Harman PB 105 Installation & Operating Manual

Pellet boiler

Hide thumbs

Also See for PB 105:

- Installation and operating manual (49 pages) ,

- Installation & operating manual (48 pages) ,

- Owner's manual (52 pages)

Table of Contents

Advertisement

Quick Links

Installation & Operating manual

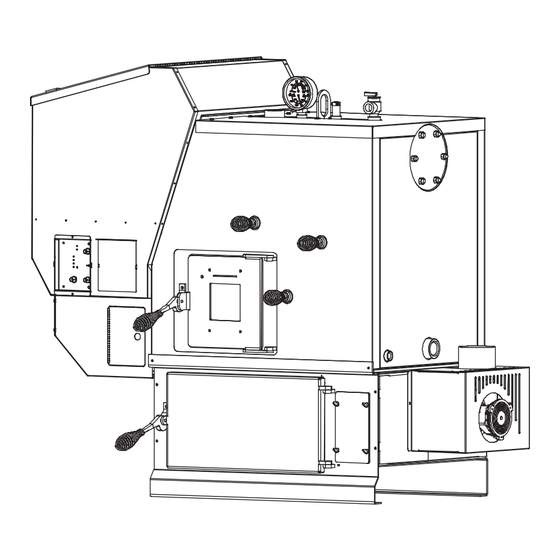

The harman Pb 105 Pellet boiler

Portland

"Ce manuel est disponible en Français sur demande"

R3

SAFETY NOTICE

PlEASE rEAd ThIS ENTIrE mANuAl bEFOrE YOu INSTAll ANd uSE YOur NEw bOIlEr. FAIlurE TO

FOllOw INSTruCTIONS mAY rESulT IN PrOPErTY dAmAgE, bOdIlY INjurY, Or EvEN dEATh.

FOr uSE IN ThE u.S. ANd CANAdA. SuITAblE FOr INSTAllATION IN mObIlE hOmES

IF ThIS hArmAN PEllET bOIlEr IS NOT PrOPErlY INSTAllEd, A hOuSE FIrE mAY rESulT. FOr YOur

SAFETY, FOllOw INSTAllATION dIrECTIONS.

CONTACT lOCAl buIldINg Or FIrE OFFICIAlS AbOuT rESTrICTIONS ANd INSTAllATION INSPECTION

rEQuIrEmENTS IN YOur ArEA.

CONTACT YOur lOCAl AuThOrITY (SuCh AS muNICIPAl buIldINg dEPArTmENT, FIrE dEPArTmENT, FIrE

PrEvENTION burEAu, ETC.) TO dETErmINE ThE NEEd FOr A PErmIT.

CETTE guIdE d'uTIlISATION EST dISPONIblE EN FrANCAIS. ChEz vOTrE CONCESSIONNAIrE dE hAr-

mAN STOvE COmPANY.

SAvE ThESE INSTruCTIONS

manual #3-90-07205

Advertisement

Table of Contents

Summary of Contents for Harman PB 105

- Page 1 FOllOw INSTruCTIONS mAY rESulT IN PrOPErTY dAmAgE, bOdIlY INjurY, Or EvEN dEATh. FOr uSE IN ThE u.S. ANd CANAdA. SuITAblE FOr INSTAllATION IN mObIlE hOmES IF ThIS hArmAN PEllET bOIlEr IS NOT PrOPErlY INSTAllEd, A hOuSE FIrE mAY rESulT. FOr YOur SAFETY, FOllOw INSTAllATION dIrECTIONS.

- Page 3 Pb105 Parts...

