Toshiba NB250 Maintenance Manual

Personal computer

Hide thumbs

Also See for NB250:

- Maintenance manual (222 pages) ,

- User manual (142 pages) ,

- User manual (197 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

User Manual

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Toshiba NB250

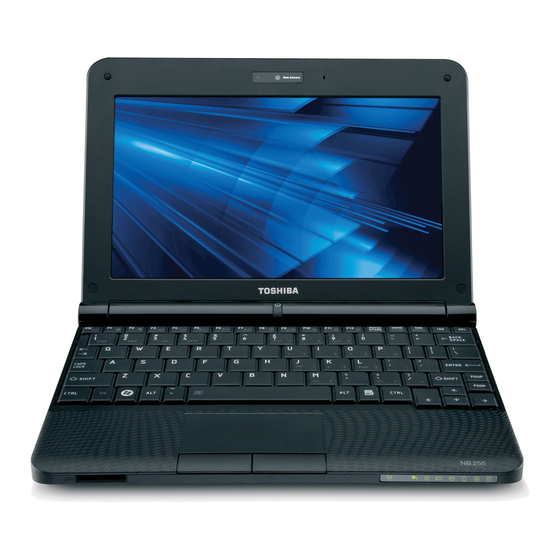

- Page 1 Toshiba Personal Computer NB250/NB255 Maintenance Manual TOSHIBA CORPORATION...

- Page 2 Copyright © 2010 by Toshiba Corporation. All rights reserved. Under the copyright laws, this manual cannot be reproduced in any form without the prior written permission of Toshiba. No patent liability is assumed with respect to the use of the information contained herein.

- Page 3 Preface This maintenance manual describes how to perform hardware service maintenance for the Toshiba Personal Computer Satellite, referred to as the Satellite Series in this manual. The procedures described in this manual are intended to help service technicians isolate faulty Field Replaceable Units (FRUs) and replace them in the field.

-

Page 4: Hardware Overview

For example: Read Only Memory (ROM) Keys Keys are used in the text to describe many operations. The key top symbol as it appears on the keyboard is printed in boldface type. Key operation NB250/NB255 Series Maintenance Manual... - Page 5 Text that you are instructed to type in is shown in the boldface type below: DISKCOPY A: B: The display Text generated by the computer that appears on its display is presented in the typeface below: Format complete System transferred NB250/NB255 Series Maintenance Manual...

- Page 6 2.9 2in1 card Troubleshooting ............ Error! Bookmark not defined. 2.12 HDD/SSD Troubleshooting ..........Error! Bookmark not defined. 2.13 CRT Troubleshooting............Error! Bookmark not defined. 2.14 LAN Troubleshooting ............Error! Bookmark not defined. 2.17 3G Troubleshooting............Error! Bookmark not defined. NB250/NB255 Series Maintenance Manual...

- Page 7 LAN Test ..........................20 3.14 RTC Test..........................23 3.15 3D-Gsensor……..…...………….…….…………….…….………...……...24 3.16 1stHDDTest …………………………..………….……….……..….…………...28 3.17 RDMI Test………………...………………………………….…...…..…………….30 3.18 WDMI Test ………….…………………...….…………….…..…..……………31 3.19 Toshiba Logo set……………………………............33 3.20 Dynabook Logo set…………………………………………..……………………..35 3.21 TP TYPE R/ W TEST……………… …………………….…...………………..38 3.22 EEPROM setting…………………………………………………………………….41 NB250/NB255 Series Maintenance Manual...

- Page 8 Installing the Hinge Cover and Keyboard ......Error! Bookmark not defined. Power Board ..............Error! Bookmark not defined. Removing the Power Board..........Error! Bookmark not defined. Installing the Power Board ..........Error! Bookmark not defined. Logic Upper Assembly............Error! Bookmark not defined. NB250/NB255 Series Maintenance Manual viii...

- Page 9 Installing the LCD Module ..........Error! Bookmark not defined. 4.15 Camera module LVDS cable ..........Error! Bookmark not defined. Removing the Camera module and LVDS Cable ....Error! Bookmark not defined. Installing the Camera module and LVDS Cable....Error! Bookmark not defined. NB250/NB255 Series Maintenance Manual...

-

Page 10: Table Of Contents

Figure 4.28 Removing screws from the LCD Bezel AssemblyError! Bookmark not defined. Figure 4.29 Removing the bezel from the hinge wall ..... Error! Bookmark not defined. Figure 4.30 Removing the bezel from the display assembly .. Error! Bookmark not defined. NB250/NB255 Series Maintenance Manual... - Page 11 Handling the LCD Module ..................A-1 Appendix B Board Layout ....................... B-1 Appendix C Pin Assignments......................C-1 Appendix D Keyboard Scan/Character Codes ................. D-1 Appendix E Key Layout........................E-1 Appendix F Series Screw Torque List ....................F-1 Appendix G Reliability........................G-1 NB250/NB255 Series Maintenance Manual...

- Page 12 Chapter 1 Hardware Overview...

- Page 13 1 Hardware Overview Chapter 1 Contents Features ........................1-1 2.5-inch HDD ......................1-8 Power Supply ......................1-9 Batteries........................ 1-11 1.4.1 Main Battery ..................1-11 1.4.2 Battery Charging Control ..............1-11 1.4.3 RTC Battery..................1-12 NB250/NB255 Maintenance Manual 1-ii...

- Page 14 1 Hardware Overview Figures Figure 1-1A ID Parts Description Placement Part A............1-4 Figure 1-2 S-ATA HDD ....................1-8 Tables Table 1-1 HDD Specifications ..................1-8 Table 1-2 Quick/Normal Charging Time ..............1-11 NB250/NB255 Maintenance Manual 1-iii...

- Page 16 1.1 Features 1 Hardware Overview Features ® The Toshiba NB200 is a small-size PC notebook equipped with an Intel Atom Processor, providing high-speed processing capabilities and advanced features. The computer employs a lithium ion battery that allows it to be battery-operated for long periods of time. The display uses 10.1-inch WSVGA LCD panel.

- Page 17 The integrated sound system is composed of one 1.0W Zylux / FG internal speaker, an internal microphone and standard MIC-IN ports. Internal Camera A VGA webcam supports 0.3M pixels and comes with an LED indicator. The camera is not a rotation type. NB250/NB255 Maintenance Manual...

- Page 18 10/100BASE-T). It employs a Realtek 8105E for 10M/100Mbit LAN. Wireless LAN (BTO) Some computers in this series are equipped with a Wireless LAN (WLAN) card. This WLAN module may come with the following types (depending on the model): Atheros 802.11 bg (HB95 1x1) NB250/NB255 Maintenance Manual...

- Page 19 Figure 1-1A shows the computer and its system unit configuration. External monitor port Thermal vent holes USB ( USB Sleep and Charge function is supported by this port only. ) Figure 1-1A ID Parts Description Placement Part A NB250/NB255 Maintenance Manual...

-

Page 20: Hardware Overview

DEPARTMENT EXCEPT AS AUTHORIZED BY COMPAL ELECTRONICS, INC. NEITHER THIS SHEET NOR THE INFORMATION IT CONTAINS MAY BE USED BY OR DISCLOSED TO ANY THIRD PARTY WITHOUT PRIOR WRITTEN CONSENT OF COMPAL ELECTRONICS, INC. D ate: Monday, March 23, 2009 Sheet NB250/NB255 Maintenance Manual... - Page 21 Audio volume output control Battery scope report and control Power switch control Internal Keyboard country selection Graphics Controller Intel ® NM10 Express Chipset for integrated graphics display. TVAP and Smart External Monitor Support NB250/NB255 Maintenance Manual...

- Page 22 One Audio-out port: Headphone-out/Line-out Internal Microphone (MIC with echo cancellation) Volume control: Digital control, Hot keys (Fn+3, Fn+4) Microsoft inbox audio driver support Wireless LAN Controller Atheros 802.11 bg (HB95 1x1) WPS supported NB250/NB255 Maintenance Manual...

