Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Farm King 45 Series

- Page 1 OperatOr and parts Manual Rotary Tiller 45 Series - 60"& 72" 092010 FK366...

-

Page 3: Table Of Contents

Table of Contents - 45 Series Rotary Tiller Table of Contents Introduction ..........................5 Safety ............................6 • Safety ..........................6 • General Safety ........................7 • Start-up Safety .........................7 • Operation Safety ......................7 • Transport Safety .......................7 • Service and Maintenance Safety ..................8 •... - Page 4 Table of Contents - 45 Series Rotary Tiller • Troubleshooting ......................27 Bolt Torque ..........................28 • Checking Bolt Torque .....................28 Parts Drawings ...........................29 • Tiller Drawings .......................29 • Tiller Parts List ........................31 • PTO Assembly Drawing ....................34 • PTO Assembly Parts List ....................35 •...

-

Page 5: Introduction

Farm King has a collection of rotary tiller models to suit your garden and landscaping needs. The 45 Series Tiller attaches to the 3-point hitch as well as Cat. 1 Quick Hitch and is designed to fit a variety of tractors, from 25 hp to 45 hp. Tilling widths range from 55" to 69" in the 45 Series. -

Page 6: Safety

Safety - 45 Series Rotary Tiller Safety Safety Instructions Remember, YOU are the key to safety. Good safety practices not only protect you, but also the people around you. Make these practices a working part of your safety program. Be certain that everyone operating this equipment is familiar with the recommended operating and maintenance procedures and follows all the safety precautions. -

Page 7: General Safety Instructions

Safety - 45 Series Rotary Tiller General Safety Instructions • Have a first-aid kit available for use and know how to use it. • Have a fire extinguisher available, stored in a highly visible location, and know how to use it. -

Page 8: Service And Maintenance Safety

Safety - 45 Series Rotary Tiller Service and Maintenance Safety • Stop engine, set brake, remove ignition key, and wait for all moving parts to stop before servicing, adjusting, repairing, or unplugging. • Support the equipment with blocks or safety stands before working beneath it. - Page 9 Safety - 45 Series Rotary Tiller • Replace safety signs immediately should they become damaged, torn or illegible. Obtain replacements from your authorized dealer using the part numbers shown.

-

Page 10: Assembly

Assembly / Start-up - 45 Series Rotary Tiller Assembly Instructions The machine is shipped with the PTO shaft not installed. To install the PTO driveline on the machine, follow this procedure. Clear the area of bystanders, especially small children. 2. Clean the splines on the yoke and the input shaft. -

Page 11: Pre-Operation Checklist

Start-up - 45 Series Rotary Tiller Pre-operation Checklist Efficient and safe operation of the Rotary Tiller requires that each operator reads and understands the operating procedures and all related safety precautions outlined in this section. A pre-operation checklist is provided for the operator. It is important for both personal safety and maintaining the good mechanical condition of the Tiller that this checklist is followed. -

Page 12: Operation Instructions

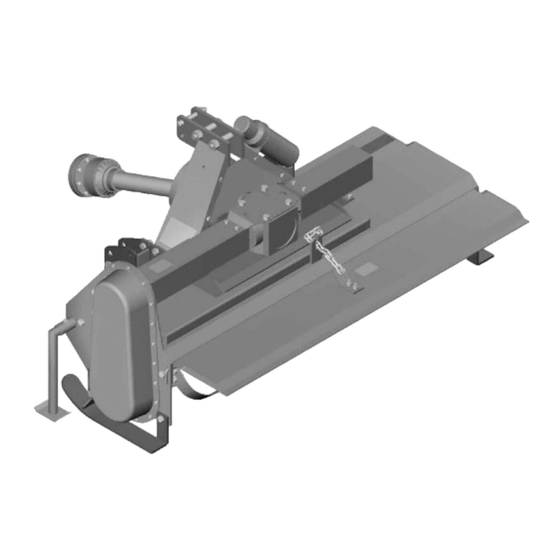

Tiller will provide many years of trouble free service. Machine Components The Farm King 45 Series Rotary Tiller consists of a rotating drum that is equipped with bent blades for breaking up and leveling soil. The blades are turned through the soil while the machine moves over the working area. -

