Viking Access Systems K-2 Installation Instructions And Safety Information

Hide thumbs

Also See for K-2:

- Installation instructions manual (44 pages) ,

- Installation instructions manual (48 pages)

Table of Contents

Advertisement

INSTALLATION

INSTRUCTIONS

AND SAFETY INFORMATION

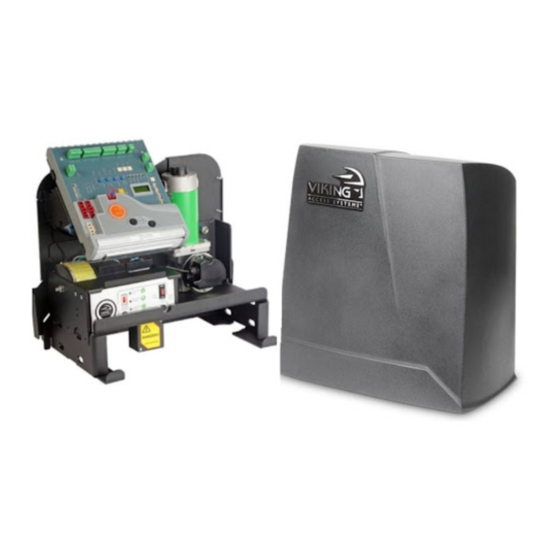

F O R T H E V I K I N G K-2 G AT E O P E R ATO R

F O R T H E V I K I N G K-2 G AT E O P E R ATO R

NEW IMAGE

NEW IMAGE

C L A S S I , C L A S S I I I , A N D C L A S S I V

C L A S S I , C L A S S I I I , A N D C L A S S I V

Residential Vehicular Slide Gate

Residential Vehicular Slide Gate

Operator

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Viking Access Systems K-2

- Page 1 AND SAFETY INFORMATION F O R T H E V I K I N G K-2 G AT E O P E R ATO R F O R T H E V I K I N G K-2 G AT E O P E R ATO R...

- Page 2 The K-2™ gate operator has the capacity to operate slide gates up to 700 lbs. and 30 ft. in length at 100% duty cycle under extreme conditions. This effi cient operator provides a solution for high traffi c residential slide gate applications. The Viking K-2™ gate operator offers effi...

- Page 3 K-2 Vehicular Gate Operator • Revision K2NXMN10.D • August 2013...

-

Page 4: Parts Diagram/Parts List

PARTS DIAGRAM: Item Description Part No. Chassis VNXK2CH Gear Box VNXK2GB Motor VNXK2MO Brush Kit VAMBK Electronic Positioning Sensor 2 (EPS2) VNXL3EPS2 40B17 Sprocket VNXFSP17 Idler Pulley DSIP10 Idler Bushing (w/hardware) DSIB10 Manual Release Switch DUMRS10 Battery Switch DUAL10 120V Receptacle DUOL120 Battery DUBA12S... -

Page 5: Operator References

OPERATOR REFERENCES: 1. OPERATOR COVER 8. BATTERY SWITCH disconnects batteries from the charging circuit 2. COVER LOCK during troubleshooting 3. VFLEX CONTROL BOARD 9. BATTERY BACKUP SYSTEM 4. MANUAL RELEASE/MOTOR SWITCH 10. EMI FUSE discontinues power to the motor and allows for main power supply protection manual operation of the gate 11. -

Page 6: Control Board References

24. EXPANSION PRODUCT CONNECTIONS available for future developments connections for additional products 16. CONTROL BOARD MOUNTING HOLES from Viking Access Systems. pg 46 6. “EPS2” CONNECTOR secures and grounds the control board. monitors the limit positions. 25. “FAIL SAFE/SECURE” Jumper 17. -

Page 7: Table Of Contents

TABLE OF CONTENTS: PARTS DIAGRAM/PARTS LIST PARTS DIAGRAM/PARTS LIST OPERATOR REFERENCES OPERATOR REFERENCES CONTROL BOARD REFERENCES CONTROL BOARD REFERENCES IMPORTANT SAFETY INFORMATION IMPORTANT SAFETY INFORMATION 6-12 6-12 Important Safety Instructions Important Installation Instructions Maintenance General Safety Precautions Operator Classification Photo Beam (non-contact sensor) Installation Edge Sensor (contact sensor) Installation Manual Release Audible Alarm Reset Installation... -

Page 8: Important Safety Information

IMPORTANT SAFETY INFORMATION WARNING! Not Following these instructions may cause severe injury or death. IMPORTANT SAFETY INSTRUCTIONS WARNING! To reduce the risk of severe injury or death. READ AND FOLLOW ALL INSTRUCTIONS . 2. Never let children operate or play with gate controls. Keep the remote away from children. -

