Table of Contents

Advertisement

Quick Links

APPLICATION

The Honeywell Braukmann D05 Pressure Regulating

Valve is a high quality pressure regulating valve that

maintains a constant outlet pressure over a wide range

of inlet supply pressures. It is ideally suited for new

residential and light commercial construction, drip

irrigation, and applications requiring highly sensitive and

accurate regulation.

The wide inlet pressure range of the D05 gives flexibility

without compromising reduced outlet pressure accuracy

or capacity. The superior balanced single seat design

maintains a constant outlet pressure over a wide range

of inlet pressures. The noncorroding unitized cartridge

insert contains all the working parts and is easily

replaceable.

The D05 is used for water or air regulation. It is not

suitable for steam.

SPECIFICATIONS

Model:

D05 Pressure Regulating Valves

Construction Materials:

Body: Bronze.

Internal Parts: Stainless steel and engineered plastic.

Regulator Mechanism: Fabric-reinforced diaphragm.

Inlet Pressure:

400 psi maximum.

Reduced Pressure Range:

15 to 150 psi (1/2 in. to 1 in.).

15 to 130 psi (1-1/4 in.).

Outlet Pressure:

Factory set at 60 psi.

Differential:

14 psi minimum (inlet to outlet).

Reduced Ratio:

10:1 maximum.

Copyright © 1996 Honeywell Inc. • All Rights Reserved

Pressure Regulating Valves

Fluid Temperature (Maximum):

Ambient Temperature:

Pipe Sizes:

Connections:

Strainer Screen Size:

Gauge Tap:

Approvals:

Dimensions:

Water Capacities (See Table 1):

Given these variables, use Table 1 to determine the

proper size pressure regulator valve for your application.

Example: An installation has 135 psi inlet pressure, 60 psi

INSTALLATION INSTRUCTIONS

Air: 158 F (70 C).

Water: 180 F (82 C).

33 F to 140 F (1 C to 60 C)

1/2 in., 3/4 in., 1 in., and 1-1/4 in. available.

Can be configured as female thread-by-thread, single-

or double-union, NPT threaded or sweat.

0.032 in. (0.8 mm)

1/4 in. NPT (available on all models).

ASSE (Std. 1003) Certified.

IAPMO, CSA, and City of L.A. Listed.

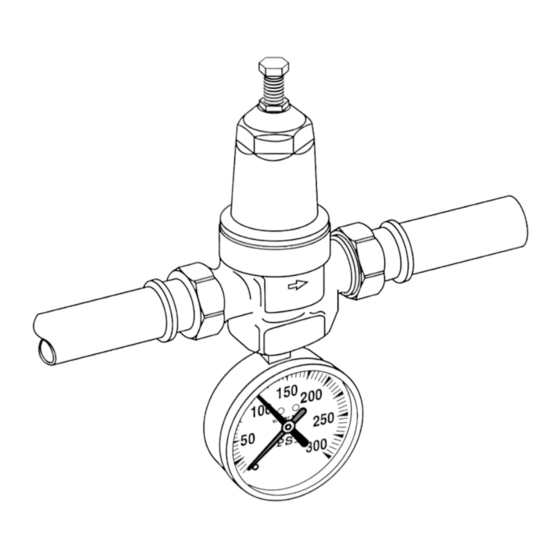

See Fig. 1.

The suitability of a given regulator size is dependent

on the pressure requirements of each installation.

To determine the pressure regulator valve size

required for a specific installation, determine the

following:

1. Pressure differential between inlet and outlet

pressure in pounds per square inch (psi),

2. Capacity in gallons per minute (gpm), and

3. Allowable reduced pressure falloff in psi.

outlet pressure (75 psi pressure differential). If

12 gpm capacity is required with only 10 psi

falloff allowable, a 1/2 in. D05 is required.

X-XX UL

D05

62-3028-4

Advertisement

Table of Contents

Summary of Contents for Honeywell Braukmann D05

-

Page 1: Specifications

Gauge Tap: 1/4 in. NPT (available on all models). The D05 is used for water or air regulation. It is not suitable for steam. Approvals: ASSE (Std. 1003) Certified. SPECIFICATIONS IAPMO, CSA, and City of L.A. -

Page 2: Installation

Read these instructions carefully. Failure to follow Changing the Outlet Pressure (See Fig. 1) them could damage the product or cause a The D05 is factory set to 60 psi. To change the outlet hazardous condition. pressure, turn the adjusting bolt counterclockwise... - Page 3 Replacing the Cartridge (See Fig. 2) Remove the bonnet and washer using an adjustable wrench, socket, or box-end wrench. The working parts of the D05, including diaphragm, valve Remove the cartridge using two screwdrivers as seat, strainer, and disk are all contained in a replaceable levers.

- Page 4 SCREW COUNTER CLOCKWISE REMOVE SPRING TENSION REMOVE BONNET USING AN ADJUSTABLE WRENCH, SOCKET, OR BOX END WRENCH REMOVE CARTRIDGE USING TWO ENSURE O-RINGS AND WASHER SCREWDRIVERS AS LEVERS ARE PROPERLY INSTALLED WASHER (LIP UP) O-RINGS M761A Fig. 2. Replacing D05 cartridge. 62-3028—4...

- Page 5 D05 PRESSURE REGULATING VALVES ADJUSTING SCREW LOCKING NUT BONNET SPRING CUP SPRING WASHER CARTRIDGE O-RING SCREEN O-RING GASKET TAILPIECE TAILPIECE GASKET BODY GAUGE TAP PLUG M760A Fig. 3. D05 exploded view. 62-3028—4...

-

Page 6: Cleaning The Cartridge Screen

Fig. 3. outlet set pressure. Remove and clean the cartridge screen. Once the outlet pressure is set, the D05 regulates to NOTE: D05G models can be cleaned partially by maintain that pressure downstream. See Fig. 4 for the removing the gauge tap plug and using internal construction of the D05. -

Page 7: Troubleshooting

Union Kit — 1 in., includes nut, female NPT threaded tailpiece and gasket. K06U1135 Union Kit — 1-1/4 in. for D05/D505, includes nut, female NPT threaded tailpiece and gasket. K06U1093 Union Kit — 1/2 in., includes nut, sweat tailpiece and gasket. - Page 8 D05 PRESSURE REGULATING VALVES Home and Building Control Home and Building Control Helping You Control Your World Honeywell Inc. Honeywell Limited-Honeywell Limitée 1985 Douglas Drive North 155 Gordon Baker Road Golden Valley, MN 55422 North York, Ontario M2H 2C9 www.honeywell.ca/braukmann 62-3028—4...

Need help?

Do you have a question about the Braukmann D05 and is the answer not in the manual?

Questions and answers