Jabiru 2200 Maintenance Manual

Gen 4 aircraft engine

Hide thumbs

Also See for 2200:

- Overhaul manual (202 pages) ,

- Instruction and maintenance manual (116 pages) ,

- Maintenance manual (106 pages)

Table of Contents

Advertisement

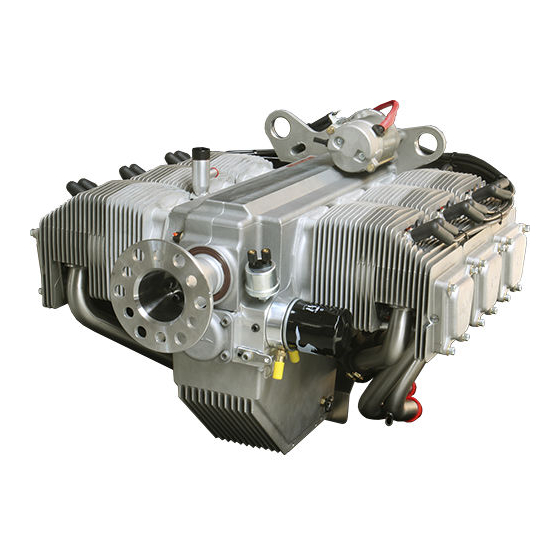

JABIRU 2200 Gen 4 AIRCRAFT ENGINE

JABIRU 3300 Gen 4 AIRCRAFT ENGINE

This Manual has been prepared as a guide to correctly operate, maintain and

It is the owner's responsibility to regularly check the Jabiru web site at

www.jabiru.net.au for applicable Service Bulletins and have them

implemented as soon as possible. Failure to do this may render the

aircraft un-airworthy and void Jabiru's Limited, Express Warranty.

This document is controlled while it remains on the Jabiru server. Once

this no longer applies the document becomes uncontrolled.

Every effort is made to ensure that the information provided is accurate and up to date. However, there is an

inherent risk in the use of Jabiru® engines in aircraft and in the operation of aircraft generally. The operator

of any type of aircraft powered by Jabiru® engines assumes any and all risk relating to such use.

Accordingly, use of the information herein is at the user's risk and Jabiru disclaims any responsibility for any

errors or omissions. In the event that you have any questions or concerns with regard to any information

herein, please contact Jabiru Aircraft Pty Ltd.

MAINTENANCE MANUAL

DOCUMENT No. JEM0005-2

th

DATED: 25

service Jabiru 2200 Gen 4 & 3300 Gen 4 engines.

FOR

September 2018

Advertisement

Table of Contents

Summary of Contents for Jabiru 2200

- Page 1 Every effort is made to ensure that the information provided is accurate and up to date. However, there is an inherent risk in the use of Jabiru® engines in aircraft and in the operation of aircraft generally. The operator of any type of aircraft powered by Jabiru® engines assumes any and all risk relating to such use.

-

Page 2: Table Of Contents

OOLS : ............................24 QUIPMENT : ............................24 ENERAL This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS Page: 2 of 74... - Page 3 HROUGH BOLT AND STUD BOLT TORQUE CHECK ..................43 RESSURE ELIEF ALVE DJUSTMENT This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS Page: 3 of 74 ISSUE...

- Page 4 Continued Operational Safety Reporting ....................74 16.1.2 Owner Change of Address Notice ......................74 This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS...

- Page 5 Figure 14 – Safety Wire Installation Using a Twister/Pliers & By Hand ............47 Figure 15 – Choke Schematic ......................... 57 This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018...

-

Page 6: General Information

Jabiru harmless from any injury, loss, damage, or mishap that I, my spouse, heirs, or next of kin may suffer as a result of my use of any Jabiru product, except to the extent due to gross negligence or wilful misconduct by Jabiru. I understand that proper skills and training are essential to minimize the unavoidable risks of property damage, serious bodily injury and death that arise from the use of Jabiru products. -

Page 7: List Of Effective

Australia website – www.jabiru.net.au – or the website of their local Jabiru representative to check for new or updated additional service information. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 8: 2200/3300 Gen 4 Engine Manuals

Distributor Cap BOSCH GH506 (4 cyl) GB74 (6 cyl) This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS Page: 8 of 74... -

Page 9: Owner/Operator Responsibilites (Lsa Aircraft)

Section 16 provides forms which may be filled out and submitted for the purposes of fulfilling Owner/Operator COSM (Continued Operating Safety Management) requirements. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 10: Design Details

Electric 12 V / 1.5 kW Oil Filter RYCO Z 386 or equivalent This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS... -

Page 11: Full Power Static Rpm

Jabiru Aircraft may choose to void any warranty for engines which have been damaged due to “bad” MOGAS. Operators use MOGAS at their own risk. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 12: Fuel

Table 8 – Oil SAE VS Commercial Designations Equivalence of SAE and commonly used Commercial Grade designations: This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated :... -

Page 13: Cooling System

Values will differ for other installations or configurations; refer to the Jabiru Engine Installation Manual for additional details. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 14: Operating Speeds And Limits

Constant monitoring is critical to the continued health and performance of the engine. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated :... -

