Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for MK Diamond Products MK-20 SERIES

-

Page 1: Operating Instructions

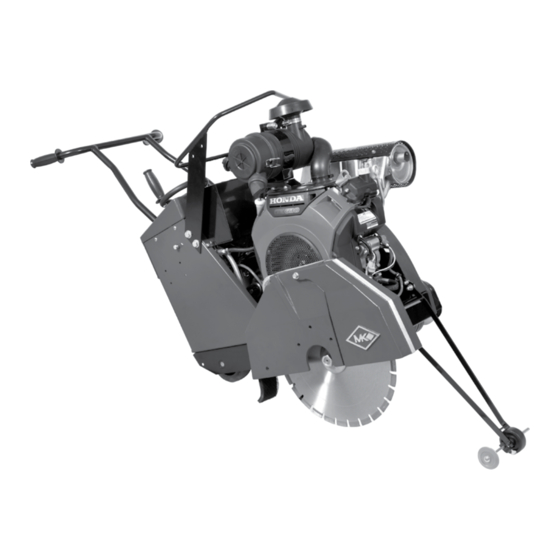

MK-20 SERIES OWNER’S MANUAL, OPERATING INSTRUCTIONS & PARTS LIST Gas Powered Concrete Saw 05.2013 Revision 304 Manual Part# 156777 Caution: Read all safety and operating instructions before using this equipment. This owner’s manual MUST accompany the equipment at all times. - Page 2 INTRODUCTION Congratulations on your purchase of a MK-20 Series. We are certain that you will be pleased with your purchase. MK Diamond takes pride in producing the finest construction power tools and diamond blades in the industry. Operated correctly, your MK-20 Series should provide you with years of service. In order to help you, we have included this manual.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SAFETY Safety Messages Damage Prevention Message General Safety Precautions and Hazard Symbols California Proposition 65 Message Prestart Safety Safety Label Locations Product Specifications UNPACKING, TRANSPORT and ASSEMBLY Unpacking Contents Transport Assembly 14-15 SET-UP, OPERATION and SHUTDOWN Set-Up 16-18 Operation 19-22... -

Page 4: Safety Messages

This Operation Manual has been developed to provide complete instructions for the safe and efficient operation of the MK-20 Series. For additional instruction concerning engine operations and care refer to the engine manufacturers instructions. Before using this saw, ensure that the person operating the equipment has read and understands all instructions in this manual. -

Page 5: General Safety Precautions And Hazard Symbols

MK-20 SERIES SAFETY GENERAL SAFETY PRECAUTIONS AND HAZARD SYMBOLS SAFETY PRECAUTIONS In order to prevent injury, the following safety precautions and symbols should be followed at all times! GENERAL SAFETY DO NOT operate or service this equipment before reading this entire manual. - Page 6 MK-20 SERIES SAFETY ACCIDENTAL STARTS Before starting the engine, be sure the ON/OFF switch is in the “OFF” position to prevent accidental starting. Place the ON/OFF switch in the OFF position before performing any service operation. ROTATING OR MOVING PARTS Keep hands, feet, hair, and clothing away from all moving parts to prevent injury.

- Page 7 MK-20 SERIES SAFETY DO NOT FORCE THE TOOL A power tool will do a job better and safer operating at the rate for which it was designed. USE THE RIGHT TOOL Do not force a tool or an attachment, to do a job that it was not designed to do.

-

Page 8: California Proposition 65 Message

MK-20 SERIES SAFETY SILICA DUST WARNING Grinding/cutting/drilling of masonry, concrete, metal and other materials with silica in their composition may give off dust or mists containing crystalline silica. Silica is a basic component of sand, quartz, brick clay, granite and numerous other minerals and rocks. Repeated and/or substantial inhalation of airborne crystalline silica can cause serious or fatal respiratory diseases, including silicosis. - Page 9 SAFETY OPERATION & SAFETY DECALS The MK-20 Series Concrete Saw is equipped with a number of safety decals. These decals are pro- vided for operator safety and maintenance information. Should any of these operation or safety de- cals become unreadable, replacements can be obtained by calling (800) 262-1575.

