Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Eclipse Combustion Vortometric v2.00

- Page 1 Installation Guide 248 4/10/07 E clipse Vortometric Burners yyyy yyyy yyyy yyyy...

- Page 2 WARRANTY or otherwise, is limited to the furnishing of replacement parts and Eclipse Combustion will not be liable for any other injury, loss, damage or expenses, whether direct or consequential, including but not limited to loss of use, income of, or damage to material arising in connection with the sale, installation, use of, inability to use or the repair or replacement of Eclipse Combustion’s products.

-

Page 3: About This Manual

ONLY and does not include the burner control system (such as fuel/air ratio controls, flame supervision systems, etc.). When Eclipse Combustion sells the burner as part of a complete package, then schematic piping and wiring diagrams will be furnished which explain the control system operation. - Page 4 ELATED PUBLICATIONS • EFE-825 (Combustion Engineering Guide) • Eclipse Bulletins & Instruction Manuals: 818, 820, 826, 832, 852, 854, 856 MPORTANT NOTICES • Read this manual carefully. Make sure that you understand the structure and contents of this manual. • Obey all the safety instructions.

-

Page 5: Table Of Contents

Gas, Gas/Oil or Oil Gun Positioning ........Install the flame sensor ............... Pilot ....................Piping ....................Strainers ..................3-10 Atomizing Control Methods ............. 3-10 Installing and Curing Refractory Block ........3-11 Checklist after Installation ............. 3-14 Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... - Page 6 Table A.4– Oil Nozzle Press. Drop vs. Burner Heat Input ..Table A.5– Atomizing Air Press. Drop vs. Air Flow ....Table A.6– Atomizing Steam Press. Drop vs. Steam Flow ..Recommended Spare Parts ............Conversion Factors ................. System Summary ................Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07...

-

Page 7: Introduction

Introduction RODUCT The Eclipse Vortometric v2.00 is a dual-fuel, high intensity burner which operates at maximum efficiency whether firing fuel oils or DESCRIPTION natural, propane, butane, manufactured or other mixed gases. The Vortometric’s versatility and rugged design make it the right... - Page 8 Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07...

-

Page 9: Safety

Read this entire manual before you attempt to start the system. If you do not understand any part of the information in this manual, then contact your Eclipse representative or Eclipse Combustion before you continue. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... -

Page 10: Capabilities

Regular retraining must be scheduled to maintain a high degree of proficiency. EPLACEMENT PARTS Order replacement parts from Eclipse only. Any customer-supplied valves or switches should carry UL, FM, CSA, CGA and/or CE approval where applicable. -

Page 11: Installation

When the refractory combustion block is supplied with the burner, it is critical that the instructions for handling and storage are followed. The refractory should be considered fragile; improper handling and storage will cause premature failure. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... -

Page 12: Approval Of Components

Quincy, MA 02269 The ANSI Standards are available from: American National Standard Institute 1430 Broadway New York, NY 10018 The UL Standards are available from: United Laboratories 333 Pfingsten Road Northbrook, IL 60062 Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... -

Page 13: Checklist Before Installation

• type and supply pressure of the fuel • availability of enough fresh, clean combustion air • humidity, altitude and temperature of air • presence of damaging corrosive gases in the air. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... -

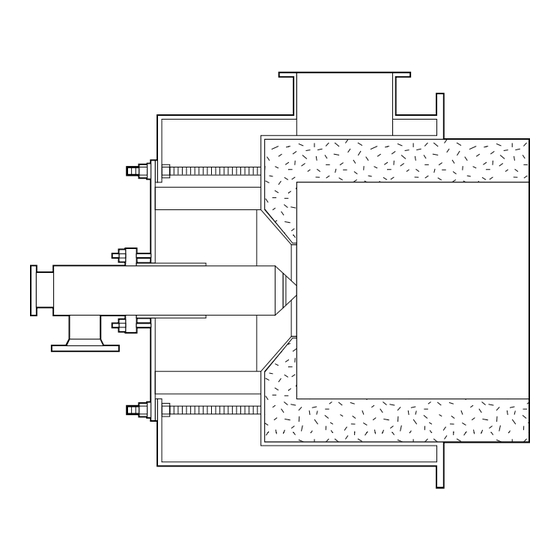

Page 14: Burner Mounting

Note: Failure to center the gun in the burner throat will cause uneven air flow and flame instability. The gun should be centered with +/- 1/8". Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... - Page 15 End of Gas Gun oil atomizer Throat Cone is flush with Air Inlet throat cone ring Gland “A” Refractory Block Walls Used to adjust the position of oil gun within gas gun. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07...

