Mitsubishi Electric City Multi PUMY-P36NHMU Technical & Service Manual

Split-type, heat pump air conditioners

Hide thumbs

Also See for City Multi PUMY-P36NHMU:

- Datasheet (2 pages) ,

- Installation manual (32 pages)

Table of Contents

Advertisement

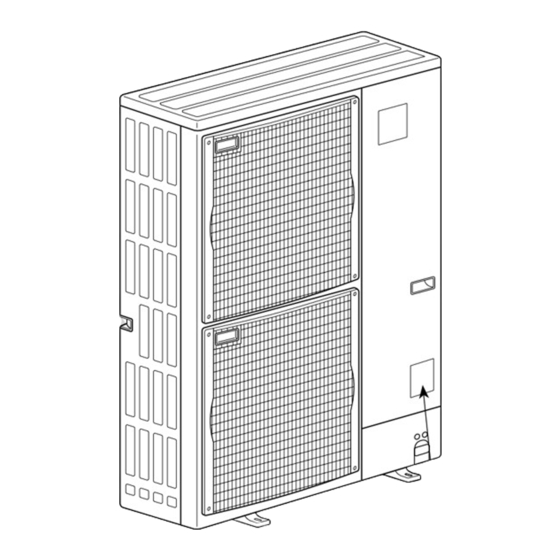

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

[Model name]

(Standard type)

PUMY-P36NHMU

PUMY-P48NHMU

(Salt proof type)

PUMY-P36NHMU-BS

PUMY-P48NHMU-BS

OUTDOOR UNIT

NOTE :

· This service manual describes technical data of out-

door unit.

As for indoor units, refer to its service manual.

·

RoHS compliant products have <G> mark on the spec

name plate.

[Service Ref.]

PUMY-P36NHMU

PUMY-P48NHMU

PUMY-P48NHMU

PUMY-P48NHMU

PUMY-P36NHMU-BS

PUMY-P48NHMU-BS

PUMY-P48NHMU

PUMY-P48NHMU

Model name

indication

1

2

-BS

1

-BS

2

CONTENTS

1. TECHNICAL CHANGES ................................... 2

2. SAFETY PRECAUTION .................................... 5

3. OVERVIEW OF UNITS ...................................... 8

4. SPECIFICATIONS ........................................... 10

5. DATA ................................................................ 12

6. OUTLINES AND DIMENSIONS ...................... 18

7. WIRING DIAGRAM ......................................... 20

9. TROUBLESHOOTING .................................... 34

10. ELECTRICAL WIRING .................................... 81

11. REFRIGERANT PIPING TASKS ..................... 84

12. DISASSEMBLY PROCEDURE ........................ 88

13. PARTS LIST ..................................................... 93

14. RoHS PARTS LIST .......................................... 96

15. OPTIONAL PARTS .......................................... 99

July 2008

No. OC366

REVISED EDITION-C

HFC

utilized

R410A

Revision:

• 9. TROUBLESHOOING

has been modified.

• Tester check point is added

(PCB, FAN MOTOR).

• Please void OC366

REVISED EDITION-B.

Advertisement

Table of Contents

Summary of Contents for Mitsubishi Electric City Multi PUMY-P36NHMU

- Page 1 SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS July 2008 No. OC366 REVISED EDITION-C utilized R410A TECHNICAL & SERVICE MANUAL [Model name] [Service Ref.] Revision: (Standard type) • 9. TROUBLESHOOING PUMY-P36NHMU PUMY-P36NHMU has been modified. PUMY-P48NHMU PUMY-P48NHMU • Tester check point is added (PCB, FAN MOTOR).

-

Page 2: Technical Changes

TECHNICAL CHANGES PUMY-P48NHMU PUMY-P48NHMU PUMY-P48NHMU PUMY-P48NHMU · Compressor (MC) and oil have been changed. ANB33FDCMT (Ester oil: MEL56) ANB33FDHMT(Ether oil: FV50S) · Electrical parts have been changed. Multi controller board (MULTI. C.B.) Noise filter circuit board (N.F.) Active filter module (ACTM) Relay (52C) , Resister (RS) (including N.F.) PUMY-P48NHMU PUMY-P48NHMU... - Page 3 (4) Determine Fan Airflow setting during Indoor Thermo OFF conditions: a) These settings are done within Indoor DIPSW1-7 and DIPSW1-8, see chart below for options. b) Recommended SW1-7 OFF and SW1-8 ON will determine airflow based on "Setting on the remote controller". Auxiliary Heating Fan speed Fan speed...

- Page 4 (6) Locally procured wiring A basic connection method is shown. (i.e. interlocked operation with the electric heater with the fan speed setting on high Indoor unit Outdoor unit Remote control Board Relay circuit control board control board Adapter Dip switch SW4-4 "ON"...

