Summary of Contents for Meta System ARCHIMOD 20

- Page 1 ARCHIMOD ® Operating and Maintenance Manual Rev. September 2010 Code 5040275001 The original of this document is drawn up in the Italian language...

-

Page 3: Table Of Contents

Operating and Maintenance Manual Index of Contents GENERAL INDEX ............CERTIFICATION OF CONFORMITY ....... 1. FOREWORD ............Overview ........... Purpose of the manual ....... Where and how to keep the manual ... Manual update ........Collaboration with the user ....Manufacturer ........ - Page 4 Operating and Maintenance Manual 4. UNPACKING ............Visual inspection........ 4.1.1 Checking the equipment and accessories supplied ......Positioning ......... Positioning and unpacking ....Checking the contents of the pack ..Handling ..........Storing ..........4.6.1 UPS ........... 4.6.2 Batteries ..........5.

- Page 5 Operating and Maintenance Manual 10. DISMANTLING ............10-1 10.1 Disposing of the batteries ....10-1 10.2 Dismantling the UPS ......10-1 10.3 Disposing of the electronic components .. 10-1 11. TABLES ............11-1 12. NOTES ............12-1 code 5040275001 Rev. September 2010...

- Page 6 73/23/EEC amended with directives 93/68/EEC 89/336/EEC amended with directives 92/31/EEC 93/68/EEC 62040-2 Standards to which conformity is declared: EN 62040-1-1, EN EN 62040-3 Manufacturer: Meta System S.p.A. Address: Via Majakovskij, 10/b Reggio Emilia, Italy Type of equipment: Models: ARCHIMOD ®...

-

Page 7: Foreword

This equipment will be referred to simply as ‘equipment’ or even ‘machine’ in this manual and is manufactured by Meta System S.p.A. whose address can be found further on in this chapter. The contents of this manual are intended for an operator who has already been instructed on the precautions to be taken in relation to the presence of electricity. -

Page 8: Purpose Of The Manual

Operating and Maintenance Manual PURPOSE OF THE MANUAL The purpose of this manual is to provide indications for using the equipment safely and to carry out routine maintenance procedures. Adjustments and extraordinary maintenance jobs are not dealt with in this manual as they are reserved exclusively to the assistance technician who must observe to the technical and design characteristics for which the equipment was made when working on it. -

Page 9: Collaboration With The User

Manufacturer, giving him the address of the new user so the latter can be reached if there are any communications and/or updates deemed indispensable. META SYSTEM S.p.A. reserves the property rights of this publication and forbids the total or partial reproduction of it without prior written consent. MANUFACTURER The equipment’s identification data are given on the ID plate. -

Page 10: Guarantee Terms

All pieces repaired or replaced remain the property of Meta System S.p.A.. Meta System S.p.A. is not liable for costs such as: loss of profits or failed turnover, loss of equipment, loss of data or software, complaints from third parties and so on. -

Page 11: Technological Description

2. Technological description ARCHIMOD TECHNOLOGY ® Congratulations on your purchase of a UPS ARCHIMOD product from Meta System S.p.A.. ® Thanks to the UPS ARCHIMOD your critical equipment will be protected by a constant and ® reliable supply of power for years to come. -

Page 12: Features

Operating and Maintenance Manual FEATURES Power module The basic module 6,700 VA is basically made up of the following functional blocks: command and control logic (microprocessor controlled), rectifier/PFCr, inverter, booster, battery charger, automatic bypass. The power unit is the Plug & Play type to facilitate power expansion and all maintenance works. Each module is paralleled with other identical ones until the UPS power wanted on each phase is reached. -

