EarthQuake 3365B Operator's Manual

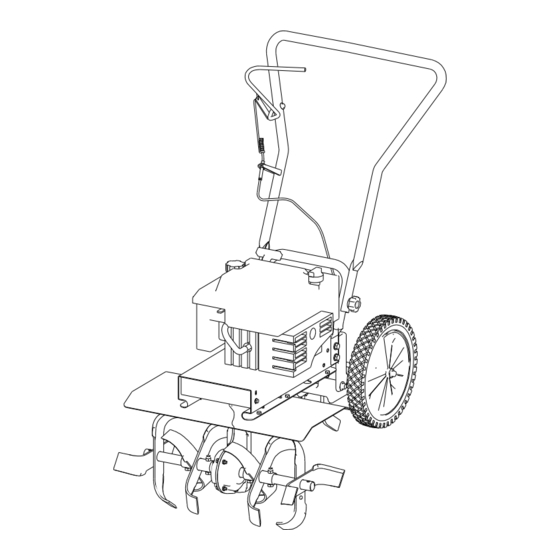

Front-tine tiller

Hide thumbs

Also See for 3365B:

- Operating and parts manual (28 pages) ,

- Operator's manual (24 pages) ,

- Operator's manual original operating instructions (24 pages)

Table of Contents

Advertisement

Model 3365B

Briggs & Stratton

6.75 ft-lbs Gross Torque

Model 3365CE

Briggs & Stratton

6.75 ft-lbs Gross Torque

Get parts online at

www.getearthquake.com

Model 3365PS

Briggs & Stratton

6.75 ft-lbs Gross Torque

Operator's Manual

Original Operating Instructions

3365 Series

Front-Tine Tiller

3365PSCE

Briggs & Stratton

8.5 ft-lbs Gross Torque

GAS/OIL

RATIO

50:1

Rev. 06/12/12

© 2012 Ardisam, Inc.

All Rights Reserved.

OMFT

Advertisement

Table of Contents

Summary of Contents for EarthQuake 3365B

- Page 1 Operator's Manual Original Operating Instructions 3365 Series Front-Tine Tiller Model 3365B 3365PSCE Briggs & Stratton 6.75 ft-lbs Gross Torque Briggs & Stratton Model 3365CE 8.5 ft-lbs Gross Torque Briggs & Stratton Model 3365PS 6.75 ft-lbs Gross Torque Briggs & Stratton 6.75 ft-lbs Gross Torque...

-

Page 3: Table Of Contents

Front Tine Models 3365 Series INTROdUCTION Congratulations on your investment in quality. Thank you for purchasing an Earthquake® Front Tine Tiller. We have worked to ensure that your tiller meets the highest standards for usability and durability. With proper care, your powerhead will provide many years of service. -

Page 4: Warnings And Safety Precautions

• Read and follow all safety instructions. • Carefully follow all assembly instructions. WARNING • Maintain the tiller according to directions and schedule WARNING INdICATES A SERIOUS INjURY OR FATAlITY included in this Earthquake operator’s manual. COUld RESUlT IF THE SAFETY INSTRUCTIONS THAT FOl- • Ensure that anyone who uses the tiller is familiar with all lOW THIS SIGNAl WORd ARE NOT OBEYEd. controls and safety precautions. - Page 5 OPERATOR INSTRUCTIONS ANd PARTS Front Tine Models 3365 Series c. Fill fuel tank outdoors with extreme care. Never fill fuel ImPORTANT tank indoors. THE RIGHT ANd lEFT SIdES OF YOUR RO- d. Replace gasoline cap securely and clean up spilled fuel TOTIllER ARE dETERmINEd FROm THE before restarting.

