Table of Contents

Advertisement

Available languages

Available languages

293 Wright Street, Delavan, WI 53115

Phone: 1-800-535-4950

Fax: 1-800-526-3757

Web Site: tractorsupply.com

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-800-535-4950

English . . . . . . . . . . . . . . . Pages 2-9

©2011

O U

T

I N

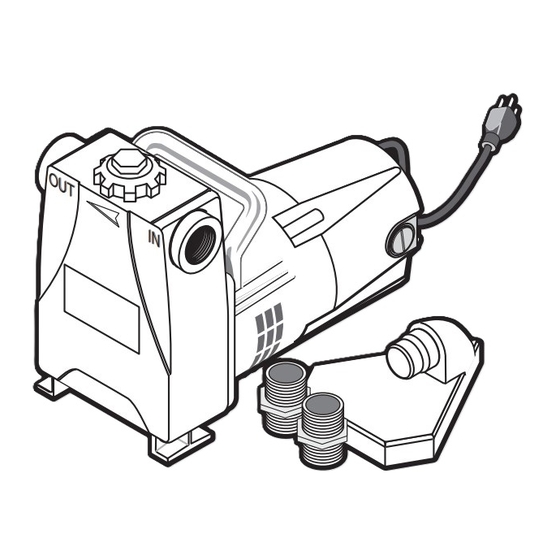

CLBU10C

OWNER'S MANUAL

Cast Iron Transfer Utility Pump

MANUAL DEL USUARIO

Bomba de transferencia de uso

general en hierro fundido

5613 0407

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-535-4950

Español . . . . . . . . . . . Páginas 10-17

CL819 (11/21/11)

Advertisement

Table of Contents

Summary of Contents for CountyLine CLBU10C

- Page 1 293 Wright Street, Delavan, WI 53115 MANUAL DEL USUARIO Phone: 1-800-535-4950 Bomba de transferencia de uso Fax: 1-800-526-3757 Web Site: tractorsupply.com general en hierro fundido CLBU10C 5613 0407 Installation/Operation/Parts Instalación/Operación/Piezas For further operating, installation, Para mayor información sobre el or maintenance assistance: funcionamiento, instalación o...

-

Page 2: Important Safety Instructions

Safety Important Safety Instructions C. Ground electrical outlet box. D. Use only Ground Fault Circuit Interrupter (GFCI) SAVE THESE INSTRUCTIONS - This manual contains protected grounded outlet for cord plug. important instructions that should be followed during installation, operation, and maintenance of the product. Risk of burns. -

Page 3: Limited Warranty

Claims made under this warranty shall be made by returning the product (except sewage pumps, see below) to the retail outlet where it was purchased or to the factory immediately after the discovery of any alleged defect. CountyLine will subsequently take corrective action as promptly as reasonably possible. -

Page 4: Specifications

Installation • Operation Description NOTICE Pump motor is equipped with carbon brushes with a normal operating life of about 300 hours. One This pump is designed for general purpose clear water extra set of brushes is included. Replacement brushes are pumping needs. -

Page 5: Maintenance

Operation • Maintenance Seal Changing Procedure All suction connections must be airtight. Make sure suction lift is not more than 25’ (7.6M). Fill pump body Risk of electric shock. Can shock, burn or through priming port before starting pump. Start pump; it kill. Unplug pump before continuing. should pump water in under 10 minutes (depending on 1. -

Page 6: Cord Replacement

Maintenance 7. Place a cardboard washer over the seal face to 4. Strip all the wires back about 5/8” from the protect it and use a tube to push the stationary seal wire ends. half into the seal plate until it seats (Figure 4C). Be NOTICE Make connections with wire nuts designed sure you don’t scratch or mar the polished face of for connecting 2 #16 AWG wires (see the wire... - Page 7 Brush Changing Procedure Step 1 Step 4 5602 0407 Step 2 5606 0407 Step 5 5604 0407 Step 3 5607 0407 Step 6 " 5605 0407 5604 0407...

