, observe the vibration values in accordance with DIN ISO 10816‑3. Note You can find more information in Chapter 2 of catalog D81.8. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 104: Switching Off

Provided permitted by the application, the space-vector modulation can be changed manually to an optimized pulse pattern for SIMOTICS FD motors. The SINAMICS parameter is p1802 = 19 in the STARTER and in the AOP30. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 105: Selecting The Motor Type And Motor Data In The Starter Program

Subsequent motor assignment is simplified by selecting a unique name. 2. Select the "Enter motor data" option. 3. In the "Motor type" field, select the entry "[14] SIMOTICS FD induction motor series". Figure 7-1 Selecting a motor type SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 106: Figure 7-2 Entering The Motor Data

– The value for parameter p335 (motor cooling method) is encrypted from the motor order number: Motor order number Cooling method Parameter p335 1LL1 IC01 1LP1 IC06 1LM1/1MM1 IC411 1LQ1/1MQ1 IC416 1LH1/1MH1 IC71W 1LN1/1MN1 IC86W Figure 7-2 Entering the motor data 6. Click "Continue" to confirm your entries. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 107: Commissioning At The Sinamics S/G Converter Using The Aop30

● Navigate within the selection fields using <F2> and <F3>. ● In the entry fields, you can either directly enter the required value or select it from a list. ● Activate the selection with <F5>. SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 108 – The value for parameter p335 (motor cooling method) is encrypted from the motor order number: Motor order number Cooling method Parameter p335 1LL1 IC01 1LP1 IC06 1LM1/1MM1 IC411 1LQ1/1MQ1 IC416 1LH1/1MH1 IC71W 1LN1/1MN1 IC86W SIMOTICS FD 1LH1 Operating Instructions 01/2019...

- Page 109 Start-up 7.10 Setting the motor parameters at the converter 3. Exit the motor data input by selecting the "Continue" field and activating the selection with <F5>. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 110: Commissioning At The Sinamics G120P Inverter Using The Iop

– Motor voltage – Motor current – Rated power – Rated power factor cos φ – Motor speed The optimized pulse patterns are activated automatically once the "SIMOTICS FD" motor type is selected (p300=14). SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 111: Operation

"Five safety rules": ● When the machine is in operation, the terminal boxes must remain closed at all times. Terminal boxes may be opened only when the machine is stopped and in a no-voltage condition. SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 112 Material damage can result. ● Make sure that the anti-condensation heating is switched off before the machine is switched ● Only operate anti-condensation heating when the machine is switched off. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 113: Switching On The Machine

Damage may occur to the motor if it is not stored properly. If the machine is to be taken out of operation for more than 12 months, suitable anti-corrosion, preservation, packaging, and drying measures must be taken. See also Transport (Page 40) Start-up (Page 97) SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 114: Avoidance Of Frost And Corrosion Damage In The Cooling System

Use the fitted key or the coupling halves as reference markers. ● During re-commissioning, refer to the information in the "Commissioning" section. See also Start-up (Page 97) SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 115: Measurement Of The Insulation Resistance After An Extended Stoppage

● Only switch off the water cooling system once the machine has cooled down. This will prevent the accumulation of residual heat. Draining the coolant If you take the machine out of service, drain the coolant if this is necessary for the ambient conditions. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 116: Re-Commissioning The Machine

Start-up (Page 97) Switching on again after an emergency switching-off ● Check the machine before recommissioning the driven machine after an Emergency Off. ● Eliminate all the causes that have led to the emergency off SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 117: Faults

Immediately perform an inspection after such faults. Correct the cause of the fault as described in the respective remedial measures section. Repair any damage to the machine. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 118: Electrical Faults

Possible causes of faults Remedial measures Rotating parts are grinding Establish the cause and realign the parts. Rotor not balanced Decouple the rotor and then rebalance it. Rotor out of true, shaft bent Contact the Service Center. SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 119 Reduced air supply, direction of rotation of fan Check the air ducts; clean the machine. possibly incorrect X Uneven gearbox operation Resolve any gearbox faults. Take into account possible changes which may occur during overheating. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 120: Water Cooling Faults

Cooling water contains too many or unsuit‐ Use cooling water of the agreed quality. able antifreeze and corrosion-protection agents Leaks in the cooling system Consult the manufacturer. Defective cooling water connection Find the leak and seal it. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 121: Roller Bearing Faults