-

Page 6: Safety Decals

ARDISAM, INC. 1160 8th Avenue | Cumberland, WI 54829 | USA Serial No. LBLINFO3365PSCE Earthquake 3365PSCE Front Tine Tiller Year: 2010 Mass: 48 kg Max. Eng. Operating Speed: 3600 rpm Nominal Power Rating: 3.36 kW Part No. lBlINFO3365PSCE... -

Page 7: Unpacking And Assembly

TOTIllER ARE dETERmINEd FROm THE 1. Open top of carton and remove handlebar assembly. OPERATING POSITION AS YOU FACE THE 2. Find parts packet. Parts packet for 3365B/3365CE contains: dIRECTION OF FORWARd TRAVEl. ENGINE IS SHIPPEd FROm FACTORY WITH- 6- 5/16-18 x 1-3/4” bolts OUT OIl. -

Page 8: Features

Front Tine Models 3365 Series FEATURES (3365B/3365CE) The advantage of the EARTHQUAkE® gear drive front tine rototiller over other front tine tillers is the exclusive unfolding and flexible drag bar. This gives the tiller its stability and versatility. For easy transport, fold the wheels under the engine. Dur- ing operation, the wheels unfold back and the drag bar folds down. The long length between the tines and the drag bar make this the most comfortable front tine tiller on the market. -

Page 9: Belt Tension Adjustment

1/4” stretch upper jam nut upper jam nut lower jam nut lower jam nut forward cable forward cable models 3365PS and 3365PSCE handlebar models 3365B and 3365CE handlebar Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 CST... -

Page 10: Operation

START-UP THE TANk. TEmPERATURE OF mUFFlER ANd NEARBY AREAS mAY For models 3365B, 3365CE, and 3365PS only. ExCEEd 150° F. AVOId THESE AREAS. The controls required to start and run the rototiller are located on the dO NOT mOVE CHOkE CONTROl TO CHOkE TO STOP engine and are marked CHoKE and THRoTTlE. - Page 11 SHUTTING dOWN 1. Adjust the depth regulator lever to desired tilling depth. For models 3365B, 3365CE and 3365PS only. NOTE: Raise depth regulator lever up one hole at a time, testing To stop the engine at any time, move the throttle control to the OFF tiller operation after each raise.

-

Page 12: Maintenance And Storage

OPERATOR INSTRUCTIONS ANd PARTS Front Tine Models 3365 Series mAINTENANCE ANd STORAGE mAINTENANCE SCHEdUlE Your rototiller has been designed and produced by the industry’s leading manufacturer of outdoor power equipment to provide you with years of reliable operation. Keeping your tiller in top running condition will prolong its life, and help you obtain optimum performance. Please read this normal care schedule, and note the recommended care operating intervals to extend the life of your unit. Before 50 hours or maintenance Operation... - Page 13 OPERATOR INSTRUCTIONS ANd PARTS Front Tine Models 3365 Series CHECk BElT TENSION WARNING Belt tension may decrease over time. It must be adjusted within the CHECk FORWARd BElT TENSION REGUlARlY. TOO mUCH first half hour of operation and checked after every two hours of OR TOO lITTlE TENSION WIll CAUSE PREmATURE BElT operation.

- Page 14 OPERATOR INSTRUCTIONS ANd PARTS Front Tine Models 3365 Series ENGINE mAINTENANCE ImPORTANT Refer to the engine manual included in your parts packet for information on engine maintenance. Your engine manual provides ENGINE IS SHIPPEd FROm FACTORY WITHOUT OIl. YOU detailed information and a maintenance schedule for performing mUST Add ENGINE OIl BEFORE STARTING ENGINE.

- Page 15 OPERATOR INSTRUCTIONS ANd PARTS Front Tine Models 3365 Series STORAGE WARNING PREPARE FOR STORAGE dO NOT STORE TIllER IN AN UNVENTIlATEd AREA Follow the steps below to prepare your tiller for storage. Read your WHERE FUEl FUmES mAY REACH FlAmE, SPARkS, PIlOT lIGHTS OR AN IGNITEd OBjECT.

-

Page 16: Troubleshooting And Repair

OPERATOR INSTRUCTIONS ANd PARTS Front Tine Models 3365 Series TROUBlESHOOTING ANd REPAIR WARNING TROUBlESHOOTING GUIdE PRACTICE SAFETY AT All TImES. ENGINE mUST BE TURNEd OFF ANd AllOWEd TO COOl, ANd SPARk PlUG While normal care and routine maintenance will extend the WIRE mUST BE dISCONNECTEd ANd SECUREd BEFORE life of your rototiller, prolonged or constant use may eventu- ATTEmPTING ANY mAINTENANCE OR REPAIR. -