-

Page 10: Product Specifications

MK-20 Series will provide years of dependable service. General Description The MK-20 Series is engineered as a portable concrete saw powered by a Honda, Kohler, Subaru or Vanguard gas engine. The saw is capable of 6-5/8” depth of cut with an 18” blade and 7-5/8” depth of cut with a 20”... -

Page 11: Unpacking

Remove the saw from the pallet and place it on a flat surface. Two people are required to lift saw. CONTENTS In the containers, you will find one (1) MK-20 Series Saw, one (1) Blade Nut Wrench, one (1) Handle- bar, two (2) Handlebar Bolts and Washers, one (1) Pointer, one (1) MK-20 Series Owner’s Manual, one (1) Engine Owners Manual, one (1) Warranty Card. -

Page 12: Transport

MK-20 SERIES TRANSPORT TRANSPORT CAUTION 1. The MK-20 Series weighs approximately two hundred and thirty-five (235 pounds), use care when transporting. 2. Two people are required to lift and transport the MK-20 Series. DESCRIPTION OF CONTROLS The Depth Control Wheel raises the blade when rotated clockwise, and lowers the blade when rotated counterclockwise. -

Page 13: Assembly

MK-20 SERIES ASSEMBLY Follow the assembly instructions to prepare your saw for operation. HANDLEBAR ASSEMBLY Locate the threaded holes on Align the handlebar with the Install one Washer onto each bolt. both sides of the handlebar. holes on both sides of the frame at Install bolt through the Handlebar the desired height. - Page 14 MK-20 SERIES ASSEMBLY HYDRO-STATIC TRANSMISSION The Hydro-Static Transmission is factory filled with fluid having a viscosity equivalent to SAE 20 W Do not overfill the expansion tank. Notice that the full level line is near the NOTICE bottom of the expansion tank. Over filling will result in rupturing the seals on the hydromatic transmission and subsequent mechanical damage.

- Page 15 MK-20 SERIES ASSEMBLY DIAMOND BLADE INSTALLATION NOTE: 1. When installing the blade retaining-bolt, ensure the threads of the bolt are aligned with the threads of the drive shaft so as not to “cross-thread” the bolt. 2. When installing the blade ensure that the blade shaft and flanges are free from dirt and all foreign material before mounting blade on the blade shaft.

-

Page 16: Set-Up

MK-20 SERIES SET-UP FILLING FUEL TANK WARNING 1. Gasoline is highly flammable and explosive. You can be burned or seriously injured when handling fuel. 2. To fuel, stop engine if running, and allow it to cool. 3. Fuel in a well-ventilated area. - Page 17 • Unauthorized equipment modifications will void all warranties. Manufacturer does not assume responsibility for any accident due to equipment modifications. • NEVER use accessories or attachments, which are not recommended by MK Diamond for this equipment. Damage to the equipment and/or injury to user may result.

- Page 18 Never exceed 3600 rpm blade shaft speed. * The MK-20 Series, it is possible to cause overspeeding of the blade at throttle settings above those stipulated on the above chart; DO NOT EXCEED THESE ENGINE RPM SETTINGS!

- Page 19 OPERATION STANDARD OPERATION The MK-20 Series is intended for industrial applications and operated by experienced professionals. The operator must be aware of the machine’s capabilities and limitations. It is the operators respon- sibility to use this machine under safe working conditions and conform with federal, state and local codes or regulations pertaining to safety, air, pollution, noise etc...