-

Page 23: S-Ata Hdd

The HDD is shown in Figure 1-2 and some of its specifications are listed in Table 1-1. Figure 1-2 S-ATA HDD Table 1-1 HDD Specifications Specifications Item Capacity (GB) 160 GB 250G Rotational Speed (RPM) 5400 RPM 5400 Height 9.5mm, 2.5” 9.5mm, 2.5” User Data Sectors 312,581,808 488,397,168 Bytes / Sector NB250/NB255 Maintenance Manual... -

Page 24: Power Supply

Turns on the Power LED (in Green). Battery indicator (in Green or Amber). DC-IN indicator (in Green) 5. External interface Performs communication through the I2C bus (via the internal EC/KBC). Transfers the power supply operation mode. NB250/NB255 Maintenance Manual... - Page 25 Monitors the voltage output to the system block (load/logic circuit side). Monitors the voltage, over voltage, input/output current of the battery pack. Monitors the internal temperature of the battery pack. Monitors the supply voltage from the AC adapter. NB250/NB255 Maintenance Manual 1-10...

-

Page 26: Table 1-2 Quick/Normal Charging Time

Table 1-2 Quick/Normal Charging Time State Charge Time 3 Cell About 4 hours Off-State Charge 6 Cell About 6 hours On-State Charge 3/6 Cell About 12 hours NB250/NB255 Maintenance Manual 1-11... - Page 27 1. The current in the battery charging circuit drops below the predetermined value. 2. The charging time exceeds the fixed limit. 1.4.3 RTC Battery The RTC battery provides power to keep the current date, time and other system information in memory while the computer is turned off. NB250/NB255 Maintenance Manual 1-12...

-

Page 28: Troubleshooting Procedures

Chapter 2 Troubleshooting Procedures... - Page 30 2.5 External USB Devices Troubleshooting................19 2.6 TouchPad Troubleshooting.....................21 2.7 Speaker Troubleshooting ....................23 Wireless LAN Troubleshooting.................25 Camera Troubleshooting ...................27 Bluetooth Troubleshooting ..................29 2in1 card Troubleshooting..................31 2.10 HDD/SSD Troubleshooting..................33 2.13 CRT Troubleshooting ....................36 2.14 LAN Troubleshooting....................38 17 3G Troubleshooting ....................44 NB250/NB255 Series Maintenance Manual...

-

Page 31: Figure

LAN troubleshooting process ……………………………………………….41 Figure 2-15 MIC troubleshooting process ………………………………………………..43 Figure 2-16 3D sensor troubleshooting process ……………………………………………45 Figure 2-17 3G troubleshooting process …………………………………………………...47 Tables Table 2-1 Battery LED ....................... 10 Table 2-2 DC-IN LED ......................11 NB250/NB255 Series Maintenance Manual... -

Page 32: Troubleshooting Introduction

Ask the user if a password is registered, if it is, ask him or her to enter the password. Verify with the customer that Toshiba Windows XP/Vista/Linux is installed on the hard disk. Operating systems that were not preinstalled by Toshiba can cause the computer to malfunction. NB250/NB255 Series Maintenance Manual... - Page 33 2 Troubleshooting Procedures Make sure all optional equipment is removed from the computer. NB250/NB255 Series Maintenance Manual...

- Page 34 ? a n d s e le c t th e H A R D D IS K ite m . Y e s Figure 2-1 Troubleshooting flowchart (1/2) NB250/NB255 Series Maintenance Manual...

- Page 35 Allow each test to perform automatically After confirming which diagnostics test has detected Is an error detected by any of the an error, perform the diagnostics tests? appropriate procedure as outlined below. System is normal Figure 2-1 Troubleshooting flowchart (2/2) NB250/NB255 Series Maintenance Manual...

- Page 36 4. If an error is detected by the TouchPad test, perform the TouchPad Troubleshooting procedures in Section 2.7 5. If an error is detected by the audio test, perform the Speaker Troubleshooting procedures in Section 2.8 and the Optical Drive Troubleshooting Procedures in Section 2.9 NB250/NB255 Series Maintenance Manual...

- Page 37 4. If an error is detected when using the Bluetooth, perform the Bluetooth Troubleshooting procedures in Section 2.12 5. If an error is detected when using the MIC, perform the MIC troubleshooting procedures in Section 2.16 NB250/NB255 Series Maintenance Manual...

-

Page 38: Power Supply Troubleshooting

E N D Figure 2-2 Power Supply Troubleshooting Process The power supply controls many functions and components. To determine if the power supply is functioning properly, start with Procedure 1 and continue with the other Procedures NB250/NB255 Series Maintenance Manual... - Page 39 The following LEDS indicate the power supply status: Battery LED DC-IN LED The power supply controller displays the power supply status through the Battery and the DC- IN LEDS as listed in the tables below. Table 2-1 Battery LED NB250/NB255 Series Maintenance Manual...

- Page 40 A faulty adaptor may not supply power or may not charge the battery. Perform Check 1. Check 1 Connect a new AC adaptor. If the problem is not resolved, go to Check 2. Check 2 Insert a new battery. If the problem is still not resolved, go to Procedure 3. NB250/NB255 Series Maintenance Manual...

- Page 41 If the battery LED does not light, go to Check 6. Check 6 Make sure the battery pack is installed in the computer correctly. If the battery is properly installed and the battery LED still does not light, go to Procedure 4. NB250/NB255 Series Maintenance Manual...

- Page 42 Make sure that the battery cable is firmly connected to the system board. If it is connected firmly, go to Check 3. Check 3 The system board may be damaged. Replace it with a new one following the instructions in Chapter 4. NB250/NB255 Series Maintenance Manual...

-

Page 43: Display Troubleshooting

( P ro c e d u r e 3 ) R e p la c e s y s te m b o a rd E N D Figure 2-3 Display troubleshooting process NB250/NB255 Series Maintenance Manual... - Page 44 Refer to Chapter 3, Tests and Diagnostics for details. If an error is detected, go to Procedure 3. If an error is not detected, the display is functioning properly. NB250/NB255 Series Maintenance Manual...

- Page 45 Check 3 Replace the LCD cable with a new one and test display again. If the problem still exists, perform Check 5. Check 4 The system board may be damaged. Replace it with a new one. NB250/NB255 Series Maintenance Manual...

-

Page 46: Keyboard Troubleshooting

( P r o c e d u r e 3 ) R e p la c e s y s te m b o a r d E N D Figure 2-4 Keyboard troubleshooting process NB250/NB255 Series Maintenance Manual... - Page 47 The keyboard may be damaged. Replace it with a new one following the instructions in Chapter 4. If the problem still exists, perform Check 3. Check 3 The system board may be damaged. Replace it with a new one following the instructions in Chapter 4. NB250/NB255 Series Maintenance Manual...

-

Page 48: External Usb Devices Troubleshooting

R e p la c e s y s te m b o a r d ( P r o c e d u r e 2 ) E N D Figure 2-5 External USB device troubleshooting process NB250/NB255 Series Maintenance Manual... - Page 49 USB small board may be damaged. Go to Procedure Procedure 2 Replace system board If the error persists, the system board or USB small board may be damaged. Replace it with a new one following the instructions in Chapter 4. NB250/NB255 Series Maintenance Manual...

-

Page 50: Touchpad Troubleshooting

2 Troubleshooting Procedures TouchPad Troubleshooting START TouchPad connection check (Procedure 1) TouchPad replacement check (Procedure 2) Replace system board Figure 2-6 Touchpad troubleshooting process NB200 Series Maintenance Manual... - Page 51 2 Troubleshooting Procedures To determine if the computer’s built-in TouchPad is functioning properly, perform the following procedures. Figure 2-9 outlines the process. Start with Procedure 1 and continue as instructed. Procedure 1: TouchPad connection check Procedure 2: TouchPad replacement check Procedure 1 TouchPad connection check The TouchPad is connected via the TouchPad FPC to the system board.

-

Page 52: Speaker Troubleshooting

2 Troubleshooting Procedures Speaker Troubleshooting S T A R T P e r f o r m a u d io s o u r c e te s t ( P r o c e d u r e 1 ) S p e a k e r s a r e n o t D o a ll s o u r c e s h a v e f a u lty . - Page 53 2 Troubleshooting Procedures To determine if the computer’s built-in speakers are functioning properly, perform the following procedures. Figure 2-10 outlines the process. First adjust the speaker volume to an appropriate level. Start with Procedure 1 and continue as instructed. Procedure 1: Audio source test Procedure 2: Earphone test Procedure 3: Connection check Procedure 4: Replacement check...

