Table of Contents

Advertisement

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Westerbeke Universal M-50

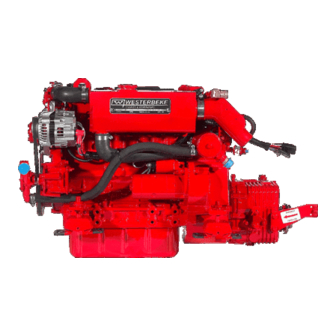

- Page 1 SERVICE MANUAL MODELS M - 50 M - 30 PIN 200154...

-

Page 2: Table Of Contents

CONTENTS NOTE: Refer to the beginning of the individual sections for a cqrnplete table of contents for that section. SECTION I - SPECIFICATIONS ............ 1-18 SECTION II - PREVENTIVE MAINTENANCE ........19-24 SECTION III - CONSTRUCTION AND FUNCTION ........25-30 SECTION IV - LUBRICATION, COOLING, AND FUEL SySTEMS ....... - Page 3 NOTES...

- Page 4 SECTION 1- SPECIFICATIONS Model M-30 ..............Model M-40 ..............Model .M-50 .........., ...., . 6,7 Parts Specifications .............. 8-15 Bolt Torques ..............16-18...

-

Page 5: Section I - Specifications

UNIVERSAL MODEL M-30 SPECIFICATIONS Horsepower 24 @ 2800 No. of Cylinders Bore x Stroke 3.00 x 3.23 Cubic Inch Maximum R.P.M. 2800 Cruising Range (Approx.) 2000-2400 R.P.M. Compression Ratio 21:1 Electrical Equipment 12 Volt - 51 Amp W/Glow Plugs Lubrication (Eng. Approx. Qts) 5.0 to 5.5 (SAE 30 HD. -

Page 6: Model M-30

UNIVERSAL MODEL M-30 FUEL LINES AIR BREATHER GLOW _ _ _ _ __ PLUG~- FUEL AIR LEED VALVE SEA WATER OVERBOARD HEAT EX. DRAIN & ZINC_ STOP LEVER c - - - _ TRANS. DIP STICK OIL FILL HOLE - - - SHIFT LEVER '----OIL FILTER BLOCK COOLANT DRAIN... -

Page 7: Model M-40

UNIVERSAL MODEL M-40 SPECIFICATIONS Horsepower 32 @ 2800 No. of Cylinders Bore x Stroke 3.00 x 3.23 Cubic Inch Maximum R.P.M. 2800 Cruising Range (Approx.) 2000/2500 R. P.M. Compression Ratio 21:1 Electrical Equipment 12 Volt - 51 Amp WIGlow Plugs Lubrication (Eng. -

Page 8: Model M-40

UNIVERSAL MODEL M-40 FUEL LINES AIR BREATHER FUEL RETURN GLOW PLUGS-_ _ _ _ _ FUEL AIR BLEED VALVE SEA WATER OVERBOARD ---THROTTLE HEAT EX. DRAIN & ZIN - - STOP LEVER TRANS. DIP STICK OIL FILL HOLE - - - - - O I L FILTER BLOCK COOLANT DRAIN ENGINE COUPLING/... -

Page 9: Model .M-50

UNIVERSAL MODEL M-50 SPECIFICATIONS Horsepower 3000 No. of Cylinders Bore x Stroke 3.35 x 3.23 Cubic Inch Maximum R.P.M. 3000 Cruising Range (Approx.) 2000/2500 R.P.M. Compression Ratio 21:1 Electrical Equipment 12 Volt - 51 Amp Plugs WIGlow Lubrication (Eng. Approx. Ots.) (SAE 30 HD. -

Page 10: Model .M-50

UNIVERSAL MODEL M-50 FUEL LINES AIR BREATHER INJECTOR PUMP FUEL RETURN FUEL AIR GLOW PLUGS-_ _ _ _ _ - - , ... , EED VALVE SEA WATER OVERBOARD ------ TH ROTTLE ,..--- STOP LEVER HEAT EX. DRAIN & ZINC_ TRANS. - Page 11 ENGINE SPECIFICATIONS ENGINE BODY Cylinder Head Item M-30 M-40 Cylinder head surface 0.05 mm 0.05 mm flatness (0.002 in.) (0.002 in.) 0.7 to 0.9 mm 0.7 to 0.9 mm Top clearance (0.028 to 0.035 in.) (0.028 to 0.035 in.) 1.30 to 1.60 mm 1.30 to 1.60 mm Free (0.051 to 0.063 in.)

- Page 12 ENGINE SPECIFICATIONS Allowable M-50 Limit 0.05 mm (0.002 in.) 0.7 to 0.9 mm (0.028 to 0.035 in.) 1.30 to 1.60 mm (0.051 to 0.063 in. 1.05 to 1.15 mm (0.041 to 0.045 in.) 0.2 mm (0.008 in.) 448 psi 350 psi 0.18 to 0.22 mm...

- Page 13 ENGINE SPECIFICATIONS Rocker Arm M-30 M-40 Item 0.Q18 to 0.070 mm Clearance between rocker 0.Q18 to 0.070 mm (0.0007 to 0.003 in.) (0.0007 to 0.003 in.) arm and bushing 13.973 to 13.984 mm 13.973 to 13.984 mm 0.0. Rocker arm shaft (0.550 to 0.551 in.) (0.550 to 0.551 in.) 14.002 to 14.043 mm...

- Page 14 ENGINE SPECIFICATIONS Allowable M-50 Limit 0.Q18 to 0.070 0.15 (0.0007 to 0.003 in.) (0.006 in.) 13.973 to 13.984 (0.550 to 0.551 in.) 14.002 to 14.043 (0.551 to 0.553 in. 0.05 (0.002 in.) 33.36 33.31 (1.313 in.) (1.315 in.) 0.050 to 0.091 0.15...

- Page 15 ENGINE SPECIFICATIONS M-40 Item M-30 0.02 mm 0.02 mm Crankshaft alignment (0.0008 in.) (0.0008 in.) 0.040 to 0.118 mm Oil clearance between crank- 0.040 to 0.118 mm shaft journal and bearing (0.002 to 0.004 in.) (0.002 to 0.004 in.) Front and 51.921 to 51.940 mm 51.921 to 51.940 mm intermediate...

- Page 16 ENGINE SPECIFICATIONS Allowable M-50 Limit 0.02 mm 0.08 mm (0.0008 in.) (0.003 in.) 0.040 to 0.118 mm 0.20 mm (0.002 to 0.004 in.) (0.008 in.) 51.921 to 51.940 mm (2.044 to 2.045 in.) 51.921 to 51.940 mm (2.044 to 2.045 in.) 51.980 to 52.039 mm...

- Page 17 ENGINE SPECIFICATIONS COOLING SYSTEM Fan Belt Item M-30 M-40 Belt deflection under load of 7 to 9 mm 7 to 9 mm 98 N (10 kgf, 21 Ibs.) (0.275 to 0.355 in.) (0.275 to 0.355 in.) Heat Exchanger 1.2 kgf/cm 2 1.2 kgf/cm 2 Exchanger water tightness (14 to 15 psi)

- Page 18 ENGINE SPECIFICATIONS Allowable M-50 Limit 7 to 9 mm (0.275 to 0.355 in.) 1.2 kgf/cm2 (14 to 15 psi) 0.9 to 0.6 kgf/cm2 (15 to 9 psi) 73.9 C (165<» F 23° to 25° before TOC 600 to 500 kgf/cm2 (8532 to 7110 Ibs.)