-

Page 20: Operation

MK-20 SERIES OPERATION Push Engine Throttle Handle up Place Transmission Speed Verify Neutral Engagement Handle half-way. Lever in Neutral. is down, in Neutral. Choke engine as required for cold starting. Start engine by rotating Ignition For Wet Cutting, open Cooling Move the throttle all the way for- Switch to the right. - Page 21 MK-20 SERIES OPERATION NOTE: Do not turn off engine while at full throttle. NOTICE If the engine has been running hard and is hot do not shut en- gine off abruptly. Cool engine by removing load and allowing en- Turn off engine by rotating Move the Throttle Lever to lower gine to run idle for 3 to 5 minutes.

- Page 22 MK-20 SERIES OPERATION BLADE GUARD REPOSITIONING WARNING Do not operate saw with any guards removed. Turn master engine switch to off position to avoid accidental starts when removing guards. Remove Diamond Blade. Remove the Cooling Transfer Locate the four Blade Guard Re- Hose from the Blade Guard by taining Bolts.

-

Page 23: Shutdown

MK-20 SERIES CLEANUP Install the Blade Shaft Cover. Remove the Pointer. Install the Pointer on the opposite side, next to Blade Guard. (See Front Pointer alignment Page EMERGENCY ENGINE SHUTDOWN Place Engine Master Switch in the Move the Throttle Lever to lower OFF position. -

Page 24: Maintenance Maintenance

MK-20 SERIES MAINTENANCE Clean the remainder of the exterior Verify the engine is off and cool be- Clean water system outlets, surface (except the engine). fore beginning to clean. Clean the including water tubes in blade saw with soap and water. - Page 25 MK-20 SERIES MAINTENANCE MAINTENANCE SAFETY • Always turn the master engine switch to the off position. • NEVER lubricate components or attempt service on a running machine. • Keep the machinery in proper running condition. • Fix damage to the machine immediately and always replace broken parts, or missing decals.

- Page 26 MK-20 SERIES MAINTENANCE Lubricate the zerk fitting on each Lubricate the Cooling Verify the tightness of all bolts and wheel. Supply Valve. screws. Clean the saw (except the engine) with soap and water. Weekly (50 hours) and Monthly (200 hours) The following should be performed monthly.

- Page 27 MK-20 SERIES MAINTENANCE 500 Hours and 1000 Hour Maintenance Perform the following maintenance every 500 hours. Replace Spark Plug. Refer to En- Have Authorized Repair Shop per- Have Authorized Repair Shop per- gine Manual for details. form 500-hour maintenance. form 1000-hour maintenance.

- Page 28 Honda, Vanguard, Kohler or Subaru engine manual provided separately. Remove the Diamond Blade. Lower the MK-20 Series to Free the Oil Drain Line. its lowest position. Place a catch basin below the Oil Drain Line.

- Page 29 MK-20 SERIES MAINTENANCE Engine Air Filter Inspection, Cleaning and Replacement Clean the Air Filter. Refer to Engine Manual for details. Spark Plug Adjustments and Replacement For all Engine related maintenance and troubleshooting refer to the Engine Manual. CAUTION DO NOT work around the engine while hot.

- Page 30 MK-20 SERIES MAINTENANCE Battery Check water level weekly. Add distilled water if necessary. Check terminal cables and remove any de- posits. Remove the battery for recharging and follow the instructions for recharging. Damage can result to the battery and electrical system if the battery is charged or installed in reverse polarity. Make sure that the negative terminal is connected to ground.

- Page 31 NOTES...

- Page 32 MK-20 SERIES EXPLODED VIEW FIGURE 1 - PARTS LIST: MK-2020HSP CONCRETE SAW - P/N 156498...

- Page 33 MK-20 SERIES PARTS LIST FIGURE 1 - PARTS LIST: MK-2020HSP CONCRETE SAW - P/N 156498 ITEM PART OR QTY. DESCRIPTION IDENTIFYING NO. REQ. NUT, HEX, 5/16 - 18 101196 BELT, BX34 150764 SCREW, 3/8 - 16 X 1 -1/4 HEX HEAD CAP...