-

Page 54: Wireless Lan Troubleshooting

2 Troubleshooting Procedures Wireless LAN Troubleshooting START Perform diagnostic test (Procedure 1) Wireless LAN system is not faulty. Continue Was a wireless LAN problem delected? troubleshooting - refer to Figure 2.1 Perform connector and replacement check (Procedure 2) Replace wireless LAN antenna/unit Replace system board Figure 2-8 Wireless LAN troubleshooting process The wireless LAN antenna wire, wireless LAN unit or system board may each be the source... - Page 55 2 Troubleshooting Procedures computer’s wireless LAN system is functioning properly, perform the following procedures. Figure 2-15 outlines the process. Start with Procedure 1 and continue with the other procedures as instructed. Procedure 1: Diagnostic test Procedure 2: Connector and replacement check Procedure 1 Diagnostic test Run the Diagnostic Program, which will automatically execute the wireless LAN test.

-

Page 56: Camera Troubleshooting

2 Troubleshooting Procedures Camera Troubleshooting Figure 2-9 Camera troubleshooting process NB200 Series Maintenance Manual... - Page 57 2 Troubleshooting Procedures The Camera board or system board may be the reason of a Camera fault. Either of these two components may be damaged. To determine if the computer’s Camera is functioning properly, perform the following procedures. Figure 2-14 outlines the process. Start with Procedure 1 and continue with the other procedures as instructed.

-

Page 58: Bluetooth Troubleshooting

2 Troubleshooting Procedures Bluetooth Troubleshooting Figure 2-10 Bluetooth troubleshooting process NB200 Series Maintenance Manual... - Page 59 2 Troubleshooting Procedures The Bluetooth antenna wire, Bluetooth module or system board may be the reason of a Bluetooth fault. Any of these components may be damaged. To determine if the computer’s Bluetooth is functioning properly, perform the following procedures. Figure 2-16 outlines the process.

-

Page 60: 2In1 Card Troubleshooting

2 Troubleshooting Procedures Check 4 The system board may be damaged. Replace it with a new one following the instructions in Chapter 4. 2in1 card Troubleshooting START Perform 2 in 1 CARD test (Procedure 1) Do errors occur during 2 2 IN 1 unit is not IN 1 CARD test? faulty. - Page 61 2 Troubleshooting Procedures This section describes how to determine if the 2 IN 1 Card is functioning properly. The process is summarized in Figure 2-16. Perform the steps below starting with Procedure 1 and continuing with the other procedures as required. Procedure 1: 2 in 1 card test Procedure 2: 2 in 1 card socket check Procedure 1...

-

Page 62: Hdd/Ssd Troubleshooting

2 Troubleshooting Procedures 2.10 HDD/SSD Troubleshooting Figure 2-12 HDD troubleshooting process NB200 Series Maintenance Manual... - Page 63 2 Troubleshooting Procedures The HDD or system board may be the reason of a HDD fault. Either of these two components may be damaged. To determine if the computer’s HDD is functioning properly, perform the following procedures. Figure 2-15 outlines the process. Start with Procedure 1 and continue with the other procedures as instructed.

- Page 64 2 Troubleshooting Procedures NB200 Series Maintenance Manual...

-

Page 65: Crt Troubleshooting

2 Troubleshooting Procedures 2.13 CRT Troubleshooting S T A R T P e r f o r m C R T c o n n e c t i o n c h e c k ( P r o c e d u r e 1 ) D o e s r e p l a c e m e n t R e p l a c e C R T C R T c a b l e... - Page 66 2 Troubleshooting Procedures Procedure 1: CRT connection check Procedure 2: CRT set check Procedure 1 CRT connection check The CRT cable may be damaged or the connections may be loose. Perform Check 1: Check 1 Make sure CRT cable is firmly plugged into both the CRT set and the CRT port of the computer.

-

Page 67: Lan Troubleshooting

2 Troubleshooting Procedures 2.14 LAN Troubleshooting S T A R T P e r f o r m L A N c o n n e c t i o n c h e c k ( P r o c e d u r e 1 ) D o e s r e p l a c e m e n t R e p l a c e L A N L A N c a b l e... -

Page 68: Mic Troubleshooting

2 Troubleshooting Procedures Procedure 1: LAN connection check Procedure 2: LAN set check Procedure 1 LAN connection check The LAN cable may be damaged or the connections may be loose. Perform Check 1: Check 1 Make sure LAN cable is firmly plugged into both the LAN set and the LAN port of the computer. - Page 69 2 Troubleshooting Procedures Figure 2.15. MIC troubleshooting process The MIC line or system board may be the reason of a MIC fault. Either of these two components may be damaged. To determine if the computer’s MIC is functioning properly, perform the following procedures. Figure 2-15 outlines the process. Start with Procedure 1 and continue with the other procedures as instructed.

-

Page 70: D Sensor Troubleshooting

2 Troubleshooting Procedures Procedure 2: Connector and replacement check Procedure 1 Diagnostic test Run the functioning Program on Windows model, which will display the MIC test result. If tests and diagnostics result abnormal go to Procedure 2. If an error is not located, the MIC module functioning is properly. - Page 71 2 Troubleshooting Procedures Figure 2.16. 3D sensor troubleshooting process The operation or system board may be the reason of 3D sensor fault. Either of these two may be damaged. To determine if the computer’s 3D is functioning properly, perform the following procedures.

- Page 72 2 Troubleshooting Procedures Procedure 2 Replacement check Disassemble the computer following the steps described in Chapter 4, Replacement Procedures, and perform the following checks. Check 1 Make sure that 3D sensor test operation is correct, go to Check 2. Check 2 The system board may be damaged.

-

Page 73: Troubleshooting

2 Troubleshooting Procedures 2. 17 3G Troubleshooting STA R T Perform diagnostic test (Procedure 1) 3G system is not faulty. C ontinue W as a 3G problem detected? troubleshooting - refer to Figure 2.1 Y es Perform connector and replacem ent check (Procedure 2) R eplace 3G antenna/unit R eplace system board... - Page 74 2 Troubleshooting Procedures Procedure 1: Diagnostic test Procedure 2: Connector and replacement check Procedure 1 Diagnostic test Run the Diagnostic Program, which will automatically execute the 3G test. Test and Diagnostic for more information on the program. If an error is located, go to Procedure 2. If an error is not located, 3G system is functioning properly.

- Page 75 3. Tests and Diagnostics Chapter 3 Tests and Diagnostics...

- Page 76 Magnetic switch Test ......................18 3.13 LAN Test........................... 20 3.14 RTC Test ........................... 23 3.15 3D-Gsensor……..…………...………….…….…………….…….………...……...24 3.16 1stHDDTest ……………………………..…………….……….……..….…………...28 3.17 RDMI Test………………...……………………………………….…...…..…………….30 3.18 WDMI Test ………….………………………...….…………….…..…..……………31 3.19 Toshiba Logo set…………………………………............33 3.20 Dynabook Logo set………………………………………………..……………………..35 3.21 TP TYPE R/W TEST……………………………………………….…...………………..38 3.22 EEPROM setting………………………………………………………………………….41...

-

Page 77: Main Battery Charge Test

HDD Test RDMI Test WDMI Test Memory Test Toshiba Logo set Dynabook Logo set TP TYPE R/W TEST EEPROM Setting You will need the following equipment to perform some of the Diagnostic test programs. -

Page 78: Memory Check

I. LCD PIXELS MODE TEST J. MAGNETIC TEST K. LAN TEST L. RTC TEST M. 3D G-SENSOR TEST N. 1st HDD Test O. RDMI Test P. WDMI Test Q. Toshiba Logo set R. Dynabook Logo set S. TP TYPE R/W TEST T. EEPROM Setting... - Page 79 3. Tests and Diagnostics The below display will show up at the beginning of T&D program If the test result passes, the following display will show up:...

- Page 80 3. Tests and Diagnostics If an error is detected and a test fails, the following message displays: Then press any key for next actions – the below display presented if copying test log file onto diskette is necessary. This action will be executed when “Y” key pressed.

- Page 81 3. Tests and Diagnostics It will skip this process if “N” key pressed. And then it will check if it’s necessary to leave this program. Program will quit when “Y” key pressed and it will go back main menu for next test if “N” key pressed.