-

Page 4: Table Of Contents

Quick Reference Start-Up Back Cover Please read this entire manual before you install and use your new boiler. Failure to follow instructions may result in property damage, bodily injury, or even death. SAVE THESE INSTRUCTIONS Harman Home Heating 352 Mountain House Road Halifax, PA 17032... -

Page 5: Assembly

Assembly... - Page 6 Assembly Installation of the Flue Tunnel Weldment, Boiler Kit Materials: (Refer to pages 4 & 5) Combustion Blower and Wiring, ESP and Heat List of items contained within the boiler kit shipped with Shield: the unit. Step 1: First install the flue tunnel weldment by 1 - Control board cover aligning the (4) studs up with the (4) holes in the ash 1 - Access cover (Hopper Swing Plate Knob)

- Page 7 Assembly MINIMUM NON-COMBUSTIBLE FLOOR PROTECTION After assembly of the flue tunnel weldment, combustion AREA blower assembly with wiring and heat shield, the boiler can now be installed. 1. Install the control board cover as well as the access cover located on the feeder cover. 2.

- Page 8 Assembly When installing the PB105 in a mobile home several INSTALLATION IS TO BE PERFORMED BY A requirements must be followed: QUALIFIED INSTALLER. 1. The unit must be bolted to the floor. 2. The unit must be connected to outside air. NOTE: All installation clearances and restrictions 3.

-

Page 9: Venting

venting Requirements for Terminating the Venting H. A vent must not be installed within 3 feet (90 WARNING: Venting terminals must not be re- cm) above a gas meter/regulator assembly when mea- cessed into a wall or siding. sured from the horizontal center-line of the regulator. I. - Page 10 venting...

- Page 11 Venting venting Venting Use 4” pellet vent pipe to vent your PB105. A combustion blower is used to extract the combustion gases from the firebox. This creates a negative pressure in the firebox and a positive pressure in the venting system as shown in Fig.

-

Page 12: Installation

venting Installation NOTE: Use only 4” diameter type “L” or “PL” venting system. Be sure to inspect and clean exhaust venting system frequently. INSTALLATION IS TO BE PERFORMED BY A QUALIFIED INSTALLER. DO NOT INSTALL A FLUE DAMPER IN THE EXHAUST VENTING SYSTEM OF THIS UNIT. - Page 13 Installation Outside Air Outside air is optional, although it may be required by some building codes. The benefit of outside air is higher efficiency and reduced venting restrictions. To install outside air, use 2 3/4” I.D.galvanized steel flex pipe, part # 2-00-08544 ( 12’ 6” length) or part # 2-00-08545 ( 25’...

- Page 14 main wiring Installation...

- Page 15 Installing Duct Installation...

- Page 16 Installing Duct/Air Conditioning Installation Boilers intended to be connected to an existing boiler or boiler system shall: 1. Be capable of being installed without interfering with the normal delivery of heated water from the original boiler to the radiation system. 2.

- Page 17 Installation...

- Page 18 Installation...

- Page 19 Installation...

- Page 20 Installation Draft Test Procedure After the venting is completed, the firebox low draft will need to be checked and possibly adjusted. Firebox Door After removing the 3/8” bolt from the draft hole shown in Fig. 9, insert the draft meter tube. The hopper lid must Draft Bolt Location be latched during this test.

-

Page 21: Operation

Dealer Diagnostic Port For dealer maintenance only. Igniter Light Requires special DDM monitor Indicates power to the igniter supplied to Harman Dealers exclusively. Max Temp dial The “Max Temp Dial” is used to set the desired maximum operating temperature of the boiler. -

Page 22: Water Temperature

Operation Setting The Boiler Temperature Without the Outdoor Air Temperature Sensor Installed To set the maximum boiler water temperature, sim- ply turn the Max. Temp. water temperature dial to the desired setting. The control and the boiler will then perform to achieve and maintain the set temperature. The Min. - Page 23 Operation...

- Page 24 Operation Starting A Fire Automatically 1. Turn Mode Selector to “OFF”. This resets the control in addition to turning it off. 2. Clean Burnpot with scraper, if necessary. This is usually a weekly maintenance proce- dure. Cleaning the burn pot with the scraper with a small amount of new fuel in the bottom is not a problem.

- Page 25 Operation 4. If Starting After an Empty Hopper, Turn Feed Adjuster to “TEST” (for one 60 second cycle). This will purge pellets into the auger tube and also allow you to check the motors for operation. NOTE: The auger motor will not operate with any of the doors open.