Page 9: Important Installation Instructions

IMPORTANT SAFETY INFORMATION WARNING! Not Following these instructions may cause severe injury or death. IMPORTANT INSTALLATION INSTRUCTIONS (Continued) 6. Controls intended for user activation must be located at least six feet (6’) away from any moving part of the gate and where the user is prevented from reaching over, under, around or through the gate to operate the controls. -

Page 10: Maintenance

IMPORTANT SAFETY INFORMATION WARNING! Not Following these instructions may cause severe injury or death. MAINTENANCE Remove the Power Harness from the Control Board (refer to page 18) • Clean and lubricate the turning pins and gate hinges using the recommended lubricant. • Check that all mounting hardware of the gate operator is properly tighten. • Ensure that the gate moves freely. • Check for corroded parts and replace if necessary. • Check the battery for the following: - Battery connections must be free of corrosion. - Battery voltage must be 26v DC (fully charged battery). -

Page 11: Operator Classification

IMPORTANT SAFETY INFORMATION CAUTION: To Reduce the Risk of Fire or Injury to Persons: a. Use only the following type and size battery(ies): Yuasa NP7-12 b. Do not dispose of the battery(ies) in fire. The cells may explode. Check with local codes for possible disposal instructions. c. Do not open or mutalate the battery(ies). Released electrolyte is corrosive and may cause damage to the eyes or skin. -

Page 12: Photo Beam (Non-Contact Sensor) Installation

IMPORTANT SAFETY INFORMATION WARNING! Not Following these instructions may cause severe injury or death. NOTE: This type on installation dOEs NOT reverse the gate all the way back to its limits when the photo beam is obstructed. This installation is only to protect against entrapment and to comply with UL325. -

Page 13: Edge Sensor (Contact Sensor) Installation

IMPORTANT SAFETY INFORMATION WARNING! Not Following these instructions may cause severe injury or death. NOTE: This type on installation dOEs NOT reverse the gate all the way back to its limits when the edge sensor is obstructed. This installation is only to protect against entrapment and to comply with UL325. -

Page 14: Audible Alarm Reset Installation

IMPORTANT SAFETY INFORMATION WARNING! Not Following these instructions may cause severe injury or death. Audible Alarm Reset Switch Installation Manual Reset for the Audible Alarm • UL325 standard requires an audible alarm to go off after two consecutive events detected by the primary entrapment protection of the gate operator (obstruction sensor). -

Page 15: Important Installation Information

IMPORTANT INSTALLATION INFORMATION CAUTION: To Reduce the Risk of Fire or Injury to Persons: WARNING: For use with gates at a maximum 700 lbs. in weight or 30 ft. in length. DO NOT allow pedestrian use of this gate DO NOT install the gate operator to lift gates Locate Control Buttons: 1. -

Page 16: Gate Operator Installation

Follow the local building code to determine the required depth of the con- crete pad. 2. Pad measurements recommended by Viking Access Systems are at lease 24” long, 18” wide and 24” deep to ensure the stable operation of the op- erator, and a minimum of 4”... -

Page 17: Post Mounting Option

GATE OPERATOR INSTALLATION Post Mounting Option Vikings Pipe Stand Kit for K-2 Operator (part # VA-PSKT) is an efficient and effective solution when your application requires the operator to be post mounted. Consult the local building codes for the depth and concrete requirements. -

Page 18: Operator Positioning

GATE OPERATOR INSTALLATION Operator Positioning IMPORTANT: All openings of a horizontal slide gate are guarded or screened from the bot- tom of the gate to a minimum of 4 feet (1.22 m) above the ground to prevent a 2-1/2 inch (57.2 mm) diameter sphere from passing through the openings anywhere in the gate, and in that portion of the adjacent fence that the gate covers in the open position. - Page 19 GATE OPERATOR INSTALLATION ! TECHNICAL TIP: Before starting the installation procedure; • Open and close the gate manually, making sure there is sufficient space between the gate and adjacent walls. • Check that the wheels are turning freely on the track and there are no restrictions while pushing the gate to the open and closed positions. • Confirm that there is adequate spacing for the guide rollers and that there are no restrictions throughout the travel of the gate.

