Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Factory Cat 29ss Series

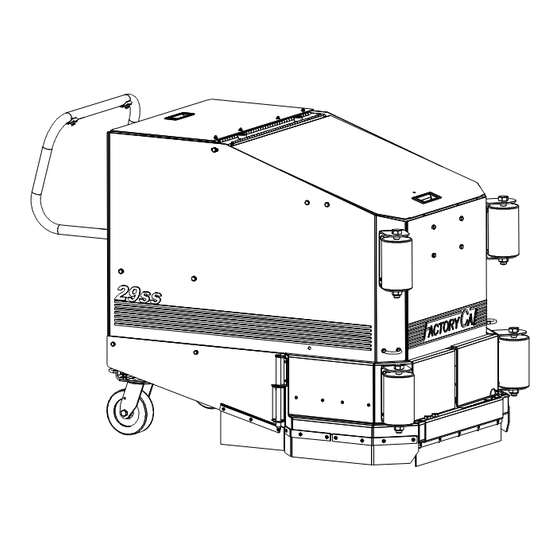

- Page 1 ACTORY Operator, Parts, & Service Manual 29", 33" Disk Scrubber 28", 32" Cylindrical R.P.S. Corporation Phone: 1-800-634-4060 P.O. Box 368 Fax: 1-866-901-3335 Racine, Wisconsin 53401 www.factorycat.com Copyright R.P.S. Corporation 2003 Edition 1, World Rights Reserved.

- Page 2 Operator, Parts, & Service Manual 29", 33" Disk Scrubber 28", 32" Cylindrical Mid-Central Corporation Phone: 1-800-450-9824 P.O. Box 241 Fax: 1-866-632-6961 Racine, Wisconsin 53401 www.tomcatequip.com Copyright Mid-Central Corporation 2003 Edition 1, World Rights Reserved.

-

Page 3: Table Of Contents

TABLE OF CONTENTS OPERATING ILLUSTRATIONS PARTS SECTION ILLUSTRATIONS Table of Contents ....Solution System ....Page 1 Page 20-21 Machine Delivery Form . -

Page 4: Table Of Contents

MACHINE DELIVERY FORM Dealer: ________________________________________________ Serial Number: _ __________________ Location: (City, ST): ______________________________________ Install Date: _____________________ Hour Meter: _____________________ Customer: _____________________________________________ Installed By: _____________________ Contact: _______________________________________________ Address: _______________________________________________ City: ____________________ State: _________ Zip: ____________ Phone: ____________________ Fax: _______________________ Model Number: _____________________________ Options: 1. -

Page 5: Specifications

SPECIFICATIONS 29ss 35ss BODY CONSTRUCTION/DIMENSIONS Tank Construction: (7/16 ) Roto-Poly (7/16 ) Roto-poly Frame Construction: 3/16 (Stainless Steel) 3/16 (Stainless Steel) Drive Wheel: (2) 11 diameter x 4 (2) 11 diameter x 4 Casters: (2) 6 Diameter x 2 (2) 6 Diameter x 2 Height: 43 inches 43 inches... -

Page 6: Machine Specifications

COMMON WEAR PARTS ITEM Model 29ss Model 29ss Model 35ss Model 35ss Brush Type Disk Cylindrical Disk Cylindrical BRUSHES Super-Grit 15-421SS 17-421SS Tough-Grit 15-421S 28-521S 17-421S 32-521S Midi-Grit 15-421C 28-521C 17-421C 32-521C Light-Grit 15-421PS 28-521PS 17-421PS 32-521PS Poly (.028) 15-421P 17-421P Nylon (.012) 15-421N... -

Page 7: Wear Parts

!! SAFETY MESSAGES !! Your safety, and the safety of others, is very important, and operating this unit safely is an important responsibility. To help you make informed decisions about safety, we have provided operating procedures and other safety information in the manual. This information informs you of potential hazards that could hurt you or others. -

Page 8: Safety

!! SAFETY PRECAUTIONS !! Hazardous voltage. Shock or Always use the charger provided WARNING: WARNING: electrocution can result. Always disconnect by the manufacturer to charge the machine. the batteries before servicing this machine. It is an automatic charger, specifically designed to charge at the appropriate rate. If Batteries emit hydrogen gases, WARNING: you must use a different charger, disconnect... - Page 9 CONTROL FUNCTIONS 1. Serial Number Plate: Used to identify the date of manufacture & customer information. 2. Main Power Switch: Turns the machine on and off. 3. Speed Control Knob: Controls the drive speed on the machine. Rotate (clockwise) to increase speed. 4.

