Table of Contents

Advertisement

Quick Links

OWNER'S

MANUAL

MODEL NO.

315.275062

CAUTION:

Read Rules for

Safe Operation

and All Instruc-

tions Carefully

CRRFTSMRN

Industrial Electronic

Plunge Router

Double Insulated

Thank You for Buying

Craftsman Tools

Warranty

Introduction

Unpacking

Features

Adjustments

Operation

Maintenance

Repair Parts

Designed exclusively lot and sold only by

SEARS, ROEBUCK AND (30, Ho[fman Estates, IL 60t 79

6-95

Prlnled in U,S,A

Advertisement

Table of Contents

Summary of Contents for Craftsman 315.275062

- Page 1 Plunge Router tions Carefully Double Insulated Warranty Introduction Unpacking Features Adjustments Operation Thank You for Buying Maintenance Craftsman Tools Repair Parts Designed exclusively lot and sold only by SEARS, ROEBUCK AND (30, Ho[fman Estates, IL 60t 79 Prlnled in U,S,A 6-95...

-

Page 2: Rules For Safe Operation

It thisCraftsmanIndustrial E lectronic PlungeRouterfails due to a defectin matedal orworkmanship withinoneyear fromthe dateof purchase,Sears willrepairit free of charge, Thiswarrantyapplies onlywhilethis productis in use in the United States. WARRANTY SERVICE IS AVAILABLE BY SIMPLY RETURNING THE TOOL TO THE NEAREST SEARS STORE OR SERVICE CENTER THROUGHOUTTHE LINrrED STATES. This warrantygives you specifto legal rights, and yDumay also haveother rights whichvary from stateto state. - Page 3 Do not operate tool while under the influence oFdrugs, alcohol, or any medication WHEN SERVICING USE ONLY IDENTICAL CRAFTSMAN REPLACEMENT PARTS. POLARIZED PLUGS, To reduce the rfskofelectricshock,thistoolhasa polarizedplug(one blade iswiderthan the other), This plugwtl!fit in a polarized outlet only one way. If the plugdoes not fit fully in the outlet, reverse theplug.

- Page 4 UNPACKING Yournew plungerouter comesfullyassembled. After removing it fromthe box.inspecti_carefufly to makesure that it Is not damagedend that no partsare missing, See Figure Io The following aocesso_es should also be included in the box" 1o Combination Wrench(3/8 In - 718In.,) 4., Roller(Contour)Guide 2, 1t4In.

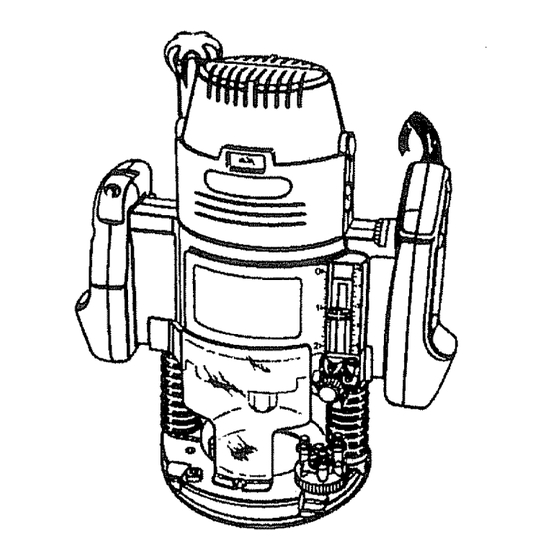

- Page 5 FEATURES KNOW YOUR ELECTRONIC ROUTER Belote altempting to use your router, familiarize yourse|l with all operating features and safely requirements. See Figures 1 and 2. DE 'cobOL KNOB" FRONT VIEW OF ROUTER SPINDLE LOCK INDICATOR LIGHT POSILOCK SPINDLE LOCK LOCK HANDLE SWITCH HANDLE PLUNGE RELEASE...