-

Page 82: Display Configuration

3. Tests and Diagnostics Display Configuration This Item will show the unit configuration. It includes: CPU (CPU type) DDRAM SIZE Panel ID HDD1 type & capacity (Vendor ID. Model .Firmware) VRAM size / VGA CHIP TYPE ... -

Page 83: Audio Sound Test

3 Tests and Diagnostics 3.4 Audio sound test The audio sound test allows the user to aurally confirm the speaker functions. And the speaker will send out music during test. NOTE: Remember to tune up the volume as “Maximum” before this test starts. Buffalo only have one speaker, no need test Left/Right Speaker The screen should display as below, indicating whether the test is passed or failed after the question. - Page 84 3. Tests and Diagnostics The computer will let the fan be “ON” after any key pressed. Feel the wind or listen the rotating sound to check whether the fan is working or not. NOTE: Remember to approach fan outlet that is near right side of unit whether fan is “ON”.

-

Page 85: Main Battery Charge Test

3. Tests and Diagnostics 3.6 Main Battery Charge Test NOTE: The AC adaptor should be connected to successfully run this test . 30W with 19V DC for ALL SKU This test shows and measures the main battery: Battery type (Lion) ... -

Page 86: Fdd Test

3. Tests and Diagnostics 3.7 Main Battery Change Test 3. 7 FDD Test NOTE: Before running the FDD test, prepare a formatted work diskette (1.44 MB). Need to insert FDD when power on machine. Otherwise the Floppy can be not detected. The Floppy Disk Test includes three subtests of the: 1. - Page 87 3. Tests and Diagnostics...

-

Page 88: Memory Check

3 Tests and Diagnostics Memory check This test will check if the computer’s Memory Frequency and Size is correct in every slot. Before Memory test start, you should choice the below item: 1. Memory Read test 2. Memory Write test 3. - Page 89 3. Tests and Diagnostics The keyboard test checks the all keys function. NOTE: The Num Lock and the Overlay mode must be off to execute the keyboard test. Before keyboard test starts, the keyboard matrix code should be chosen as below display: 1.

- Page 90 3 Tests and Diagnostics Japan keyboard UK keyboard...

-

Page 91: Mouse (Pad) Test

3. Tests and Diagnostics NOTE: The “Fn” key cannot be tested in the keyboard test. To determine whether the “Fn” key is working correctly, press “Fn+F6 ” or “Fn+F7 ” keys to check if LCD display brightness change gradually. 3.10 Mouse (Pad) Test The Mouse test allows the user to select and assign values to the following, using the Touch Pad or “Tab”... -

Page 92: Lcd Pixels Mode Test

3. Tests and Diagnostics The Touch Pad button subtest allows users to test their Touch Pad buttons. If the buttons are clicked, the cursors should appear in the corresponding box of the button figure that is displayed on the screen as below. After checking T/Pad buttons and cursor’s function, use “Tab”... -

Page 93: Magnetic Switch Test

3. Tests and Diagnostics 640*480 (2/16/256 colors), 800*600 (256 colors) and 1024*768 (256 colors). The screen should display as below, indicating whether the test is passed or failed after the question. 3.12 Magnetic Switch Test The Magnetic switch test checks the Magnetic function of the unit. When LCD cover closed, the Magnetic should enable to turn off the display. - Page 94 3. Tests and Diagnostics 2>. If the Magnetic switch test pass, it will show below display:...

-

Page 95: Lan Test

3. Tests and Diagnostics 3.13 LAN Test The LAN test checks the LAN full-duplex environment. NOTE: LAN loopback needs to plug in before test begins. And LAN information will show on the test screen: IO Base – Port: A000H ... - Page 96 3. Tests and Diagnostics The LAN test includes three subtests of the: 1. Speed1000 2. Speed100 3. Speed10 The subtests run automatically. The screen should display as below, indicating whether the subtests pass or fail when finished.

- Page 97 3. Tests and Diagnostics If an error is detected and a test fails, the following message displays:...

-

Page 98: Rtc Test

3. Tests and Diagnostics 3.14 RTC Test Checks the computer’s RTC (Real Time Clock) and calendar functions by comparing the DOS and CMOS values. The test runs automatically. The screen should display as below, indicating whether the test is passed or failed when finished. -

Page 99: D-Gsensor

3. Tests and Diagnostics 3.15 3D G-sensor test NOTE: please keep 90 degree between logic upper and LCD panel when test The display of a test program and the set method of PC are shown below. Display of a Test Program,The portion which PC and Test-Fixture contact is green. Upper Set method of PC <A>... - Page 100 3. Tests and Diagnostics Front Uppe Set method of PC <4> Test 5: Left Uppe Set method of PC <5> Test Result A test result is displayed when a test is completed. A display of result is O.K. or NG. And an error flag is returned at the end of a program.

- Page 101 3. Tests and Diagnostics If the picture shows as below, it means the 3D G-sensor function is NG...

-

Page 102: 1Sthddtest

3. Tests and Diagnostics 3.16 1 HDD Test The HDD test allows the user to verify the 1 HDD ok or not. First, please select HDD test method, Screen would display as below: After you select the method, then input password: “hard disk”, if input password is Right, the screen would display as below:... - Page 103 3. Tests and Diagnostics If input password is wrong, the screen would display as below: The screen will display as below picture to show the subtest is passed or failed when finished: If it is show the picture as below, it means HDD function is OK...

- Page 104 If the picture shows as below, it means he HDD function is NG 3.17 Read DMI Compal write Toshiba Part No (version), Toshiba Serial No (Serial No), Product Name, OEM string and UUID, If you want to double check the DMI data, please select Read DMI item, the...

- Page 105 3. Tests and Diagnostics 3.18 Write DMI When you want to write DMI data, please select which data you want to write, the figure below will be displayed: 1. Write OME string 2. Write Version 3. Write Serial 4. Write Product 5.

- Page 106 3. Tests and Diagnostics After write OK, you should reboot the system that can make the setting effective, or you can write next data before reboot system, the figure below will displayed:...

-

Page 107: Toshiba Logo Set

NOTE: should input correct DMI data, and should reboot the system that can make the setting effective. 3.19 Toshiba Logo set Set the computer’s Toshiba Logo for other region except Japan SKU. The screen should display as below, indicating whether the test is passed or failed when finished. - Page 108 3. Tests and Diagnostics Press any key continue to auto set, if write OK, the following message displays: When Toshiba Logo set finish, please restart machine, when show below Logo:...

-

Page 109: Dynabook Logo Set

3. Tests and Diagnostics If an error is detected and a test fails, the following message displays: 3.20 Dynabook Logo set Set the computer’s Dynabook Logo for Japan SKU. - Page 110 3. Tests and Diagnostics The screen should display as below, indicating whether the test is passed or failed when finished. Press any key continue to auto set, if write OK, the following message displays: When Dynabook Logo set finish, please restart machine, when show below Logo:...

- Page 111 3. Tests and Diagnostics If an error is detected and a test fails, the following message displays:...

-

Page 112: Tp Type R/W Test

3. Tests and Diagnostics 3.21 TP TYPE R/W TEST This T/P TYPE R/W test checks the computer’s T/P TYPE and users write T/P vendor ID into EEPROM The test runs automatically. The screen should display as below, indicating whether the test is passed or failed when finished. - Page 113 3. Tests and Diagnostics If write T/P type fail, the screen would display as below If read T/P type fail, the screen would display as below...

- Page 114 3. Tests and Diagnostics If W/R T/P type passes, the screen would display as below...

-

Page 115: Eeprom Setting

3. Tests and Diagnostics 3.22 EEPROM Setting This EE-PROM SETTING will set the computer’s function status into EEPROM, included supported function and no support function. NOTE: Should perform EE-PROM SETTING once change M/B. It defined as normal rule. The screen should display as below: If press “1”... - Page 116 3. Tests and Diagnostics If this unit has MIC function, press “Y” then program will set MIC enable automatically as below: If this unit has no MIC function, press “N” then program will set MIC disable automatically as below: Then press any key go back to EE-PROM SETTING option as below:...

- Page 117 3. Tests and Diagnostics If press “7” to disable all no support function, program will perform automatically as below:...

- Page 118 3. Tests and Diagnostics...