-

Page 20: Electrical Installation

ELECTRICAL INSTALLATION High Voltage Supply Option ! Caution: Always turn off power breakers when working with high voltage. DO NOT connect the “Power Harness” to the Control Board until the electrical installation is complete and ready for verification. STEP 1 ! WARNING: If 230VAC is supplied, disconnect the “120V Receptacle”... -

Page 21: Low Voltage Supply Option

ELECTRICAL INSTALLATION Low Voltage Supply Option TIP: As an alternative to high voltage, the operator can be power by 24VAC. It is recommended to use Vikings Modular Power Box (part # VNXMPB) as the source. ! Caution: Always turn off power breakers when working with high voltage. DO NOT connect the “Power Harness”... -

Page 22: Limits Setup

LIMITS SETUP ! IMPORTANT: In the event of a complete power failure, including battery backup, the limits positions may have been cleared and will need to be reset by following the steps below.. STEP 1 Connect the “Motor Harness” to the Control Board. - Page 23 LIMITS SETUP ! NOTE: The 1st cycle after the limit setup is the “Learn Cycle”. Allow a complete cycle to confirm your settings. 2. During the initial limit setup, the operator will run at half speed. To Readjust the Open Limit: To Readjust the Close Limit: Clear the current limit setting by Clear the current limit setting by...

-

Page 24: Master/Slave Setup

MASTER/SLAVE SETUP Two Wire Communication ! IMPORTANT: DO NOT run the Master/Slave communication cable in the same conduit or within 12” of 115 - 230v power supply cables. ! Technical Tip: DO NOT set the “Timer” and/or “Overlap” features on both operators Control Boards. -

Page 25: Wireless Communication Options

MASTER/SLAVE SETUP Wireless Communication Options ! Technical Tip: DO NOT set the “Timer” and/or “Overlap” features on both operators Control Boards. Only turn these features on at the Master Control Board. REQUIRED ADD-ON: Choose option A or B A. Viking Konnect - Wireless Master/Slave Kit PART# VA-KONNECT-MS B. -

Page 26: Control Board Setup

CONTROL BOARD SETUP Initial Settings “Timer” “Overlap” Hold Open Timer Overlap Delay Automatically closes the gate after Delays the gate from opening for the the selected amount of time from 1-60 selected amount of time from 1-6 seconds. seconds. Turning the dial to between “0” and Typically not used on slide gates. -

Page 27: Initial Settings

CONTROL BOARD SETUP Initial Settings NOTE: Installing a shunt, or jumper, on the pins will activate the feature. “Auto Open” - Power Failure Option Opens the gate automatically during power failure. Resumes normal operation when power is restored. “Last Open” - Power Failure Option Will open the gate automatically when batteries critically low. -

Page 28: Obstruction Detection Sensor (Primary Entrapment Protection)

CONTROL BOARD SETUP Obstruction Sensor (Primary Entrapment Protection) ! IMPORTANT: The appropriate “ODS” setting is dependant upon the gate installation and construction. Set this feature accordingly. Additional Safety equipment should be used to reduce possible risk of injury or vehicle damage. “ODS”... -

Page 29: Heater, Lock Mode

CONTROL BOARD SETUP Viking Heater The operator has an integrated heater that is thermostatically controlled. Activate this feature when the operator is used in application temperatures down to -20°F (-29°C). To set the heater to turn on at the Close Limit: HEATER 1. - Page 30 (THIS PAGE LEFT BLANK INTENTIONALLY) VIKING TECHNICAL SUPPORT 1.800.908.0884...

-

Page 31: Accessory Connections

ACCESSORY CONNECTIONS Re-Open Photo Beam (vehicular Safety) NOTE: This type of photo-beam installation will stop then RE-OPENS the gate all the way to the open limit when the an beam is obstructed. Intended for vehicular safety ONLY. For the purpose of pedestrian entrapment, see pages 10-11. N.O. -

Page 32: Radio Receiver (Typical)

ACCESSORY CONNECTIONS Radio Receiver (Typical) ! IMPORTANT: The Hold Open “Timer” setting (page 24) effects how the gate will respond to the radio receiver command. The control board provides two modes of operation that a radio receiver can control the gate: Open-Stop-Close 1. -

Page 33: Anti-Tail Gate, Open Commands, Guard Station

ACCESSORY CONNECTIONS Anti-Tail Gate, Open Commands & Guard Station TECHNICAL TIP: For more information regarding accessory connections and terminal functions, refer to “Appendix (A)” on pages 42-43. Open Commands “Exit ”, “Fire” and “Strike” input terminals all provide an open command to the control board. -

Page 34: Viking Loop Rack

ACCESSORY CONNECTIONS Viking Loop Rack TIP: This operator may be equipped with a pre-wired Loop Rack that plug-in type loop detectors can be connected to. This provides a convenient alternative to the box type loop detectors that would need to be wired to the control board. Viking does not provide either type of loop detectors. -

Page 35: Guidelines For Loop Installations

ACCESSORY CONNECTIONS Guidelines for Loop Installation 1. Prevent sharp corners in the geometry of the loop sensor. 2. Install the appropriate number of turns for your loop geometry based on the loop perimeter. Use Table C (below) as a guide. 3. -