- Page 26 Operation Fig. 12 7. Open hopper swing plate as shown in Fig. 13 (See “NOTE” on page 24.) 8. Turn the MIN. TEMP. Dial on the control board to the desired Minimum temperature. This will start the lighting process if the temperature at the aquastat sensor is approximately 5°...

- Page 27 Operation 11. Apply starting gel as shown in Fig.15 12. Light The Starting Gel With A Match. Fig. 15 NOTE: Stirring the starting gel into the pellets usu- 13. Close The Doors ally allows the fire to become established quicker. The fire will light and the PB105 will adjust the fire to proper level according to the MAX TEMP dial CAUTION: A vapor flash could occur if too much...

-

Page 28: Maintenance

maintenance Burnpot Cleaning: The burnpot should be cleaned no less than once a week. For best operation the burnpot should be cleaned every time the hopper is filled with pellets. The fire does not have to be out to scrape the burnpot although it is recomended the boiler be on minimum burn at the time of cleaning. - Page 29 maintenance Ash Pan Handle Ash Door Ash Pan Ash Door Handle Fig. 21 Ash Removal Disposal of Ashes It is recommended to remove the ashes when the Ashes should be placed in a metal container with boiler is not in operation. This lessens the chances a tight fitting lid.

- Page 30 maintenance Heat Exchanger Cleanout Rod Handles Firebox Door Heat Exchanger Tube Secondary Ash Chamber Access Plate Fines Cleanout Cover Firebox Wall Ash Door Cleaning -Open ash door and remove the ash pan. Dispose This cleaning should be done after each ton of of any ash that has accumilated in the ash pan as well pellets used.

- Page 31 maintenance The furnace MUST be OFF and COOL before you should attempt to clean the combustion blower. The wire to the combustion blower doesn’t need to be disconnected during the cleaning process. Loosen the three (3) thumb screws about 4 turns each. See Fig.

-

Page 32: Troubleshooting

Troubleshooting FEEdEr dOES NOT FEEd SmOKE IS vISIblE COmINg OuT OF vENT 1. No pellets in hopper. 1. Air-fuel ratio is too rich. 2. Firebox draft may be too low for low draft pres- A. Feed rate too high. sure switch in feeder circuit to operate. Check B. -

Page 33: Feeder Parts

Feeder Parts ITEM Part No. Part Name 1-10-06810 PELLET AIR INTAKE ASSY 1-10-677139 HIGH BTU SLIDE PLATE ASSY 1-10-677154 ULFEEDER CAM BLOCK LONG ASSY 1-10-677130 PB-105/PF100 ULFEEDER PUSHER ARM WELDMENT 105X6 1-10-72222 PB105-P38-43-PC45/61/68/PF100/HF60 UL FEEDR AIR INT WELD 1-10-724132 ULTRALIGHT FEEDER WELDMENT 2-00-04035 PELLET FEEDER BEARING RETAINER 2-00-247406... -

Page 34: Specifications

Specifications... -

Page 35: Wiring Diagram

Wiring Diagram wiring diagram... -

Page 36: Parts List & Options

Parts List ITEM NUMBER DESCRIPTION 0-88-00248 RUBBER GROMMET (Hopper Lid - 7’ Needed) 0-88-88100 1” WHITE GASKET W/PSA SINGLE PLY (FDR Swing Plate - 5’ Needed) 0-88-88250 1” WHITE GASKET W/PSA DOUBLE PLY (Firebox Door - 3.5’ Needed) 1” WHITE GASKET W/PSA DOUBLE PLY (Flue - 1.5’ Needed) 3-20-06783 IGNITER ELEMENT 1-10-73403... -

Page 37: Warranty

MERCHANTABILITY, OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE. No employee, agent, dealer, or other person is authorized to give any warranty on behalf of Harman Home Heating. This warranty does not apply if the product has been altered in any way after leaving the factory. Harman Home Heating and its agents assume no liability for “resultant damages of any kind”... -

Page 38: Testing Label

Testing label... - Page 39 NOTES...

Need help?

Do you have a question about the PB 105 and is the answer not in the manual?

Questions and answers