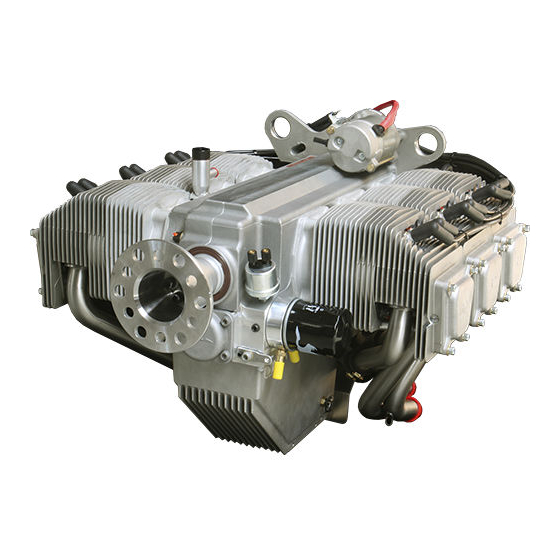

Jabiru 2200 Instruction And Maintenance Manual

Aircraft engine

Hide thumbs

Also See for 2200:

- Overhaul manual (202 pages) ,

- Maintenance manual (106 pages) ,

- Installation manual (55 pages)

Table of Contents

Advertisement

Quick Links

INSTRUCTION AND MAINTENANCE MANUAL

FOR

JABIRU 2200 AIRCRAFT ENGINE

DOCUMENT No. JEM2204-9

This Manual has been prepared as a guide to correctly operate, maintain and

service the Jabiru 2200 engine.

It is the owner's responsibility to regularly check the Jabiru web site at

www.jabiru.net.au for applicable Service Bulletins and have them

implemented as soon as possible. Failure to do this may render the

aircraft un-airworthy and void Jabiru's Limited, Express Warranty.

This document is controlled while it remains on the Jabiru server. Once

this no longer applies the document becomes uncontrolled.

Should you have any questions or doubts about the contents of this manual, please

contact Jabiru Aircraft Pty Ltd.

Applicable to Jabiru 2200 Models from S/No 2068 and above (Hydraulic Lifter Type)

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Jabiru 2200

- Page 1 Should you have any questions or doubts about the contents of this manual, please contact Jabiru Aircraft Pty Ltd. Applicable to Jabiru 2200 Models from S/No 2068 and above (Hydraulic Lifter Type)

-

Page 2: Table Of Contents

Indefinite Storage ............................25 5.8.6 Returning Engine to Service After Temporary Storage ................25 This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... - Page 3 UBASSEMBLY OMPONENT EGISTER AND ARTS NSPECTION ECORD This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 3 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx...

- Page 4 16 NEW ENGINE – JABIRU’S LIMITED, EXPRESS WARRANTY ........... 113 17 JABIRU’S LIMITED, EXPRESS WARRANTY: CLAIM FORM ..........116 This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010...

- Page 5 Figure 40. Drawing 9486091 – Run-In Schedule ............... 95 Figure 41. Oil System Schematic ..................98 This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010...

-

Page 6: List Of Effective Pages

Add new engine storage details Prop flange fitting details added Starter motor overhaul, prop strike details added This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 7: Description

Jabiru products. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 8: General Description

Thrust bearings are located fore and aft of the front double bearing allowing either tractor or pusher installation. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... - Page 9 Jabiru recommend a TBO of 2000 hours, with a top end overhaul done at 1000 hours, or when engine condition indicates the need to overhaul earlier. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010...