Too much grease in bearing Remove surplus grease. Wrong grease in the bearing Use the correct grease. Friction marks on raceway Replace the bearing. Brinelling or scoring Replace the bearing. Avoid any vibration at standstill SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 122 Operation 8.10 faults SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 123: Maintenance

● Switch off the machine and ensure that it is in a no-voltage condition. Carefully comply with the "5 safety rules". ● Only open the terminal box when the motor is stationary and in a no voltage condition. SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 124 They can also damage the motor. ● Ensure that no foreign bodies are left in or on the motor. ● Securely attach all loose parts once you have completed the work. ● Carefully remove any dirt. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 125: Measuring The Insulation Resistance During The Course Of Maintenance Work

The smooth running characteristics and machine running noise have not deteriorated. The motor foundation has no cracks and indentations. (*) (*) You can perform these checks while the motor is running or at a standstill. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 126: General Inspection

When carrying out the inspection, if you detect any impermissible deviations from the normal state, you must rectify them immediately. They may otherwise cause damage to the machine. See also Set values for monitoring the winding temperature (Page 102) SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 127: Servicing And Maintaining The Anti-Condensation Heating

Initial lubrication The grease specified on the lubricant plate is selected according to the operating conditions known at the time of ordering and should be used for initial lubrication. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 128: Table 9-3 Criteria For Selecting Rolling Bearing Greases

Behavior in the presence of water DIN 51807 0 or 1 at a test temperature of +90° C Corrosive effect on copper DIN 51811 0 or 1 at a test temperature of +120° C Korr.° SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 129: Table 9-4 Rolling Bearing Greases For Vertical And Horizontal Types Of Construction

Shell Retinax LX2 Arcanol Multi 2 Lubrication data The following data is provided on the lubricant plate of the machine. ● Regreasing intervals in operating hours ● Regreasing amount in grams ● Grease type SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 130 ● When commissioning, the bearings must be relubricated with twice the amount of lubricating grease. When doing this, the shaft must rotate so that the grease is replaced in the bearings. ● Carefully observe the information relating to long-term storage. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 131: Sealing The Rolling-Contact Bearings ("Increased Degree Of Protection" Option)

Contact the Service Center (Page 163) before you repair any paint damage. They will provide you with more information about the correct paint system and methods of repairing paint damage. 9.1.13 Maintaining terminal boxes Requirement The machine is de-energized. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 132: Corrective Maintenance

● Document the type, dimensions and arrangement of the parts so that you will be able to reassemble the machine to its original state. ● Use suitable tools to disassemble the machine. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 133: Screws With Precote Coating

The motor can partly be fitted with screws with preCOTE coating. To ensure screw locking, use new screws with preCOTE coating during assembly/repair. As an alternative, use normal screws with a threadlocker such as Loctite. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 134: Roller-Contact Bearings

Remove V ring Depending on the particular version, there is a V ring. The V ring must be replaced if unusual amounts of grease escape the roller bearing or the V ring is visibly damaged. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 135: Removing The Labyrinth Sealing Ring

1. Mark the components of the bearing units so that they can be assembled correctly. 2. Remove the protective coating from the shaft in front of the Iabyrinth sealing ring. 3. Unscrew the three radially arranged set screws for fixing the ring axially. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 136: Installing Roller Bearings

9. Depending on the particular version, fix the bearing with a locking ring or shaft nut. 10.Support the rotor when installing the bearing housing or bearing end shield. 11.Use a suitable sealant when assembling. 12.Assemble the bearing shield or bearing housing together with the bearing shield. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 137: Install The V Ring

2. Verify that the ring is sufficiently pretensioned. Replace the protective ring, if necessary. 3. Position the protective ring so that one of the longitudinal grooves meets the corresponding water separation groove at the bottom in the bearing cover flange or end shield. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 138: Installing The V Ring ("Increased Degree Of Protection" Option)

1. Apply a soluble adhesive to the three set screws such as Loctite 243) and screw them partially into the labyrinth sealing ring. 2. Apply an corrosion protection paint to the shaft in the area of the labyrinth sealing ring. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 139: Seal The Motor