-

Page 10: Machine Controls

MACHINE CONTROLS AND FEATURES 1. Serial Number Plate 11. Drive Buttons 21. Solution Fill Door 2. Main Power Switch 12. Handle Bar 22. Rec. Drain Hose 3. Speed Control Knob 13. Squeegee Lift Lever 23. Sol. Drain Hose/Sight Tube 4. Reverse Switch 14. -

Page 11: Machine Setup

MACHINE PREP MACHINE SETUP UNCRATING MACHINE ATTACHING SQUEEGEE Carefully check the crate for any signs of Lower the squeegee mounting plate by damage. Check the crate to ensure that all releasing the lever. (See Fig. 2) accessories are included. Batteries are in the unit. -

Page 12: Machine Prep & Operation

WARNING: TURN OFF MACHINE BEFORE INSTALLING BRUSHES. INSTALLING DISK BRUSH OR PAD INSTALLING CYLINDRICAL BRUSH Unscrew the three wingnuts on the brush Raise scrub head. Turn the machine on access door and remove the door. Be and press the bottom half of the brush careful not to lose the wingnuts and lock up/down on/off switch (o). - Page 13 FILLING SOLUTION TANK ONE PASS SCRUBBING Transport the machine to the filling STEPS: (See Fig. 10) station. Raise the scrub head and squeegee when transporting. Turn machine on, make sure the speed knob is at a low setting. Turn machine off. Lower squeegee by moving the lift Open front lid at the front of the lever all the way to the right.

-

Page 14: Operating Hints

OPERATING HINTS Observe the amount of solution the machine is dispensing on the floor and adjust to the desired flow. To increase the solution flow rate, rotate the solution control knob clockwise. To shut the solution off completely just release the drive buttons. Solution stops when brushes stop. Keep an eye on foam buildup in the recovery tank. -

Page 15: Draining Tanks

DRAINING TANKS DRAINING RECOVERY TANK Alway's empty recovery tank when refilling the solution tank. To drain the recovery tank, perform the follwing steps. 1. Remove drain hose from the expansion plug holder by turning the T-Handle counter clockwise, lower to drain. (See Fig.11A &... -

Page 16: Battery Charging

BATTERY CHARGING DRAINING SOLUTION TANK CAUTION: The following instructions are To drain leftover cleaning solution from the intended for the 24V charger supplied with solution tank, perform the following steps. the machine. (Part # 7-244) 1. Remove end cap and clear sight tube/ CHARGER SPECIFICATIONS drain hose off the bracket, lower to drain. -

Page 17: Storing Machine

Wipe down machine if needed. Use a non-abrasive, non-solvent cleaner, or a clean damp cloth. Recharge the batteries if needed. WEEKLY MAINTENANCE Check water level in each cell of the batteries, and fill as needed. Always use distilled water to refill batteries. Batteries SHOULD NOT be filled to the tops of the Fig. -

Page 18: Machine Maintenance & Storage

PREVENTATIVE MAINTENANCE RECORDS USE THIS FORM TO MAKE COPIES FOR YOUR INTERNAL RECORDS PREVENTATIVE MAINTENANCE CHECKED NOTE Rotate Brushes / Replace Pads __________ ________________________________ Rotate Side Brooms __________ ________________________________ Drain Solution Tank __________ ________________________________ Flush Solution System __________ ________________________________ Clean Solution Screen __________ ________________________________ Drain Recovery Tank... -

Page 19: Trouble Shooting

TROUBLE SHOOTING PROBLEM CAUSE SOLUTION No power, nothing operates Faulty main switch Contact local servicing dealer Batteries need charging See CHARGING BATTERIES Faulty battery(s) Replace battery(s) Loose battery cable Tighten loose cable Interrupt switch on charger plug is stuck Unstick switch Brush motor(s) do not operate Brush deck is not down Put brush deck down w/ switch... -