Page 13: Equipment Matching

Operation - 45 Series Rotary Tiller Equipment Matching To insure the safe and reliable operation of the Tiller, it is necessary to use a tractor with the correct specifications. Use the following list as a guide in selecting a tractor to use on the machine. -

Page 14: Driveline Dimension

Operation - 45 Series Rotary Tiller Driveline Dimension A PTO driveline is supplied with the machine. To accommodate the variety of 3-point hitch geometry available today, the driveline can be too long for some machines and must be cut. It is very important that the driveline be free to telescope but not bottom out when going through its working range. - Page 15 Operation - 45 Series Rotary Tiller Pull the driveline apart and cut 1/2 of the dimension determined in step 5 from each end. Add another 1/2" (12mm) to each cut off segment. 8. Be sure to use a hacksaw to cut 1/2 from each end of the separated shaft. Cut both the plastic tube and the metal cores.

-

Page 16: Attaching/Unhooking

Operation - 45 Series Rotary Tiller Attaching/Unhooking The Tiller should always be located on a level, dry area that is free of debris and other foreign objects. When attaching the machine to a tractor, follow this procedure: Clear the area of bystanders, especially small children. -

Page 17: Field Operation

11. Reverse the above procedure when unhooking from the tractor. Field Operation Farm King 45 Series Rotary Tillers are designed with the inherent flexibility of operating well in almost any kind of soil and terrain conditions. However, the operator has the responsibility of being familiar with all operating and safety procedures and following them. - Page 18 Operation - 45 Series Rotary Tiller 6. Align the unit with the working area. Starting Machine: - Run the engine at low idle - Slowly engage the PTO control to start the machine. - Slowly bring the engine to the rated PTO speed. Never exceed rated speed.

-

Page 19: Transporting

Operation - 45 Series Rotary Tiller Transporting When transporting the machine, review and follow these instructions: Be sure all bystanders are clear of the machine. 2. Be sure that the machine is securely attached to the tractor and all retainer pins are installed. -

Page 20: Theory Of Operation

Operation - 45 Series Rotary Tiller Theory of Operation... -

Page 21: Storage

Operation - 45 Series Rotary Tiller Storage After the season's use, the machine should be thoroughly inspected and prepared for storage. Repair or replace any worn or damaged components to prevent any unnecessary down time at the start of next season. To insure a long, trouble free life, this procedure should be followed when preparing the unit for storage: Clear the area of bystanders, especially small children. -

Page 22: Maintenance

Maintenance - 45 Series Rotary Tiller Maintenance Service Follow Maintenance Safety Instructions as outlined. Fluids and Lubricants Hydraulic Oil: - Use standard hydraulic oil for all operating conditions. 2. Gear Box Oil: - Use an SAE 85W90 gear oil for all operating conditions. -

Page 23: Servicing Intervals

Maintenance - 45 Series Rotary Tiller Servicing Intervals If fittings will not take grease, remove and clean thoroughly. Also clean lubricant passageway. Replace fitting if necessary. 8 Hours or Daily: Telescoping Tubes and Quick Disconnect 20 Hours Lubricate PTO driveline (7 locations). -

Page 24: A-Frame Adjustment

Maintenance - 45 Series Rotary Tiller 40 Hours Check gearbox oil level. - add as required. 2. Add approximately 10 squirts of grease in chain case. Annually Change gear box oil. Refill with SAE 85W90 gear oil. 2. Wash machine. -

Page 25: Time Replacement

Maintenance - 45 Series Rotary Tiller Tine Replacement When the Tines are damaged in any way, they will need to be replaced. When replacing, follow this procedure: Clear the area of bystanders, especially small chidlren. 2. Raise the machine until the Tines are slightly above the ground. -

Page 26: Clutch Maintenance

Maintenance - 45 Series Rotary Tiller Clutch Maintenance Before first use or after storage of more than one month, the clutch should be checked. 2. Disengage clutch by turning in the four socket set screws. 3. Run the PTO at low idle to slip the clutch linings. This will help remove the dirt, corrosion, and surface gloss from the clutch plates and also ensure that the linings are loose. -

Page 27: Troubleshooting

Maintenance - 45 Series Rotary Tiller Troubleshooting The Buhler Farm King 65 Series Rotary Tiller moves curved Tines on a turning rotor through the ground to break it up and prepare a seed bed. It is a simple and reliable system that requires minimal maintenance. -

Page 28: Bolt Torque

Bolt Torque - 45 Series Rotary Tiller Bolt Torque Checking Bolt Torque The tables shown below give correct torque values for various bolts and hex bolts. Tighten all bolts to the torques specified in chart unless otherwise noted. Check tightness of bolts periodically, using bolt torque chart as a guide. -

Page 29: Parts Drawings

Parts - 45 Series Rotary Tiller 45 Series Rotary Tiller Assembly Drawings... - Page 30 Parts - 45 Series Rotary Tiller...