Page 17: Parts Breakdown

OPERATOR INSTRUCTIONS ANd PARTS Front Tine Models 3365 Series PARTS BREAkdOWN 3365B/3365CE HANdlEBAR PARTS REF. NO. PART # dESCRIPTION QTY. REF. NO. PART # dESCRIPTION QTY. 3108A CABLE ASSEMBLY W/FERREL loCKWASHER, SPRINg 5/16” 53606 NUT, HEX NYloC 10-24 3170 NUT, PUSH 3/8” DIA. 53607 NUT, HEX JAM 5/16-24 32621 DRIVE SAFETY CONTROL... - Page 18 OPERATOR INSTRUCTIONS ANd PARTS Front Tine Models 3365 Series 3365PS HANdlEBAR PARTS REF. PART # dESCRIPTION QTY. REF. PART # dESCRIPTION QTY. 1501 BolT, SoC Flg HEX HD 5/16-18 X 3/4” 53612 lINK 11-5/8” loNg 53614 PIN, CLEVIS 1/4 X 1-1/2” 2104 NUT, BI-WAY HEX loCK 3/8-16 53620 SPRING, COMPRESSION 3108A CABLE ASSEMBLY W/FERREL 53629 BRACKET, CABlE MoUNT 3358...

- Page 19 OPERATOR INSTRUCTIONS ANd PARTS Front Tine Models 3365 Series 3365PSCE HANdlEBAR PARTS REF. PART # dESCRIPTION QTY. REF. PART # dESCRIPTION QTY. 331059 BolT, HEX 53607 NUT, HEX JAM 5/16-24 W1265V0913 NUT, HEX 53612 lINK 11-5/8” loNg 3310118 KIT, THRoTTlE CoNTRol W/HARD- 53614 PIN, CLEVIS 1/4 X 1-1/2” WARE 53620 SPRING, COMPRESSION 1501 BolT, SoC Flg HEX HD 5/16-18 X...

- Page 20 OPERATOR INSTRUCTIONS ANd PARTS Front Tine Models 3365 Series 3365B/3365CE/3365PS/3365PSCE mOTOR mOUNT ANd HOOd PARTS model 3365PS, 3365B, 3365CE drive Pulley mOdEl 3365PS, 3365PSCE BUmPER Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 CST...

- Page 21 OPERATOR INSTRUCTIONS ANd PARTS Front Tine Models 3365 Series 3365B/3365CE/3365PS/3365PSCE mOTOR mOUNT ANd HOOd PARTS REF. PART # dESCRIPTION QTY. REF. PART # dESCRIPTION QTY. 1401 BolT, HHCS 5/16-18 X 1-1/4” gR5 3370 BELT, FORWARD 1407 SPRING, FORWARD ARM 48300 BolT, HHCS 5/16-18 X 2-1/4” gR5 1413 PULLEY, FORWARD IDLER...

- Page 22 OPERATOR INSTRUCTIONS ANd PARTS Front Tine Models 3365 Series TINES & TRANSmISSION PARTS REF. PART # dESCRIPTION QTY. REF. PART # dESCRIPTION QTY. 1511 BolT, SFHH 1/4-20 X 7/8” 3364 KEY 3/16 X 1/2” 1601 BEARING, TAPERED loCKWASHER, SPRINg 5/16” (includes cone & race) 56100B CASTINg, RIgHT SIDE 1701 KEY, HAlF MooN 1/4 X 1” 56101B CASTING, LEFT SIDE 1810 SNAP RING, EXTERNAL 60G56...

-

Page 23: Warranty

Terms and Conditions Ardisam, Inc., a manufacturing company, warrants this EARTHQUAkE® FRONT TINE ROTOTIllER to be free from defects in the material or workmanship for a period of one year from the date of purchase. During the one-year warranty of this product, Ardisam will, at their discretion, furnish parts and labor to correct any defect caused by faulty material or workmanship. - Page 24 WINCANTON BUSINESS PARk , WINCANTON SOmERSET, ENGlANd, BA9, 9RS Earthquake®, Division of Ardisam, Inc. 1160 8th Avenue, PO Box 666 Cumberland, WI 54829 800-345-6007 | Fax 715-822-2223 Email: info@ardisam.com Check for parts online at www.earthquake.com or call 800-345-6007 M-F 8-5...

Need help?

Do you have a question about the 3365B and is the answer not in the manual?

Questions and answers