Table of Contents

Advertisement

Safety • Assembly • Operation • Adjustments • Maintenance

• Troubleshooting

• Parts Lists • Warranty

OF

A

O

AL

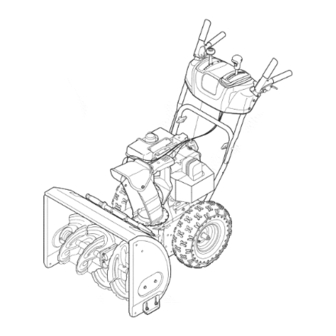

Two-Stage Snow Thrower-

Model 5ML

iMPORTANT

READ SAFETY

RULES AND iNSTRUCTiONS

CAREFULLY

BEFORE

OPERATION

Warning:

This unit is equippedwith an internal combustionengineand shouldnot be usedon or nearany unimproved forest-covered, b rush-

coveredor grass-covered land unlesstheengine'sexhaustsystemis equippedwith a sparkarrestermeetingapplicablelocalor statelaws(if any).

If a sparkarresteris used,it shouldbe maintainedin effectiveworkingorder by the operator.In theState of Californiathe aboveis requiredbylaw

(Section4442 of the CaliforniaPublicResources Code). Otherstatesmay havesimilarlaws.Federallaws applyon federallands.A sparkarrester

for the muffleris availablethroughyour nearestengineauthorizedservicedealeror contactthe servicedepartment,RO. Box361131 Cleveland,

Ohio 44136-0019.

PRINTEDIN U.S.A.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136=0019

FORMNO.769-01309C

6/07/2005

Advertisement

Table of Contents

Summary of Contents for MTD 31BE5MLG729

- Page 1 If a sparkarresteris used,it shouldbe maintainedin effectiveworkingorder by the operator.In theState of Californiathe aboveis requiredbylaw (Section4442 of the CaliforniaPublicResources Code). Otherstatesmay havesimilarlaws.Federallaws applyon federallands.A sparkarrester for the muffleris availablethroughyour nearestengineauthorizedservicedealeror contactthe servicedepartment,RO. Box361131 Cleveland, Ohio 44136-0019. FORMNO.769-01309C PRINTEDIN U.S.A. 6/07/2005 MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136=0019...

-

Page 2: Customer Support

MTD LLC P.O. 361131 web site and/or obtain assistancefrom the Customer Support CLEVELAND, ON 44136 Department or an authorizedservice dealer. 330-220-4683 www. mtd prod ucts.com 800-800-7310 Customer Support Please do NOTreturn the unit to the retailer from which it was... - Page 3 1. KEEP AWAY FROMROTATING IMPELLER ANDAUGER. C ONTACT WITH IMPELLER OR AUGER CAN AMPUTATE H ANDS ANDFEET. iil _I ii_ _ i _iii_!i _ _ii_ ii USECLEAN-OUT TOOLTOUNCLOG DISCHARGE C HUTE. DISENGAGE CLUTCH L EVERS, STOP ENGINE, ANDREMAIN BEHIND HANDLES U NTIL ALL MOVING PARTS HAVE STOPPED BEFORE UNCLOGGING ORSERVICING MACHINE.

- Page 4 WARNING: Engine Exhaust, some of its constituents, and certain vehicle compo- nents contain or emit chemicals known to State of Californiato cause cancer and birth defects or other reproductiveharm. DANGER: This machine was built to be operated according to the rules for safe operation in this manual.

-

Page 5: Maintenance

Operation Maintenance & Storage 1. Donot put hands or feet near rotatingparts, inthe 1. Nevertamper withsafetydevices.Checktheir proper auger/impellerhousingor chuteassembly.Contactwiththe operationregularly.Referto the maintenanceandadjust- mentsectionsof this manual. rotatingparts can amputatehands andfeet. 2. The auger/impellercontrolleveris a safetydevice.Never 2. Beforecleaning,repairing,or inspectingmachinedisen- bypassits operation.Doingso makesthe machineunsafe gageall control leversandstop the engine.Wait untilthe and may causepersonalinjury. - Page 6 IMPORTANT: T woreplacementaugershearpins are includedwith this manual(or stowedin the plastichandle panel).Referto Augerson page 21 for moreinformation regardingshearpin replacement. Observethe lowerarea of the snowthrowerto be surebothcables are alignedwith roller guidesbefore pivotinghandleupward. a. Pull up and backon upperhandleas shownin Figure1.Align upper handlewith the lowerhandle. b.

