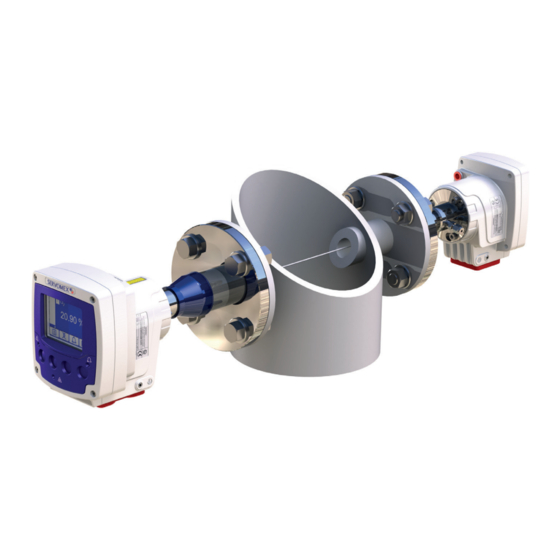

Servomex SERVOTOUGH LaserSPII mini Manuals

Manuals and User Guides for Servomex SERVOTOUGH LaserSPII mini. We have 1 Servomex SERVOTOUGH LaserSPII mini manual available for free PDF download: Operator's Manual

Servomex SERVOTOUGH LaserSPII mini Operator's Manual (162 pages)

Brand: Servomex

|

Category: Measuring Instruments

|

Size: 6 MB

Table of Contents

Advertisement