-

Page 10: Details

Installation Manual Parts Catalogue All manuals are available on the Jabiru web site www.jabiru.net.au This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 11: Specifications

System. Ignition Unit Jabiru dual ignition - breakerless transistorized. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 11 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 12: Performance

21 L/hr @ Takeoff/Max Continuous Rating Oil Consumption 0.1 L/hr (max) This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 12 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 13: Fuel

(clean stall speed) is 4.3 cm (1.7") water gauge, minimum. A minimum of 6cm (2.4”) is recommended at cruise speed. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 14: Operating Speeds And Limits

2-bladed, fixed-pitch wooden propellers manufactured by reputable companies are recommended by Jabiru Aircraft. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 15: Dimensions

Dimensions Figure 1. Drawing 9404041/1 Engine Dimensions This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 15 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 16: Denomination Of Cylinders

3.11 Distributor Cylinder Map Figure 3. Distributor Cylinder Map This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 16 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 17: Power Curve

Note: Multiply Kilowatts (kW) by 1.341 to get Horesepower (hp). i.e. 63.5 kW x 1.341 = 85 hp. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 18: Operating Instructions

DO NOT apply full power until Oil Temperature reaches 50°C (104°F) DO NOT allow cylinder heads to rise above 150°C (302°F) during ground running. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 19: Take-Off

& with choke for a cold engine. Note: Engine cools quickly with propeller stopped in flight. Choke will therefore normally be needed to restart. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 20: Checks On Engine & Installation

Check temperatures & pressures. Conduct a short ground test at full power (a few seconds) (consult aircraft Flight Manual). This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 21: Periodic Checks

Check fuel system for leaks & abrasion. Check wiring for damage & for tightness. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 22: Check After Initial 25 Hours

50 Hours Check Details of specific operations are shown in "Maintenance" section of this manual. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 23: 100 Hours Check

Every 7 th day the propeller should be rotated through 5 revolutions, without running the engine. Leave the propeller in the horizontal position to ensure even distribution of This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 24: Returning Engine To Service From Flyable Storage

The engine must not be started with the seals in place. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 25: Inspection During Storage

Check fuel tank and fuel lines for moisture and sediment. Drain enough fuel to eliminate any moisture and sediment. Check fuel tank breather is clear. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 26: New Engine Storage

(or a mixture of water & alcohol) may settle & could cause problems. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 27: Icing Due To High Air Humidity

When using auto fuels, ensure all components of the fuel delivery system are cooled to prevent fuel vaporization. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 28: Maintenance

If EGT readings fall outside the range given above, contact Jabiru Aircraft or our local authorised representative. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 29: Compression Check

If low compression is found which cannot be solved by reference to the Troubleshooting section below, please contact Jabiru Aircraft or our local authorized representative. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 30: Ignition System

6.5.1 High-Tension Lead Connections Figure 6. High-Tension Lead Connections This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 30 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 31: Spark Plugs

This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... - Page 32 Accordingly, care must be taken to ensure different types of lifter are not confused during maintenance. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010...

-

Page 33: Head Bolts

Check engine for ease of starting. Conduct idle test run. Checklist of engine inspection. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 34: Propeller

Electronic fuel boost pump and fittings Fuel lines and connectors, fire sleeves. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 35: Engine Inspection Chart

Up to engine S/No. 2732 – not required on engines with the “starfish” steel flywheel adaptor plate This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... - Page 36 Electronic fuel boost pump and fittings Fuel lines and connectors Fire sleeves This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 36 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx...

-

Page 37: Service & Repair

Section 13.1 Early Operation of an engine must be understood. Initial performance data must be recorded. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 38: Top End Overhaul

- (disconnect at cold junction) Lead 14 Remove Exhaust Gas temperature Gauge Lead This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 38 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 39: Engine Disassembly

5/16 Ring O/End spanner 14 Remove Ignition Coils from Alternator Mount 3/16" Allen Key This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... - Page 40 Front Oil Seal Carrier is removed This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS...

- Page 41 Remove Bolts from Conrod ¼ allen key Note 3/8 Ratchet This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 41 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx...

