Advertisement

Quick Links

To make your modeling experience totally enjoyable, we recommend that you get experienced, knowledgeable help

with assembly and during your first flights. Your local hobby shop has information about flying clubs in your area

whose membership includes qualified instructors. We also recommend that you contact the AMA at the address below.

They will be able to help you locate a flying field in your area.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

(800) 435-9262

www.modelaircraft.org

Global guarantees this kit to be free from defects in both material and workmanship at the date of purchase. This does

not cover any component parts damaged by use, misuse or modification. In no case shall Global's liability exceed

the original cost of the purchased kit.

In that Global has no control over the final assembly or material used for final assembly, no liability shall be assumed

for any damage resulting from the use by the user of the final user-assembled product. By the act of using the final

user-assembled product, the user accepts all resulting liability.

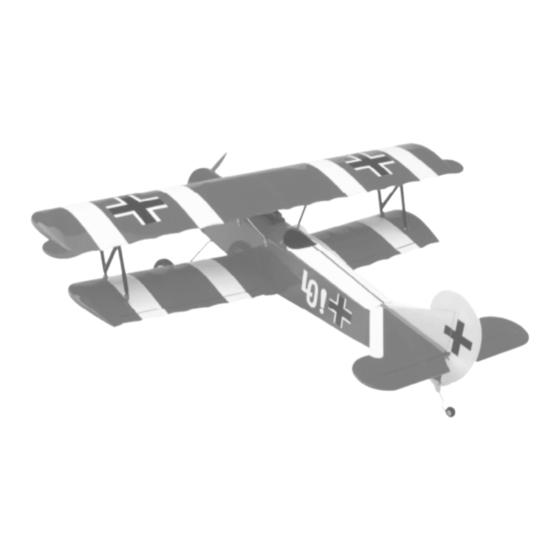

The Fokker D-VII ARF is distributed exclusively by Global Hobby Distributors

18480 Bandilier Circle, Fountain Valley, CA 92728

All contents copyright © 2000, Global Hobby Distributors Version V1.0 9/00

1

Advertisement

Summary of Contents for Global Hobby Fokker D-VII

- Page 1 By the act of using the final user-assembled product, the user accepts all resulting liability. The Fokker D-VII ARF is distributed exclusively by Global Hobby Distributors 18480 Bandilier Circle, Fountain Valley, CA 92728...

- Page 2 Installing the Battery and Receiver ...... 36 Tail Wheel Installation ..........18 Balancing ..............36 Tail Wheel Bracket Assembly ......18 Balancing the Fokker D-VII ......... 36 Mounting the Tail Wheel Bracket ......18 Lateral Balancing ..........37 Installing the Tail Wheel ........19 Control Throws ............

- Page 3 The Fokker D-VIIs were so successful that, in August of 1918 alone, they shot down 565 Allied aircraft. One thing that made the Fokker D-VII such a formidable opponent was the fact that it could hang 45 degrees on its prop and shoot without stalling. By doing this, the Fokker D-VII could fly up under the bellies of enemy aircraft and shoot them down.

- Page 4 {1} Fuselage w/Pushrod Housings {1} 1.5mm x 350mm Wire w/Z-Bend {1} Top Wing - Right & Left Halves {1} Adjustable Servo Connector Assembly {1} Bottom Wing - Right & Left Halves {1} Horizontal Stabilizer w/Elevator & Hinges {4} Aluminum Cabane Struts (2 left & 2 right) {1} Vertical Stabilizer w/Rudder &...

- Page 5 {1} Hitec Focus 4FM Radio w/4 Servos {1} Dubro 1/4" Foam Rubber # 868638 {1} Williams Bros. 2-5/8" Pilot # 592659 {1} Global XX-Silicon Fuel Line # 115923 {1} Ernst External Charge Jack # 223730 {1} Magnum Fueling Valve # 237500 {1} Cirrus On-Board Battery Indicator # 444762 {1} Formula-U Flat Black Paint # 586859 {1} Goldberg 1/4"...

- Page 6 The covering material used on the Fokker D-VII is a heat shrink polyester material. Because of this, it is possible with heat and humidity changes that the covering on your airplane may wrinkle or sag. This trait is inherent in all types of heat shrink material. To remove the wrinkles you will need to purchase, or borrow from a fellow modeler, a heat iron.

- Page 7 The dihedral brace is cut in the shape of a "V". 10) Mix a generous amount of Kwik Bond 30 Minute Epoxy. Apply a thin layer of epoxy to the The "V" shape should face the top surface of the wing exposed half of the dihedral brace, the inside of the when the brace is installed.