- Page 7 4. Finishsecunngchute controlassemblyto chute ..... support bracketwith wingnut and hexscrew removed earlier.See Figure4. 5. Checkthat all cablesare properlyroutedthroughthe cable guideon topof the engine.See Figure5. The extensioncord is fastenedwith a cabletie to the rear of the auger housingfor shippingpurposes.Cut thecable Your Snow tie and removeit beforeoperatingthe snowthrower.

- Page 8 Drift Cutters (if Equipped) Driftcutters shouldbe usedwhenoperatingthe snow throwerinheavy drift conditions. • On modelsso equipped,drift cuttersare assembledto the augerhousinginverted. See Figure7. Removethecarriagebolts by unthreading the hex nuts whichsecurethem,and reinstallthe drift cutters facingforwardbeforeoperatingthe snow thrower. Your Snow Referto Figure8. Secureto the auger housingwith carriagebolts and Thrower hexnuts previouslyremoved.See Figure9.

- Page 9 Chute Clean-Out Tool The clean-outtool isconveniently fastenedto the rearof the auger housingwith a mountingclip. See Figure10. Chute Clean-out Tool 1. Releaseboththe augercontroland the drive/auger control lock. 2. Stop theengine bymovingthe throttleto the stop position. 3. Removethe clean-outtool from the mountingclip. Your Snow 4.

-

Page 10: Know Your Snow Thrower

Know Your Snow Thrower p_e----- DriveControl "_ ,ShiftLever Four-Way ChuteControl er Control Operating Headli( Wheel Steering Your Snow Control Th rower Electric StartButton-_ EngineControls RecoilStarter Handle ElectricStarter Outlet WARNING Read, understand, Choke 1 and follow all instruc- Control -- eo n-Out tions and warnings on the machine and ____Drift... - Page 11 Auger Control squeeze the buttonon thejoy-stickand pivot the AUGER joy-stick t o the rightor to the left. CONTROL Tochangethe angle/distance which snow isthrown, & pivotthejoy-stick forwardor backward. Wheel Steering Controls The left and rightwheelsteeringcontrolsare locatedon the undersideof the handles.Squeezethe rightcontrolto turn right;...

-

Page 12: Stopping The Engine

6. Asthe enginewarms,slowlyrotatethe chokecontrol Gas & Oil Fill-Up to the OFFposition.If the enginefalters,quicklyrotate Servicethe enginewith gasolineand oil as instructedin thechokecontrol back to FULLand then slowlyinto theTecumsehEnginesmanualpackedseparatelywith theOFF positionagain. yoursnowthrower.Readinstructionscarefully. 7. Whendisconnectingtheextensioncord, always Starting The Engine unplugtheend at thethree-prongwalloutlet before 1. Attachsparkplug wireto sparkplug. Makecertain the unplugging the oppositeend from the snowthrower. -

Page 13: To Engage Drive

3. Whendisconnecting theextensioncord, always 3. Releasethe augercontrol;the interlockmechanism unplugthe end at the three-prongwalloutlet before shouldkeepthe augercontrolengageduntilthe drive control is released. unpluggingtheoppositeend from the snowthrower. 4. Movethrottlecontrolto STOPposition. 4. Releasethe drivecontrolto stop boththe augersand the wheeldrive.To stopthe auger,both leversmust 5. Removethe ignitionkey (Do notturn key) to prevent be released. - Page 14 Shift Cable If the full rangeof speeds(forwardand reverse)cannot be achieved,referto the figureto the left and adjustthe shiftcable as follows: 1. Placethe shiftleverin the fastest forwardspeed position. 2. Loosenthe hex nuton the shiftcable indexbracket. Adjustments See Figure13. 3. Pivotthe bracketdownwardto take up slack in the cable.

-

Page 15: Making Adjustments

5. Loosenthe lowerhex nut on the drivecablebracket. See Figure16. 6. Positionthe bracketupwardto providemoreslack(or downwardto increasecabletension). 7. Retightenthe lowerhexnut. Making You canalso checktheadjustmentas follows: 1. With the snowthrowertippedforward(be certain to Adjustments drain gasolineor placeplasticfilm underthe gas cap if the snowthrowerhas alreadybeen operated),remove the framecover underneaththe snowthrowerby removing the self-tappingscrews.Referto Figure21 on page 17. - Page 16 disconnect spark plug wire before ARNING:Alwaysstopengineand performing any maintenance or adjust- ments. Always wear safety glasses during operation or while performing Shear Pin Spacers Bearing any adjustments or repairs. Engine Referto the separate Tecumseh Enginesmanualpacked with yourunit for all enginemaintenance. Lubrication 1.