-

Page 34: Exploded View & Parts List

MK-20 SERIES EXPLODED VIEW & PARTS LIST FIGURE 1 - PARTS LIST: MK-2020HSP CONCRETE SAW - P/N 156498 ITEM PART OR QTY. DESCRIPTION IDENTIFYING NO. REQ. WRENCH, BOX END, 1-1/2 X 9/16 137976 GRIP, HANDLE, 1/0 ID 150842 WASHER, FLAT, SAE, 3/8 150923 WASHER, LOCK, SPLIT, 3.8... - Page 35 MK-20 SERIES EXPLODED VIEW & PARTS LIST FIGURE 1 - PARTS LIST: MK-2020HSP CONCRETE SAW - P/N 156498 ITEM PART OR QTY. DESCRIPTION IDENTIFYING NO. REQ. NUT, HEX, 1/4 -20 151893 WASHER, 1/4 SAE FLAT 151915 NUT, 3/8 -16 NYLOK HEX...

- Page 36 MK-20 SERIES EXPLODED VIEW & PARTS LIST FIGURE 1 - PARTS LIST: MK-2020HSP CONCRETE SAW - P/N 156498 ITEM PART OR QTY. DESCRIPTION IDENTIFYING NO. REQ. SCREW, BTN HD 3/8 16 X 3/4 SOCK 156635 SCREW, PAN HD PHIL MS 10 24 X 3/4...

- Page 37 MK-20 SERIES EXPLODED VIEW FIGURE 2 - PARTS LIST: MK-2024HSP CONCRETE SAW - P/N 158777...

- Page 38 MK-20 SERIES PARTS LIST FIGURE 2 - PARTS LIST: MK-2024HSP CONCRETE SAW - P/N 158777 ITEM PART OR QTY. DESCRIPTION IDENTIFYING NO. REQ. NUT, HEX, 5/16 - 18 101196 BELT, BX34 150764 SCREW, 3/8 - 16 X 1 -1/4 HEX HEAD CAP...

- Page 39 MK-20 SERIES EXPLODED VIEW & PARTS LIST FIGURE 2 - PARTS LIST: MK-2024HSP CONCRETE SAW - P/N 158777 ITEM PART OR QTY. DESCRIPTION IDENTIFYING NO. REQ. WRENCH, BOX END, 1-1/2 X 9/16 137976 GRIP, HANDLE, 1/0 ID 150842 WASHER, FLAT, SAE, 3/8 150923 WASHER, LOCK, SPLIT, 3.8...

- Page 40 MK-20 SERIES EXPLODED VIEW & PARTS LIST FIGURE 2 - PARTS LIST: MK-2024HSP CONCRETE SAW - P/N 158777 ITEM PART OR QTY. DESCRIPTION IDENTIFYING NO. REQ. NUT, HEX, 1/4 -20 151893 WASHER, 1/4 SAE FLAT 151915 NUT, 3/8 -16 NYLOK HEX...

- Page 41 MK-20 SERIES EXPLODED VIEW & PARTS LIST FIGURE 2 - PARTS LIST: MK-2024HSP CONCRETE SAW - P/N 158777 ITEM PART OR QTY. DESCRIPTION IDENTIFYING NO. REQ. SCREW, BTN HD 3/8 16 X 3/4 SOCK 156635 SCREW, PAN HD PHIL MS 10 24 X 3/4...

- Page 42 MK-20 SERIES EXPLODED VIEW & PARTS LIST FIGURE 3 - PARTS LIST: FRAME, LESS ENGINE - P/N 169719 ITEM PART OR QTY. DESCRIPTION IDENTIFYING NO. REQ. WHEEL, REAR CONCRETE SAW 138529 WASHER, 1/2 SAE FLAT 150924 WASHER, 7/16 SPLIT LOCK...