-

Page 42: 2200 Engine Overhaul

Overhaul: The overhaul of any engine is an exacting science. Approved Jabiru service centres as well as Jabiru can provide this service. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 43: Jabiru 2200 Component Inspection And Assembly Procedure

(18 ft/lbs) 3) Wipe off excess locktite at bases of cap screws on the end cap This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 44: Figure 8. Drawing 9429063 - Crank & Rod Assembly

6) Fit gears and new bolts. Use Loctite 620 torque to 8 ft lbs & Lock Wire Figure 9. Drawing 9433064 – Cam Lift Measurement This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 45: Sub-Assembly B - Crankcase And Camshaft

1. Lightly blue bearing shells and one crankcase half 2. Fit bearing shells. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 46: Figure 11. Drawing 9435064 - Oil Pressure Relief Valve Assy

4. Fit old nuts and torque to 40 NM (30 ft/lbs) in two stages This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 47: Figure 13. Drawing 9442064 - Crankcase Spacer

Check cam shaft end float in both halves. Record in build sheet. Check crankshaft end float in both halves and record in build sheet. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 48: Crankcase Decking / Machining

Advice is available on request. 6. Mount head up and cut seats as per drawing This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 49: Figure 14. Drawing 944064 - Valve Guide Replacement

8. Heads of valves must be above the level of the combustion chamber. If they are below, the valves and heads must be replaced. Minimum deck This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 50: Figure 16. Drawing 9444064 - Valve Details

2. Measure valve springs. Replace if they are shorter than service limits. (See Section 12.3.) This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 51: Figure 17. Drawing 9443064 - Valve Spring Measurement

Install Push Rod Tube O'Rings with a small amount of rubber grease Rocker Assembly This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 52: Figure 19. Drawing 9449064 - Rocker Bush Removal

0.4mm (0.004" to 0.010"). 2. Clean up, oil well and reassemble. Cylinders This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 53: Figure 21. Drawing 9436064 - Barrel Hone

(Top and Bottom). Ring manufacturers will specify machinings and orientation of first and second rings. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 54: Sub-Assembly D - Sump And Oil Pump

1. Inspect oil pump inner and outer for damage to rotor surfaces 2. Measure rotor clearance This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 55: Sub-Assembly E - Flywheel, Ignition Coils, Alternator & Alternator Operation

7.5.1.6 Flywheel Inspection Inspect ring gear for damaged teeth This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 55 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 56: Figure 25. Drawing 9437064 - Magnet Pull Test Flywheel

1. Using a multimeter measure the primary resistance (from the earth terminal to the iron core). It should be 0.8 Ω to 1.0 Ω. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 57: Figure 27. Drawing 9439064 - Ignition Primary Resistance

1.1 Ω. 2. Use multi meter to test resistance to ground. Resistance should be infinite This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 58: Permanent Magnet Alternator (Pma) Operation

– Generally, the output leads follow direction of prop rotation. Coils are set at a gap of between .010” - .012” This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 59: Regulator

Figure 30. – Alternator Core Assy 7.5.1.8 Regulator Figure 31. Regulator Wiring This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 59 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 60: Sub-Assembly F - Gear Case

2) Torn diaphragm 3) Weak springs 4) Broken actuating lever. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 60 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... - Page 61 In this position the point on the float hinge is set in such a way that the float top edges are parallel to the top edge of the float chamber. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010...

- Page 62 The vacuum increases with increasing speed. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS...

- Page 63 (7); it then reaches the choke tube via bypass or transition passages (BP) where it is mixed further with pure air. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010...

- Page 64 (50) between the two. The starting shaft is also sealed against the starting carburettor housing by a rubber ring (49). This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010...

-

Page 65: Sub-Assembly H - Final Assembly

1. Photocopy Degree Wheel (increase by 226% to bring to full size) then glue to stiff cardboard and cut out. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 66: Figure 33. Drawing 9427063 - Degree Wheel

Instruction & Maintenance Manual Hydraulic Valve Lifter Models Figure 33. Drawing 9427063 – Degree Wheel This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 67: Figure 34. Drawing 9429063 - Crank & Rod Assy

2. Inspect Bearing shell in position Loctite on all areas This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 67 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... - Page 68 Camshaft Timing 1. Fit crankshaft gear as drawing and put one bolt in crankshaft to hold gear This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010...