-

Page 8: Troubleshooting

Troubleshooting Risk of electrical shock, cuts, and possible unexpected starts. Can result in electrical shock or pinching of hands or tools. If power to pump is on when thermal overload resets, pump may start without warning. Disconnect power before servicing pump. Symptom Possible Cause(s) Corrective Action... -

Page 9: Repair Parts

Repair Parts 4A 4B 5676 0807 Ref. Description Qty. Part Number Pump Body 3/4” NPT x 3/4” Garden Hose Adapter † Fill Plug Overhaul Kit (Includes 4A, 4B, 4C) FPPKG 225-P2 Impeller Shaft Seal Square Cut O-Ring Seal Plate Handle With Hardware C54-30 Power Cord PS17-1507... -

Page 10: Instrucciones Importantes De Seguridad

Seguridad In strucciones importantes de seguridad Conecte a tierra la caja de distribución eléctrica. D. Para el cordón de alimentación use solamente una Guarde estas instrucciones - Este manual contiene instrucciones toma de corriente conectada a tierra protegida por un importantes que se deben seguir durante la instalación y el interruptor accionado por corrientes de pérdida a tierra. - Page 11 Usted deberá pagar por todos los gastos de mano de obra y de envío necesarios para reemplazar el producto cubierto por esta garantía. Esta garantía no se aplicará en las siguientes situaciones: (1) caso de fuerza mayor (2) productos que, a sólo juicio de CountyLine hayan sido sometidos a negligencia, abuso, accidente, mala aplicación, manejo indebido o alteraciones; (3) fallas debido a instalación,...

-

Page 12: Operación

Instalación • Operación Descripción AVISO El motor de la bomba está equipado con escobillas de carbón con una duración de operación de aproximadamente Esta bomba está diseñada para necesidades de bombeo de aguas 300 horas. Se incluye un conjunto de escobillas adicional. Las clara de propósito general. -

Page 13: Mantenimiento

Operación • Mantenimiento Procedimiento para cambiar la junta Todas las conexiones de succión deben ser herméticas. Cerciórese de que la altura de succión no sea mayor que 7,6 m (25 pies). Riesgo de choque eléctrico. Puede provocar choque, Llene el cuerpo de la bomba por el orificio de cebado antes de quemadura o muerte.Desenchufe la bomba antes de continuar. - Page 14 Electricidad Coloque una arandela de cartón sobre la cara de la junta para Pele todos los cables hasta unos 5/8” del extremo de protegerla y use un tubo para empujar la mitad fija de la junta los mismos. dentro de la placa de estanqueidad hasta que quede asentada AVISO Haga las conexiones con conectores de cables (Figura 4C).

- Page 15 Procedimiento para cambiar las escobillas Paso 1 Paso 4 5602 0407 Paso 2 5606 0407 Paso 5 5604 0407 Paso 3 5607 0407 Paso 6 " 5605 0407 5604 0407...

-

Page 16: Localización De Fallas

Localización de fallas Riesgo de choque eléctrico, cuchilla peligrosa y posibles arranques inesperados. Puede provocar choque eléctrico o apretar las manos o las herramientas. Si la corriente a la bomba está conectada cuando se repone el protector térmico de sobrecarga, la bomba podrá... -

Page 17: Piezas De Repuesto

Piezas de repuesto 4A 4B 5676 0807 Ref. Descripción Cant. No. de piezas Unidad de la bomba Adaptador para manguera de jardín de 3/4” NPT x 3/4” † Tapón de llenado Juego de revisión (Incluye 4A, 4B, 4C) FPPKG 225-P2 Impulsor Junta del eje Aro tórico de corte recto...

Need help?

Do you have a question about the CLBU10C and is the answer not in the manual?

Questions and answers

How I start the pump

To start the CountyLine CLBU10C pump:

1. Make sure the pump casing and suction line are completely filled with water (primed).

2. Ensure all wiring is correctly connected and no wires are exposed.

3. Plug in the pump briefly to check that everything is properly connected and there are no shorts.

4. Do not touch the pump while testing.

5. Once confirmed, the pump is ready for operation.

Note: Disconnect power before servicing the pump.

This answer is automatically generated

How do I adjust the pressure. Need more

The manual does not provide instructions for adjusting the pressure on a CountyLine CLBU10C pump. Therefore, pressure adjustment is either not supported or not user-configurable.

This answer is automatically generated