Page 15: Torque Specifications

Continuous electrical load exceeding the maximum rated load for the alternator will cause the stator windings to overheat and the alternator stator to fail. DO NOT overload the alternator. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 16: Engine Dimensions And Layout

3.13 Engine dimensions and layout Figure 2 – 2200 Gen 4 Engine dimensions and layout This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS... -

Page 17: Figure 3 - 3300 Gen 4 Engine Dimensions And Layout

Jabiru Gen4 2200 & 3300 Aircraft Engines Figure 3 - 3300 Gen 4 Engine dimensions and layout This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated :... -

Page 18: Distributor Cylinder Map

3300 3500 Figure 5 – Power / Torque Curves – Typical 3300 Gen 4 engine This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS... -

Page 19: Operating Instructions

When engine runs, adjust the throttle to achieve smooth running at approximately 1200 RPM. Deactivate Choke. Check Oil Pressure has risen within 5 seconds - if not, shut down. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 20: Cold Engine

Switch ignitions OFF. At higher speeds (above 90 KIAS) the propeller may windmill – reduce aircraft speed until propeller stops turning. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 21: Operation In Winter

This engine has been ground run to a specific run in program and is ready for flight when delivered. Before initial start add oil to engine (2.3 litres with cooler for 2200 engine, 3.5L with cooler for 3300 engine). -

Page 22: Engine Installation

Damage to engines caused by installation issues may not be covered by Jabiru’s Limited, Express Warranty. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 23: Maintainer Requirements

Feeler gauges: metric and imperial sizes Torque wrench: 3/8” drive, “name” brand (Snap-On, Warren & Brown etc), recently calibrated This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated :... -

Page 24: Sealants And Compounds

Sealants and Compounds See JEM0004 for a list of the sealant and compounds used in Jabiru 2200 Gen 4 and 3300 Gen 4 configuration engines. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. -

Page 25: Storage & Cleaning

Service Letter JSL007 for details. Then: Clean engine thoroughly. Seal or cover all openings. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS... -

Page 26: Inspection During Storage

When the engine is to be run the storage measures must be reversed as detailed in the appropriate sections above. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 27: Cleaning Engine And Engine Compartment

In some cases it may be necessary to also clean the firewall. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated :... -

Page 28: Service Interval Tolerance

100 hourly – More extensive than a 50 hourly, replacement of several disposable parts Annual – Similar in scope to a 100 hourly inspection This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 29: Standard Engine Maintenance Tasks

Test runs are to be carried out by appropriately trained, authorised personnel only This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 30: Engine Cowlings

For operation in heavy dust conditions, replace air filter at shorter intervals than recommended for normal conditions. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS... -

Page 31: Induction Air Scat Hose

Each cap should fit with a clear “click” as it connects to the distributor cap or spark plug. Take care not to over-bend and contact and replace any which are damaged. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 32: Pressure Differential (Leak-Down) Test

With the problem narrowed down, correction work can more easily be carried out. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated :... -

Page 33: Spark Plugs

9.2). If all through bolt torque seals are found intact no torque check is necessary. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated :... -

Page 34: Crankcase Seals

Remove rocker covers and visually check the rocker covers Check the rocker chamber has been sufficiently lubricated (i.e. is oil in the chamber) This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated :... -

Page 35: Hydraulic Lifter Maintenance

This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 36: Empty Oil Collection Bottle

JEM0005-1 Jabiru 2200 & 3300 Aircraft Engines Remove dipstick and fill the engine with oil. (approx. 2.3 litres for 2200 Gen 4 engine, 3.5 litres for 3300 Gen 4 engine) Check the oil level using the dipstick. It should lie within the minimum and maximum marks. -

Page 37: Mechanical Fuel Pump

L1, L2 or LAME (A&P or LSA Repairman / Maintenance) Return to Service: L1, L2 or LAME (A&P or LSA Repairman / Maintenance) This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated :... -

Page 38: Engine Mount Points

Be mindful when working around the starter solenoid, that hands or tools do not bridge the two contacts completing the circuit. Electrical shock will result and the starter motor will be activated. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 39: Ignition Coil

When working at the rear of the engine care must be taken to ensure no metallic materials are captured by the ignition or alternator magnets. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 40: Alternator Inspection

Use a multimeter to measure the resistance of the windings, refer to section 3.12 for the allowable range. Resistance to ground should be infinite. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 41: Special Maintenance Tasks

The alternator stator need not be removed since the access hole through the stator mount provided is sufficient for tool access. All 2200 Gen 4 / 3300 Gen 4 engine use Nordloc washers under the retaining capscrews. Set a torque wrench to the installation torque setting for flywheel capscrews (refer to JEM0004). ... -

Page 42: Through Bolt And Stud Bolt Torque Check

(or it may indicate the torque wrench being used is not calibrated correctly). If fretting is suspected a crankshaft friction test should be conducted (refer to JEM0004). This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated :... -

Page 43: Oil Pressure Relief Valve Adjustment

Ensure that the spring is not coil-bound: press on the tip of the oil valve plunger and ensure there is a minimum of 1mm movement. Figure 11 – Oil Pressure Relief Valve Assembly This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated :... -