- Page 119 3. Tests and Diagnostics Then press any key to go back to EE-PROM SETTING option as below: If press “9” program will go back to test title as below:...

- Page 120 3. Tests and Diagnostics...

- Page 121 Chapter 4 Replacement Procedures...

- Page 122 Installing the WLAN Card ................4-16 Hinge Cover and Keyboard.................. 4-17 Removing the Hinge Cover................4-18 Removing the Keyboard................4-19 Installing the Hinge Cover and Keyboard............ 4-20 Power Board......................4-21 Removing the Power Board ................. 4-21 NB250/NB255 Maintenance Manual 4-ii...

- Page 123 LCD Module ......................4-41 Removing the LCD Module................. 4-41 Installing the LCD Module ................4-43 4.15 Camera module LVDS cable................4-44 Removing the Camera module and LVDS Cable ........4-44 Installing the Camera module and LVDS Cable.......... 4-46 NB250/NB255 Maintenance Manual 4-iii...

- Page 124 Figure 4.28 Removing screws from the LCD Bezel Assembly........... 4-38 Figure 4.29 Removing the bezel from the hinge wall............4-39 Figure 4.30 Removing the bezel from the display assembly ..........4-39 Figure 4.31 Removing the screws from the LCD module ........... 4-41 NB250/NB255 Maintenance Manual 4-iv...

- Page 125 4 Replacement Procedures Figure 4.32 Removing the LCD Hinge Assembly............... 4-42 Figure 4.33 Removing the Camera from the LCD panel............. 4-44 Figure 4.34 Removing the LVDS cable from the LCD module .......... 4-45 NB250/NB255 Maintenance Manual...

-

Page 127: General

4.10 Touch Pad Upper Assembly 4.13 Thermal 4.14 3G Module 4.15 WiMax 4.11 Bluetooth For removing the LCD Fan Module (Optional) Module (Optional) Card Module: First, remove Logic Upper Assembly, then remove the LCD Bezel Assembly. NB250/NB255 Maintenance Manual... -

Page 128: Safety Precautions

DANGER: Always use the original batteries or replacement batteries authorized by Toshiba. Batteries other than those differ in specifications and are incompatible with the laptop. They may burst or explode. To avoid leakage of alkaline solutions, never heat or disassemble the battery packs. - Page 129 For AC input, be sure to use the AC adapter and AC power cable that come with your laptop or Toshiba-recommended equivalents. To avoid the risk of electrical shock, make sure that all the replacement components meet the specifications of the laptop and that all the cables and connectors are fastened securely.

-

Page 130: Before You Begin

See the appropriate explanations and figures for screw sizes. To avoid personal injury, use care to handle components that have sharp edges or corners. After you have replaced a FRU, check that the FRU works correctly to ensure normal laptop operation. NB250/NB255 Maintenance Manual... -

Page 131: Disassembly Procedures

Check that all the required screws are used to secure the FRUs. Using wrong screws can damage the threads or heads of the screws or does not ensure that the FRUs are secure. After installing a FRU, make sure that the FRU and laptop work normally. NB250/NB255 Maintenance Manual... -

Page 132: Tools And Equipment

M2 (2 mm) 0.15~0.20 N・m (1.5~2.0 kgf・cm) M2.5 (2.5 mm) 0.26~0.30 N・m (2.5~3.0 kgf・cm) M3 (3 mm) 0.26~0.30 N・m (2.5~3.0 kgf・cm) M2.5x4 screws 0.26~0.30 N・m (2.5~3.0 kgf・cm) M2.5x6 screws 0.26~0.30 N・m (2.5~3.0 kgf・cm) NB250/NB255 Maintenance Manual... -

Page 133: Colors Of Screw Shanks

U (stands for unique-pan head screws, studs, etc.) Symbol examples 6 mm bind screw 12 mm bind screw 5 mm stud (The numeral represents the rounded length of the threaded portion regardless of the entire stud length.) NB250/NB255 Maintenance Manual... -

Page 134: Figure 4.1 Removing The Battery Pack

3. Slide the battery release latch and remove the battery pack from the laptop as shown in Figure 4.1. Figure 4.1 Removing the Battery Pack NOTE: Dispose of the used battery packs as required by local ordinances or regulations. NB250/NB255 Maintenance Manual... -

Page 135: Installing The Battery Pack

NOTE: Visually check the battery's terminals. If they are dirty, clean them with a dry cloth. 1. Gently insert a new or recharged battery pack into place. Check that the battery release latch slides in and stops with a click. 2. Slide in the battery safety lock to the lock position. NB250/NB255 Maintenance Manual... -

Page 136: Figure 4.2 Removing The Hdd Door

1. To remove the HDD, remove two M2.5x4 HDD door TORX screws that secure the HDD door and then remove the HDD door as shown in Figure 4.2. M2.5x4 TORX*2 Figure 4.2 Removing the HDD door NB250/NB255 Maintenance Manual 4-10... -

Page 137: Figure 4.3 Removing The Hdd From The Hdd Bay

Figure 4.3 Removing the HDD from the HDD bay NOTE: Do not disassemble the HDD pack when it is working normally. Disassemble or replace the HDD pack only if it fails. Place the HDD pack on a flat surface such as a desk. NB250/NB255 Maintenance Manual 4-11... -

Page 138: Figure 4.4 Removing The Hdd Plate

HDD pack. Always hold the HDD pack by its sides. 3. Install the HDD pack into the correct position in the laptop. Connect the HDD pack to the laptop. 4. Secure the main HDD door by tightening two M2.5x4 TORX screws. NB250/NB255 Maintenance Manual 4-12... -

Page 139: Figure 4.5 Removing The Ram Door

3. Remove the RAM door as shown in Figure 4.5. CAUTION: Do not touch the connectors on the memory or in the laptop. Contaminated connectors can cause memory access problems. M2.5Dx4*1 Figure 4.5 Removing the RAM door NB250/NB255 Maintenance Manual 4-13... -

Page 140: Figure 4.6 Removing The Ram From The Laptop

After the laptop is turned on, check the hardware configuration in the Hardware Setup or TESTUP program to make sure that the installed memory has been recognized by the system. If it has not been recognized yet, check the connections. NB250/NB255 Maintenance Manual 4-14... -

Page 141: Figure 4.7 Removing The Wlan Card

1. Detach the two antennas on the WLAN card. 2. Remove two M2x3 screws that secure the WLAN card as shown in Figure 4.7. 3. Pull the WLAN card out at an angle. M2x3*2 WLAN Card Figure 4.7 Removing the WLAN card NB250/NB255 Maintenance Manual 4-15... -

Page 142: Installing The Wlan Card

2. Press the card down and secure it with two M2x3 screws. 3. Attach the two antennas to the WLAN card. The white (MAIN) antenna to the #1 connector and the black (AUX) antenna to the #2 connector. NB250/NB255 Maintenance Manual 4-16... -

Page 143: Hinge Cover And Keyboard

1. Remove the following twelve screws as shown in Figure 4.8: seven M2.5x6 screws five M2.5x4 screws 2. Detach any WLAN and modem antennas from their respective cards. M2.5x4*5 M2.5x6*7 Figure 4.8 Removing the screws from the bottom of the laptop NB250/NB255 Maintenance Manual 4-17... -

Page 144: Figure 4.9 Detaching Three Hinge Cap Hooks

3. Push the hinge cover toward the battery bay with an outward rolling motion until the hinge cover tabs are released from the system and the hinge cover comes loose as shown in figure 4.10. 4. Remove the hinge cover from the system. Figure 4.10 Removing the Hinge Cover NB250/NB255 Maintenance Manual 4-18... -

Page 145: Figure 4.11 Removing The Keyboard

NOTE: Hooks fastening flat-type keyboards will be located on the logic upper assembly rather than the keyboard itself. 3. Remove the keyboard. Hooks Hooks Figure 4.11 Removing the keyboard NB250/NB255 Maintenance Manual 4-19... -

Page 146: Installing The Hinge Cover And Keyboard

5. Turn the laptop upside down. Make sure all three hinge cap hooks are firmly in place. 6. Secure the laptop with twelve screws as indicated in Figure 4.8: seven M2.5x6 screws five M2.5x4 screws 7. Fasten any WLAN or modem antennas to their respective connectors. NB250/NB255 Maintenance Manual 4-20... -

Page 147: Figure 4.12 Removing The Power Board

4. Remove the power board from the logic upper assembly. Figure 4.12 Removing the Power Board Note: Be careful not to damage the Power Board when connecting it with the cable. Make sure the card is seated in the correct position. NB250/NB255 Maintenance Manual 4-21... -

Page 148: Installing The Power Board

4. Use tweezers and a finger to push down on the left and right latches of the connector. Both latches must be pushed simultaneously to secure the power board cable. 5. Secure the power board cable with adhesive tape. NB250/NB255 Maintenance Manual 4-22... -

Page 149: Logic Upper Assembly

Remove the logic upper assembly according to the following procedures and Figure 4.13, 4.14, 4.15, 4.16 and 4.17. 1. Remove four 2.5x6 screws from the logic upper assembly. M2.5x6*4 Figure 4.13 Removing three screws from under the keyboard NB250/NB255 Maintenance Manual 4-23... - Page 150 NOTE: When removing the hinge screws, the cables and antennas on the left and right sides will be obstacles. Be sure to move any cables securely out of the way to ensure no scratching or damage occurs. NB250/NB255 Maintenance Manual 4-24...