Page 20: Troubleshooting Guide

TROUBLE SHOOTING PROBLEM CAUSE SOLUTION No solution flow No solution in tank Fill solution tank Solution knob OFF Turn solution knob counter- clockwise Faulty solution valve Contact local servicing dealer Faulty solution reostat Contact local servicing dealer Poor water recovery Recovery tank is full Empty recovery tank Ball/Screen in recovery... - Page 21 SPARE PARTS BOOK Walk-Behind Scrubbers Spare parts are sold through authorized Dealers. If you have forgotten your dealer's name, or you have moved the machine to a new location, please Call us at: 1 (800) 634-4060, or and we will re-establish a dealer contact for you. Fax us at: 1 (866) 901-3335 TO ORDER PARTS: Please provide the machine's Serial No.

- Page 22 Model 29ss/35ss Parts Breakdown...

-

Page 23: Solution System

Solution System CLEANOUT DOOR W/GASKET (FITS BOTH TANKS) TANK SCREW ON LID WITH GASKET & SCREWS PN 7-415 PN 7-425 SOLUTION LEVEL SIGHT TUBE AND DRAIN HOSE 1" ID WITH HOSE CAP & END BARB PN 7-417 Page 20... - Page 24 Solution System Item Part No. Part Desription Comments 7-414 SOLUTION TANK 7-425 TANK SCREW ON LID W/GASKET PN 7-425 INCLUDES ITEMS 2,18,19 7-414A BULKHEAD FITTING, 3/4" FNPT 7-454 3/4 NPT TO 5/8 STRAIGHT BARB H-62005 CLAMP 5/8 - 1 1/2" SS PN 7-417 INCLUDES ITEMS 5, 10, 11, 12 7-112C 1.0 OD X .50 GROMMET...

-

Page 25: Recovery System

Recovery System RECOVERY TANK LID (COMPLETE) PN 7-423 DRAIN HOSE ASS'Y PN 5-730 CLEANOUT DOOR (INCLUDES GASKET) PN 7-415 TO SQUEEGEE Page 22... - Page 26 Recovery System Item Part No. Part Desription Comments 5-225 VAC MOTOR INCLUDES PN 5-708A 5-708A VAC MOTOR GASKET 5-719 CLAMP 1 9/16 - 2 1/2 " SS 5-730 INCLUDES ITEMS 3,4,5,6 5-720 DRAIN HOSE END TUBE 5-730 INCLUDES ITEMS 3,4,5,6 5-721 TANK DRAIN HOSE 5-730 INCLUDES ITEMS 3,4,5,6...

-

Page 27: Body Parts

Body Parts 54 50 54 50 50 54 58 60 58 ROLLER ASS'Y (SET OF 2) P/N 7-125 Page 24... - Page 28 Body Parts Item Part No. Part Desription Comments 290-2110 BATTERY 6 VOLT 395 AH 4-101 SERIAL NO. PL. (FACTORY CAT) 21-0101 SERIAL NO. PL. (TOMCAT) 4-127 HANDLE 4-131 HINGE 23 3/4" SS 4-529 CURTAIN CLAMP 5-886 WAND CLIP 7-110S MAINFRAME...

-

Page 29: Jaw Assembly

Jaw Assembly TO BODY 9 13 ROLLER ASS'Y (SET OF 2) P/N 7-125 Page 26... - Page 30 Jaw Assembly Item Part No. Part Desription Comments 7-120 LH JAW MODEL 29 7-135 LH JAW MODEL 35 7-122F JAW CURT CLAMP FRT MODEL 35 7-122R JAW CURTAIN CLAMP REAR 7-122S INT SPL GUARD MNT 7-125A ROLLER 7-126 HD ROLLER BRACKET 7-129 RH JAW MODEL 29 7-136...