Page 36: Magnetic Lock, Lock Solenoid

ACCESSORY CONNECTIONS Magnetic Lock, Lock Solenoid NOTE: Viking Access Systems does not provide external gate lock devices. These items can be purchases from your dealer or distributor. Power Do not use the 24v DC power supplied by the control board. An external power... -

Page 37: Barrier Arm (B-12) Synchronization Option

SYNCHRONIZATION WITH B-12 Barrier Arm (B-12) Synchronization Option NOTE: The Control Board provides a convenient solution for applications that require synchronized operation with the Viking Barrier Arm Operator model B-12. This type of application opens and closes in the follow pattern: 1. -

Page 38: Troubleshooting

TROUBLESHOOTING LED References In addition to the LCD Display, the control board LEDs monitor the various circuits of the control board. Use the table below to identify the corresponding “TS Ref#” and refer to page 38-41 for further troubleshooting. Page 41 # LED Status Meaning... - Page 39 TROUBLESHOOTING LED References Use the table below to identify the corresponding “TS Ref#” and refer to page 38-41 for Page 41 further troubleshooting. # LED Status Meaning TS Ref#(s) “C Loop” Normal Condition. SOLID Control Board is receiving an input from a device connected to the 9, 10 C Loop terminal (pages 32, 42).

-

Page 40: Lcd Display References

TROUBLESHOOTING LCD Display References The control board is equipped with a LCD Display that provides operator information, current conditions, settings, diagnostics and error messages. Use the table below to identify the corresponding “TS Ref#” and refer to page 41 for further troubleshooting. 1. - Page 41 TROUBLESHOOTING LCD Display References Page 41 Meaning LCD MSG TS Ref #s Multi Meter Displays MOT AMP This is the motor current amperage during operation __._ A MOT VOLT This is the actual motor voltage during operation __._ VDC AC VOLT This is the actual low voltage AC to the Control Board from the transformer __._ VAC CHARGE...

- Page 42 TROUBLESHOOTING LCD Display References Page 41 Meaning LCD MSG TS Ref #s Error Messages ERR AC Indicates that the is 24 VAC supply to the VFlex Board is too low from the 1, 3, 20 115/230 power supply. ERR AC Indicates that the is 24 VAC supply to the VFlex Board is too high from the 1, 3, 20 115/230 power supply.

-

Page 43: Solutions

TROUBLESHOOTING Solutions Begin the troubleshooting process by referring to the error messages on the LCD Display and/or the Status LEDs on the control board. Use pages 36-40 to identify the Troubleshooting Reference # (TS Ref#) then reference the table below. TS Ref# CHECK Page Ref# Check that the high voltage power supplied to “J-Box”... -

Page 44: Appendix A, B & C

Appendix (A) Access Control Connections Power Connections The control board provides a 24v DC output to power external devices and controls. Alternatively, for devices that require a power supply other than 24v DC , the operators Power Box contains a convenient 120v AC receptacle to connect a plug-in transformer. - Page 45 APPENDIX (A) Relays In General NOTE: Viking Access Systems does not provided the external safety devices and access controls. These items can be purchases from your dealer or distributor. In General Glossary of Terms 1. Terminal: Wire Connections. In regards to the Viking control board, 2.

- Page 46 Appendix (B) Common Radio Receivers - Connections VIKING TECHNICAL SUPPORT 1.800.908.0884...

- Page 47 One low voltage, low current loop detector c. One low voltage, low current photo beam If more specific information is needed please consult with Viking Access Systems. For more information regarding solar energy refer to www.nrel.gov/solar VIKING TECHNICAL SUPPORT 1.800.908.0884...

-

Page 48: Viking Expansion Products

VIKING EXPANSION PRODUCTS VIKING KONNECT Master/Slave Kit Secure and reliable Master/Slave communication using Vikings Konnect technology. Paired with the Viking App, each module also doubles as a diagnostic tool. Part# VA-KONNECT-MS ***Q -7, B-12 & ECU Operators require (2) Antenna Extension Cables (part# VA- RPSMA)*** VIKING KONNECT Diagnostic Tool On-site remote access to the operator from the convenience of a compatible hand held... - Page 49 OUR CONTINUOUS COMMITMENT TO EXCELLENCE Viking Access Systems is continuously working hard to identify and design products that will appeal to the industry and it’s needs. As technology continues to advance, we have developed a completely effi cient and intelligent line of gate operators to meet the changing demands.

- Page 50 STANDARD FEATURES AND OPERATOR SPECIFICATIONS • UL325 and UL991 Compliant by Underwriter • On-Board LCD Display provides diagnostics, Laboratories (UL) standards. operator status, settings and real-time volt and amp readings • Fail-Safe option sets the gate to automatically transfer to a fail-safe mode •...

Need help?

Do you have a question about the K-2 and is the answer not in the manual?

Questions and answers