- Page 151 4.5 WLAN Card 4 Replacement Procedures 5. Close the laptop. Remove two M2.5x6 screws from the hinge saddle as shown in Figure 4.15. M2.5x6*2 Figure 4.15 Removing the first pair of screws from the hinge saddle NB250/NB255 Maintenance Manual 4-25...

- Page 152 4 Replacement Procedures 4.5 WLAN Card 6. Open the laptop and remove two M2.5x6 screws from the hinge saddle as shown in Figure 4.16. M2.5x6*2 Figure 4.16 Removing the second pair of screws from the hinge saddle NB250/NB255 Maintenance Manual 4-26...

-

Page 153: Figure 4.17 Detaching The Cables From Under The Keyboard

Both latches must be pushed simultaneously to secure the touch pad cable. 4. Secure the LCD display assembly with two M2.5x6 screws and attach the LVDS cable to the motherboard as shown in Figure 4.16. NB250/NB255 Maintenance Manual 4-27... - Page 154 8. Route the camera cable and microphone cable through the trough and secure in the logic upper assembly with adhesive tape. NOTE: Take extra care in routing cables and antennas on Logic upper assembly. Improperly routed cables can become pinched or damaged and cause malfunction. NB250/NB255 Maintenance Manual 4-28...

-

Page 155: Figure 4.18 Removing The Speaker

Installing the Speaker Install the speaker according to the following procedures. Seat the speaker in the correct position on the logic lower assembly. Secure the speaker with two M2.5x7.7 screws. Attach the speaker cable to the motherboard. NB250/NB255 Maintenance Manual 4-29... -

Page 156: Touch Pad

Remove the touch pad bracket from the logic upper assembly. Installing the Touch Pad Bracket Install the touch pad bracket according to the following procedures. Seat the touch pad bracket in the correct position, Secure the bracket with two M2.5x2.5 screws. NB250/NB255 Maintenance Manual 4-30... -

Page 157: Motherboard

Remove the motherboard according to the following procedures and Figure 4.20, 4.21, 4.22 and 4.23. 1. Remove two M2.5x4 screws and FAN cable from the motherboard as indicated by the arrow in Figure 4.20. M2.5x4*2 Figure 4.20 Removing the motherboard from logic lower assembly NB250/NB255 Maintenance Manual 4-31... -

Page 158: Figure 4.21 Removing The Dc In Plate

Figure 4.21 Removing the DC IN plate 3. Gently pull the cable out of the routing channel in the logic lower assembly from right to left, as shown in Figure 4.22. Figure 4.22 Removing the DC IN connector and cable NB250/NB255 Maintenance Manual 4-32... -

Page 159: Figure 4.23 Picking Up The Motherboard

4 Replacement Procedures 4. Use your hands to pick up the motherboard in the direction of the arrows as shown in figure 4.23. Figure 4.23 Picking up the motherboard 5. Remove the motherboard from the logic lower assembly. NB250/NB255 Maintenance Manual 4-33... -

Page 160: Figure 4.24 Aligning The Motherboard Connectors

2. Align the connectors on the left side to their corresponding holes in the logic lower assembly as shown in Figure 4.24. Figure 4.24 Aligning the motherboard connectors 3. Seat the motherboard down in the lower logic assembly. NB250/NB255 Maintenance Manual 4-34... -

Page 161: Figure 4.25 Installing The Dc In Connector

Figure 4.25 Installing the DC IN connector 5. Seat the DC IN plate in its correct position. 6. Secure two M2.5x4 screws and attach FAN cable to the motherboard as indicated by the arrow in Figure 4.20. NB250/NB255 Maintenance Manual 4-35... -

Page 162: Figure 4.26 Removing The Thermal Fan Module

Remove three M2.5x3 screws securing the thermal fan module to the motherboard in order as shown in Figure 4.26. Remove the thermal module from the motherboard. M2.5x3*3 Figure 4.26 Removing the Thermal Fan Module NB250/NB255 Maintenance Manual 4-36... -

Page 163: Installing The Thermal Fan Module

Figure 4.27 Applying the thermal pad on the thermal module 2. Seat the thermal fan module in the correct position on the motherboard and secure it with three M2.5x3 screws in reverse order (3-2-1) of that shown in Figure 4.26. NB250/NB255 Maintenance Manual 4-37... -

Page 164: Lcd Bezel Assembly

Remove the LCD bezel assembly according to the following procedures and Figures 4.28, 4.29 and 4.30. 1. Remove the two mask seals that cover the screws. 2. Remove two M2.5x5 screws as shown in Figure 4.28. M2.5x5*2 TOBSHIBA Figure 4.28 Removing screws from the LCD Bezel Assembly NB250/NB255 Maintenance Manual 4-38... -

Page 165: Figure 4.29 Removing The Bezel From The Hinge Wall

Figure 4.29 Removing the bezel from the hinge wall 4. Push the bezel from the left and right side as shown in Figure 4.30 and remove the bezel from the display assembly. Figure 4.30 Removing the bezel from the display assembly NB250/NB255 Maintenance Manual 4-39... -

Page 166: Installing The Lcd Bezel Assembly

2. Press the bezel hinge wall against the cover hinge wall. Press the left and right side of the bezel as shown in Figure 4.31. Make sure the bezel clicks into place. 3. Secure it to the display assembly with two M2.5x5 screws. 4. Adhere the two mask seals to the screws. NB250/NB255 Maintenance Manual 4-40... -

Page 167: Lcd Module

NOTE: Camera module is fastened by adhesive tape. Remove it slowly and carefully. M2.5x5*4 Figure 4.31 Removing the screws from the LCD module 3. Lift the LCD module out of the LCD cover assembly and remove it. NB250/NB255 Maintenance Manual 4-41... - Page 168 Integrated Circuits (ICs) are fragile. Use extreme care not to apply pressure to the ICs along the edges of the LCD module. Dispose of used LCD panels (fluorescent (FL) tubes) as required by local ordinances or regulations. NB250/NB255 Maintenance Manual 4-42...

-

Page 169: Installing The Lcd Module

1. Seat the LCD hinges in the correct positions on the LCD panel and secure them with four M2x3 screws. 2. Seat the LCD module in the correct position in the LCD cover assembly. 3. Secure the LCD module to the LCD cover assembly with four M2.5x4 screws. NB250/NB255 Maintenance Manual 4-43... -

Page 170: Camera Module Lvds Cable

1. Turn the LCD panel over and place it face down on a protective surface such as a foam pad. 2. Disconnect the camera from the connector and remove it, as shown in Figure 4.33. Figure 4.33 Removing the Camera from the LCD panel NB250/NB255 Maintenance Manual 4-44... - Page 171 3. Carefully peel up the LVDS cable, starting from the top, as shown in Figure 4.34. Once the LVDS cable has been peeled up disconnect it from the LCD panel, taking care not to damage the connector. Remove the LVDS cable. Figure 4.34 Removing the LVDS cable from the LCD module NB250/NB255 Maintenance Manual 4-45...