- Page 8 2) Using a straight edge ruler and a pen, locate 6) Following the instructions on the packaging, and mark the centerline of the plywood dihedral brace mix a generous amount of Kwik Bond 30 Minute (W-25). Draw one vertical line, on each side of the Epoxy.

- Page 9 6) Remove the two ailerons from the wing and set them aside for now. PARTS REQUIRED 7) Check that the wing is square to the fuse- {1} Wing Bolt Doubler (W-30) lage. To do this use a ruler and carefully measure {2} 4mm x 25mm Machine Screws from the trailing edge of each wing tip to the back {2} 4mm Flat Washers...

- Page 10 12) Install the two 4mm blind nuts into the bot- 18) Apply a generous amount of Kwik Bond tom of the plywood mounting plate. Use a pair of Thick C/A to the bottom of the doubler. Set the dou- needle nose pliers to squeeze the blind nuts up into bler back into place and realign it.

- Page 11 2) Using a ruler and a pen, locate and mark the stabilizer tip on the same side. Do this for both centerline of the horizontal stabilizer, at the trailing sides. When the stabilizer is aligned properly, both edge, and place a mark. Using a builder's triangle, of these measurements should be the same.

- Page 12 12) Set the stabilizer back into place and realign lines you drew and from the bottom edge of the sta- it, double checking all of your measurements once bilizer. Also remove the covering from inside the more. When satisfied with the alignment, hold the outline you drew on top of the horizontal stabilizer.

- Page 13 10) Working with one piece of triangle stock for TOOLS AND SUPPLIES REQUIRED now, align it in the joint between the horizontal and Kwik Bond 30 Minute Epoxy vertical stabilizers. When it's properly aligned, the Pacer Blue Thread Lock triangle stock should be even with the trailing edges Robart Incidence Meter of the stabilizers.

- Page 14 The top wing does not have predrilled outer 6) Install one aluminum wing mount onto each N-Strut mounting tabs. of the two rear cabane struts using two 3mm x 10mm machine screws, two 3mm split washers and two 3mm 3) Thread the two upper strut stabilizer rods nylon insert nuts.

- Page 15 It may be necessary to bend or change the angle of the cabane struts to help align the wing. 11) Install the bottom wing onto the fuselage. Set the fuselage in your airplane stand and use a 15) At this point the top wing should be cen- couple of large rubber bands or small weights to hold tered on the fuselage and parallel with the bottom the airplane firmly in place.

- Page 16 22) One at a time, remove the aluminum wing 28) Mix a small quantity of Kwik Bond 30 mounts from the cabane struts and install them into Minute Epoxy. One at a time, remove the wood their proper positions on the wing. Use eight 3mm x screws that hold the aluminum wing mounts to the 12mm wood screws to secure them into place.

- Page 17 13) Test fit the C/A hinges into the hinge slots in Photo # 20 the elevator. Each hinge should be inserted far enough into the slots so that the centerline of the hinges are flush with the leading edge. If the hinges cannot be inserted deeply enough, use a modeling knife to care- fully cut the hinge slots deeper.

- Page 18 2) Thread one 3mm x 6mm machine screw 20) Using a modeling knife, remove the cover- through the side of the nylon arm and into the wheel ing from over the precut notch in the leading edge of collar. Do not tighten the screw at this time. the rudder.

- Page 19 9) Place a couple of pieces of masking tape be- tween the rudder and the vertical stabilizer to hold PARTS REQUIRED the rudder centered. Using a drill with a 1/16" drill {2} Wire Spoke Main Gear Wheels bit, carefully drill a hole through the rudder to ac- {1} Precovered Landing Gear Wing cept the mounting screw for the nylon clasp.

- Page 20 5) Set the gear bracket back into place and re- 10) Remove the gear wing from the wire. Us- ing a drill with a 1/16" drill bit, drill four pilot holes align it. Install the four nylon straps using eight into the ends of the gear wing at the four locations 3mm x 12mm wood screws.

- Page 21 4) Install the engine onto the mounting beams using four 3mm x 25mm machine screws, eight 3mm PARTS REQUIRED flat washers and four 3mm lock nuts. Tighten the screws and nuts completely to hold the engine firmly {2} Nylon Motor Mount Beams in place.

- Page 22 14) Hold the motor mount/engine assembly up 9) Using a ruler and a pen, measure up 3/16" to the firewall (the motor is mounted upright). Double from the angled horizontal line you drew and draw a check that the four predrilled holes in the motor mount line parallel to it.

- Page 23 5) Using the Magnum Tubing Bender, carefully bend the longer of the two tubes up at a 45º angle. PARTS REQUIRED When the stopper assembly is installed in the {1} Molded Fuel Tank fuel tank, the top of the vent tube should rest inside {1} Rubber Stopper the bubble in the top of the tank.