-

Page 19: Bolt Torques

BOLT TORQUES As a lot of bolts and nuts in the engine are of special shape, be careful to tighten them correctly using a torque wrench. When tightening, follow this method: First tighten all the bolts 50% of the regular torque, then tighten them fully. TIGHTENING BOLTS OF IMPORTANT PARTS Marked bolts must be tightened after applying oil. - Page 20 M-50 8.0 kgf/m (54.2 57.9 ftllbs.) 3.5 kgf/m (21.7 25.3 ftllbs.) 3.5 kgf/m (21.7 25.3 ftllbs.) 11 kgf/m (72.3 79.6 ftllbs.) 4.2 kgflm (26.8 30.4 ftllbs.) 2.1 kgf/m (12.3 15.2 ftllbs.) 1.15 kgf/m (7.23 8.31 ftllbs.) 2.5 kgf/m (14.5 18.1 ftllbs.) 4.5 kgf/m...

-

Page 21: Bolt Torques

Bolt Torques Material Grade Standard Bolt Special Bolt Special Bolt Nominal Dia. SS41,S20C S43C, S48C (Refined) SCR3, SCM3 (Refined) 5.8 - 6.9 Ibs/ft. 7.2 - 8.3 Ibs/ft. 9.0 - 10.5 Ibs/ft. 13.0 - 15.2 Ibslft. 17.4 - 20.3 Ibs/ft. 21.7 - 25.3 Ibs/ft. M 10 28.9 - 33.3 Ibs/ft. -

Page 22: Section Ii - Preventive Maintenance

SECTION II - PREVENTIVE MAINTENANCE General Warnings ..............20 Maintenance Check List ............21 POINTS OF INSPECTION AND CHANGING Engine Lubricating Oil ............. 22 Changing Engine Oil Level ............22 Changing Engine Oil .............. 22 Changing Engine Oil Filter Cartridge ..........23 Inspection of Fuel Filter ............ -

Page 23: General Warnings

GENERAL WARNINGS • When disassembling engine, arrange each part on a clean surface. Do not mix them up. Replace bolts and nuts in their original positions. • When servicing voltaged parts or connecting instruments to electrical equipment, first "disconnect negative battery terminal. •... -

Page 24: Maintenance Check List

MAINTENANCE CHECK LIST To maintain long-lasting and safe engine performance, make it a rule to carry out regular inspections by following the table below. Service Interval every every every every every every every every every every Item one or three 50 hrs. -

Page 25: Points Of Inspection And Changing

POINTS OF INSPECTION AND CHANGING ENGINE LUBRICATING OIL Brand name oil (for diesel engines) or CC/CD class oils defined by SPI. It should be as follows according to temperature. HD or SAE-30 10W-40 CHECKING ENGINE OIL LEVEL Stop for 5 minutes or more and remove the dip stick, wipe off dip stick and recheck. Read the engine oil level on the dip stick. -

Page 26: Changing Engine Oil Filter Cartridge

CHANGING ENGINE OIL FILTER CARTRIDGE Remove the oil filter cartridge with a filter wrench. Apply a slight coat of oil to the rubber gasket on the new cartridge. Screw the new cartridge in by hand. Over-tightening may cause deformation of rubber gasket. After cartridge has been replaced, engine oil normally decreases a little. -

Page 27: Venting The Fuel System

VENTING THE FUEL SYSTEM - Models 18, 25, 25XP and 35 Air must be vented when:, • The fuel filter and piping are removed. • The fuel tank becomes completely empty. • The engine has not been used for an extended time, Veriting procedure is as follows: Fill the fuel tank with fuel, and open the fuel cock. -

Page 28: Section Iii - Construction And Function

SECTION III - CONSTRUCTION AND FUNCTION Cylinder Block ..............26 Cylinder Head ..............26 Crankshaft ............... 27 Piston and Piston Rings ............28 Connecting Rods ..............28 Camshaft and Fuel Camshaft ............29 Rocker Arm Assembly ............. 29 Inlet and Exhaust Valves ............30 Flywheel ................ -

Page 29: Cylinder Block

CYLINDER BLOCK The engine features a high durability tunnel-typed cylinder in which the crank bearing part is constructed body. Furthermore, dry-type cylinder liners, being pressure-fitted into cylinders, allow effective cooling, less distortion, higher wear-resistance qualities and each cylinder having its own chamber helps to minimize noise. -

Page 30: Crankshaft

CRANKSHAFT The crankshaft is driven by the pistons and connecting rods, and translates its reciprocating movement into a circular movement. It also drives the oil pump, camshaft and fuel camshaft. Six counterweights are integrated into one unit to minimize bearing wear and lubricating oil temperature rise. -

Page 31: Piston And Piston Rings

PISTON AND PISTON RINGS Piston circumference has a special elliptic shape in consideration of expansion due to explosion heat. Piston head is flat-formed. Furthermore, ribs are provided between the piston head and top ring to reduce distortion and to help heat radiation. Piston is made of special aluminum alloy of low thermal expansion and high temperature resistance. -

Page 32: Camshaft And Fuel Camshaft

CAMSHAFT AND FUEL CAMSHAFT The camshaft is made of special cast iron and the journal and cam sections are chilled to resist wear. The journal sections are force-lubricated. The fuel camshaft controls the reciprocating movement of the injection pump, and is equipped with a ball to control the governor. Fuel camshaft is made of carbon steel and cam sections are quenched and tempered to provide greater wear resistance. -

Page 33: Inlet And Exhaust Valves

INLET AND EXHAUST VALVES The inlet and exhaust valves and their guides are different from each other. Other parts, such as valve springs, valve spring retainers, valve spring collets, valve stem seals, and valve caps are the same for both the inlet and exhaust valves. All contact or sliding parts are quenched and tempered to resist wear. -

Page 34: Section Iv - Lubrication, Cooling, And Fuel Systems

SECTION IV - LUBRICATION, COOLING, AND FUEL SYSTEMS LUBRICATION SYSTEM Lubrication System Diagram ............32 Engine Oil Flow Diagram ............33 Relief Valve ..............34 By-pass Valve ..............34 Oil Switch ............... 35 Oil Pump ................ 35 COOLING SYSTEM Water Pump ..............36 Thermostat .............. -

Page 35: Lubrication System

LUBRICATION SYSTEM Oil Filter Cartridge and Relief Valve Crankpin Bearing (1) To rocker arm shaft and camshaft (2) To crankshaft Piston Oil Filter 1... -

Page 36: Engine Oil Flow Diagram

ENGINE OIL FLOW (181 ROCKER ARM SHAFT (221 SWITCH 1(201 1(201 1(201 ,..-_...J : DRAIN DRAIN I DRAIN (151 (151 (161 (151 CAMSHAFT (121 TAPPETS TA;ETS (141 (191! (1911 SPLASH SPLP.SH TIMING (19) SPLASH GEAR '\ )II __ .J _+-_1 (61 MAIN OIL GALLERY ----, ~-_-_-_-_-_-_... -