-

Page 5: Safety Precaution

SAFETY PRECAUTION 2-1. CAUTIONS RELATED TO NEW REFRIGERANT Cautions for units utilizing refrigerant R410A Use new refrigerant pipes. Do not use refrigerant other than R410A. Avoid using thin pipes. If other refrigerant (R22 etc.) is used, chlorine in refrige- rant can cause deterioration of refrigerant oil etc. Use a vacuum pump with a reverse flow check Make sure that the inside and outside of refrige- valve. - Page 6 Unit Gravimeter [3] Service tools Use the below service tools as exclusive tools for R410A refrigerant. Tool name Specifications Gauge manifold ·Only for R410A ·Use the existing fitting specifications . ·Use high-tension side pressure of 5.3MPa·G or over. Charge hose ·Only for R410A ·Use pressure performance of 5.09MPa·G or over.

- Page 7 2-3. Cautions for refrigerant piping work New refrigerant R410A is adopted for replacement inverter series. Although the refrigerant piping work for R410A is same as for R22, exclusive tools are necessary so as not to mix with different kind of refrigerant. Furthermore as the working pressure of R410A is 1.6 time higher than that of R22, their sizes of flared sections and flare nuts are different.

-

Page 8: Overview Of Units

OVERVIEW OF UNITS 3-1. UNIT CONSTRUCTION Outdoor unit Type 06 ~ Type 36 Type 06 ~ Type 54 Capacity Indoor unit that Number of units 1~ 6 unit 1~ 8 unit can be connected 50% ~130% of outdoor unit capacity Total system wide capacity CMY-Y62-G-E CMY-Y64-G-E... -

Page 9: Unit Specifications

3-2. UNIT SPECIFICATIONS (1) Method for identifying MULTI-S model ■ ■ Outdoor unit <When using model 48 > Indoor unit < When using Model 30 > P L F Y - P 30 N B M U - E PU M Y - P 48 N H M U -BS UL model Outdoor unit Refrigerant... -

Page 10: Specifications

SPECIFICATIONS Service Ref. Item PUMY-P36NHMU(-BS) Cooling Capacity Btu/h 36,000 Heating Capacity Btu/h 40,000 Input ( Cool ) 3.22 Input Current ( Cool ) 14.23/15.74 Power factor (Cool) 98.4 Input ( Heat ) 2.93 Input Current ( Heat ) 12.88/14.24 Power factor (Heat) 98.9 EER ( Cool ) Btu/h/W... - Page 11 Service Ref. Item PUMY-P48NHMU/NHMU /NHMU (-BS) Cooling Capacity Btu/h 48,000 Heating Capacity Btu/h 54,000 Input ( Cool ) 4.97 Input Current ( Cool ) 24.0/21.7 Power factor (Cool) 99.5 Input ( Heat ) 4.88 Input Current ( Heat ) 23.6/21.3 Power factor (Heat) 99.5 EER ( Cool )

-

Page 12: Data.

DATA 5-1. COOLING AND HEATING CAPACITY AND CHARACTERISTICS 5-1-1. Method for obtaining system cooling and heating capacity: To obtain the system cooling and heating capacity and the electrical characteristics of the outdoor unit, first add up the ratings of all the indoor units connected to the outdoor unit (see table below), and then use this total to find the standard capacity with the help of the tables on 5-2.STANDARD CAPACITY DIAGRAM. - Page 13 5-2. STANDARD CAPACITY DIAGRAM * Before calculating the sum of total capacity of indoor units, please convert the value following the formula on 5-1-1. 5-2-1. PUMY-P36NHMU(-BS) Capacity(Btu/h) Power Consumption(kW) Current(A)/230V Current(A)/208V Total capacity of Indoor units* Cooling Heating Cooling Heating Cooling Heating Cooling...

- Page 14 5-2-2. PUMY-P48NHMU/NHMU /NHMU (-BS) Capacity(Btu/h) Power Consumption(kW) Current(A)/230V Current(A)/208V Total capacity of Indoor units* Cooling Heating Cooling Heating Cooling Heating Cooling Heating 24,000 26,900 2.11 2.32 10.2 10.2 11.2 25,000 28,000 2.20 2.41 10.5 10.6 11.6 26,000 29,200 2.29 2.50 10.0 10.9 11.1...

-

Page 15: Correcting Cooling And Heating Capacity

5-3. CORRECTING COOLING AND HEATING CAPACITY 5-3-1. Correcting Changes in Air Conditions (1)The performance curve charts (Figure 1, 2) show the ratio by the temperature condition change when the rated capacity (total capacity) and the rated input are presumed 1, under standard length (7.6m [25ft]) and standerd temperature condition. •... - Page 16 5-3-2. Correcting Capacity for Changes in the Length of Refrigerant Piping • During cooling, to obtain the ratio (and the equivalent piping length) of the outdoor units rated capacity and the total in-use indoor capacity, first find the capacity ratio corresponding to the standard piping length from Figure 3 at first, and then multiply by the cooling capacity from Figure 1 to obtain the actual capacity.