- Page 24 10) When satisfied with the alignment of the the two preinstalled balsa support rails glued to the stopper assembly, tighten the machine screw using a fuselage sides. Position the tray so that the front edge of the tray is 1-1/2" behind the forward bulkhead. phillips screwdriver until the rubber stopper expands See photo # 37 below.

- Page 25 6) Remove both of the blocks. Using a model- Photo # 39 ing knife, carefully remove the covering material from inside the two outlines you drew. 7) Apply a generous amount of Kwik Bond Thick C/A onto the bottoms of each mounting block. Set the blocks back into place and realign them.

- Page 26 2) Install one adjustable servo connector output shaft. The servo connector should be point- through the third hole out from the center of one of ing toward the rudder servo. See photo # 40 below. the arms. When you thread on the nut, don't tighten Photo # 40 it completely.

- Page 27 4) Place the nylon backplate onto the machine screws, aligning the two holes in the backplate with PARTS REQUIRED the two screws. Using a phillips screwdriver, evenly tighten both machine screws to draw the {1} Nylon Pushrod Tube backplate into place. Be careful not to overtighten {1} 2mm x 90mm Threaded Wire w/L-Bend the screws.

- Page 28 12) Slide the plain end of the rudder pushrod 20) Plug the battery into the switch and the assembly into the nylon pushrod housing (from the switch into the receiver. Plug the rudder servo lead back) until the clevis lines up with the control horn. into the proper slot in the receiver and turn on the radio system.

- Page 29 equipped with End Point Adjustments (EPA), make control horn, it should be angled in about 1/16" to- those adjustments using the transmitter. (Refer to your ward the fuselage side and its centerline should be radio guide for further details.) If your radio does not 1-1/2"...

- Page 30 It is important to glue the threaded wire into the 16) Insert the L-bend in the 2mm x 90mm wire down through the hole. Place a nylon snap keeper nylon pushrod tube. This will prevent the wire from turning or pulling out during flight. over the wire to hold it securely to the servo arm.

- Page 31 their final positions. They should both be 1" above 24) If the control surface deflection is more or the top surface of the wing. See figure # 17 below. less than 3/8" it must be changed. If your radio is equipped with End Point Adjustments (EPA), make Figure # 17 those adjustments using the transmitter.

- Page 32 16) If the ailerons are moving more than 3/8", 10) Snap the clevises into the adjustable con- move both snap keepers in one hole toward the cen- trol horns and carefully slide the pieces of clear tubing ter of the servo horn to decrease the control deflection. up over the clevises to secure them in place.

- Page 33 pieces of masking tape to hold it securely in place 5) Test fit the two machine gun halves together. until the glue fully cures. See photo # 45 below. The edges of each half should be even with each other and there should be little or no gaps between the two Photo # 45 halves.

- Page 34 top screw should be centered down the middle of the cowl and the two holes on each side of the cowl should PARTS REQUIRED be spaced equally between the top and bottom. {1} Molded Fiberglass Cowl {6} 3mm x 6mm Wood Screws 5) All five cowl mounting screws will be lo- cated 1/4"...

- Page 35 # 49 below. 18) Install the propeller onto the engine and Photo # 49 tighten the propeller nut securely. The full-scale Fokker D-VII did not use a spinner assembly. TOOLS AND SUPPLIES REQUIRED Excel Modeling Knife Ernst Airplane Stand...

- Page 36 Do not fly the Fokker D-VII beyond the recom- don't permanently install it at this time. You may mended balance range or an uncontrollable crash...

- Page 37 2) Check every bolt and every glue joint in the Fokker D-VII to ensure that everything is tight and While not absolutely necessary, lateral balanc- well bonded. This should include all of the control ing will make the airplane easier to trim and will make surface hinges as well.

- Page 38 ______________________________________ rudder. ______________________________________ In the air the Fokker D-VII is a very smooth ______________________________________ flyer. Set up with low rate settings, the airplane ______________________________________ behaves very gently. It will fly very smooth and ______________________________________ stable throughout the entire flight envelope.

- Page 39 Simply fold this form on the dotted lines, seal with tape and mail it to us. Do not use staples and make sure our address faces out. 1) Kit: FOKKER D-VII ARF 7) Was any of the assembly difficult for you? If yes, please explain.

- Page 40 Post Office ___________________________ will not ___________________________ deliver without ___________________________ proper (Return Address Here) postage Global Hobby Distributors Attn: Customer Care 18480 Bandilier Circle Fountain Valley CA 92728-8610 Fold along dotted line...

Need help?

Do you have a question about the Fokker D-VII and is the answer not in the manual?

Questions and answers