Page 37: Relief Valve

RELIEF VALVE Relief valve prevents damage to the lubrication system due to high oil pressure. Control range of the relief valve is 196 to 441 KPa, (28 to 64 psL) When oil pressure exceeds the upper limit, the ball is pushed back by high pressure oil and the oil escapes. BY·PASS VALVE Oil filter cartridge has a by-pass valve inside, to prevent the lack of lubrication oil in the engine, if the oil filter element is clogged. -

Page 38: Oil Switch

OIL SWITCH Oil switch is provided on the way for the oil pressure. If the oil pressure is proper, it is switched off, if oil pressure falls below 49.0 kPa (7.1 psi), the oil warning lamp etc. will light, warning the operator. -

Page 39: Water Pump

WATER PUMP 35 Imino (7.7 IMp.gals/min. 9.2 U.S. gals/min) of water is forced into the crank case and cyliinder head to cool them. The impeller, of backward type, is bent as far as possible from the center, in the opposite direction to rotation. The bearing unit prevents cooling water from entering by a special mechanical seal. -

Page 40: Oberdorfer Water Pump

OBERDORFER WATER PUMP PUMP ASSEMBLY 301357 Item Unit Description Cover Screws Pump Cover Cover Gasket Impeller Snap Ring Impeller PUmp Shaft Old Style 1 pc. Shaft New Style Carbon Bushing Cam Locking Screw Oil Seal Drain Plug... -

Page 41: Sherwood Water Pump

SHERWOOD WATER PUMp· PUMP ASSEMBLY 300986 Item Unit Description Cover Screws Pump Cover Cover Gasket Impeller Snap Ring Impeller Pump Shaft Old Style 1 pc. Shaft New Style Water Seal Pump Body Cam Locking Screw Oil Seal Drain Plug... -

Page 42: Johnson Water Pump

JOHNSON WATER PUMP PUMP ASSEMBLY 302259 Item Unit Description Cover Screws Pump Cover Cover Gasket Impeller Pump Shaft Caqm Wear Plate Cam Locking Screw PUmp Body Lip Seal O-Ring Washer Ball Bearing Guide Ring Service Kit... -

Page 43: New Style Sherwood Water Pump

PUMP ASS EMBLY 302648 =-------~- Description Impeller-H::· Housing -Ring Cam Screw Impeller Cir-Clip Flat Washer Seal Seat Not Available Cir-Cr rder #13 Ip Internal - Ip External Ball Bearing Seal & Seat A Cir-Cr ssembly ip External Shaft End Plate Gasket Pump Body Lock Washer... -

Page 44: Fuel System

FUEL SYSTEM While the engine is running, fuel is fed from the fuel tank (optional part) through the fuel filter to the fuel pump, which feeds fuel to the injection pump. The injection pump then feeds the fuel through the injection pipes, to the nozzles which inject fuel to the cylinders for combustion. Any fuel leaking from nozzles is collected in the fuel overflow pipes which drain into the tank. -

Page 45: Fuel Pump

FUEL PUMP Filtered fuel is forcibly sucked from the tank by the fuel pump and fed under pressure to the injection pump. Inlet and discharge pressures are produced by a vertical movement of the diaphragm which is caused by the special cam (for pump) of the fuel camshaft. Fuel is suctioned on the downward stroke, and discharged on the upward stroke. - Page 46 Fuel Pressure-feed 1. Bottom dead center of plunger: At bottom dead center, fuel enters the delivery chamber through the fuel chamber and the feed hole. (Fuel chamber is always kept full by the fuel pump.) 2. Pressure-feed start 3. Pressure-feed process: Plunger is pushed up by camshaft to close the feed hole, and fuel pressurization starts.

- Page 47 Injection Control 1. Injection "zero": The feed hole meets the control groove before it is closed by the plunger top. Therefore, fuel is not pressurized, and is not injected even if the plunger moves up. 2. Injection "medium": When the plunger is rotated a certain amount in the direction of the arrow by the control rack, stroke A is effective until the feed hole meets the control groove and fuel is injected as the stroke amount.

- Page 48 Delivery Valve The delivery valve is composed of the valve and the valve seat. It performs two functions: 1. Reverse flow prevention: If the circuit between the delivery chamber and the nozzle is always closed, a time lag will occur between pressure feed start of valve element and start of nozzle injection. This, in turn, will prevent injection from stopping properly until after completion of pressure-feed.

-

Page 49: Injection Nozzle

INJECTION NOZZLE This nozzle is throttle-type. Fuel fed from the pump pressurized to push the needle valve up and the fuel is then injected. The needle valve is pressed by the nozzle spring through the push rod. Fuel overflow is passed from nozzle holder center through the fuel overflow nipple and the fuel overflow pipe to the fuel tank. -

Page 50: Governor

GOVERNOR With centrifugal ball weight system this mechanical governor works in the whole range of speeds. It keeps the engine speed and controls the engine output. At Start When the engine is started, more fuel is required than in running. At starting, fork lever 1 is pulled rightward by starter spring because ball weights have no centrifugal force. - Page 51 At middle/high speed running The engine speed is controlled when the tension of governor springs 1 and 2, which are pulled speed control lever, and the centrifugal force of ball weights are balanced. When the speed is reduced (A - 8) with load increased (a - b), the centrifugal force of ball weights becomes smaller than the tension of governor springs 1 and 2.

- Page 52 At high speed running with overload When an overload is applied to the engine running at a high speed, the centrifugal force of ball weights become small as the speed is reduced, and fork lever 2 is pulled rightward by governor springs 1 and 2, increasing fuel injection.

- Page 53 NOTES.

- Page 54 SECTION V - ELECTRICAL SYSTEM Wiring Diagram ....: ............ 52 General Information ............... 53 Alternator, General Information ............ 54-57 Alternator Schematic Diagrams ............55 Alternator Rear Housing Rotation ............ 57 Belt Installation, Alignment and Tightening ..........58 Ammeter ................ 58 Alternator/Regulator Test Procedure ..........

-

Page 55: Wiring Diagram

WIRING DIAGRAM r--------------{10'r---------~ per cyl., Glow Pktp ~'23. ~1.5 l~l----~_~_~~~~------- '-__ ..-_-_-_-_-_-_-_-_-_-_-...:-=-~~-~~I~~ ~~~~~~~~~~~~~~~~ WIRE NO. COLOR WIRE SIZE Black Grey Yellow-Red Orange Purple Blue Open Grey Orange-Red... -

Page 56: Section V - Electrical System

ELECTRICAL SYSTEM General Information The 8E series of charging systems were designed for the replacement of many current Motorola models. Models are available for 51 amp, 12 volt, negative ground systems with or without an integral, solid-state voltage regulator. The integral voltage regulator incorporates an IC, all silicon semiconductors and thick-film construction. -

Page 57: Alternator, General Information

ALTERNATOR These alternators are available in two basic versions. One version includes a solid-state regulator and forms a complete charging system. The other version does not include a regulator. However, it is equipped with a blade terminal for connection to a remote regulator. The alternator portions of these charging systems are three-phase, diode rectified machines with die cast aluminum housings to provide the necessary strength while keeping the weight to a minimum. -

Page 58: Alternator Schematic Diagrams

The stator is connected to a three-phase, full-wave bridge rectifier package which contains six diodes. The bridge converts the A.C. generated in the stator to a D.C. output for battery charging and accessories such as radio, heater, lights, ignition, etc. See illustrations below. Power to the regulator and the field of the integral regulator alternators is provided by the field diode (or diode trio) package contained in the alternator. - Page 59 INTEGRAL REGULATOR Integral Voltage Regulator The voltage regulator is an electronic switching device which senses system voltage level and switches the voltage applied to the field in order to maintain proper system voltage. The regulator design utilizes all silicon semi-conductors and thick-film assembly techniques. After the voltage has been adjusted to the proper regulating valve, the entire circuit is encapsulated to protect the circuit and the components from possible damage due to handling or vibration and moisture encountered in a vehicle.