-

Page 17: Table Of Contents

5-4. NOISE CRITERION CURVES PUMY-P36NHMU(-BS) PUMY-P48NHMU(-BS) SPL(dB) MODE LINE MODE SPL(dB) LINE COOLING PUMY-P48NHMU (-BS) COOLING HEATING HEATING PUMY-P48NHMU (-BS) NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 APPROXIMATE APPROXIMATE THRESHOLD OF THRESHOLD OF HEARING FOR NC-20 HEARING FOR CONTINUOUS NC-20 CONTINUOUS... -

Page 18: Outlines And Dimensions

OUTLINES AND DIMENSIONS PUMY-P48NHMU Unit : mm <inch> PUMY-P48NHMU-BS PUMY-P48NHMU PUMY-P48NHMU... - Page 19 PUMY-P36NHMU Unit : mm <inch> PUMY-P36NHMU-BS PUMY-P48NHMU PUMY-P48NHMU...

-

Page 20: Wiring Diagram

WIRING DIAGRAM PUMY-P48NHMU PUMY-P48NHMU-BS PUMY-P48NHMU PUMY-P48NHMU SYMBOL NAME SYMBOL NAME SYMBOL NAME Terminal Block <Power Supply> Multi Controller Board N.F. Noise Filter Circuit Board MULTI.B. Terminal Block <Transmission> Fuse<6.3A> Connection Lead<L-Phase> F1,F2 LI/LO Terminal Block <Contralized Control> F500 Fuse<3A> NI/NO Connection Lead<N-Phase>... - Page 21 63HS TH7TH6 TH3 TH4 MULTI. B. CN3D CN3S CN3N SWU2 SWU1 1 2 3 1 2 1 2 CNF1 4 5 6 7 (WHT) (RED) (BLU) (WHT) 63HS TH7/6 1 2 3 1 2 3 1 2 3 (WHT) (RED) (WHT) (WHT) CNF2...

- Page 22 PUMY-P36NHMU PUMY-P36NHMU-BS PUMY-P48NHMU PUMY-P48NHMU SYMBOL NAME SYMBOL NAME SYMBOL NAME Terminal Block <Power Supply> P.B. Power Circuit Board Switch<Function Selection> Terminal Block <Comunication Line> TABU/V/W Connection Terminal<U/V/W-Phase> Switch<Function Selection> Terminal Block <Centralized Control Line> TABS/T Connection Terminal<L/N-Phase> Switch<Function Selection> Motor For Compressor TABP1/P2/P Connection Terminal<DC Voltage>...

- Page 23 TH7 TH6 TH3 TH4 63HS C. B. CNF1 CN3D CN3S CN3N CNLVB SWU2 SWU1 (WHT) (WHT) (RED) (BLU) (RED) 63HS TH7/6 (WHT) (RED) (WHT) (WHT) CNF2 (WHT) (RED) CN51 (WHT) M-NET P.B. LED1 LED2 (WHT) (WHT) (YLW) TRANS LED3 (WHT) CNDC TP1 BLK (PNK)

-

Page 24: Necessary Conditions For System Construction

NECESSARY CONDITIONS FOR SYSTEM CONSTRUCTION 8-1. TRANSMISSION SYSTEM SETUP... - Page 25 8-2. REFRIGERANT SYSTEM DIAGRAM PUMY-P48NHMU PUMY-P48NHMU PUMY-P48NHMU PUMY-P48NHMU-BS PUMY-P48NHMU PUMY-P48NHMU PUMY-P36NHMU PUMY-P36NHMU-BS Refrigerant flow in cooling Refrigerant flow in heating Pressure sensor Service Thermistor(TH7) (63HS) port High pressure Stop valve (Outdoor temperature) switch(63H) 4-way valve Refrigerant Gas pipe Solenoid <5/8 inch> Strainer valve(SV1) Capillary tube...

-

Page 26: System Control

8-3. SYSTEM CONTROL 8-3-1. Example for the System • Example for wiring control cables, wiring method and address setting, permissible lengths, and the prohibited items are listed in the standard system with detailed explanation. The explanation for the system in this section : Use one single outdoor unit and multiple outdoor units for M-NET remote control system. - Page 27 • Name, Symbol and the Maximum Remote controller Units for Connection Name Symbol Maximum units for connection Outdoor unit — One OC unit can be connected to 1-6(P36)/1-8(P48) IC units Indoor unit M-NET remote Maximum 2 RC for 1 indoor unit, Maximum 16 RC for 1 OC controller Permissible Lengths Prohibited items...