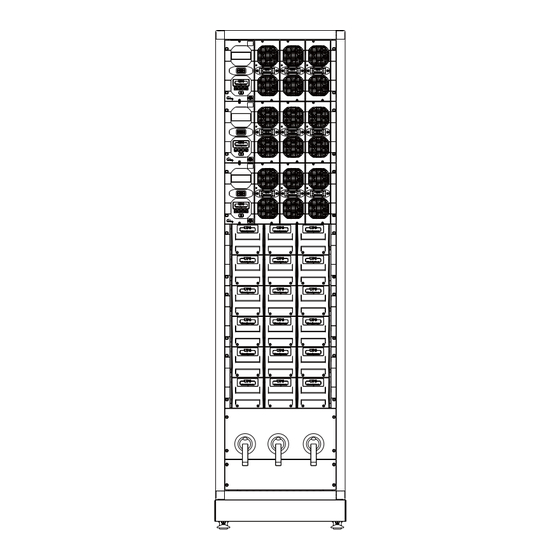

Page 13: Models

Operating and Maintenance Manual MODELS UPS ARCHIMOD UPS ARCHIMOD 20+18U UPS ARCHIMOD ® ® ® Technological Description code 5040275001 Rev. September 2010... - Page 14 Operating and Maintenance Manual UPS ARCHIMOD UPS ARCHIMOD UPS ARCHIMOD ® ® ® Technological Description code 504275001 Rev. September 2010...

- Page 15 Operating and Maintenance Manual UPS ARCHIMOD UPS ARCHIMOD BATTERY ® ® Technological Description code 5040275001 Rev. September 2010...

-

Page 16: Technical Specifications

96 KW Technology: On Line, double conversion VFI – SS - 111 Triphase / Triphase Configuration I/O: (Only Archimod 20/40KVA can be configured single/single, single/tri, tri/single, tri/tri by user) UPS architecture: Modular with 6,7 KVA power modules (cos Ê 0,8). - Page 17 Operating and Maintenance Manual FUNCTIONAL ELECTRICAL CHARACTERISTICS Model: 20 KVA 40 KVA 60 KVA 80 KVA 100 KVA 120 KVA Command board: Redundacy of command board: Over load with one command (50÷75)% (60÷80)% board failed: Percentage of load admitted (50÷75)% (60÷80)% after rupture of a control board:...

- Page 18 Operating and Maintenance Manual FUNCTIONAL ELECTRICAL CHARACTERISTICS Maintenance By-pass: Automatic by-pass: Expendable: Yes (power modules and battery drawers) Redundancy: Restart: Yes (after complete battery run down) Other: Max battery charging current for each module 2,5A Technological Description code 504275001 Rev. September 2010...

- Page 19 Operating and Maintenance Manual Protections Output short-circuits: Input Overvoltage: Overtemperature: Overload: Powering surge limiter: Excessive battery discharging: Differenziale: Epo: Input breaker - no fuse (front panel) Input fuse: Output fuse: Output breaker - no fuse (front panel) Battery breaker - fuse (20/40/60 KVA) Battery fuse: (there are internal fuses not removable by the user) (front panel) Back Feed protection:...

- Page 20 Operating and Maintenance Manual Hp) Standard autonomies Load 80%, efficiency 91% 20kVA 40kVA 60kVA 80kVA 100kVA 120kVA (14066W) (28132W) (42198W) (56264W) (70330W) (84396W) 10min 7.2Ah (218) ( W /batt) 9Ah (263) 30min 7.2Ah (105) 25.5 ( W /batt) 9Ah (112) 7.2Ah (60) 60min ( W /batt)

-

Page 21: Communication Devices

Operating and Maintenance Manual 2.5 COMMUNICATION DEVICES The uninterrupted power supply units of the UPS ARCHIMOD type have, for each control board: ® 2 RS232 serial ports, 1 relay interface, 1 logic level output on a male DB15 connector and an SNMP slot. -

Page 22: Logic Level Interface

Operating and Maintenance Manual 2.5.3 Logic level interface Logic level interface is available on connector DB15 and it allows the UPS to be connected to a remote system for monitoring its operating status, making available the following indica- tions and controls: •... -

Page 23: Communication Slot

Operating and Maintenance Manual 2.5.4 Communication slot A slot at the back of the UPS ARCHIMOD® is for the SNMP board (optional). Attention: the maximum current taken from pin4 of connector DB15 “RS232 power supply” and from the SNMP slot for the network board to work must be, in total, less than 700mA. Technological Description 2-13... -