-

Page 60: Alternator Rear Housing Rotation

Alternator Excitation The residual magnetism of an alternator is very low therefore some field current must be supplied to the rotor to initiate the generation of power by the machine. CHARGE IND. LIGHT ' " ING. SW FIELD ING. SW (ON) (IND. -

Page 61: Belt Installation, Alignment And Tightening

BELT INSTALLATION, ALIGNMENT & TENSIONING Correct belt alignment is essential for maximum alternator and belt service life. The center line of all pulleys related to the alternator drive must be within 1/32" of the true center line. See illustration below. Tighten drive belts by applying pressure to the alternator front housing ONLY. -

Page 62: Alternator/Regulator Test Procedure

ALTERNATOR/REGULATOR TEST PROCEDURE General It is desirable to test the charging system (alternator and voltage regulator) in the vehicle using the vehicle wiring harness and electrical loads that are a permanent part of the system. In-vehicle testing will then provide the technician with an operational test of the charging system as well as the .major components of the electrical system. -

Page 63: Test Procedure - Integral Regulator Systems

TEST PROCEDURE - (INTEGRAL REGULATOR SYSTEMS) (See Pages 64-66 for Remote Regulator Systems) ACTAP BACK AC TAp· BACK COVER (TACH) COVER (TACH) (D+) INDICATOR (D+) INDICATOR LIGHT TERM. LIGHT TERM. GROUND-~ GROUND SENSE (TO BATT. +) ALTERNATOR INTEGRAL INTEGRAL SENSE REGULATOR REGULATOR REMOTE... - Page 64 PROBLEM AREA DETERMINATION SECTION CONDITIONS: Engine Idling For All Tests (Unless otherwise specified) A. BATTERY UNDERCHARGED Remove Battery sense only. Perform Harness Voltage Test (Test No.3) 2. Indicator Lamp On Perform Open Diode-Trio Test (Test NO.1) Indicator Lamp Off (Ignition on and engine stopped) a.

- Page 65 Alternator/Regulator Tests Test No. 1 Open Diode-Trio Test With ignition on and engine not running and jumped not attached (no electrical load), check for battery voltage at terminal A and for 1.5 to 3.0 volts at terminal B. Add jumper JUl between terminals A and B. Start engine and run at idle. If indicator lamp now goes "ott"...

- Page 66 Test No. 3 Harness Voltage Test (Remove Battery Sense Only) Remove harness sense lead from sense terminal and connect voltmeter leads as shown in Figure below. Voltmeter should indicate battery voltage (approx. 12.6 volts for a fully charged battery with ignition key off).

-

Page 67: Test Procedure - Remote Regulator Systems

TEST PROCEDURE-(REMOTE REGULATOR SYSTEMS) ACTAP (TACH) (D+) INDICATOR LIGHT TERM. GROUND ALTERNATOR TERMINAL IDENTIFICATION (REMOTE REGULATOR) TROUBLESHOOTING GUIDE REMOTE REGULATOR SYSTEMS PROBLEM PROBABLE CAUSES CORRECTIVE ACTION Battery undercharged Defective cables, dirty battery Check, clean, repair or replace ammeter (if used) indicates posts, corroded terminals, etc. - Page 68 Problem Area Determination Section A. BATTERY UNDERCHARGED Indicator Lamp On. Perform Open Diode-Trio Test (Test No.1). 2. Indicator Lamp Off (Ignition on and engine stopped). a. Perform Regulator Test (Test No.2) If Regulator is O.K., the cause is probably an open field circuit and Alternator must be removed for repair.

- Page 69 Test No.2 Open Regulator Test With ignition on and engine not running and jumper not attached check for battery voltage at terminal A and terminal B. Indicator light will be off. Add jumper between terminals Band C. 11 1.5 to 3.0 volts is present at terminal B and the indicator light is on, an open (defective) regulator is indicated.

-

Page 70: Alternato~ Repair Procedure

ALTERNATOR REPAIR PROCEDURE General The following instructions are presented as a general overall procedure for complete disassembly of an alternator. However, it should be pOinted out that following the complete procedure whenever a repair is necessary will seldom, if ever, be required. In cases where the causes of the malfunction are known, it is only necessary to follow that portion of the procedure directly related to resolving the problem. - Page 71 Remove Brush Holder: Remove two locknuts securing brush holder. Pull out brush holder. See illustration below. (2) BRUSHOLDER MOUNTING LOCKNUT REMOVING BRUSH HOLDER Inspect and Test Brush Assembly: The illustration below shows the terminals brush arrangement and testing procedure. The original brush set may be reused if the brushes are 3/16"...

- Page 72 Remove Integral Voltage Regulator: Remove two screws securing integral voltage regulator to rear housing. NOTE: Alternators with remote voltage regulator systems will have a space part mounted to the rear housing instead of the integral voltage regulator. (2) REGULATOR MOUNTING SCREWS REMOVING VOLTAGE REGULATOR Remove Diode-Trio (Field Diode) and Rectifier Diode Bridge: The diode-trio and rectifier diode bridge are detached as an assembly.

- Page 73 Test Diode Trio Assembly: Using a commercial diode tester or 12 volt DC test lamp; check for continuity from each terminal separately to the 0+ stud; continuity should be observed in one direction (polarity) only, and all diodes should check alike. If any diode is defective replace the entire diode trio assembly. See illustration below.

- Page 74 Separate Stator/Rear Housing Assy. from Front Housing: Remove four thru-bolts. See illustration below. Carefully insert two screwdriver blades in opposite openings between the stator and front housing, as shown in illustration below. Pry units apart. CAUTION: Do not insert screwdriver blades deeper than 1/16" to avoid damaging stator winding.

- Page 75 Remove Pulley, Fan and Spacer: The pulley is a slip-fit on the rotor shaft, positioned with a Woodruff Key. Remove the nut and lockwasher from the shaft using an impact wrench or other suitable tool. After nut and lockwasher are removed the alternator can be separated from the pulley. The fan will slide over the key.

-

Page 76: Rotor Inspection And Electrical Testing

Remove Front Bearing from Housing: Remove three bearing retainer screws. Position housing on support blocks placed on an arbor press. Using a tool that contacts inner race of bearing, press out front bearing. See illustrations below. (3) BEARING RETAINIER SCREW BEARING INNER RACE REMOVING RETAINER SCREWS... - Page 77 REAR BEARING SLIP BEARING RING~ AREA KEY SLOT SHAFT THREADS TEST CURRENT DRAW OR RESISTANCE BEWEEN RINGS NOTE: PLACE TEST LEADS ON EDGES OF SLIP RINGS TO AVOID CREATING ARCS ON BRUSH CONTACT SURFACES. ROTOR INSPECTION AND ELECTRICAL TESTING B. Grounded Slip Ring or Winding Use 12 volt DC test lamp, ohmmeter, or 110V AC test lamp.