- Page 28 B. Example of a group operation system with 2 or more outdoor units and a M-NET remote controller. (Shielding wires and address settings are necessary.) (51) (01) (02) (05) (06) M1M2 S M1 M2 S M1 M2 S M1 M2 S M1 M2 S M1 M2 S (101)

- Page 29 • Name, Symbol, and the Maximum Units for Connection [ 500 meters [1640ft] (1.25mm • Longest length via outdoor units : L [AWG16]) [ 200 meters (1.25mm • Longest transmission cable length : L [AWG16]) [ 10 meters [33ft] (0.5 to 1.25mm •...

- Page 30 C. Example of a MA remote controller system (address setting is not necessary.) NOTE : In the case of same group operation, need to set the address that is only main indoor unit. Example of wiring control cables Wiring Method and Address Setting 1.

- Page 31 • Name, Symbol, and the Maximum Units for Connection Permissible Lengths Prohibited items The MA remote controller and the Longest transmission cable length [ 200m [656ft] M-NET remote controller cannot be used together with the indoor unit (1.25 mm [AWG16]) the of the same group.

- Page 32 D. Example of a group operation with 2 or more outdoor units and a MA remote controller. (Shielding wires and address settings are necessary.) (51) (01) (02) (05) (06) TB15 TB15 TB15 TB15 M1M2 S M1 M2 M1 M2 S M1 M2 S M1 M2 S M1 M2 S...

- Page 33 • Name, Symbol, and the Maximum Units for Connection Longest length via outdoor unit (M-NET cable): L and L 500 m [1640ft] (1.25 mm [AWG16] or more) Longest transmission cable length (M-NET cable): L and L and L and L and L 200 m [656ft] (1.25 mm...

-

Page 34: Troubleshooting

TROUBLESHOOTING 9-1. CHECK POINTS FOR TEST RUN 9-1-1. Procedures of test run (1) Before test run, make sure that following work is completed. • Installation related : Make sure that the panel of cassette type and electrical wiring are done. Otherwise electrical functions like auto vane will not operate normally. - Page 35 9-1-2. Special Function Operation and Settings (for M-NET Remote Controller) • It is necessary to perform “group settings” and “paired settings” at making group settings of different refrigerant systems (multiple outdoor unit). (A) Group settings: Enter the indoor unit controlled by the remote controller, check the content of entries, and clear entries, etc.

- Page 36 (2) Address check: Refer to section (1) regarding address entry. a) In making group settings: • Turn off the remote controller: Press the remote controller's ON/OFF button to stop operation (the indicator light will go off). • Locate the indoor unit address display mode: Press the FILTER and k buttons on the remote controller simultaneously and hold for 2 seconds.

-

Page 37: Countermeasures For Error During Test Run

9-1-3. Countermeasures for Error During Test Run • If a problems occurs during test run, a code number will appear in the temperature display area on the remote controller (or LED on the outdoor unit), and the air conditioning system will automatically cease operating. Determine the nature of the abnormality and apply corrective measures. - Page 38 Display Abnormal point and detecting method Check points Causes High discharging temperature Over-heated compressor operation Check intake super heat. 1102 Abnormal if discharge temperature thermistor caused by shortage of refrigerant Check leakage of refrigerant. (TH4) exceeds 125 [257°F] or 110 [230°F] Defective operation of stop valve Charge additional refrigerant.

- Page 39 Display Abnormal point and detecting method Check points Causes Gas leakage, Gas shortage Check the refrigerant amount. Refrigerant shortage 1501 When the conditions of below detecting When heating operation, refrigerant mode are satisfied during the shortage feeling operation (When Check the operation condition and compressor operation.

- Page 40 Display Abnormal point and detecting method Check points Causes 2502 Drain pump (DP) Malfunction of drain pump Check if drain-up machine works. (Drain Let drain sensor self-heated, and if Defective drain Check drain function. sensor temperature rises slightly, as suspensive Clogged drain pump model) Clogged drain pipe...

- Page 41 Display Abnormal point and detecting method Check points Causes Drain pump (DP) 2502 Check if drain-up machine works. Malfunction of drain pump Judge whether the sensor is in the water or (Float Check drain function. Defective drain in the air by turning the float switch switch Clogged drain pump ON/OFF.

- Page 42 Display Causes Abnormal point and detecting method Check points Overvoltage or voltage shortage Decrease of power supply voltage Check the facility of power supply. 4220 Disconnection of compressor wiring Correct the wiring (U·V·W phase) to Abnormal if any of followings are detected Defective 52C compressor.

- Page 43 Display Abnormal point and detecting method Check points Causes Stop valve of outdoor unit is closed. (2) Compressor overcurrent interruption Open stop valve. 4250 Decrease of power supply voltage Abnormal if overcurrent DC bus or Check facility of power supply. Looseness, disconnection or converse compressor is detected after compressor Correct the wiring (U·V·W phase) to...