- Page 17 "x Shave Plate and Skid Shoes The shaveplateand skid shoeson the bottomof the snow throwerare subjectto wear,Checktheseperiodi- caNyand replaceas necessary, Replacing Skid Shoe 1. Removefourcarriageboltsand lock nuts whichattach two skid shoesto the snowthroweron two sides.See Maintaining Figure19. Your Snow 2. Reassemble newskid shoeswith the same hardware. Makecertainthe skid shoesare adjustedto be level.

- Page 18 Auger Belt 1. Rollauger beltoff the pulleyas shownin Figure22. 2. a. Turnthe shoulderscrewa halfa turn and slideit out of the mountingbracket.See Figure23. b. Unhookspringto releasetensionon the auger belt. See Figure23. 3. Removeold belt and replacewith newbelt wrappingit aroundtheauger pulley.See Figure24. 4.

- Page 19 Drive Belt 1. a. Graspthe idlerpulleyand pivotit towardthe right. See Figure25. Inserta screwdriverthroughalign- ingholesin boththe idlerbracketand the engine. This will releasetensionon drivebelt. b. Rollthe augerbelt off the enginepulley. c. Lift the drivebeltoff enginepulley.See Figure25. Maintaining 2. Slip the drive beltoff the pulleyand betweenfriction wheeland frictionwheeldisc.

-

Page 20: Preparing Engine

If the snowthrowerwill not be usedfor30 daysor longer, Removeall gasolinefrom thecarburetorand the fuel or if it is the end of the snow seasonwhenthe last pos- tank to preventgumdepositsfromformingon these sibilityof snow is gone,the equipmentneedsto be stored partsand harmingtheengine. properly.Followstorageinstructionsbelowto ensuretop Runthe engineuntilthe fuel tank is emptyand it stops performance from the snowthrowerfor many moreyears. - Page 21 4. Carburetoroutof adjustment. 4. Contact MTDServiceCenter. further details, Contact aMTD authorized service center or call Engine overheats 1 carburetor notadjustedproperly, li Contact MTD serViCe Center: 1(800) 800-7310for assistance Excessive 1. Looseparts or damagedauger. Stop engineimmediately and Vibration disconnectsparkplug wire.Tighten all bolts and nuts.If vibration continues,haveunit servicedby a MTDServiceCenter.

- Page 22 Model 51VlL '_ _ _2_,...

-

Page 23: Parts List

731-2643 Clean-OutTool 29. 741-0662 FlangeBearing 30. 718-04071 ThrustCollar 712-04065 FlangeLockNut 756-0981A Flat ldler Pulley 31. 741-0663 FlangeBearing 710-0347 Hex Bolt,3/8-16x 1.75 32. 710-0642 TT Screw,1/4-20x 0.75 ¸ 790-00080 Augerldler Bracket 33. 790-00087A BearingHousing Parts List 736-0174 WaveWasher 34. 721-0325 Plug 738-0281 ShoulderScrew 35. - Page 24 Model 51VlL...

- Page 25 684-04109A HandleEngagement A ssemblyRH 34. 790-00131 JoystickBracket 738-04194 FlangeShoulderScrew 35. 710-04187 Hi-LoScrew,1/4-15x 0.5 731-04894A Lock Plate 36. 684-04116A 4-WayChute Control Assembly (IncludesRef.#57) 711-04287 Pivot Rod 37. 749-04142 UpperHandleLH 735-0199A RubberBumper 38. 710-04326 Screw,#8-16x0.50 710-04354 Screw,1/4-20x.375 39. 732-04219 ClutchLock Spring 731-04896A ClutchLock Cam 40.

- Page 26 Model 51VlL...

- Page 27 39. 738-04184 ShoulderScrew 710-1652 AB Screw,1/4-20x 0.625 731-05353 BeltCover 40. 790-00226 FrameCover 732-0705 CableGuide 41. 656-04025 FrictionWheelDiscAssembly 711-1268B ActuatorShaft 42. 618-04283 DriveShaft Assembly 746-04229 DriveClutchCable 43. 684-04159 FrictionWheelAssembly 732-0209 ExtensionSpring 735-04054 FrictionWheelRubberOnly 790-00207 DriveClutchCableGuide Bracket 44. 716-0136 RetainerRing 684-04156 Shift RodAssembly 45.

- Page 28 To locate the dealer in your area, check your Yellow Pages, or lasts, so the aboveexclusionsor limitationsmay notapplyto you. contact MTD LLC at RO. Box 361131,Cleveland, Ohio 44136-0019,or In no eventshall recoveryof any kind be greaterthan theamountof the call 1-800-800-7310 or 1-330-220-4683 or log on to our Web site at purchasepriceof the productsold.

Need help?

Do you have a question about the 31BE5MLG729 and is the answer not in the manual?

Questions and answers