Table of Contents

Advertisement

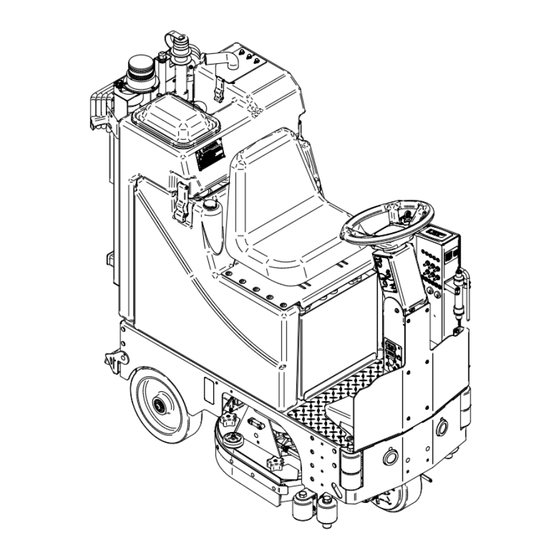

Model GTX-V2

Model

Parts Manual

R.P.S. Corporation

P.O. Box 368

Racine, Wisconsin 53401

www.factorycat.com

1711 South Street

Racine, WI 53404 (USA)

1-262-681-3583

© 2022 RPS Corporation, All Rights Reserved.

Parts Manual

2018 Version 1.0

2021 Version 2.0

R.P.S. Corporation

Phone: 1-800-634-4060

P.O. Box 368

Fax:

Racine, Wisconsin 53401

Phone: 1-800-634-4060

Fax:

1-866-901-3335

V

Operating Instructions (EN)

1-866-901-3335

2.0

2.0

2.0

V V V

V

Models:

26''-28'' Disk

25'' - 29'' Cylindrical

24'' & 28'' ORBITAL

26'', 30'' Disk

25'', 29'', 33'' Cylindrical

28'', 32' ORBITAL

30'', 34'' & 36'' Disk

29'', 33'', 37'' Cylindrical

N/A ORBITAL

Read these Instructions before

using the machine.

Read these Safety Messages

before using the machine.

FC-RIDER-v2-1-OP-EN

2.0

2.0

2.0

V

V V V

Pilot

GTX

GTR

v22.235

Advertisement

Table of Contents

Need help?

Do you have a question about the Pilot and is the answer not in the manual?

Questions and answers