- Page 44 Display Abnormal point and detecting method Check points Causes 5102 Liquid pipe temperature thermistor (TH22) When the thermistor detects short/open Connector (CN21 or CN44) contact Check whether the connector (CN21 during the operation, the operation stops failure or CN44) in the indoor controller and the operation changes to protect mode board is connected or not.

- Page 45 Display Abnormal point and detecting method Check points Causes 5103 Gas pipe temperature thermistor (TH23) When the thermistor detects short/open after 3minutes-continuous thermo ON Connector (CN29 or CN44) contact Check whether the connector (CN29 during cooling or dry operation, the failure or CN44) in the indoor controller board operation stops and the operation...

- Page 46 Display Abnormal point and detecting method Check points Causes 5106 Outdoor temperature thermistor (TH7) Connector (TH7) contact failure Check whether the connector (TH7) in the multi controller board is connected When controller detects short/open in or not. thermistor during the operation, the outdoor unit stops once and restarts operation in 3minutes.

- Page 47 Display Abnormal point and detecting method Check points Causes 5201 Pressure sensor (63HS) When detected pressure in high-pressure High-pressure sensor failure Check the high-pressure sensor. sensor is 1 MPa [145PSIG] or less during the operation, the compressor stops and restarts operation in 3 minutes. When the detected pressure is 1 MPa Internal pressure decrease by gas Check the internal pressure.

- Page 48 Display Abnormal point and detecting method Check points Causes 6603 Transmission bus busy error Over error by collision The transmission processor cannot be Check whether the transmission line of transmitted since a short cycle voltage the indoor unit, fresh master, lossnay Abnormality when the state, which cannot of the noise etc.

- Page 49 Display Abnormal point and detecting method Check points Causes No ACK (Acknowledgement) 6607 Factor that does not related to origin Turn off power supply of outdoor unit, indoor unit fresh master and lossnay Abnormality which controller of the Since the address switch was changed for 2 minutes or more at the same sending side detects when there is no with the current passed, the unit in the...

- Page 50 Display Abnormal point and detecting method Check points Causes When the cause of displayed address and When operating with multi refrigerant 6607 attribute is on the remote controller side system indoor units, the indoor units transmits the signal to the remote controller after the other refrigerant (The indoor unit detects when there is no system outdoor unit is turned off or...

- Page 51 Display Abnormal point and detecting method Check points Causes Transmission repeats the failure by the 6608 Check the transmission wave and No response noise etc. noise on the transmission line. Though there was a replay (ACK) of having received signal from the other side, it is the abnormality when the response command does not return.

- Page 52 Display Abnormal point and detecting method Check points Causes 7101 Capacity code error When the connected indoor unit models The indoor unit models is not possible Check the model code registration cannot be connected, <7101> is displayed. to connect. switch (indoor controller board SW2) in the connected indoor unit.

-

Page 53: Remote Controller Diagnosis

9-2. REMOTE CONTROLLER DIAGNOSIS · MA remote controller is equipped with the diagnosis function If the air conditioner cannot be operated from the remote controller, diagnose the remote controller as explained below. First, check that the power-on indicator is lit. If the correct voltage (DC12 V) is not supplied to the remote controller, the indicator will not light. - Page 54 9-3. REMOTE CONTROLLER TROUBLE CENTRALLY CONTROLLED 1Hr. ON OFF °C CLOCK CHECK FILTER CHECK MODE °C TEST RUN STAND BY ERROR CODE FUNCTION “ ” indicator: Appears when current is carried. NOT AVAILABLE DEFROST TEMP. ON/OFF FILTER CHECK TEST TIMER SET (M-NET Remote controller) (1) For M-NET remote controller systems Symptom or inspection code...

- Page 55 9-4. THE FOLLOWING SYMPTOM DO NOT REPRESENT TROUBLE (EMERGENCY) Symptom Display of remote controller CAUSE "Cooling (Heating)" blinks Even the cooling (heating) The indoor unit can not cool (heat) if other indoor units are heating operation selection button (cooling). is pressed, the indoor unit cannot be operated.

- Page 56 9-5. INTERNAL SWITCH FUNCTION TABLE PUMY-P48NHMU/NHMU /NHMU (-BS) PUMY-P36NHMU(-BS) Operation in Each Switch Setting Switch Step Function Remarks When to Set <Initial settings> SW U1 1s digit Before turning the power on SW U2 SWU2 SWU1 SWU2 SWU1 10ths digit (10ths digit) (1s digit) (10ths digit)

- Page 57 Operation in Each Switch Setting Switch Step Function Remarks When to Set — — — — <Initial settings> Switch of current limitation reading Before turning the Normal Enable in a different way power on. — — — — 2 3 4 5 6 7 8 Restriction of maximum Can be set when Enable...