-

Page 31: Traction Drive

Traction Drive 31 32 28 AXLE BEARING WITH FLANGES (SET OF 2) PN-7-357 26 23 Page 28... - Page 32 Traction Drive Item Part Number Part Description Comments 32-3040 TIRE, GRAY, PNEUMATIC, 4.10/3.50-5 32-3045 TIRE, BLACK, PNEUMATIC, 4.10/3.50-5 32-3050 TIRE, GRAY, FOAM, 4.10/3.50-5 32-3055 TIRE, BLACK, FOAM, 4.10/3.50-5 5-131S CURTAIN CLAMP 5-431A 1/4" X 1" KEY INCLUDES ITEM 17, PN H-1032HCN 5-768 SQUEEGEE BALL JOINT 7-123...

-

Page 33: Squeegee System

Squeegee System BACKUP WHEEL (SET OF 2) PN 5-757 SIDE WHEEL (SET OF 2) PN 5-760 Page 30... - Page 34 Squeegee System Item Part Number Part Description Comments 21-7220 SQUEEGEE TRAIL MOUNTS 21-7570 BACK UP WHEEL (GREY) 21-7575 INCLUDES ITEMS 2,24,25,26 28-7160 38" SQUEEGEE BAND, REAR 290-7160 45" SQUEEGEE BAND, REAR 28-7170 38" SQUEEGEE BAND, FRONT 290-7170 45" SQUEEGEE BAND, FRONT 28-7181 38"...

-

Page 35: Central Command Ii

CENTRAL COMMAND II Page 32... - Page 36 CENTRAL COMMAND II Item Part No Part Description Comments 21-2007 COMPONENT PLATE 21-2230 MICRO SWITCH 21-4510 SOLUION CONTROL KNOB, BLUE 21-4520 SPEED CONTROL KNOB, RED 290-2020 BRACKET 290-2815 CIR. BREAKER - 15A, 24V 290-2890 COMPUTER CONTROL 290-2891 LCD SCREEN 4-257 CONNECTOR, RED 50 5-223 LIMIT SWITCH...

-

Page 37: Squeegee Lift (Optional)

Electric Squeegee Lift Page 34... - Page 38 Electric Squeegee Lift Item Part No. Part Desription Comments 7-224 ACTUATOR 7-822 TROLLEY FACE PLATE 7-823 LIFT TROLLEY 7-824 GUIDE BLOCK 7-827 CABLE PULLEY 7-828 CABLE STOP 7-829 CABLE ADJUSTER 7-830 LIFT CABLE 7-833 GUIDEBLOCK CABLE STOP 7-835 GUIDE BLOCK SPACER 7-837 FUSE RESETTABLE 2 AMP H-00592...

-

Page 39: Water Jet System

WATER JET SYSTEM TO ELBOW BETWEEN TEE & FILTER TO ADJUSTABLE FLOW VALVE Page 36... - Page 40 WATER JET SYSTEM Item Part Number Part Description Comments 21-1601 1/2" BARBED ELBOW INCLUDES ITEM 7 5-446 1/2 " PLASTIC BARB TEE 5-891 PUMP, WATER JET 5-891B FLO - JET 5-895 SPRAY NOZZLE 5-896 9FT GARDEN HOSE 5-898 HOSE ADAPTER 7-112C 1.0 OD X .50 GROMMET 7-4041...

-

Page 41: Disk Scrub Head System

Disk Scrub Head System TO ADJ. SOLUTION FLOW VALVE Page 38... - Page 42 Disk Scrub Head System Item Part Number Part Description Comments .375 OD. X .31 ID. X .5 LG 21-5000 BRUSH DRIVER 290-1243 3/8" ID, 1/2" OD, 1/4" LG BEARING 290-1245 3/8" ID, 1/2" OD, 3/8" LG, FLANGE BEARING 290-1247 FW BRONZE .50" ID X 1.0" OD X .062 38-222 MOTOR 1 HP X 350 RPM 5-124...

-

Page 43: Cylindrical Deck

Item Part No. Part Desription Comments CYLINDRICAL BRUSH SEE COMMON WEAR PARTS 1-305 BEARING HOUSING 1-421 IDLER BEARING 22-2110 2 HP MOTOR 22-7970 MOVABLE IDLER ARM 35 Cylindrical 25-8320 HOPPER RAIL, 25" 28-8320 HOPPER RAIL, 28" 5-832 HOPPER RAIL, 32" 4-317 IDLER PULLEY 4-319...

Need help?

Do you have a question about the 29ss Series and is the answer not in the manual?

Questions and answers