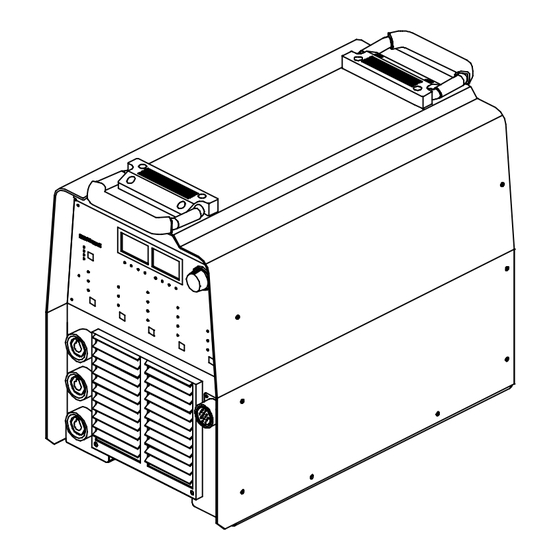

Miller Maxstar 300 SD Manuals

Manuals and User Guides for Miller Maxstar 300 SD. We have 3 Miller Maxstar 300 SD manuals available for free PDF download: Owner's Manual

Miller Maxstar 300 SD Owner's Manual (84 pages)

Brand: Miller

|

Category: Welding System

|

Size: 2 MB

Table of Contents

Advertisement

Miller Maxstar 300 SD Owner's Manual (86 pages)

Brand: Miller

|

Category: Welding System

|

Size: 2 MB

Table of Contents

Miller Maxstar 300 SD Owner's Manual (84 pages)

Arc Welding Power Source

Brand: Miller

|

Category: Portable Generator

|

Size: 2 MB

Table of Contents

Advertisement

Advertisement