-

Page 31: Tiller Parts List

Parts - 45 Series Rotary Tiller When Ordering Parts Always give your dealer the Model, Color and Serial Number of your machine to assist him in ordering and obtaining the correct parts. Use the exploded view and tabular listing of the area of interest to exactly identify the required part. - Page 32 Parts - 45 Series Rotary Tiller Item Part Number Description 903171 Spacer 1.05"OD x 2-1/4" 906837 A-Frame Bottom Weldment 903159 A-Frame Top Weldment - Left 903160 A-Frame Top Weldment - Right 906838 A-Frame Brace Plate 909731 Drag Shield Weldment (60") 909732 Drag Shield Weldment (72")

- Page 33 Parts - 45 Series Rotary Tiller Item Part Number Description 967361 7/8" x 4" Clevis Pin 86171 3/8" x 1-1/4" Hex Bolt 811790 3/4" x 4-1/2" Hex Bolt 81701 3/4" Lock Washer 81700 3/4" Hex Nut 81593 3/8" Lock Washer 81592 3/8"...

-

Page 34: Pto Assembly Drawing

Parts - 45 Series Rotary Tiller PTO Assembly Drawing... -

Page 35: Pto Assembly Parts List

Parts - 45 Series Rotary Tiller Item Part Number Description F0409 Shaft Complete 907193 Outer Half Shaft - Tractor 907194 Inner Half Shaft - Implement 907186 Yoke - Tractor End 936540 Repair Kit 936344 Outer Tube Yoke 936351 Flex Pin Outer Yoke... -

Page 36: Gearbox Drawing And Parts List

Parts - 45 Series Rotary Tiller Gearbox Drawing Item Part Number Description 906913 Gearbox Complete 907151 Housing 907152 Ball Bearing 967303 Snap Ring E.35 Din 471/2 907153 Oil Seal 907154 Ring 967305 Snap Ring 1.80 Din 472 907155 Roller Bearing... -

Page 37: Shipping Kit And Bundle Numbers

Shipping Kit and Bundle Numbers - 45 Series Rotary Tiller Shipping Kit and Bundle Numbers The following is a list of Kit Numbers for this product and the Bundle Numbers, Descriptions, and Quantities for each Kit. Quantity Bundle Number Description C4560 - 60"... -

Page 38: Warranty

Warranty - 45 Series Rotary Tiller Farm King Limited Warranty This document limits your warranty rights. Base Limited Warranty Buhler Industries Inc. provides this warranty only to original retail purchasers of its product. Buhler Industries Inc. warrants to such purchasers that all Buhler Industries Inc. manufactured parts and components used and serviced as provided for in the Operator’s Manual shall be free... - Page 39 Warranty - 45 Series Rotary Tiller Authorized Dealer and Labor Costs Repairs eligible for labor under this limited warranty must be made by Buhler Industries Inc. or an authorized Farm King dealer. Buhler Industries Inc. retains the exclusive discretion to determine whether it will pay labor costs for warranty repairs or replacements, and the amount of such costs that it will pay and the time in which the repairs will be made.

- Page 40 Warranty - 45 Series Rotary Tiller (Note that some provinces or states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or consequential damages, so the above limitations and exclusion may not apply to you.) This warranty gives you specific legal rights and you may also have other rights, which vary from province to province or state to state.

- Page 42 1330 43rd Street NW Fargo, ND USA 58102 Ph.: 701.282.7014 | Fax: 701.282.5865 Toll Free: 888.524.1004 E-mail: info@buhler.com www.farm-king.com Equipment shown is subject to change without notice. ©2010 Buhler Trading Inc. Printed in USA. TSX:BUI a division of Buhler Industries Inc.

Need help?

Do you have a question about the 45 Series and is the answer not in the manual?

Questions and answers