- Page 78 Remove Slip Rings from Rotor Assembly Unsolder the rotor leads from the slip ring terminals. Carefully unwind the ends of the rotor coil leads from the slip ring terminals, as shown in illustration below. REMOVE ALL RESIDUE FROM BETWEEN SLIP RINGS UNSOLDER -"==~-r:J I"T"...

-

Page 79: Alternator Reassembly

DRESS ROTOR LEADS AWAY FROM PULLER REMOVING REAR BEARING ALTERNATOR REASSEMBLY General The general reassembly instructions are reverse order to the procedures given for disassembly. Therefore, only information pertaining to special reassembly requirements will be covered in this section. Install Rear Bearing Place rotor on a press as shown in illustration below. - Page 80 Install Slip Ring Assembly Guide rotor leads through one of the oval passages in the slip ring assembly. Be sure oval passages is in line with groove in rotor shaft. Place rotor on a press as shown in illustration below. Choose a driver sleeve with a diameter that clears leads.

- Page 81 Assemble Rotor and Front Housing Place the rotor on the bed of an arbor press, using two steel blocks for support, as shown in illustration below. Place front housing over shaft. Using driver sleeve that contacts inner bearing race only, press front housing down until inner bearing race contacts shoulder on the shaft. CAUTION: Be sure rotor leads clear blocks.

-

Page 82: Alternator Performance Tests

Install Brush Assembly Insert brush holder into grooves in hub of rear housing. Place D strap (or male terminal where applicable) on stud and secure brush holder with locknuts (two places). Secure other end of D strap. Install Rear Cover Be sure felt gasket is in place (see illustration below). -

Page 83: Cranking System

MINIMUM ACCEPTABLE OUTPUT VAWES AT 70° TO 800 RATING OUTPUT 51 AMP 46 AMP AC TAP (TACH) FIELD RHEOSTAT EXCITE IGN. SW. OR OIL PRESS. SW.) WLTS POS + OUTPUT ·REMOTE BATT SENSE ONLY BATTERY DIAGRAM A-REMOTE REGULATOR MODEL DIAGRAM B-INTEGRAL REGULATOR MODEL TYPICAL ALTERNATOR PERFORMANCE TESTS CRANKING SYSTEM Starter... - Page 84 Starter circuit 1. PC :Pull-in Coil 2. HC :Holding Coil 3. S :Switch 4. Drive Lever clutch 5. Screw Spline 6. Armature 7. Pole Core 8. Commutator 9. Contact Plate When Start Button is Pushed: When the start button is pushed on, a current flows from the battery through the pull-in coil in the magnet switch section to the holding coil, energizing the plunger to pull it in.

- Page 85 When Push Button is Released: When the push button is released, a current flows instantaneously through the pull-in coil in the opposite direction as shown in Figure below. Therefore, the forces of the holding coil and pull-in coil are balanced. a result, the plunger is returned by the return spring.

-

Page 86: Section Vi - Disassembly And Reassembly

SECTION VI - DISASSEMBLY AND REASSEMBLY CYLINDER Removing Head Cover ............. 86 Removing Injection Pipes 1, 2 and 3 ..........86 Removing Nozzle Holder Assemblies ..........87 Removing AC Dynamo and Fan Belt ..........87 Removing Rocker Arm ............. 88 Removing Push Rods .............. - Page 87 SECTION VI - CONTENTS (Continued) PISTON AND CRANKSHAFT (Continued) Removing Bearing Case Cover ............. 102 Removing Bearing Case Bolt 2 ............. 103 Removing Crankshaft ............. 103 Removing Main Bearing Case ............104 Removing Cylinder Liner ............104 THERMOSTAT, WATER PUMP Removing Thermostat ............

- Page 88 SECTION VI - CONTENTS (Continued) PISTON, CONNECTING ROD Checking Inside Diameter of Piston Bosses ........... 121 Checking Clearance Between Piston Pin and Small End Bushing ......121 Checking Piston Ring Clearance ............ 122 Checking Side Clearance of Ring in Groove .......... 122 Checking Connecting Rod Alignment ..........

-

Page 89: Removing Head Cover

ATTENTION: When reassembling, replace all the O-rings and gaskets with new ones. CYLINDER HEAD REMOVING HEAD COVER Remove the head cover nuts. Remove the head cover. NOTE FOR REASSEMBLING: Check to see if the head cover gasket is not defective. To prevent valve stem seizure, apply enough engine oil to the valve guide and valve stem. -

Page 90: Removing Nozzle Holder Assemblies

REMOVING NOZZLE HOLDER ASSEMBLIES Remove the pipe clips holding the fuel overflow pipes, and detach the pipes. Detach the nozzle holders using a 27mm nozzle holder socket wrench, after loosening (1-1/16") the rock nuts. Detach the copper gaskets on the seats on which the nozzles are to be installed. NOTE FOR REASSEMBLING: Return the nozzle holders after confirming that there are no metallic particles or foreign matter on the surface on which the nozzles are to be installed. -

Page 91: Removing Rocker Arm

REMOVING ROCKER ARM Remove the set nuts for the rocker arm brackets. Detach the whole rocker arm. NOTE FOR REASSEMBLING: Always adjust the valve clearance. Before installing the rocker arm bracket, check to see if there are any metallic particles on the surface on which the assembly is mounted. -

Page 92: Removing Cylinder Heads

REMOVING CYLINDER HEADS Remove the twelve cylinder head set bolts and two nuts. 2. Lift up the cylinder head to detach. NOTE FOR REASSEMBLING: Tighten the bolts and nuts after applying sufficient oil. Tighten the bolts and nuts in diagonal sequence starting from the center. Tighten them uniformly, or the head may deform in the long run. -

Page 93: Removing O-Ring

REMOVING O-RING Remove the O-ring from the periphery of the oil pipe on the crankcase. 1. O-ring Pipe Pin REMOVING TAPPETS Remove the six tappets from the crankcase. NOTE FOR REASSEMBLING: Visually check the contact between tappets and cams for proper rotation. -

Page 94: Removing Valves

REMOVING VALVES Remove the valve caps. 2. Remove the valve spring collet, pushing the valve spring retainer by valve spring replacer. Remove the valve spring retainer, valve spring and valve stem seal. Remove the valve. IMPORTANT: Don't change the combination of valve and valve guide. 1. -

Page 95: Injection Pump

INJECTION PUMP REMOVING INJECTION PUMP COVER Remove the injection pump cover. NOTE FOR REASSEMBLING: Before installing the pump cover gasket, apply a non-drying adhesive to it. REMOVING INJECTION PUMP Remove the injection pump mounting bolts and nuts. 2. Detach the injection pump. To prevent the pump rack from being caught, detach the pump along the removal groove. -

Page 96: Gear Case, Timing Gear, Camshaft, Oil Pump

GEAR CASE, TIMING GEAR, CAMSHAFT, OIL PUMP DETACHING GOVERNOR SPRING Detach the governor springs 1 and 2 from governor fork lever 2. NOTE FOR RE,ASSEMBLING: Fix the governor spring to the speed control lever, and pull the spring or wire through the window of the injection pump, and spring will be able to be hooked on the governor fork with ease. -

Page 97: Detaching Start Spring

DETACHING START SPRING Remove the start spring from the gear case. How to remove start spring 1. Detach Start Spring on the Side of Gear Case 2. Gear Case REMOVING FAN DRIVE PULLEY Flatten the crankshaft washer. Loosen and remove the crankshaft nut. Draw out the pulley with a puller. -