-

Page 172: Installing The Camera Module And Lvds Cable

1. Connect the LVDS cable to the connector on the back of the LCD module. 2. Adhere the LVDS cable in the correct position on the LCD module. 3. Connect the camera to the camera connector on the LVDS cable. NB250/NB255 Maintenance Manual 4-46... -

Page 173: Appendix A Handling The Lcd Module

LCD cover before securing the module with screws. Do not force the module into place, because stress can affect its performance. Note: The panel’s polarized surface is easily scratched and damaged, so handle it carefully. [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual... - Page 174 Do not apply cleanser directly to the panel. Cleaner 4. If water or other liquid is left on the panel’s surface for a long period, it can change the screen’s tint or stain it. Be sure to quickly wipe off any liquid. [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual...

- Page 175 5. Glass is used in the panel, so be careful not to drop it or let it strike a hard object, which could cause breakage or cracks. 6. CMOS-LSI circuits are used in the module, so guard against damage from electrostatic discharge. Be sure to wear a wrist or ankle grounding device when handling the module. NB250 Series Maintenance Manual [CONFIDENTIAL]...

- Page 176 8. Do not store the module at temperatures below its specifications. Cold can cause the liquid crystals to freeze, lose their elasticity or otherwise suffer damage. 9. Do not disassemble the LCD module. Disassembly can cause malfunctions. [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual...

- Page 177 10. If you transport the module, do not use packing material that contains epoxy resin (amine) or silicon glue (alcohol or oxime). These materials can release gas that can damage the panel’s polarization. NB250 Series Maintenance Manual [CONFIDENTIAL]...

-

Page 178: Appendix B Board Layout

Appendix B Appendix B Board Layout B.1 System Board Top View JLVDS JTOUCH JMIC JPOWER JFAN JCARD JSPKR Figure B-1 System Board Layout (Top) [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual... - Page 179 B.2 System Board Bottom View PJP2 JCRT PJP1 Figure B-2 System Board Layout (Bottom) JWLAN JEXMIC JSATA JLINE JDDR1 JLAN JUSBA JUSBC JUSBB UL3 UL1 [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual...

- Page 180 Table B-1 System Board ICs (top and bottom) Number Name Intel Atom_ Thermal Sensor_EMC1402 Clock Generator_RTM875N-397-GR South Bridge_Intel NM10 EC_KB926QFE0 FAN Control IC_APL5607KI-TRG BIOS ROM Codec_ALC259-VB5-GR Card Reader_RTS5138-GR 10/100 LAN_RTL8105E-GR LAN Transformer_S X'FORM_ NS681695 Table B-2 System Board Connectors (top and bottom) [CONFIDENTIAL] NB250 Series Maintenance Manual...

- Page 181 Speaker conn. JLAN LAN conn. JWLAN WLAN conn. JUSBA USB/A conn. JUSBB USB/B conn. JUSBC USB/C conn. JLINE Headphones conn. JEXMIC External MIC conn. Keyboard conn. JTOUCH TP/B conn. PJP1 AC Adaptor conn. PJP2 Battery conn. [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual...

-

Page 182: Appendix C Pin Assignments

FAN_SPEED1 JLVDS Table C-2 LVDS I/F pin assignments (20-pin) Pin No. Signal name Pin No. Signal Name +LEDVDD +LCDVDD_L +3VS LCD_PWM BKOFF# LVDS_SDA LVDS_SCL LVDS_A0 LVDS_A0# LVDS_A1 LVDS_A1# LVDS_A2 LVDS_A2# LVDS_ACLK LVDS_ACLK# USB_N7_R USB_P7_R +5VS [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual... - Page 183 +CRT_VCC CRT_DDC_DAT HSYNC VSYNC CRT_DDC_CLK JSATA Table C-4 HDD I/F pin assignments (22-pin) Pin No. Signal name Pin No. Signal Name SATA_ITX_C_ DRX_P0 SATA_ITX_C_ DRX_N0 SATA_IRX_DT SATA_IRX_DT X_N0 X_P0 +3VS +3VS +3VS +5VS +5VS +5VS [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual...

- Page 184 Signal name Signal Name +3V_WLAN WLAN_BT_DATA WLAN_BT_CLK +1.5VS WLAN_CLKREQ# LPC_FRAME#_R LPC_AD3_R CLK_PCIE_WLAN# LPC_AD2_R CLK_PCIE_WLAN LPC_AD1_R LPC_AD0_R XMIT_OFF# PLT_RST# PCIE_PTX_C_IRX_N +3V_WLAN PCIE_PTX_C_IRX_P +1.5VS CLK_SMBCLK PCIE_ITX_C_PRX_N CLK_SMBDATA PCIE_ITX_C_PRX_P USB20_N4 USB20_P4 +3V_WLAN +3V_WLAN LED_WIMAX# +1.5VS EC_TX_P80_DATA EC_RX_P80_CLK +3V_WLAN [CONFIDENTIAL] NB250 Series Maintenance Manual...

- Page 185 JLAN Table C-6 LAN Connector pin assignments (12-pin) Pin No. Signal name Pin No. Signal Name RJ45_MIDI0+ RJ45_MIDI0- RJ45_MIDI1+ RJ45_MIDI1- +3V_LAN LAN_SK_LAN_LINK# +3V_LAN LAN_ ACTIVITY# [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual...

- Page 186 Table C-7 SODIMM I/F pin assignments (204-PIN) (1/4) Pin No. Signal name Pin No. Signal Name +DIMM_VREF DDR_A_D4 DDR_A_D0 DDR_A_D5 DDR_A_D1 DDR_A_DQS#0 DDR_A_DM0 DDR_A_DQS0 DDR_A_D2 DDR_A_D6 DDR_A_D3 DDR_A_D7 DDR_A_D8 DDR_A_D12 DDR_A_D9 DDR_A_D13 DDR_A_DQS#1 DDR_A_DM1 DDR_A_DQS1 DRAMRST# [CONFIDENTIAL] NB250 Series Maintenance Manual...

- Page 187 DDR_A_D23 DDR_A_D19 DDR_A_D28 DDR_A_D24 DDR_A_D29 DDR_A_D25 DDR_A_DQS#3 DDR_A_DM3 DDR_A_DQS3 DDR_A_D26 DDR_A_D30 DDR_A_D27 DDR_A_D31 DDR_CKE0 DDR_CKE1_DI +1.5V +1.5V DDR_A_BS2 DDR_A_MA14 +1.5V +1.5V DDR_A_MA12 DDR_A_MA11 DDR_A_MA9 DDR_A_MA7 +1.5V +1.5V DDR_A_MA8 DDR_A_MA6 DDR_A_MA5 DDR_A_MA4 +1.5V +1.5V DDR_A_MA3 DDR_A_MA2 [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual...

- Page 188 DDR_A_RAS# +1.5V +1.5V DDR_A_WE# DDR_CS0_DIM DDR_A_CAS# M_ODT0 +1.5V +1.5V DDR_A_MA13 M_ODT1 DDR_CS1_DIM +1.5V +1.5V +VREF_CA DDR_A_D32 DDR_A_D36 DDR_A_D33 DDR_A_D37 DDR_A_DQS#4 DDR_A_DM4 DDR_A_DQS4 DDR_A_D38 DDR_A_D34 DDR_A_D39 DDR_A_D35 DDR_A_D44 DDR_A_D40 DDR_A_D45 DDR_A_D41 DDR_A_DQS#5 DDR_A_DM5 DDR_A_DQS5 DDR_A_D42 DDR_A_D46 [CONFIDENTIAL] NB250 Series Maintenance Manual...

- Page 189 Pin No. Signal name Pin No. Signal Name DDR_A_D48 DDR_A_D52 DDR_A_D49 DDR_A_D53 DDR_A_DQS#6 DDR_A_DM6 DDR_A_DQS6 DDR_A_D54 DDR_A_D50 DDR_A_D55 DDR_A_D51 DDR_A_D60 DDR_A_D56 DDR_A_D61 DDR_A_D57 DDR_A_DQS#7 DDR_A_DM7 DDR_A_DQS7 DDR_A_D58 DDR_A_D62 DDR_A_D59 DDR_A_D63 PM_EXTTS#0 +3VS CLK_SMBDATA CLK_SMBCLK +0.75VS +0.75VS [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual...