Page 24: Safety Provisions

Operating and Maintenance Manual 3. Safety Provisions GENERAL NOTES WARNING Before doing any operation on the equipment, it is necessary to read through the whole manual carefully, paying attention to this chapter in particular. The equipment has been built for the application specified in the declaration of conformity enclosed with this manual. -

Page 25: Definitions Of 'Operator' And 'Specialized Technician

Operating and Maintenance Manual DEFINITIONS OF ‘OPERATOR’ AND ‘SPECIALIZED TECHNICIAN’ The professional figure that is going to access the equipment for normal use is defined by the term ‘operator’. With this definition we mean personnel who know how to use and service the equipment and have the following requirements: specific training that authorises them to work according to the safety standards in relation to the dangers that the presence of electricity can bring about. -

Page 26: Individual Protective Gear

Operating and Maintenance Manual WARNING The person in charge of safety is responsible for the protection against and prevention of company risks in accordance with the European Directive 89/391 EEC (safety at the work place), in ITALY it is part of the Law Decree dated 12/11/1994. The person in charge of safety must ensure that all people working on the machine have received all the relevant instruc- tions of this manual, included start-up and commissioning, and with particular reference to the contents of this chapter. -

Page 27: Indications Of Danger In The Work Place

Operating and Maintenance Manual INDICATIONS OF DANGER IN THE WORK PLACE The following signs must be placed in all points of access to the premises where the equipment is installed. Electric current It indicates the presence of live parts. Emergency interventions Do not use water to extinguish a fire but only the extinguishers designed specifi- cally for putting fires out on electronic equipment. -

Page 28: General Warnings

Operating and Maintenance Manual WARNING risk drastically reduced wearing Individual Protective Gear listed in this chapter, considered indispensable. Always work with due caution when near the dangerous areas indicated by the signs on board the equipment. GENERAL WARNINGS ATTENTION The equipment generates, uses and can radiate energy and radio frequencies. If not installed and used in agreement with the indications given in this manual, it can inter- fere with radio communications. -

Page 29: Emergency Interventions

Operating and Maintenance Manual - In the case of breakages, deformation or malfunctions of the equipment or parts of it, repair or replace immediately, avoiding ‘emergency’ repairs. - It is not allowed, for any reason, to modify, manipulate or in any way alter the structure of the equipment, the devices mounted on it, operating sequence, etc., without having first consulted the Manufacturer. -

Page 30: Unpacking

‘Shock Watch’ labels. If either possible or ascertained damage is found report it immediately to: - the carrier; - the Meta System S.p.A. Technical Assistance Centre. Make sure that the unit received corresponds to the material specified on the delivery docu- ment. -

Page 31: Positioning And Unpacking

Operating and Maintenance Manual Minimum clearances recommended for the UPS X=100 mm / Y=200 mm Battery Cabinet Minimum clearances recommended for the UPS ARCHIMOD + ARCHIMOD BATTERY ® ® X=100 mm / Y=200 mm To better protect the batteries bear in mind that the average life of the batteries is strongly influenced by the environmental operating temperature. -

Page 32: Checking The Contents Of The Pack

Operating and Maintenance Manual CHECKING THE CONTENTS OF THE PACK Below is a list of the materials supplied. The list is general. Please refer to the packing list for shipment details. ARCHIMOD ® INVERTER - No. 1 UPS ARCHIMOD unit; ®... - Page 33 The charging cycle can be stopped at any time by pressing the ‘ESC’ key. If the UPS is delivered without batteries, Meta System S.p.A. is not liable for any damage or bad operation caused to it by an incorrect wiring of the batteries.