Page 98: Removing Gear Case

REMOVING GEAR CASE Remove the gear case cover. Remove the O-ring. NOTE FOR REASSEMBLING: Check to see if there are three O-rings inside the gear case. Apply a thin film of engine to the oil seal, and install it, noting the lip come off. Before installing the gear case gasket, apply a non-drying adhesive. -

Page 99: Removing Idle Gear

REMOVING IDLE GEAR Remove the external circlip. Detach the idle gear collar 2. Detach the idle gear Detach the idle gear collar 1. NOTE FOR REASEMBLlNG: Check to see each gear is aligned with its aligning mark: . 1. Idle gear and crank gear 2. -

Page 100: Removing Gear And Camshaft

REMOVING GEAR AND CAMSHAFT Draw the camshaft and the cam gear. NOTE FOR REASSEMBLING: Apply a thin film of engine oil to the camshaft before installation. 1. Camshaft Assembly REMOVING FORK LEVER ASSEMBLY Remove the two fork lever holder mounting bolts. Detach the fork lever assembly. -

Page 101: Removing Fuel Camshaft

REMOVING FUEL CAMSHAFT Remove the fuel camshaft stopper. Draw out the fuel camshaft and the injection pump gear. NOTE FOR REASSEMBLING: Apply a thin film of engine oil to each part, and reassemble so that the drive groove at the end of the camshaft engages with the drive shaft of the hydraulic gear pump. -

Page 102: Removing Oil Pump

REMOVING OIL PUMP Remove the four pump mounting bolts. Detach the oil pump. NOTE FOR REASSEMBLING: Tighten the bolts 10 to 12 Nm (1.0 to 1.2 kgf-m, 7.2 to 8.7 ft-Ibs.). Pump Assembly REMOVING CRANK GEAR Set a special puller on the crank gear. 2. -

Page 103: Piston And Crankshaft

PISTON, CRANKSHAFT REMOVING OIL PAN Lay the engine on the engine cradle on its side. 2. Remove the eighteen oil pan mounting bolts. Detach the oil pan by lightly tapping the grove of the pan with a wooden hammer. NOTE FOR REASSEMBLING: Wipe off oil on the oil pan mounting surface, apply a nondrying adhesive, and install the oil pan. -

Page 104: Removing Connecting Rod Cap

REMOVING CONNECTING ROD CAP Remove the connecting rod bolts from connecting rod cap. Detach the connecting rod caps. IMPORTANT: Apply engine oil to the connecting rod bolts and tighten them to 26 to 30 Nm (2.7 to 3.1 kgfOm, 20 to 22 ft-Ibs). Reassembling of connecting rod 1 (a) (b) 1. -

Page 105: Removing Flywheel

REMOVING FLYWHEEL Flatter the flywheel washers. Remove the flywheel bolts, except for two which must be loosened and left as they are. Set a flywheel puller, and remove the flywheel NOTE FOR REASSEMBLING:. Apply a thin film of grease to the bearing and oil seal at the back of the crankshaft. -

Page 106: Removing Bearing Case Bolt 2

REMOVING BEARING CASE BOLT 2 Straighten the washer for the bearing case bolt 2. Detach the bearing case bolts. NOTE FOR REASSEMBLING: When tightening the main bearing case bolts, align the direction of the holes so that the crankshaft can be easily installed. Tighten the bearing case bolts 2 to 30 to 34 Nm (3.0 to 3.5 kgfOm, 22 to 25 ft-Ibs). -

Page 107: Removing Main Bearing Case

REMOVING MAIN BEARING CASE Remove the two mounting bolts for main bearing case assembly 2. Detach the main bearing case, being careful with the side and crankshaft bearings. Detach the other bearing cases 2 and 3 in the same method. Be careful not to mix them up. NOTE FOR REASSEMBLIING: Clean the oil holes in the main bearing case. -

Page 108: Thermostat, Water Pump

1. Dry Liner Centering Base Bearing Cradle Center Bolt 4. Nut THERMOSTAT, WATER PUMP REMOVING THERMOSTAT Remove the thermostat cover. Remove the thermostat. NOTE FOR REASSEMBLIING: Apply a non-drying adhesive only at the thermostat cover side of the gasket. -

Page 109: Removing Water Pump

REMOVING WATER PUMP Remove the water pump from gear case cover. Remove the fan and fan pulley. IMPORTANT: If changing the water pump, change the whole pump. If disassembling the water pump, check to see the clearance between the water pump impeller and body. Water pump assembly 1. -

Page 110: Checking Flaw Of Cylinder Head Surface

How to check cylinder head surface CHECKING FLAW OF CYLINDER HEAD SURFACE Clean the surface of the cylinder head. 2. Spray the cylinder head surface:with the red permeative liquid. Wash away the red permeative liquid on the cylinder head surface with the detergent. 4. -

Page 111: Reparing Valve Seat

REPAIRING THE VALVE SEAT Clean the valve seat surface. 2. Use a 45° cutter suitable for the valve guide and the valve seat. Grind the upper surface of valve seat with 15° cutter so that the valve seat fits to the valve center (so as to ensure a b as shown in the figure.). -

Page 112: Checking Guide Clearance

CHECKING GUIDE CLEARANCE Remove carbon from the valve guide. 2. After making sure that the valve stem is straight, insert the valve into the valve guide. Measure the stem guide clearance with a dial gauge. If the measurement exceeds the allowable limit, replace the stem guide and the valve. IMPORTANT: When changing the valve guide, be sure to ream as the figure indicates after inserting the valve guide. -

Page 113: Checking Valve Spring Squareness

CHECKING VALVE SPRING SQUARENESS 1. Put the spring on a surface plate, place a square on the side of the spring, and check to see if the entire side is in contact with the square. 2. Rotate the spring and measure the maximum B. (See illustration below.). If the measurement exceeds the allowable limit, replace. -

Page 114: Checking Oil Clearance Between Rocker Arm Shaft And Bushing

CHECKING OIL CLEARANCE BETWEEN ROCKER ARM SHAFT AND BUSHING Measure the rocker arm 1.0. 2. Measure the rocker arm 0.0. If the clearance exceeds the allowable limit, replace. See engine specifications. CHECKING TOP CLEARANCE Remove the nozzle holder. 2. Lower the piston in the cylinder to be measured. Insert a high-quality fuse from the nozzle holder hole. -

Page 115: Adjusting Valve Clearance

ADJUSTING VALVE CLEARANCE 1. Measure the clearance with a feeler gauge after aligning each cylinder with the top dead center of compression. NOTE: Align the flywheel mark (TC) with the timing check mark on the crankcase. Valve clearance 0.145 0.185 0.007 in. -

Page 116: Fuel System

FUEL SYSTEM TESTING OPENING PRESSURE OF NOZZLE Move the tester hanctle up and down to prime fuel. Measure the pressure of fuel jetting from the nozzle tip. 2. If the measurement is not within the reference value, adjust with the adjustment washer inside the nozzle holder. -

Page 117: Checking Shape Of Fumes Across Nozzle Tip

CHECKING SHAPE OF FUMES ACROSS NOZZLE TIP 1. Set the nozzle to a nozzle tester and shoot it in the air. Check the shape of the fumes. If the shape is defective, replace the nozzle piece. 1. Good 2. Bad CHECKING FUEL TIGHTNESS OF FUEL INJECTION PUMP PLUNGER 1. -