- Page 43 MK-20 SERIES EXPLODED VIEW & PARTS LIST FIGURE 3 - PARTS LIST: FRAME, LESS ENGINE - P/N 169719 ITEM PART OR QTY. DESCRIPTION IDENTIFYING NO. REQ. WASHER, FLAT, SAE, 3/8 150923 WASHER, 1/2 SAE FLAT 150924 WASHER, LOCK, SPLIT, 3/8...

- Page 44 MK-20 SERIES EXPLODED VIEW & PARTS LIST FIGURE 3 - PARTS LIST: FRAME, LESS ENGINE - P/N 169719 ITEM PART OR QTY. DESCRIPTION IDENTIFYING NO. REQ. PANEL, UPPER BACK TOWER 156504 ASSY, PIN CLEVIS 3/8 X 1 - 1/4 156611...

- Page 45 MK-20 SERIES EXPLODED VIEW & PARTS LIST FIGURE 3 - PARTS LIST: FRAME, LESS ENGINE - P/N 169719 ITEM PART OR QTY. DESCRIPTION IDENTIFYING NO. REQ. WASHER, FLAT, SAE, 3/8 150923 SCREW, HEX HD, 5/16 - 18 X 1 151743...

- Page 46 MK-20 SERIES EXPLODED VIEW & PARTS LIST FIGURE 4 - PARTS LIST: BLADE SHAFT - P/N 156654 ITEM PART OR QTY. DESCRIPTION IDENTIFYING NO. REQ. NUT, 1 - 14 RIGHT HAND 138693 NUT, 1 - 14 LEFT HAND 138701 FLANGE, INNER...

- Page 47 MK-20 SERIES EXPLODED VIEW & PARTS LIST FIGURE 5 - PARTS LIST: ENGINE, HONDA GX630 - P/N 169713 ITEM PART OR QTY. DESCRIPTION IDENTIFYING NO. REQ. KEY, SQUARE, 1/4 X 1 - 3/4 150796 WASHER, FLAT, SAE, 3/8 150923 WASHER, 1/2 SAE FLAT...

- Page 48 MK-20 SERIES EXPLODED VIEW & PARTS LIST FIGURE 6 - PARTS LIST: ENGINE, HONDA GX690 - P/N 170048 ITEM PART OR QTY. DESCRIPTION IDENTIFYING NO. REQ. KEY, SQUARE, 1/4 X 1 - 3/4 150796 WASHER, FLAT, SAE, 3/8 150923 WASHER, 1/2 SAE FLAT...

- Page 49 MK-20 SERIES EXPLODED VIEW & PARTS LIST FIGURE 7 - PARTS LIST: ASSY, POINTER - P/N 166465 ITEM PART OR QTY. DESCRIPTION IDENTIFYING NO. REQ. SCREW, THUMB 1/4 - 20 X 3/4 150991 WHEEL, POINTER, 3” 155066 BUSHING, 3/8ID X 1 - 5/8L...

-

Page 50: Ordering Information

• The Part Description for the part(s) being ordered NOTE: There is a $25.00 minimum order when ordering direct from MK Diamond. A $6.00 charge will be added to orders having a net billing value under $50.00. All purchases must be made using VISA, MasterCard or American Express. -

Page 51: Warranty

© COPYRIGHT 2012, MK DIAMOND PRODUCTS, INC. ALL RIGHTS RESERVED. The MK Diamond logo is a registered trademark of MK Diamond Products, Inc. and may not be used, reproduced, or altered without written permission. All other trademarks are the property of their re- spective owners and used with permission. - Page 52 MK-20 SERIES CONCRETE SAW OWNER’S MANUAL, OPERATING INSTRUCTIONS, & PARTS LIST MK Diamond Products, Inc. 1315 Storm Parkway Torrance, CA 90501 Toll-Free: (800) 421-5830 Phone: (310) 539-5221 Fax: (310) 539-5158 www.mkdiamond.com...

Need help?

Do you have a question about the MK-20 SERIES and is the answer not in the manual?

Questions and answers