- Page 58 9-6. OUTDOOR UNIT INPUT/OUTPUT CONNECTOR State (CN51) Lamp power supply Distant control board Procure locally Relay circuit External output adapter (PAC-SA88HA-E) Max. 10m[33ft] CN51 Outdoor unit control board : Error display lamp : Compressor operation lamp X, Y : Relay (Coil standard of 0.9W or less for DC 12V) X, Y : Relay (DC1mA) Auto change over (CN3N) Remote control panel...

- Page 59 9-7. HOW TO CHECK THE PARTS PUMY-P48NHMU PUMY-P48NHMU PUMY-P48NHMU PUMY-P48NHMU-BS PUMY-P48NHMU PUMY-P48NHMU PUMY-P36NHMU PUMY-P36NHMU-BS Parts name Check points Thermistor (TH3) Disconnect the connector then measure the resistance with a tester. <Outdoor pipe> (At the ambient temperature 10 ~30 F~86 ° °...

- Page 60 Check method of DC fan motor (fan motor / outdoor controller circuit board) Notes · High voltage is applied to the connecter (CNF1, 2) for the fan motor. Give attention to the service. · Do not pull out the connector (CNF1, 2) for the motor with the power supply on. board and fan motor.) (It causes trouble of the outdoor controller circuit Self check...

- Page 61 Check method of multi controller board Multi controller board check Fuse check Check the fuse on Multi controller board Yes (blow) Replace Multi board and fan motor. Did the fuse (F500) blow? *See DC fan check Yes (blow) Did the fuse (F1 and F2) blow? Check the SV1 and 21S4 and wiring.

-

Page 62: Circuit Diagram

Check method of power board Power board check *To check the voltage of the parts on this board with a tester is difficult due to its location. Test points are limited. Is the voltage of main incoming power *Check the breaker and power supply 208/230V AC ? *Check wiring Is the voltage of CNDC(PNK) on multi... - Page 63 Check method of noise fi lter circuit board Noise filter circuit board check * To check the voltage of the parts on this board with a tester is difficult due to its location. Test points are limited. Is the voltage of main incoming power *Check the breaker and power supply 208/230V±10% AC ? Is the voltage of CNAC (RED) on multi...

- Page 64 Check method of ACTM ACTM check * To check the voltage of the parts on this board with a tester is difficult due to its location. (Active Filter Module) Test points are limited. Is the voltage of main incoming power *Check the breaker and power supply 208/230V ±...

- Page 65 Check method of M-NET transmission power board M-NET transmission power board check * To check the voltage of the parts on this board with a tester is difficult due to its location. Test points are limited. Check the voltage between M1 and M2 on the transmission terminal block TB3 24-30V DC ? *Check breaker and incoming power supply...

- Page 66 9-8. HOW TO CHECK THE COMPONENTS <HIGH PRESSURE SENSOR> Vout (V) MULTI CONTROLLER BOARD 5V DC Vout MICRO COMPUTER 63HS : 5V (DC) : Output Vout (DC) PSIG PRESSURE <Thermistor feature chart> Low temperature thermistors • Thermistor <Outdoor pipe> (TH3) •...

- Page 67 9-9. TEST POINT DIAGRAM Outdoor multi controller board PUMY-P48NHMU PUMY-P48NHMU PUMY-P48NHMU PUMY-P48NHMU-BS PUMY-P48NHMU PUMY-P48NHMU PUMY-P36NHMU PUMY-P36NHMU-BS CN51 CN102 External signal Connect to the M-P.B pump down Test run Forced defrost Model select output (Transmission power board) CN40,CN41 Demand/ Silent selection Centralized control power supply/ For storing jumper connector selection...

- Page 68 Outdoor power circuit board Brief Check of POWER MODULE W Usually, they are in a state of being short-circuited if they are broken. PUMY-P48NHMU Measure the resistance in the following points (connectors, etc.). PUMY-P48NHMU If they are short-circuited, it means that they are broken. 1.

- Page 69 Outdoor noise filter circuit board PUMY-P48NHMU LO, NO PUMY-P48NHMU-BS Voltage of 208-230V AC is output TABS PUMY-P48NHMU (Connect to the outdoor power PUMY-P48NHMU circuit board) TABT CNAC2 208/230V AC (Connect to the outdoor control- ler circuit board (CNAC)) Primary current (Connect to the outdoor power CNAC1...

- Page 70 Outdoor noise filter circuit board PUMY-P36NHMU 52C Relay PUMY-P36NHMU-BS (Coil resistance 155" (typ)) PUMY-P48NHMU PUMY-P48NHMU 52C driving signal (Connect to the outdoor controller circuit board (CNLVB)) Rush current protect resistor 20" ± 5% / 10W LO, NO Voltage of 208/230V AC is out- CNAC2 put (Connect to the 208/230V AC...