-

Page 69: Figure 35. Drawing 9432064 - Timing Gear Alignment

11. The cam shaft gear has 22 teeth and 6 bolt holes, so if it needs adjusting. Move the gear around and re check. Record final measurement in build sheet. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... - Page 70 This will prevent them from loosening. This still allows rotors to be removed when necessary. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010...

-

Page 71: Figure 36. Drawing 9430064 - Rear Plate Through Bolts

Hydraulic Valve Lifter Models Figure 36. Drawing 9430064 – Rear Plate Through Bolts This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 72: Figure 37. Drawing 9431064 - Gearbox & Distributor Rotors

H14 Fit Fuel Pump Assembly Note: Use loctite 242 on cap screws. Use molybdenum disulphide grease on push This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... - Page 73 Tension the screws in a standard diagonal tightening pattern. Torque all screws first to 27 Nm (20 lb.ft), This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010...

-

Page 74: Engine Run In

Check leak down Note: There is a run in program and run in checklist to fill out. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 75: Engine Installation

21 Check for oil. Fill if needed. 2.3L oil (2.43 US quarts) 22 Wind over to get oil pressure This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 76: Prop Strike Inspection

Figure 38 Dial Indicator Position for Crankshaft & Prop Flange Run Out Remove one spark plug from each head. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 77: Starter Motor Overhaul

AN3 bolts. These bolts are loctited on assembly and will require heating with a hot air This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 78: Reassembly

07 4155 2669 Outside Australia + 61 7 4155 2669 This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 78 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 79: Notes Before Starting Engine

For the first 25 hours of operation, add 2.2 litres of Shell 100 oil. After 25 hours drain oil, check torque of cylinder head bolts to 20 ft lbs. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... - Page 80 Limited Express Warranty. CAUTION: USE OF OIL/FUEL ADDITIVES VOIDS JABIRU’S LIMITED, EXPRESS WARRANTY This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS...

-

Page 81: Service Documentation

Production Certificate #444128 Notes: For std prop flange length only This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 81 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 82: Subassemblya - Component Register & Parts Inspection Record

Subassembly A – Component Register & Parts Inspection Record Crankshaft, Propeller Mount Flange and Conrods This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 83: Subassemblyb - Component Assembly Procedure

For Jabiru Aircraft Pty Ltd Production Certificate #444128 Notes: This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 83 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 84: Subassemblyb - Component Register & Parts Inspection Record

Subassembly B – Component Register & Parts Inspection Record Crankcase and Camshaft Assy This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 85: Subassemblyc - Component Assembly Procedure

For Jabiru Aircraft Pty Ltd Production Certificate #444128 Notes: This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 85 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 86: Subassemblyc - Component Register And Parts Inspection Record

Date ____________ For Jabiru Aircraft Pty Ltd Production Certificate #444128 This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 86 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 87: Subassemblyd - Component Assembly Procedure

For Jabiru Aircraft Pty Ltd Production Certificate #444128 Notes: This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 87 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 88: Subassemblyd - Component Register And Parts Inspection Record

Date ____________ For Jabiru Aircraft Pty Ltd Production Certificate #444128 This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 88 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 89: Subassemblye - Component Assembly Procedure

For Jabiru Aircraft Pty Ltd Production Certificate #444128 Notes: This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 89 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 90: Subassemblye - Component Register And Parts Inspection Record

Date ____________ For Jabiru Aircraft Pty Ltd Production Certificate #444128 This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 90 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 91: Subassemblyf - Component Assembly Procedure

For Jabiru Aircraft Pty Ltd Production Certificate #444128 Notes: This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 91 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 92: Subassemblyf - Component Register And Parts Inspection Record

