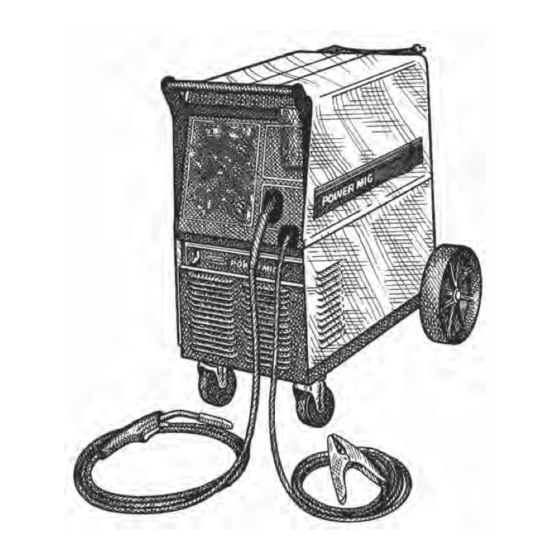

Lincoln Electric POWER MIG 215 Operator's Manual

Lincoln electric welding system user manual

Hide thumbs

Also See for POWER MIG 215:

- Specification sheet (168 pages) ,

- Service manual (99 pages) ,

- Operator's manual (35 pages)

Advertisement

RETURN TO MAIN MENU

IM828-A

POWER MIG

215

™

April, 2007

For use with machine Code Numbers

11070, 1 1 1099, 1 1 1247

For use with machine Code Numbers

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thought-

ful operation on your part. DO

NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT

READING

THIS

MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED

THROUGHOUT. And, most

importantly, think before you act

and be careful.

R

C UL

OPERATOR'S MANUAL

Copyright © 2007 Lincoln Global Inc.

• World's Leader in Welding and Cutting Products •

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

Advertisement

Summary of Contents for Lincoln Electric POWER MIG 215

- Page 1 RETURN TO MAIN MENU IM828-A POWER MIG ™ April, 2007 For use with machine Code Numbers 11070, 1 1 1099, 1 1 1247 For use with machine Code Numbers Safety Depends on You Lincoln arc welding and cutting equipment is designed and built with safety in mind.

-

Page 2: California Proposition 65 Warnings

Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS. -

Page 3: Electric Shock Can Kill

(MSDS) and follow your employer s safety practices. MSDS forms are available from your welding distributor or from the manufacturer. 5.f. Also see item 1.b. AUG 06 POWER MIG 215... - Page 4 8.c. Ground the equipment in accordance with the U.S. National Electrical Code and the manufacturer s recommendations. Jan, 07 POWER MIG 215 CYLINDER may explode if damaged. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the...

- Page 5 électricien qualifié. 3. Avant de faires des travaux à l interieur de poste, la debranch- er à l interrupteur à la boite de fusibles. 4. Garder tous les couvercles et dispositifs de sûreté à leur place. Mar. 93 POWER MIG 215...

- Page 6 Electric for advice or information about their use of our products. We respond to our customers based on the best information in our posses- sion at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such infor- mation or advice.

-

Page 7: Table Of Contents

MASTER TABLE OF CONTENTS FOR ALL SECTIONS ________________________________________________________________________ Installation ...Section A Technical Specifications ...A-1 Safety Precautions...A-2 Uncrating the POWER MIG 215 ...A-2 Location ...A-2 Input Power, Grounding and connection Diagrams ...A-2 thru A-3 Output Polarity Connections ...A-3 Gun and Cable Installation ...A-4 Shielding Gas ...A-4... - Page 8 Liner Removal and Replacement ...D-2 Gun Handle Disassembly ...D-3 Troubleshooting ...Section E How to Use Troubleshooting Guide...E-1 Troubleshooting Guide ...E-2 thru E-4 Wiring Diagram and Dimension Print ...Section F Parts Manual ...Appendix POWER MIG 215 ...P-487 Magnum 250L Gun ...P-202-H.2 POWER MIG 215 Page...

-

Page 9: Installation

TECHNICAL SPECIFICATIONS – POWER MIG 215 Standard Voltage/Phase/Frequency 208/230/1/50/60 Hz Duty Cycle Welding Current Range 30 – 250Amps RECOMMENDED INPUT WIRE AND FUSE SIZES Input Voltage/ Fuse or Breaker Frequency (Hz) Size (Super Lag) 208/50/60 230/50/60 Wire Speed Height 31.79 in... -

Page 10: Installation

UNCRATING THE POWER MIG 215 Cut banding and lift off cardboard carton. Cut banding holding the machine to the skid. Remove foam and corrugated packing material. Untape accessories from Gas Bottle Platform. -

Page 11: Output Polarity Connections

(–) labeled terminal and the work lead, which is attached to the work clamp, is to be connected to the positive (+) labeled terminal. POWER MIG 215 50/60 HZ... -

Page 12: Gun And Cable Installation

GUN AND CABLE INSTALLATION The Magnum 250L gun and cable provided with the POWER MIG 215 is factory installed with a liner for .035-.045" (0.9-1.2 mm) electrode and an .035" (0.9 mm) contact tip. Be sure that the contact tip, liner, and drive rolls all match the size of the wire being used. -