"Hylomar M". Follow the manufacturer's application and safety instructions when doing this. ● Check all sealing elements, such as those on the terminal boxes, for elasticity, aging or damage, and renew them if they are no longer effective. SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 140 Maintenance 9.2 Corrective Maintenance SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 141: Spare Parts

● Machine type ● Serial number ● Using the Data Matrix code and the "Siemens Industry Online Support" App, you can access product information such as the operating instructions and certificates of your machine. See also... -

Page 142: Ordering Spare Parts Via The Internet

The anti-condensation heater is mounted directly on the winding. The anti-condensation heater cannot be removed without causing damage to the winding. A new anti-condensation heater may only be installed by Siemens Service Center (Page 163) specialists. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 143: Housing, Stators And Rotors

Lifting lugs 20.00 Terminal box without cable entry See also Terminal box GT640 (Page 147) Terminal box 1XB1621 (Page 148) Terminal box 1XB1631 (Page 150) Terminal box 1XB7730 (Page 151) Terminal box 1XB7731 (Page 152) SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 144 Spare parts 10.4 Housing, stators and rotors Terminal box 1XB7740 (Page 153) Terminal box 1XB7750 (Page 154) SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 145: Roller Bearing Cartridge At The Drive And Non-Drive End

Bearing kit at the drive end and non-drive end consists of the following components Deep-groove ball bearing (locating bearing) Deep-groove ball bearings Shaft sealing ring, labyrinth ring (optional) Shaft sealing ring Locking ring, guard ring Locking ring SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 146: Roller Bearing Cartridge At The Drive And Non-Drive End

Bearing kit at the drive end and non-drive end consists of the following components Deep-groove ball bearing (locating bearing) Deep-groove ball bearings Shaft sealing ring, labyrinth ring (optional) Shaft sealing ring Locking ring, guard ring Locking ring SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 147: Terminal Box Gt640

Terminal link (two holes) 20.38 Seal 22.70 Fixing lug for PE conductor 21.20 Bushing insulator The terminal box can only be ordered as one component. The maximum connection cross-section for the main circuit is 240 mm SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 148: Terminal Box 1Xb1621

Part Description 20.00 Terminal box without cable entry comprising the following components: 20.20 Terminal box housing 21.41 Terminal supports 20.27 Mounting rail 21.61 Terminal strip for auxiliary circuit 20.28 Seal 22.01 Saddle terminal, complete SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 149: Table 10-6 Additional Spare Parts

Cable gland 20.66 Strain relief - lower part 20.61 Cable gland - upper part 20.68 Seal 20.62 Cable gland - lower part 20.70 Sealing insert for cable entry 20.65 Strain relief - upper part SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 150: Terminal Box 1Xb1631

Part Description Part Description 20.61 Cable gland - upper part 20.66 Strain relief - lower part 20.62 Cable gland - lower part 20.70 Sealing insert for cable entry 20.65 Strain relief - upper part SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 151: Terminal Box 1Xb7730

Seal 22.39 Neutral point connection 21.11 Connecting plate with internal cable 22.70 Fixing lug for PE conductor 21.41 Terminal bushings Table 10-9 Additional spare parts Part Description Part Description 20.51 Entry plate with seal SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 152: Terminal Box 1Xb7731

Connecting plate with internal cable 22.41 Terminal link, straight with two holes 21.41 Terminal bushings 22.70 Fixing lug for PE conductor Table 10-11 Additional spare parts Part Description Part Description 20.51 Entry plate with seal SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 153: Terminal Box 1Xb7740

21.11 Connecting plate with internal cable 22.39 Neutral point connection 21.41 Terminal bushings 22.70 Fixing lug for PE conductor Table 10-13 Additional spare parts Part Description Part Description 20.51 Cable entry plate with seal SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 154: Terminal Box 1Xb7750

Complete terminal box with undrilled cable entry 22.30 Connecting bar for the power circuit plate 20.51 Cable entry plate with seal, undrilled 22.39 Neutral point connection 22.01 Saddle terminal, complete You can only order the terminal box as part. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 155: Auxiliary Terminal Box 1Xb9014

Auxiliary terminal box 1XB9014 Figure 10-12 Auxiliary terminal box 1XB9014 The auxiliary terminal box can only be ordered as one complete part, single parts are not available. In this case, please contact the Service Center (Page 163). SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 156: Auxiliary Terminal Box 1Xb9015