- Page 71 Transmission power board PUMY-P48NHMU PUMY-P48NHMU PUMY-P48NHMU PUMY-P48NHMU-BS PUMY-P48NHMU PUMY-P48NHMU PUMY-P36NHMU PUMY-P36NHMU-BS Connect to the outdoor multi controller board 1-2: 24–30V DC 3-4: 24–30V DC Connect to the outdoor noise filter circuit board 1–3 : 208/230V AC...

- Page 72 Active filter module PUMY-P48NHMU PUMY-P48NHMU-BS PUMY-P48NHMU Connect to the out- Non-connect PUMY-P48NHMU door power circuit board(TABP2) L1, L2 Connect to the DCL(Reactor) – Connect to the out- door power circuit Connect to Connect to Not used board(CNAF) the outdoor Connect to the 52C the outdoor : GND power circuit...

- Page 73 Active filter module PUMY-P36NHMU PUMY-P36NHMU-BS Connect to the outdoor power circuit board (TABP2) PUMY-P48NHMU PUMY-P48NHMU L1, L2 Non-connect Connect to the DCL (Reactor) Lower Upper side side Non-connect Connect to the outdoor power circuit board (TABP1) Connect to the outdoor power –...

- Page 74 9-10. OUTDOOR UNIT FUNCTIONS SW:setting 0..OFF 1..ON...

-

Page 81: Electrical Wiring

ELECTRICAL WIRING This chapter provides an introduction to electrical wiring for the CITY MULTI-S series, together with notes concerning power wiring, wiring for control (transmission wires and remote controller wires), and the frequency converter. 10-1. OVERVIEW OF POWER WIRING Use a separate power supply for the outdoor unit and indoor unit. Bear in mind ambient conditions (ambient temperature, direct sunlight, rain water,etc.) when proceeding with the wiring and connections. - Page 82 10-3. DESIGN FOR CONTROL WIRING Please note that the types and numbers of control wires needed by the CITY MULTI-S series will depend on the remote controllers and whether they are linked with the system. 10-3-1. Selection number of control wires M-NET remote controller Remote controller used in system control operations.

- Page 83 10-6. METHOD FOR OBTAINING ELECTRICAL CHARACTERISTICS WHEN A CAPACITY AGREEMENT IS TO BE SIGNED WITH AN ELECTRIC POWER COMPANY The electrical characteristics of connected indoor unit system for air conditioning systems, including the MULTI-S series, will depend on the arrangement of the indoor and outdoor units. First read the data on the selected indoor and outdoor units and then use the following formulas to calculate the electrical characteristics before applying for a capacity agreement with the local electric power company.

-

Page 84: Refrigerant Piping Tasks

REFRIGERANT PIPING TASKS 11-1. REFRIGERANT PIPING SYSTEM Line-Branch Method Connection Examples (Connecting to 4 Indoor Units) Outdoor Unit First Branch Indoor unit Total Piping Length A+B+C+a+b+c+d 120m [394ft] Permissible Farthest Piping Length A+B+C+d 80m [262ft] Length Farthest Piping Length After First Branch B+C+d 30m [100ft] High/Low Difference in Indoor/Outdoor Section... - Page 85 Header-Branch Method Connection Examples (Connecting to 4 Indoor Units) Outdoor Unit First Branch Indoor unit Total Piping Length A+a+b+c+d 120m [394 ft] Permissible Farthest Piping Length 80m [262 ft] Length Farthest Piping Length After First Branch d is 30 meters[100 ft] or less High/Low Difference in Indoor/Outdoor Section 30 meters [100 ft] or less (If the outdoor unit is lower, 20 meters [70 ft] or less) Permissible High/...

- Page 86 Note: The total of downstream unit models in the table is the total of models as seen from point A in the figure above. Note: Pipe re-branching after the header branching is not possible. Method of Combined Branching of Lines and Headers Connection Examples (Connecting to 5 Indoor Units)

-

Page 87: Precautions Against Refrigerant Leakage

11-2. PRECAUTIONS AGAINST REFRIGERANT LEAKAGE The installer and system specialist shall secure safety against leakage according to local regulations or standards. The following standards may be applicable if local regulations are not available. 11-2-1. Introduction (2) Calculate room volumes (K[ft ]) and find the room with the smallest volume R410A refrigerant of this air conditioner is non-toxic and... -

Page 88: Disassembly Procedure

DISASSEMBLY PROCEDURE OUTDOOR UNIT : PUMY-P36NHMU(-BS) PUMY-P48NHMU(-BS) PUMY-P48NHMU (-BS) PUMY-P48NHMU (-BS) OPERATING PROCEDURE PHOTOS & ILLUSTRATION 1. Removing the service panel and top panel Top panel fixing screws Top panel Figure 1 (1) Remove 3 service panel fixing screws (5 × 10) and slide the hook on the right downward to remove the service Service panel panel. - Page 89 From the previous page. OPERATING PROCEDURE PHOTOS & ILLUSTRATION (6) Remove electrical parts box fixing screw (4 × 10) and Photo 4 Electrical parts box detach the electrical parts box by pulling it upward. The electrical parts box is fixed with 2 hooks on the left and 1 hook on the right.