- Page 190 Table C-10 Keyboard Connector pin assignments (34-pin) Pin No. Signal name Pin No. Signal Name CAPS_LED# +3VS KSI1 KSI6 KSI5 KSI0 KSI4 KSI3 KSI2 KSI7 KSO15 KSO12 KSO11 KSO10 KSO9 KSO8 KSO13 KSO7 KSO6 KSO14 KSO5 KSO3 KSO4 KSO0 KSO1 KSO2 [CONFIDENTIAL] NB250 Series Maintenance Manual...

- Page 191 Table C-13 USB/B Connector pin assignments (4-pin) Pin No. Signal name Pin No. Signal Name +USB_VCCB USB20_N4_R USB20_P4_R C.14 JPOWER Table C-14 POWER/B connector pin assignments (4-pin) Pin No. Signal name Pin No. Signal Name PWR_ON_LED# PWR_ON_LED ON/OFFBTN#_R [CONFIDENTIAL] C-10 NB250/NB255 Series Maintenance Manual...

- Page 192 Table C-16 EXMIC connector pin assignments (6-pin) Pin No. Signal name Pin No. Signal Name AGND MIC1_L_L MIC1_L_R MIC_SENSE AGND C.17 JSPKR Table C-17 SPKR connector pin assignments (2-pin) Pin No. Signal name Pin No. Signal Name SPK_R1 SPK_R2 [CONFIDENTIAL] NB250 Series Maintenance Manual C-11...

- Page 193 C.18 JTOUCH Table C-18 T/P connector pin assignments (6-pin) Pin No. Signal name Pin No. Signal Name TP_SWR TP_SWL TP_DATA TP_CLK +5VS [CONFIDENTIAL] C-12 NB250/NB255 Series Maintenance Manual...

- Page 194 Appendix D Appendix D Keyboard Scan/Character Codes Table D-1 Scan codes (set 1 and set 2) (1/4) Code set 1 Code set 2 Keytop Note Make Break Make Break ‘ ~ 7 & BkSp [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual...

- Page 195 Table D-1 Scan codes (set 1 and set 2) (2/4) Code set 1 Code set 2 Keytop Note Make Break Make Break Caps Lock ‘ “ Enter Shift (L) No.102 , < . > Shift (R) [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual...

- Page 196 Table D-1 Scan codes (set 1 and set 2) (3/4) Code set 1 Code set 2 Keytop Note Make Break Make Break Ctrl(L) Alt (L) Space ALT (R) Ctrl(R) Home PgUp PgDn [CONFIDENTIAL] NB250 Series Maintenance Manual...

- Page 197 5. * This key corresponds to key No. 42 in a 102-key model. 6. * Refer to Table D-6, No. 124 key scan code. 7. * Refer to Table D-7, No. 126 key scan code. [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual...

- Page 198 Shift key, scan codes are changed as listed below: With left Shift With right Shift Set 1 E0 AA ___________ E0 B6 E0 2A ___________ E0 36 Set 2 E0 F0 12_________ E0 F0 59 E0 12____________ E0 59 [CONFIDENTIAL] NB250 Series Maintenance Manual...

- Page 199 Table D-4 Scan codes with Fn key Code set 1 Code set 2 Keytop Make Break Make Break L-CTRL L-ALT Pause Break ARROW NUMERIC Scrl Note: 8. * Refer to Table D-7, No. 126 key scan code. [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual...

- Page 200 Code set 2 Keytop Make Break Make Break (–) Table D-6 No.124 key scan code Code set 1 Code set 2 Shift Make Break Make Break Prt Sc Common Ctrl Shift Alt [CONFIDENTIAL] NB250 Series Maintenance Manual...

- Page 201 Table D-7 No.126 key scan code Key top Shift Code set 1 Code set 2 Make Make Pause Common Break Common *: This key generates only make codes. [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual...

-

Page 202: Appendix E Key Layout

Appendix E Key Layout United Status (US) Keyboard Figure US keyboard Traditional Chinese (CH) Keyboard Figure CH keyboard NB250/NB255 Series Maintenance Manual... - Page 203 3. Thai (TI) Keyboard Figure TI keyboard 4. Korean (KO) Keyboard Figure KO keyboard NB250/NB255 Series Maintenance Manual...

- Page 204 5. United Kingdom (UK) Keyboard Figure UK keyboard 6. US International (UI) Keyboard NB250/NB255 Series Maintenance Manual...

- Page 205 Figure UI keyboard 7. Hebrew (HB) Keyboard Figure HB keyboard 8. Danish (DM) Keyboard NB250/NB255 Series Maintenance Manual...

- Page 206 Figure DM keyboard 9. Swiss (SW) Keyboard Figure SW keyboard NB250/NB255 Series Maintenance Manual...

- Page 207 10. Arabic (ARE) Keyboard Figure ARE keyboard 11. Czech (CZ) Keyboard Figure CZ keyboard NB250/NB255 Series Maintenance Manual...

- Page 208 2. Russian (RU) Keyboard Figure RU keyboard 3. Portuguese (PO) Keyboard Figure PO keyboard NB250/NB255 Series Maintenance Manual...

- Page 209 4. Slovakian (SL) Keyboard Figure SL keyboard 5. Italian (IT) Keyboard Figure IT keyboard NB250/NB255 Series Maintenance Manual...

- Page 210 16. French (FR) Keyboard Figure FR keyboard 17. German (GR) Keyboard Figure GR keyboard NB250/NB255 Series Maintenance Manual...

- Page 211 18. Greek (GK) Keyboard Figure GK keyboard 19. Hungarian (HG) Keyboard NB250/NB255 Series Maintenance Manual...

- Page 212 Figure HG keyboard 20. Spanish (SP) Keyboard Figure SP keyboard 21. Turkish (TR) Keyboard NB250/NB255 Series Maintenance Manual...

- Page 213 Figure TR keyboard 22. Turkish F (TF-F) Keyboard Figure TF-F keyboard NB250/NB255 Series Maintenance Manual...

- Page 214 23. Swedish (SD) Keyboard Figure SD keyboard 24. Belgian (BE) Keyboard Figure BE keyboard NB250/NB255 Series Maintenance Manual...

- Page 215 25. Yugoslavian (YU) Keyboard Figure YU keyboard 26. Norwegian (NW) Keyboard Figure NW keyboard NB250/NB255 Series Maintenance Manual...

- Page 216 27. Scandinavian (ND) Keyboard Figure ND keyboard 28. Canadian Multinational (AC) Keyboard NB250/NB255 Series Maintenance Manual...

- Page 217 Figure AC keyboard 29. Canadian Bilingual (CB) Keyboard Figure CB keyboard 30. Romania (RO) Keyboard NB250/NB255 Series Maintenance Manual...

- Page 218 Figure RO keyboard 31. Bulgaria (BU) Keyboard Figure BU keyboard 32. Japanese (JP) Keyboard NB250/NB255 Series Maintenance Manual...

- Page 219 Figure JP keyboard NB250/NB255 Series Maintenance Manual...

- Page 220 LOG UP TO LOG LOW 2.5~3.0Kgf.cm MA0000062G0 M2.5x6 (Black)) LOG LOW TO KEYBOARD 2.0~2.5Kgf.cm MA0000066G0 M2.5x4 (Black)) HDD DOOR TO LOG LOW 2.5~3.0Kgf.cm RAM DOOR TO LOW (FIX ON MA000009TG0 M2.5* 2.2+1.8L(Black) 1 2.0~2.5Kgf.cm DOOR) [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual...

- Page 221 LOGIC & LCD ASSY MA0000062G0 M2.5x6 (Black) HINGE BRACKET TO LOGIC 2.0~2.5Kgf.cm MACK25040G0 M2.5x4 (Black) LOG LOW TO UP HINGE COVER 2.0~2.5Kgf.cm [CONFIDENTIAL] NB250 Series Maintenance Manual...

-

Page 222: Appendix G Reliability

Appendix G Appendix G Reliability The following table shows MTBF (Mean Time Between Failures) for each component. Table G-1 MTBF Component Time (hours) 10,000 Keyboard 64400 300,000 Optical (DVD/CD) drive 60,000 AC adaptor 50,000 [CONFIDENTIAL] NB250/NB255 Series Maintenance Manual...

Need help?

Do you have a question about the NB250 and is the answer not in the manual?

Questions and answers