-

Page 34: Installation

Operating and Maintenance Manual 5. Installation WARNING The instructions in this chapter are not addressed to a normal operator but to a specialized technician, authorised to work only if he uses the Individual Protective Gear mentioned in Chapter 3. SAFETY RULES AND REGULATIONS Before starting installation please read and apply the following: 1 Attention: equipment with a high sneak current, it is indispensable to earth it before connect- ing the power supply. -

Page 35: Safety Recommendations

Operating and Maintenance Manual Attention: the type and cross section of the connecting cables must be chosen according to their operating current and laying must be as established by existing laws; this is the responsibility of the installer. The UPS input current and output power are given in paragraph 2.4 and the battery current in Table 7. -

Page 36: Installing The Archimod

Operating and Maintenance Manual 5.2.4 Installing the ARCHIMOD BATTERY ® It is possible to connect external batteries to increase UPS autonomy of the 20, 40 and 60kVA models. The ARCHIMOD models 80, 100 and 120kVA always need external battery cabinets for ®... -

Page 37: Protections

Operating and Maintenance Manual Please note: - The terminals of the ARCHIMOD models 20, 40 and 60kVA for connecting to the external ® battery cabinets are on the bottom plates of the internal battery disconnectors marked with + and -. - The terminals of the ARCHIMOD models 80, 100 and 120kVA for connecting to the external ®... -

Page 38: Wiring

Operating and Maintenance Manual Attention: the equipment’s neutral passes through. WARNING The neutral conductor cable of the mains input must ALWAYS be connected! If the neutral is not connected the UPS could be seriously damaged when powered off the mains. BYPASS GRID CONNECTION: The connection of a separate bypass line is only possible if the neutral conductor of the bypass line and that of the mains input are in common (the same potential). -

Page 39: Emergency Power Off (Remote E.p.o.)

Operating and Maintenance Manual 5.2.9 Emergency Power Off (Remote E.P.O.) In accordance with the standards, the UPS is fitted with an emergency device that uses a normally closed contact (already installed on the UPS) that can be opened to activate the emergency machine power off. -

Page 40: Wiring Diagrams

Operating and Maintenance Manual WIRING DIAGRAMS The following are wiring diagrams for: ARCHIMOD 60kVA ® ARCHIMOD 80-100-120kVA ® UPS ARCHIMOD FRONT PANEL ® INPUT/INGRESSO MAINTENANCE BYPASS BYPASS MANUTENZIONE OUTPUT/USCITA UPS ARCHIMOD FRONT PANEL ® Installation code 5040275001 Rev. September 2010... - Page 41 Operating and Maintenance Manual Rout Tout Sout Nout UPS ARCHIMOD FRONT PANEL ® Installation code 504275001 Rev. September 2010...

- Page 42 Operating and Maintenance Manual E.P.O. UPS ARCHIMOD 60KVA REAR PANEL ® E.P.O. UPS ARCHIMOD 80-100-120KVA REAR PANEL ® Installation code 5040275001 Rev. September 2010...

-

Page 43: Configuration And Start-Up

Operating and Maintenance Manual 6. Configuration and Start-up WARNING The instructions given in this chapter are not for an ordinary operator but for a specialized, authorised technician only if he is using the Individual Protective Gear specified in chapter 3. As illustrated in the previous chapter the default configuration for the ARCHIMOD UPS units ®... -

Page 44: Checks Prior To Switching On

Operating and Maintenance Manual CHECKS PRIOR TO SWITCHING ON Check the following before powering the equipment: 1. Make sure the carrier isolating switches for powering the UPS in the distribution box are open; 2. Ensure that the fuse carrier isolating switches of the UPS batteries (F B+ and F B-) and those of the ARCHIMOD BATTERY (if used) are open;... - Page 45 Operating and Maintenance Manual 7. Exit the Service Mode by pressing the ON/OFF button. 8. Power the UPS and close its mains input disconnector switch; ATTENTION If the “charging in standby” function has been enabled, when the unit detects the input voltage it automatically prompts starting a battery charging cycle.