Page 118: Checking Fuel Tightness Of Delivery Valve Of Fuel Injection Pump

· CHECKING FUEL TIGHTNESS OF DELIVERY VALVE OF FUEL INJECTION PUMP Set a pressure gauge to the pump. 2. Rotate the flywheel to increase the pressure to 9.8 MPa (100 kgf/cm 1422 psi). Align the plunger with the bottom dead center. Measure the time needed to decrease the initial pressure. -

Page 119: Choking And Adjusting Injection Timing

CHOKING AND ADJUSTING INJECTION TIMING Disconnect the injection pipe from the fuel injection pump. 2. Set the acceleration lever for maximum fuel discharge. 3. Turn the flywheel until fuel jets out from the delivery valve holder of the fuel injection pump. Continue to turn the flywheel slowly, and stop it as soon as the fuel level at the tip of the valve holder begins to increase. -

Page 120: Timing Gears, Camshaft

TIMING GEARS, CAMSHAFT CHECKING OIL CLEARANCE OF CAMSHAFT Measure the camshaft bearing in the crankcase with an inside micrometer. 2. Measure the camshaft journal with an outside micrometer. Calculate the clearance. If the clearance exceeds the allowable limit, replace the camshaft. See engine specifications. CHECKING CAMSHAFT ALIGNMENT Gently put the camshaft on V blocks. -

Page 121: Checking Cam Heights Of Intake And Exhaust

. CHECKING CAM HEIGHTS OF INTAKE AND EXHAUST Measure the height of the cam at its highest point with a micrometer. 2. If the measurement exceeds the allowable limit, replace the camshaft. See engine specifications. Cam height measuring points 1. Cam Height CHECKING GEAR BACKLASH Install a lever-type indicator between the gear teeth. -

Page 122: Testing Oil Pressure

WBRICATION SYSTEM TESTING OIL PRESSURE Remove the oil switch and set a pressure gauge. 2. Start the engine. Measure the oil pressure both at idling and at the rated speed. If the measurement is not within the reference value, check the oil pump, oilways, oil clearances and pressure regulating valve. - Page 123 Checking Radial Clearance Between Outer Rotor and Pump Body Insert a feeling gauge into the gap between the oil pump body and the outer rotor and measure the clearance. 2. If the measurement exceeds the allowable limit, replace. See engine specifications. Checking end Clearance Between Rotor and Cover Paste a press gauge to the surface of the gear with grease.

-

Page 124: Piston, Connecting Rod

PISTON, CONNECTING ROD CHECKING INSIDE DIAMETER OF PISTON BOSSES Measure the piston bosses with a cylinder gauge. Set the cylinder gauge's reference measurement to 23 mm, and carry out zero pOint adjustment with an outside micrometer. 2. If the measurement exceeds the allowable limit, replace. See engine specifications CHECKING CLEARANCE BETWEEN PISTON PIN AND SMALL END BUSHING Measure the piston pin with an outside micrometer. -

Page 125: Checking Piston Ring Clearance

CHECKING PISTON RING CLEARANCE Put the piston ring in the cylinder. 2. Turn the piston upside down and push the ring into the cylinder with the piston head. Insert a feeler gauge into the piston ring gap. If the clearance exceeds the allowable limit, replace. IMPORTANT: Measure the piston ring gap at the point of the minimum inside diameter of the cylinder liner. -

Page 126: Checking Connecting Rod Alignment

CHECKING CONNECTING ROD ALIGNMENT Remove the connecting rod crank pin bearing and tighten the rod bolts. Set the connecting rod to a connecting rod aligner. Place the gauge on the piston pin. Measure the gap between the pin of the gauge and the flat surface of the aligner. -

Page 127: Checking Oil Clearance Between Crankshaft Journal And Crankshaft Bearing 1

CHECKING OIL CLEARANCE BETWEEN CRANKSHAFT JOURNAL AND CRANKSHAFT BEARING 1 Measure the crankshaft journal (on the side of the crankshaft bearing 1) with an outside micrometer. Measure the crankshaft bearing 1 with an inside micrometer. Calculate the clearance. If the clearance exceeds the allowable limit, replace the crankshaft bearing 1. See engine specifications. -

Page 128: Checking Oil Clearance Between Crank Pins And Crank Pin Bearings

CHECKING OIL CLEARANCE BETWEEN CRANK PINS AND CRANK PIN BEARINGS Paste a press gauge onto the crank pin bearing with grease. 2. Tighten the connecting rod onto the crank pin to the specified torque 26.5 to 30.4 Nm. (2.7 to 3.1 kgfOm, 19.52 to 22.42 ft-Ibs). -

Page 129: Checking Wear Of Cylinder Liner

CYLINDER LINER CHECKING WEAR OF CYLINDER LINER Set a cylinder gauge and adjust it to the reference valve of the cylinder liner with an outside micrometer. To find out the maximum wear, measure the diameters at six pOints on the cylinder liner with the cylinder gauge, as shown below. -

Page 130: Crankshaft And Bearing Reference

Reference If the standard-size bearing cannot be employed due to excessive wear of the crankpin and crank journal, employ undersize or oversize bearings. For undersize or oversize bearing use, follow the precautions noted below. 3.3 to 3.7 mm (0.1300 to 0.1457 in.) 2. -

Page 131: Replacing Valve Guides, Bushings And Bearings

REPLACING VALVE GUIDES, BUSHINGS AND BEARINGS REPLACING VALVES GUIDES Prepare the necessary tool as shown in Fig (A). 2. Press out the used valve guide from the cylinder head's lower end. Apply engine oil to the outer surface of the new valve guide; press fit the valve guide from the upper end of the cylinder head until the flange part of the valve guide contacts the cylinder head. -

Page 132: Replacing Idle Gear Bushings

REPLACING IDLE GEAR BUSHINGS Prepare the necessary tool as shown in Fig. (A). Press out the used bushing and press a new one, using this tool. [B) Idle gear and bushing, as assembled [A) Tool for replacing idle gear bushing 160 (6 30") (O.39"I{O.39'"... -

Page 133: Replacing Crankshaft Bearing 1

REPLACING CRANKSHAFT BEARING 1 Prepare the necessary tool as shown in Figs (A) and (B). Press out the bearing 1, using the extracting tool. Insert a new bearing 1, using the inserting tool, taking due care to see that the contact edge of bearing 1 faces the exhaust manifold side. -

Page 134: Section Vii - Dynamo And Regulator

SECTION VII - DYNAMO AND REGULATOR BATTERY Checking Battery Charging Current ..........132 Checking AC Dynamo's No-load Voltage ..........132 STARTER No-load Testing of Starter ............133 Motor Test ..............134 Checking Magnet Switch - Pull-in Coil Attraction Test........135 Holding Coil-Retention Test ............ -

Page 135: Battery

BATTERY Checking Battery Charging Current 1. After starting the engine, disconnect lead of the battery and connect an amperemeter. Measure charging current with full electric load (with lights, etc). NOTES ON CHECKING: Connect the amperemeter only after starting the engine. In the event of a lower electric load or fully charged battery, the stipulated value may not be given. -

Page 136: Starter

200A rating because a large current flows when the starter is running. Electrical connections for no-load testing Current Voltage Rotational speed M-30 45A or less 6000 rpm or more 11.0 V M-40 gOA or less 3000 rpm or more 11.5 V M-50... -

Page 137: Motor Test

Motor Test 1. Remove the connecting leads from the starter's C terminal and connect them directly to the battery's positive terminal. Then connect the battery's negative terminal to the starter body. 2. If the starter runs normally, the magnet switch is defective; .if not, the motor is defective. Electrical connections for motor test C terminal - ' -... -

Page 138: Checking Magnet Switch - Pull-In Coil Attraction Test

Holding Coil (Retention Test) 1. Apply 1/2 the rated voltage (approx. 6V) across the S terminal and the body, push the plunger in by hand, and then release it. 2. If the plunger stays attracted, the holding coil is good; if not, it is defective. Reference value The plunger remains attracted. - Page 139 Removing Armature Brake 1. Remove the end frame cap. 2. Remove the washers. 3. Remove the packing. Removing End Frame 1. Remove the through bolts. 2. Remove the end frame. Removing Brush Holder 1. Draw out the brush from the holder while holding the spring up. 2.