- Page 16 Note: Failure to center the gun in the burner throat will cause uneven air flow and flame instability. The gun should be centered with +/- 1/8". Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07...

-

Page 17: Install The Flame Sensor

For detailed information on how to install and connect a U.V. scanner, refer to: • straight U.V. scanner; Bulletin/Instruction Manual 854 • 90° U.V. scanner; Bulletin/Instruction Manual 852 • self-check U.V. scanner; Bulletin/Instruction Manual 856. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... -

Page 18: Pilot

Avoid large pressure drops Note: The pressure drop of the gas in the piping is a critical parameter. Make sure that the size of all the piping is large enough to prevent excessive pressure losses. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... - Page 19 1. ALL supplied gas pilot piping (natural, propane, etc.) MUST be fitted with a pilot gas pressure regulator. 2. ALL supplied gas pilot piping (natural, propane, etc.) SHOULD BE fitted with an adjustable orifice valve for pilot gas flow adjustment. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07...

-

Page 20: Strainers

50/55 psig. To ensure this maximum pressure is not exceeded, adjust the pressure regulator for the incoming atomizing supply to not exceed 50/55 psig. 3-10 Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... -

Page 21: Installing And Curing Refractory Block

Vortometric combustor blocks is Plibrico 80 Air Bond with an 80% alumina plastic ramming mix. Factory installed refractory The Eclipse factory installed refractory has been oven cured at relatively low temperatures to remove most of the water content. However, some residual water may still be present and must be removed at the initial start-up. - Page 22 Plibric Plisulate. 3. Install the chosen refractory, realizing it is essential that: • the combustion block dimensions are held as given on Eclipse drawings • the inside diameter of the combustion block be concentric with the air cone in the burner.

- Page 23 76mm (3") 1. Mounting illustrations show typical Vortometric combustor blocks of high alumina maximum plastic refractory as used by Eclipse for normal duty. projection 2. The dimensions given must be held as specified, and the inner diameter of the combustor must be round and concentric with the throat cone.

-

Page 24: Checklist After Installation

Danger: If simulated limits or simulated flame failures do not shut down the fuel system within the required failure response time, then immediately correct the problem. 3-14 Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... -

Page 25: Adjustment, Start & Stop

5. Ignite the burner 6. Set low fire fuel flow 7. Set high fire fuel flow 8. Verify the settings Step 1 : Reset the system Close the automatic gas valves and the gas cocks. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... -

Page 26: Step 2: Set Low Fire Combustion Air Pressure Drop

This flame should provide a stable pilot with good flame signal readings sufficient to energize the main gas valve. 6. If necessary, adjust the position of the U.V. scanner to ensure good pilot flame detection. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... -

Page 27: Step 5: Ignite The Burner

Figure 3.2 on page 3-5 for gland “A” identification and location. When doing so, a blanking plate must be substituted for gland “A” at the rear of the gas gun. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... -

Page 28: Step 6: Adjust Low Fire

1. Drive the main gas control valve to high fire. 2. Measure the gas pressure drop at high fire and compare to the appropriate chart in the Appendix. If the maximum input is not Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... -

Page 29: Step 8: Verify Settings

90.0 16.0 14.0 chamber size and presence of 125.0 18.0 16.0 secondary air. 160.0 20.0 17.0 210.0 24.0 20.0 * MI means Medium Intensity and HI means High Intensity. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... -

Page 30: Start Procedure

Go to “Checklist after Installation” on page 3-8 and verify the steps. After that, repeat the start procedure. – the system shut downs automatically: then see the “Trouble-shooting” Tables in the next chapter. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... -

Page 31: Stop Procedure

5. Leave combustion air and atomizing medium on until the combustion chamber and block are cooled; once cooled, shut off the combustion air and atomizing medium supplies. 6. Shut off all manual valves as required. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... - Page 32 Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07...

-

Page 33: Maintenance & Troubleshooting

Test flame safeguard by manually shutting off gas to burner. 6. Test all manual fuel valves for operation. 7. Check filters on main air fan for cleanliness. 8. Check gas filter or strainers. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... -

Page 34: Yearly Checklist

Note: On a burner with CLOCKWISE air rotation, the tip head has LEFT HAND threading. On a burner with COUNTERCLOCKWISE air rotation, the tip head has RIGHT HAND threading. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... - Page 35 5. Repeat Step 2. 6. Repeat Step 3. 7. Before reassembling the oil tip in the atomizer assembly, clean out the oil feed pipe with either compressed air or solvent as necessary. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07...