-

Page 46: Control Panel

Operating and Maintenance Manual 7. Control panel The control panel, at the front of the unit, has a 4-line, 20-character LCD display, a backlit multicolour status indicator and a 5-key keypad. ARCHIMOD ® The keys on the front panel are used to gain access to the UPS menus. ESCAPE Exit a function without modifying Goes from a lower to a higher menu level... -

Page 47: Service Mode' Function

Operating and Maintenance Manual ‘SERVICE MODE’ FUNCTION Even when it is off the UPS ARCHIMOD allows you to make all the settings and programming ® described below; by pressing the ‘ENTER’ key the UPS enters the ‘Service Mode’ and from here it is possible to access the DISPLAY menu. -

Page 48: Ups Status

Operating and Maintenance Manual - EVENTS: it allows the visual display and/or deletion of stored events in the UPS log; - TOOLS: it allows a series of functional tests to be run on the UPS. By selecting one of the above listed items again with ‘ENTER’, you gain access to the relative submenu. - Page 49 Operating and Maintenance Manual Note: press ‘ENTER’ to change the X value and consequently vary the phase of which you are reading the data Measurements Input X Power Power absorbed by the UPS by the mains on phase X [W] Appar.

-

Page 50: Ups Settings

Operating and Maintenance Manual 7.2.2 UPS settings Options Startup with Battery If enabled, it allows the UPS to be started when there is a power failure Restart If enabled, it allows automatic restarts EPS mode If enabled, it allows EPS mode (*) Output Voltage It sets the output voltage value [V]... - Page 51 Operating and Maintenance Manual Batteries Threshold Values Aut end warning Setting the start time of the end of battery autonomy warning [min.] Battery Charger Charge in Standby If enabled, it enables battery charging with the UPS off Restart Restart Enabling Enables or disables restarting of the unit when mains power returns after the batteries have run down completely...

-

Page 52: Power Modules

Operating and Maintenance Manual 7.2.3 Power Modules PM status PM X Info Model of power module X SW Vers. Firmware version inside the power module X HW Vers. Hardware version of the power module X Serial number of the power module X Max VA Maximum apparent power suppliable by the power module X [VA] Max W... - Page 53 Operating and Maintenance Manual Battery X Voltage Voltage measured at the ends of the batteries by the power module X [V] Current Current required to the batteries from the power module X (negative if the batteries are being charged) [A] Batt.

-

Page 54: Events

Operating and Maintenance Manual 7.2.4 Events Events Visual display Displays all the events Critical Displays events that have generated critical alarms Warning Displays events that have generated non critical alarms Info Displays events that have generated simple informa- tion Deletion Deletes all the events Critical Deletes events that have generated critical alarms... - Page 55 Operating and Maintenance Manual If you expect to leave the UPS off for a long time, please read carefully and put into practice what is prescribed in paragraph 4.4 concerning storage. If these operations are done correctly, there will be no voltage in the UPS ARCHIMOD ®...

-

Page 56: Diagnostics

Operating and Maintenance Manual 8. Diagnostics LUMINOUS AND ACOUSTIC SIGNALS The operating status indicator, on the front panel of the UPS, and the LED on the front of each power module, change colour depending on the actual operating status of the UPS or of the single power module, according to the following table: INDICATION Some luminous signals can be accompanied by an acoustic signal. -

Page 57: Messages

Operating and Maintenance Manual MESSAGES In this paragraph the messages that appear on the unit’s display are listed, also giving the most likely cause that could have generated them. If you are unable to solve the problem then please contact the Technical Service. FIRST LINE OF THE MAIN FRAME Message Meaning... - Page 58 Operating and Maintenance Manual FRAMES DISPLAYED WHEN SHUTTING DOWN Message Meaning NO MAINS! START-UP NOT ALLOWED No mains supply. Start-up not allowed. To start the UPS on battery, select this confi guration via the display. EMERGENCY POWER OFF! The Emergency Power Off (EPO) is working, the EPO command has been given by a push button or a disconnecting switch on the input line was opened while the UPS was working.