Page 44: Tachometer And Sender

Tacho post with sender installed Figure 12 – Tacho Sender This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated :... -

Page 45: Carburettor Adjustment

EGT or Lambda sensor results. DO NOT ADJUST ENGINE TUNING BASED ON SPARK PLUG COLOURS ALONE This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 46: Use Of Safety Wire

Excessive twisting of the wire will weaken the wire. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 47: Figure 13 - Safety Wire Details

Figure 13 – Safety Wire Details Figure 14 – Safety Wire Installation Using a Twister/Pliers & By Hand This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 48: Non-Approved Propellers

(per prop strike inspection detailed below) Flywheel capscrews – REPLACE Refer to engine overhaul manual for guidance This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated :... -

Page 49: Engine Overhaul Intervals

10.1 Full Overhaul Full overhauls must be carried out as detailed in the latest approved revision of the 2200 Gen 4 / 3300 Gen 4 Engine Overhaul assembly and Parts book (JEM0004). During a full overhaul all parts are cleaned, measured, inspected and recorded in the prescribed build sheets in the manual. -

Page 50: Engine Removal Procedure

7/16" Tube Socket Undo Engine Mount Bolts 7/16" Spanner Remove Engine from Engine Mount Frame This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS... - Page 51 Jabiru Aircraft or local authorized representative This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated :...

-

Page 52: Trouble Shooting

See Section 11.7 Unsatisfactory propeller Refer to engine installation manual for prop requirements This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS... -

Page 53: Engine Runs Too Hot - Oil Temperature Above 110 O C

Unsatisfactory induction system Check induction system for sharp edges, rough corners etc. Refer to engine installation manual. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated :... -

Page 54: Low Oil Pressure

G operations. Strong turbulence in flight can have a similar effect: reduced RPM /speed is recommended when operating in strong turbulence. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated :... -

Page 55: Excessive Vibration

Changing the engine tuning to a leaner air fuel mix can cause piston damage. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... -

Page 56: Engine Hard To Start At Low Temperature - Cold Start Checklist

February 2011, however older units will need to be checked and, if necessary, enlarged. See Figure 15 This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated :... -

Page 57: Irregular / Low Compressions

Burnt or worn valve or seat Refer Engine Overhaul Manual. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS Page: 57 of 74... -

Page 58: Hydraulic Valve Lifters

Excess metal in oil filter Cam / Lifter damage surfaces. Replace if damaged. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS... -

Page 59: Engine Maintenance Worksheets

8) Check mechanical fuel pump and fuel system for leaks (refer to section 8.26 and 8.27) Comments: First 5 hours This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS... - Page 60 11) Check the security of safety wiring on the sump plug Comments: First 5 hours This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS...

-

Page 61: 25-Hour Oil And Filter Change

3) Empty oil collection bottle, note amount emptied (refer to section 8.22) Comments: hourly This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS... -

Page 62: Hour, 100 Hour And Annual Inspection Worksheet

50 hrly 100 hrly Annual ● ● ● This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS Page: 62 of 74 ISSUE... - Page 63 50 hrly 100 hrly Annual ● ● ● This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS Page: 63 of 74 ISSUE...

- Page 64 50 hrly 100 hrly Annual ● ● ● This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS Page: 64 of 74 ISSUE...

- Page 65 50 hrly 100 hrly Annual ● ● ● This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS Page: 65 of 74 ISSUE...

-

Page 66: New Engine - Jabiru's Limited, Express Warranty

Non-compliance with the conditions of this Section III constitutes a waiver of any and all benefits of this Limited, Express Warranty. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018... - Page 67 ANY PARTICULAR AIRCRAFT, OTHER THAN AIRCRAFT MANUFACTURED BY JABIRU, AND THE RESPONSIBILITY TO DETERMINE SUITABILITY RESTS WITH THE OWNER. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018...

- Page 68 Warranty, provided, however, that said parts must be delivered directly to JABIRU (Airport Drive, Hinkler Airport, Bundaberg West, Queensland, This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018...

- Page 69 JABIRU or its authorized Distributor/Dealer to repair it. Also, if requested, the owner must also present proof of purchase. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018...

- Page 70 Signed By: ___________________________Date:______________________ Name (Printed): __________________________________________________ Address (Printed): __________________________________________________ This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS Page: 70 of 74...

-

Page 71: Jabiru's Limited, Express Warranty: Claim Form

APPROVED NOT APPROVED REASON PRINTED NAME: SIGNED: DATED: This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS Page: 71 of 74 ISSUE... -

Page 72: Revisions

Initial Issue Corrections to specifications (section 3) 25/09/18 Corrections to maintenance tasks (section 8) This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS... -

Page 73: Feedback And Reporting

This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS Page: 73 of 74... -

Page 74: Continued Operational Safety Reporting

Previous Owner: New Owner: Contact Details of New Owner This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. SEP 2018 Dated : Issued By: AS Page: 74 of 74...

Need help?

Do you have a question about the 2200 and is the answer not in the manual?

Questions and answers