- Page 140 Remove Yoke 1. Draw out the yoke from the drive end frame. Take care for yoke knock pin. NOTE FOR REASSEMBLING: Removing Armature 1. Remove the set bolt from the drive lever. 2. Draw out the armature from the drive end frame. 3.

-

Page 141: Reduction Type Starter

REDUCTION TYPE STARTER Removing Motor 1. Disconnect the connecting lead. 2. Remove the through bolts. 3. Remove the motor unit. Removing Brush Holder 1. Release the spring and draw the brush out from the holder. 2. Remove the brush holder. Remove Armature 1. - Page 142 Removing Drive End Frame 1. Remove the drive end frame. 2. Remove the gears (drive pinion, idler gear) and clutch. Remove Plunger 1. Remove the end cover from the magnet switch. 2. Draw the plunger out. 3. Remove steel balls. .

-

Page 143: Servicing Starter

3. If the commutator diameter must be ground to below the allowable limit, replace it. Commutator diameter Model Reference value Allowable limit M-30 32.7 mm 32.5 mm 1.2874 in. 1.2795 in. M-40 30.0 mm 29.0 mm M-50 1.1811 in. 1.1417 in. - Page 144 Checking Mica (Undercut) 1. Check to see the mica undercut. 2. If it has high mica, rectify with a saw blade. the edge of the segment will be rough, chamfer it. Mica depth Reference value Allowable limit Model 01102-B 0.5 to 0.8 mm 01302-B 0.0197 to 0.315 in.

- Page 145 Checking Armature Flexure 1. Measure the amount of flexure; if the measurement exceeds the reference value, replace. Carefully check to see if the core is scratch. Reference value 0.1 mm 0.0039 in. Checking Armature Coil Short-Circuited 1. Set the armature on the armature tester. Rotate the armature while touching it with steel piece. 2.

- Page 146 Checking Field Coil Breakage 1. To check conduction, place the tester probes onto the lead and brush . 2. If either are not conducting, replace. Reference value Should be conducted. Grounding of Field Coil 1. To check the conduction. Place the tester probes onto the field coil and yoke. 2.

- Page 147 12 mm 0.7480 in. 0.4724 in. 0.2756 in. M-40 19 mm 25 mm M-50 0.7480 in. 09843 in. 0.3150 in. : :::1 ..' - ....... l...

- Page 148 Grounding of Brush Holder 1. Check the insulation of the positive brush holder. 2. If the insulation is defective, replace. Reference value Should not be conducted. Checking Clutch 1. Check to see if the clutch gear is worn or damaged. 2.

- Page 149 Checking and Adjusting Pinion Gap (Magnet Switch Type) 1. Disconnect the connecting lead from C terminal. 2. Energize the magnet switch and measure the gap between the pinion tip and the stop collar. 3. To adjust the gap, change the length of the magnet switch jOint to the specified one. Reference value 0.1 to 0.4 mm 0.0039 to 0.0157 in.

- Page 150 Checking Bearing (Reduction type) 1. Apply torque to the inner ring with your finger tips and check to see if it turns smoothly. 2. Check to see if there are any strange noises when driven quickly.

-

Page 151: Troubleshooting

TROUBLESHOOTING BAl1rgJ'l¥ Battery charging current otSeft,.GaS dynamo runs. is equal to or exceeds the reference value. QUICK ... ". (check 1 ) lower than the reference value. """"- dynamo does not run. slow running. does not run at all.. - Page 152 TROUBLESHOOTING ••. - --------------------------~L. ~:~I ~ ~~b~ _: Faulty battery. ' " Faulty regulator. AC dynamo's no-load Conductivity between voltage is equal or superior regulator connector Faulty wiring between regulator and to the reference value (AC) lead wires. main s/w. (AC dynamo side).

- Page 153 TROUBLESHOOTING Slow engine speed. Starter runs but engine '" does not. STARTE.R DOES NOT DRIVE ENGINE PROPERLY. No meshing sound from pinion and ring gear. Pinion shifts repeatedly. r--..Does not turn red at all. '" GI..OWPLUG IND.ICATOR meS NOT TURN RED PROPERt.

- Page 154 TROUBLESHOOTING Battery not sufficiently charged. -"" Terminal contact poor .. Faulty battery. Poor grounding . Over·running clutch slips; --'" Poor contact of contact plate. Poor contact between brush and commutator. Faulty starter. Armature and field coil shorted. Bearing worn. Pinion and ring gear worn. Pinion and ring gear do not mesh.

- Page 155 TROUBLESHOOTING Crankshaft does not turn. No or small fuel injection sounds. Crankshaft turns. Fuel injection sounds.

- Page 156 TROUBLESHOOTING Crankshaft and camshaft have seized up. Piston and cylinder liner have seized up. Frictional resistance of moving parts is too much. Bearings are oil-stuck. Lubrication system not working properly. Starter faulty. Battery capacity is low or terminal loose. Fuel pipe broken. r----+ Air er:lters fuel pipe through connection.

- Page 157 TROUBLESHOOTING Revolution is not smooth at high speeds. ENGINE DOES NOT Revolution irregular. TURN NORMALLY. Idling not smooth. ENGINE OUTPUT Slow engine revolutions. INSUFFICIENT.

- Page 158 TROUBLESHOOTING Fuel filter clogged. Fuel pipes broken or loose. Air in pump. Pump capacity noi: constant. Injection pump wrong. f - - - Tappet roller and pin worn. Delivery valve not completely oil-tight. Fuel leaks from nozzle tip. Injection nozzle faulty. Fuel not spraying properly.

- Page 159 TROUBLESHOOTING ----.c White or blue exhaust fumes. "I COLOR OF EXHAUST FUMES NOT NORMAL . " Black or dark gray exhaust fumes. ____ -------------------- ~M~ru~TJ~ CONSUMPTION. LUBRICANT INCREASING:...

-

Page 160: Troubleshooting

TROUBLESHOOTING Piston ring stuck. Piston ring worn. Lubricant rises through piston gap. Excessive gap between cylinder liner and piston. Too much oil. Injection delayed. Compression pressure insufficient. Injection too early. Injection mistimed. Injection delayed. Plunger does not return completely because Fuel pump's injecting capacity spring is stuck or broken.

Need help?

Do you have a question about the Universal M-50 and is the answer not in the manual?

Questions and answers