- Page 90 PHOTOS OPERATING PROCEDURE Photo 7 6. Removing the thermistor <Outdoor pipe> (TH3) and thermistor <Discharge> (TH4) Thermistor <Outdoor pipe> (1) Remove the service panel. (See figure 1.) (TH3) (2) Disconnect the connectors, TH3 (white) and TH4 (white), on the Multi controller board in the electrical parts box. (3) Loosen the clamp for the lead wire in the rear of the electrical parts box.

- Page 91 OPERATING PROCEDURE PHOTOS Photo 9 9. Removing bypass valve coil(SV1) and bypass valve (1) Remove the service panel. (See figure 1.) (2) Remove the top panel. (See figure 1.) (3) Remove 3 right side panel fixing screws (5 × 10) in the rear of the unit and remove the right side panel.

- Page 92 OPERATING PROCEDURE PHOTOS Photo 11 12. Removing the compressor (MC) (1) Remove the service panel. (See figure 1.) (2) Remove the top panel. (See figure 1.) (3) Remove 2 front cover panel fixing screws (5 × 10) and remove the front cover panel. (See photo 3.) (4) Remove 2 back cover panel fixing screws (5 ×...

-

Page 93: Parts List

PARTS LIST 13-1. STRUCTURAL PARTS PUMY-P48NHMU PUMY-P48NHMU-BS PUMY-P48NHMU PUMY-P48NHMU w Parts of PUMY-P48NHMU are set as the same service parts as PUMY-P48NHMU-BS. ty/set Wiring Recom- Remarks Specification PUMY-P48 PUMY-P48 Diagram mended Part Name Part No. (Drawing No.) Symbol NHMU(-BS) NHMU (-BS) SIDE PANEL (L) FAN GRILLE... - Page 94 13-2. FUNCTIONAL PARTS PUMY-P48NHMU PUMY-P48NHMU PUMY-P48NHMU-BS PUMY-P48NHMU...

- Page 95 Part numbers that are circled are not shown in the figure. ty/set Wining Recom- Remarks Part No. Part Name Specification Diagram PUMY-P48NHMU mended (Drawing No.) Symbol PUMY-P48NHMU MF1,2 FAN MOTOR PROPELLER FAN CHARGE PLUG ANB33FDCMT COMPRESSOR Including RUBBER MOUNT STOP VALVE BALL VALVE STRAINER ACCUMULATOR...

-

Page 96: Rohs Parts List

RoHS PARTS LIST 14-1. FUNCTIONAL PARTS PUMY-P36NHMU PUMY-P48NHMU PUMY-P36NHMU-BS PUMY-P48NHMU... - Page 97 Part numbers that are circled are not shown in the figure. Q'ty/set Wining Recom- Remarks Diagram Part No. Part Name Specification PUMY-P36NHMU(-BS) mended (Drawing No.) Symbol Q'ty PUMY-P48NHMU (-BS) T7W E27 763 FAN MOTOR MF1,2 PROPELLER FAN T7W E07 413 CHARGE PLUG ANB33FDHMT Including...

- Page 98 14-2. STRUCTURAL PARTS PUMY-P36NHMU PUMY-P36NHMU-BS PUMY-P48NHMU PUMY-P48NHMU w Parts of PUMY-P36/48NHMU are set as the same service parts as PUMY-P36/48NHMU-BS. ty/set Wiring Recom- Remarks Specification PUMY-P36 PUMY-P48 Diagram mended Part Name Part No. (Drawing No.) Symbol Q,ty NHMU(-BS) NHMU (-BS) T7W E03 662 SIDE PANEL (L) T7W E03 691...

-

Page 99: Optional Parts

OPTIONAL PARTS DRAIN SOCKET Part No. PAC-SG61DS-E AIR OUTLET GUIDE Part No. PAC-SG59SG-E w Need 2 pieces. AIR GUIDE Part No. PAC-SH63AG-E w Need 2 pieces. DRAIN PAN Part No. PAC-SG64DP-E BRANCH PIPE (Joint) Part No. NUMBER OF BRANCHING POINTS CMY-Y62-G-E CMY-Y64-G-E CMY-Y68-G-E... - Page 100 HEAD OFFICE : TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO100-8310, JAPAN cCopyright 2008 MITSUBISHI ELECTRIC ENGINEERING CO., LTD. Distributed in Jul. 2008 No. OC366 REVISED EDITION-C PDF 7 Distributed in Dec. 2007 No. OC366 REVISED EDITION-B PDF 9 New publication, effective Jul. 2008 Distributed in Apr.

Need help?

Do you have a question about the City Multi PUMY-P36NHMU and is the answer not in the manual?

Questions and answers