- Page 59 Operating and Maintenance Manual SIGNALLING EVENTS Message Meaning SHUTTING DOWN DUE TO END OF UPS shut down due to the end of autonomy. AUTONOMY SHUTTING DOWN DUE TO INCOR- UPS shut down due to an incorrect three-phase sequence in input. RECT THREE-PHASE SEQUENCE START-UP WITH BATTERY FAILED Start-up with battery failed.

-

Page 60: Maintenance

All the operations described in this section must be carried out by authorised technicians or qualified personnel. Meta System S.p.A. is not liable for any injury to persons or damage to things caused by incorrect operations or activities if not carried out according to the instructions given in this manual, with particular reference to the safety rules and regulations that can be found in chapter 3. -

Page 61: Periodical Checks

The periodical checks entail operations inside the UPS where dangerous voltages are present. Only maintenance personnel, trained and authorised by Meta System S.p.A., know all the parts of the UPS that are live with dangerous voltages and, therefore, authorised to work on them. -

Page 62: Hot-Swap Replacing Of Power Modules Or Adding New Modules

Operating and Maintenance Manual HOT-SWAP REPLACING OF POWER MODULES OR ADDING NEW MODULES The ARCHIMOD ® UPS allows any faulty power modules (Hot-Swap) to be replaced when they are hot. This means that the load is powered by the UPS which still protects the user points without them being powered by the bypass line. -

Page 63: Preparing The Ups For Maintenance In The Manual Maintenance Bypass Mode

Operating and Maintenance Manual PREPARING THE UPS FOR MAINTENANCE IN THE MANUAL MAINTENANCE BYPASS MODE. If the Hot-Swap replacement procedure of the power modules is not applicable (paragraph 9.4), the modules can still be replaced by putting the UPS in maintenance bypass. This mode is also necessary if ever it is requested to service or replace parts such as the control boards, backplane, etc. -

Page 64: Exiting Maintenance Bypass

Operating and Maintenance Manual Note: if the power module is not fixed with the screws prescribed, the switching-on of all the tunnel modules, controlled by the control board, is inhibited. The procedure described needs no further manual settings via the operator panel; the UPS automatically recognises the new power module and reconfigures automatically. - Page 65 Operating and Maintenance Manual Note: if the UPS goes over to running on battery while you are doing this, stop and neither extract or insert any battery boxes! You can continue when the UPS returns working On-line. Note: if mains input should fail during the operation, autonomy will be reduced: you will need to carefully evaluate such an eventuality occurring before you start.

- Page 66 Operating and Maintenance Manual 10. Dismantling ATTENTION The instructions in this chapter are to be considered indicative. Please refer to the laws in the country where the unit is used. 10.1 DISPOSING OF THE BATTERIES At the end of their life, the batteries must be disposed of in a place set aside for the collection of such waste.

- Page 67 Operating and Maintenance Manual 11. Tables Attention: the type and cross section of the connecting cables must be chosen according to their operating current and laying must be as established by existing laws; this is the responsibility of the installer. The UPS input current and output power are given in paragraph 2.4 and the battery current in Table 7.

- Page 68 Operating and Maintenance Manual Tabella 4 Valori fusibili batteria raccomandati per UPS ARCHIMOD BATTERY (1x94Ah) ® UPS ARCHIMOD BATTERY (1x94Ah) Recommended Battery Fuse Ratings ® Potenza - Power Fusibile di batteria - Battery fuse ARCHIMOD BATTERY (1x94Ah) ® F B+ F B- 20 kVA N.1 - 125A 500V aR (22 x 58)

- Page 69 Operating and Maintenance Manual 12. Notes Notes 12-1 code 5040275001 Rev. September 2010...

- Page 72 METASYSTEM S.p.A. www.metasystem.it via Galimberti, 8 42124 Reggio Emilia ITALY Tel.: + 39 0522 364111 Fax: + 39 0522 308382 info@metasystem.it METASYSTEM spa declines all liabilities for injuries to people or damage to things caused by a use of the unit that does not conform to the information given in this manual.

Need help?

Do you have a question about the ARCHIMOD 20 and is the answer not in the manual?

Questions and answers