Auxiliary terminal box 1XB9015 Figure 10-13 Auxiliary terminal box 1XB9015 The auxiliary terminal box can only be ordered as one complete part, single parts are not available. In this case, please contact the Service Center (Page 163). SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 157: 1Xb9016 Auxiliary Terminal Box

1XB9016 auxiliary terminal box Figure 10-14 1XB9016 auxiliary terminal box The auxiliary terminal box can only be ordered as one complete part, single parts are not available. In this case, please contact the Service Center (Page 163). SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 158: Auxiliary Terminal Box 1Xb302

Auxiliary terminal box 1XB302. Figure 10-15 Auxiliary terminal box 1XB302. The auxiliary terminal box can only be ordered as one complete part, single parts are not available. In this case, please contact the Service Center (Page 163). SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 159: Disposal

"list of candidates" – exists in a concentration exceeding 0.1 percent by weight. ● CAS No. 7439-92-1, lead Based on the currently available information, we assume that this substance does not represent any risk when correctly used, including its disposal. SIMOTICS FD 1LH1 Operating Instructions 01/2019... -

Page 160: Preparing For Disassembly

Sort the components for recycling according to whether they are: ● Iron and steel ● Aluminum ● Non-ferrous metal, e.g. windings The winding insulation is incinerated during copper recycling. ● Insulating materials ● Cables and wires ● Electronic waste SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 161 ● Wooden packaging for sea transport consists of impregnated wood. Observe the local regulations. ● The foil used for water-proof packaging is an aluminum composite foil. It can be recycled thermally. Dirty foil must be disposed of via waste incineration. SIMOTICS FD 1LH1 Operating Instructions 01/2019...

- Page 162 Disposal 11.5 Disposal of components SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 163: Service And Support

(www.siemens.com/yourcontact) Siemens Support for on the move With the "Siemens Industry Online Support" App, you can access more than 300,000 documents for Siemens Industry products – any time and any‐ where. The App supports you in the following areas: ●... - Page 164 Service and Support SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 165: Technical Data And Drawings

Table B-1 Tightening torques for bolted connections with a tolerance of ±10%. Case 1080 1700 2600 4200 1200 2000 3100 4700 7500 SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 166 Non-standard tightening torques Different tightening torques for electrical connections and bolted connections for parts with flat seals or insulating parts are specified in the relevant sections and drawings. See also Securing the rotor (Page 42) SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 167: Quality Documents

Quality documents You can find the quality documents here: https://support.industry.siemens.com/cs/ww/de/ps/13318/cert (https:// support.industry.siemens.com/cs/ww/en/ps/13318/cert) SIMOTICS FD 1LH1 Operating Instructions 01/2019... - Page 168 Quality documents SIMOTICS FD 1LH1 Operating Instructions 01/2019...

-

Page 169: Index

Index " "Siemens Industry Online Support" App, 163 Cable entry and routing, 87 Cable entry plate, 88 Center of gravity, 62 Centering flange, 68, 69 Certificates 5 safety rules, 15 EAC, 24 UL and cUL, 24 Checks to be carried out prior to commissioning, 97... - Page 170 Aligning to the driven machine, 66 Grease replacement intervals, 130 setting down, 63 Grease tank, 131 Machine design Grounding conductor IEC, 21 Connecting, 84 Machine expansion, 67 Grounding system Maintenance Meshed, 50 Maintenance intervals, 123 Materials, 31 SIMOTICS FD 1LH1 Operating Instructions 01/2019...

- Page 171 Sealing insert with break-off ring, 87 Selecting rolling bearing grease, 128 Setting the motor parameters, 104 Qualified personnel, 16 Shaft assembly, 39 Shipping, 42 Siemens Industry Online Support App, 163 Radial force, 69 SIMOTICS Digital Data, 141 Rating plate, 22, 23 Spare parts, 163...

- Page 172 Ground terminals, 84 Torsional loadings, 39 Transporting, 62 Turning the machine on to its side, 59 Type of balancing, 60 V ring, 134, 138 Vibration values, 39, 103 Voltage fluctuations, 38 Voltage via the converter, 99 SIMOTICS FD 1LH1 Operating Instructions 01/2019...

- Page 174 Further Information www.siemens.com/drives Siemens AG Process Industries and Drives Postfach 48 48 90026 NÜRNBERG GERMANY...