Date ____________ For Jabiru Aircraft Pty Ltd Production Certificate #444128 This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 92 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 93: Subassemblyg - Component Assembly Procedure

For Jabiru Aircraft Pty Ltd Production Certificate #444128 Notes: This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 93 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 94: Subassemblyh - Component Assembly Procedure

For Jabiru Aircraft Pty Ltd Production Certificate #444128 Notes: This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 94 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 95: 10 Jabiru 2200 Engine Run-In & Testing

10.1 Run-In Schedule Figure 40. Drawing 9486091 – Run-In Schedule This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 95 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 96: Jabiru 2200A Aero Engine Ground Test Form

Hydraulic Valve Lifter Models 10.2 Jabiru 2200A Aero Engine Ground Test Form This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 96 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 97: Run-In Checks

Cyl 1 7. Check all paper work 8. Drain fuel/oil. Prepare for Shipment. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 98: 11 Table Of Lubricants

35 o C Note: Multigrade aviation oils are also available. Figure 41. Oil System Schematic This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 99: 12 Torque Specification For Bolts & Nuts

Initially head bolts are assembled at 24 Ft Lb. After 25 hours head bolts can be checked at 20 Ft Lb. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 100: Prescribed Sealants And Primers

All gasket areas use Loctite 'Gasket Eliminator' 515 LOCTITE PRIMER 7471 used on threads before LOCTITE This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 101: New Tolerances

Note: Early engine components can exhibit slight variations to these new tolerances but still be serviceable. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 102: Maximum Allowable Clearances (Wear Limits)

Note: Variation can occur, overall tolerances may be acceptable with advice from Jabiru Aircraft Pty Ltd. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 103: Electrical Systems Specifications

14.2 VDA at 3000 RPM Tacho Coil Resistance 160 to 170R This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 103 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 104: 13 Operating Notes - Quick Reference Guide

When you change oil from the “run in” type to the “normal” oil at or around 25 hrs, replace oil filter. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 105: Normal Operation Notes

(thickness .010”). Place between magnets on flywheel and coil. Check both sides, that is each coil to each magnet (4 checks). This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 106: Oil

No low speed high nose altitude climb outs. RETORQUE heads on annual inspection. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 107: Consumables

While it is unusual for a problem to occur, a methods for finding the source of “common” problems are listed in the Trouble Shooting Section 10 of the this manual. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010... -

Page 108: 14 Trouble Shooting

Renew ignition unit Clogged fuel filter Renew fuel filter This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 108 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 109: Engine Runs Too Hot - Oil Temperature Above 110 O C

Repair of cylinder head necessary Oil leaks Seal leaks This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 109 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 110: Knocking Under Load

Notes: Refer to Section 6.8 for additional details on hydraulic lifter maintenance requirements. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 111: Troubleshooting Quick Guide

Jabiru recommend TBO of 2000 hrs, with a Top End overhaul at 1000 or when engine condition indicates the need for overhaul earlier. CAREFULLY READ MANUALS SUPPLIED This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... -

Page 112: 15 Airworthiness Limitations Section

Signed: ........Date: ........Dinh Nguyen Delegate of the Authority This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 112 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx... -

Page 113: 16 New Engine - Jabiru's Limited, Express Warranty

Alteration or modification of the engine by any party not authorised in writing by JABIRU The fitting of parts or accessories not marketed by JABIRU This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS... - Page 114 This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS...

- Page 115 This Limited, Express Warranty does not cover those parts listed as exclusions above and is subject to the same general exclusions. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010...

-

Page 116: Revision Dated : June 2010 Issued By: Dps Page: 2 Of

NOT APPROVED REASON PRINTED NAME: SIGNED: DATED: This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Dated : June 2010 Issued By: DPS Page: 116 of 116 REVISION L:\files\Manuals_For_Products\Engine_Manuals\Transition\JEM2204-9_I&M_unsigned.docx...

Need help?

Do you have a question about the 2200 and is the answer not in the manual?

Questions and answers