-

Page 36: Dismantling Of Atomizer

Foreign material such as grit can cause scoring of these surfaces and possible binding of the two surfaces. If necessary, a very fine emery cloth may be used to restore them. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... - Page 37 Size Dia. (in.) Size .0760 .0820 .0995 .1093 7/64 .1250 .1360 .1440 .1570 .1695 .1875 3/16 .1935 .2130 .2130 .2340 .1960 .2130 .2090 .2280 .2420 .2656 17/64 .2720 .2968 19/64 .3020 .3320 Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07...

-

Page 38: Assembly Of Atomizer

9. Screw the nose cone assembly into the body threads, being careful not to get it cross-threaded. Tighten the assembly securely with a spanner wrench. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... - Page 39 11. Reinstall the oil gun into the burner and connect all hoses securely. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07...

- Page 40 Check UV sensor and wiring. • Flame sensor shorted out. • Electrical noise in sensor line. Shield or separate sensor lines from high voltage. • Unit is broken. Call qualified electrician to investigate. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07...

- Page 41 Repeat start-up several times to • Air in the gas line. purge air out of gas lines. Trim pilot gas adjusting valve to give Too much gas. pressures/flows indicated on page 4-2. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07...

-

Page 42: Troubleshooting

Main flame pulsates or is unstable. • Unstable air flow. pressure pulsations. Check pressure regulator and • Unstable fuel flow. control valve for pulsations. Pull back pilot gun. • Pilot gun inserted too far. 5-10 Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... - Page 43 Carbon deposits on the inside of the refractory block. Carbon accumulation on the oil Oil nozzle is too far forward into the Move gun back 1/4" at a time until nozzle cone. throat. carbon no longer accumulates. 5-11 Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07...

-

Page 44: Appendix

0.6 0.8 1 8 10 60 80 100 Burner Gross Heat Input (MMBtu/hr.) * 7.5"w.c. is the nominal design pressure drop for all models, except for model 6V of the medium intensity burners. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07... - Page 45 • Pressure drop should be taken between the chamber and windbox pressure tap. 10V 12V 14V 16V 32V 36V 0.6 0.8 1 8 10 60 80 100 Burner Gross Heat Input (MMBtu/hr.) Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07...

- Page 46 Burner Gross Heat Input (MMBtu/hr.) or Natural Gas Flow (1000’s SCFH) * Nominal pressure drop at maximum capacity is 24"w.c. for 6V through 16V models, and 45" w.c. for all other models. Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07...

- Page 47 • When air is used for atomization of heavy oil, it should be preheated to approximately the same temperature as the oil. 10V 12V 14V 18V 22V 80 100 1,000 Atomizing Air Flow (SCFM) Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10///...

-

Page 48: Recommended Spare Parts

Oil gun assembly U.V. scanner (if used) 1-1/4" N.P.T. peepsight glass 13046 1-1/4" N.P.T. peepsight gasket 13047 Part number varies depending on burner size used. Part number varies depending on U.V. scanner used. Eclipse Vortometric Burner v2.00, Installation Guide 248, 6/00... - Page 49 Fahrenheit (°F) degrees Celsius (°C) foot (ft) meter (m) 0.3048 inches (in) millimeter (mm) 25.4 inches water column ("wc) millibar (mbar) 2.49 pound (lb) kilogram (kg) 0.454 pounds/sq in (psi) millibar (mbar) 68.95 Eclipse Vortometric Burner v2.00, Installation Guide 248, 6/00...

-

Page 50: System Summary

Oil pressure across the burner: Number of burners: Atomizing pressure: High fire input per burner: Atomizing pressure drop across the burner: Orifice sizes: Flame signal strength: Operating voltage & frequency: Flame length: Altitude: Eclipse Vortometric Burner v2.00, Installation Guide 248, 6/00... - Page 51 Offered By: Power Equipment Company 2011 Williamsburg Road Richmond, VA 23231 Phone: 804-236-3800 Fax: 804-236-3882 www.peconet.com...

Need help?

Do you have a question about the Vortometric v2.00 and is the answer not in the manual?

Questions and answers