Page 13: Operation

Read entire Operation section before operating the POWER MIG 215. Observe all safety information throughout this manual. OPERATION WARNING ELECTRIC SHOCK can kill. • Do not touch electrically live parts or electrode with skin or wet clothing. Insulate yourself from work and ground. -

Page 14: Product Description

WELDING CAPABILITY The POWER MIG 215 is rated at 215 amps @ 22 volts, at a 30% duty cycle based on a ten minute cycle time. It is capable of higher duty cycles at lower output currents. -

Page 15: Procedure For Changing Drive And Idle Roll Sets

TO START THE WELDER Turn the “Power Switch” switch to “ON”. With the desired voltage and wire speed selected, operate the gun trigger for welder output and to energize the wire feed motor. POWER MIG 215 CAUTION FIGURE B.1... -

Page 16: Feeding Electrode

2. Remove the welding wire from the wire drive. 3. Remove the thumb screw from the wire drive. 4. Remove the welding gun from the wire drive. POWER MIG 215 between 1 and 3 between 3 and 4 between 4 and 6... -

Page 17: Making A Weld

8. To stop welding, release the gun trigger and then pull the gun away from the work after the arc goes out. ® ) being Figure B.2b THUMB SCREW SOCKET HEAD CAP SCREW LOOSEN TIGHTEN POWER MIG 215 ® WARNING ® OUTER WIRE GUIDE... -

Page 18: Avoiding Wire Feeding Problems

FAN CONTROL The fan is designed to come on when input power is applied to the POWER MIG 215 and go off when power is removed. Wire Dia. Gas Type Wire Type Polarity 18 gage 16 gage 14 gage 12 gage10gage 3/16 Outershield 1"... -

Page 19: K363P Readi-Reel Adapter

DRIVE ROLL KITS Refer to Table C.1 for various drive roll kits that are available for the POWER MIG 215.The item in Bold is supplied standard with the POWER MIG 215. Wire Size .023”-.030” (0.6-0.8 mm) .035” (0.9 mm) Solid .045”... -

Page 20: Making A Weld With The Spool Gun Adapter Kit And Spool Gun Installed

Make a test weld to deter- mine the final settings. 5. To return to normal POWER MIG 215 welding, release the spool gun trigger set spool gun selector switch to normal and reset feeder gun voltage pro- cedure setting if necessary. -

Page 21: Maintenance

Repeat this procedure until no further dirt comes out. If this has been done and feed prob- lems are experienced, try liner replacement, and refer to trouble shooting section on rough wire feeding. POWER MIG 215 CAUTION... -

Page 22: Liner Removal And Replacement

KP2026-3 KP2026-2 KP2026-3 KP2026-2 KP2026-3 KP2026-2 This screw should only be gently tightened. Overtightening will split or collapse the liner and cause poor wire feeding. POWER MIG 215 FIGURE D.1 1-1/4" (31.8mm) LINER TRIM LENGTH SET SCREW GAS DIFFUSER NOZZLE INSULATOR (IF USED) -

Page 23: Power Mig

Gasless Nozzle KP1947-1 ∆ (For Innershield) GUN TUBE ASSEMBLIES Standard (60°) KP2015-1 * 45° KP2041-1 Included with POWER MIG 215 ∆ Requires KP2026-1 Gas Diffuser Assembly. POWER MIG 215 English Metric Size Size .025 – .030" 0.6 – 0.8 mm .035 –... -

Page 24: Troubleshooting

HOW TO USE TROUBLESHOOTING GUIDE Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. - Page 25 If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your LOCAL AUTHORIZED LINCOLN ELECTRIC FIELD SERVICE FACILITY for assistance before you proceed. TROUBLESHOOTING POSSIBLE...

- Page 26 If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your LOCAL AUTHORIZED LINCOLN ELECTRIC FIELD SERVICE FACILITY for assistance before you proceed. TROUBLESHOOTING...

- Page 27 Gas does not flow when gun trigger is pulled. If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your LOCAL AUTHORIZED LINCOLN ELECTRIC FIELD SERVICE FACILITY for assistance before you proceed. TROUBLESHOOTING POSSIBLE...

-

Page 28: Wiring Diagrams

WIRING DIAGRAMS POWER MIG 215... - Page 29 WIRING DIAGRAMS Enhanced Diagram POWER MIG 215...

-

Page 30: Dimension Print

DIMENSION PRINT POWER MIG 215... - Page 31 NOTES POWER MIG 215...

- Page 32 NOTES POWER MIG 215...

- Page 33 ● WARNING ● Spanish ● AVISO DE PRECAUCION ● French ● ATTENTION ● ● German WARNUNG ● Portuguese ● ATENÇÃO ● Japanese Chinese Korean Arabic ● ● ● ● ● ● ● ● ● ●...

- Page 34 ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● Spanish ● PRECAUCION French ● ATTENTION ● German WARNUNG Portuguese ● ● Japanese Chinese Korean Arabic WARNING AVISO DE ATENÇÃO...

- Page 35 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...

Need help?

Do you have a question about the POWER MIG 215 and is the answer not in the manual?

Questions and answers