-

Page 6: Electrical Connection

FEATURES REAR VIEW OF ROUTER DEPTH CONTROL KNOB VARIABLE SPEED CONTROL SELECTOR POWER CORD LOCK HANDLE "LOCK*ON BUTTON =ON-OFF TRIGGER SWITCH HANDLE SPEED SELECTION CHART ACTUATOR 5/!6-18 UNC-2E HEX NUT ROUTER BASE FLANGE SUBBASE COLL.ETNUT Fig 2 • ..L .., UJ,,.,tvu,u_ I I UII'L .. - Page 7 ADJUSTMENTS INSTALLING/REMOVING CUTTERS SPINDLE LOCK See Figures3, 4, and 5 _ INDICATOR LIGHT POSILOCK UNPLUG YOUR ROUTER, SPINDLE LOCK TO LOCK Place the posilock spfndte lock Into lock position, See Figure3. NOTE: if spindledoes not lock, turncotlet nut withwrench,applylng pressureat the sametime to Ihe spindlelock with yourthumbor finger.

-

Page 8: Depth Of Cut Adjustments

ADJUSTMENTS DEPTH OF CUT ADJUSTMENTS See Figures6, 7 and 8 When routing a_groovethat is too deep to safely cut in one pass, it is beet to make the cut in several passes.We recommendthatcute be made ala depth not exceedingU8 In,.and thatseveral passes be made re reachdeepercuts Properdepth ofcut dependson severallactors: horsepower of router motor,typeof cutterbeingused, ahd typeofwood being routed. - Page 9 ADJUSTMENTS DEPTH CONTROL KNOB F_ure 9,. Fineadjustments can be made tothe depth otcut by use el the depth controlknob, Anotherprimaryusa of the depth controlknob ts settingdepthof cutwhen ro_er is mounted upside downona fouler table. NOTE: Theweightofthemuter ;_us the awkward poslt_onit is In whenmountedto a muter table make tt necessaryto usa depth controlknob_ TO SET DEPTH OF CUT WITH DEPTH...

- Page 10 ADJUSTMENTS DEPTH STOP SYSTEM (Continued) 5+ Raisecutterbydepmsstng, p lungereleaseactuator. Place routeron fiatsurface,and lowerrouteruntiltipof cullerbarelytouchesfiat sumface Squeeze plungelock actuator to lock cutterat "zero" depthofcut° Turnadlustmentknob counteroloct,:wise to lowerstop bar against the stop, then tightenlock knob secureiy The higheststopnew becomesthe "zero' depthofcut setting Depress plungereleaseactuator andmiss router_Re- tate stop block _,othat next highestdepth stopaligns...

-

Page 11: Operation

OPERATION "LOCK-ON" BUTTON See Figure13 The "on.off" tdggerof your router isequippedwith a "lock- on" featute which ls convenientwhen operatingfor ex. tendedpedodsof time, The 'lock.on"buttonis totaled In the upperportionof the "on-off"tdggero it workssimilarto a rocker switch.,To lock on, futiy depress "on-off" trigger, then depress"lock-on=button in topo! 'on-off"triggerand release. -

Page 12: Proper Feeding

As a result, the cut produced workpiecao See Figure 15, may have dppled, instead of straight s_des., See Figure tS_ Your Craftsman router is an extremely high-speed tool "Too-slow feeding" can also cause your router to take off tn (25,000 RPM no-load speed}, and will make clean, smooth a wrong direction from the Intended line of cut. -

Page 13: Depth Of Cut

OPERATION DEPTH OFCUT As previouslymentioned, the depth of cut is important becauseit affectslhe rate of feed which,in turn,affectsthe DEPTH WIDTH OF CUT quality of a cut (and, also,the possibility of damageto your muter motor andbit). Adeep cutrequiresa s_owerfeed then a shallowone,and e toodeep cutwill causeyou to slowlhe feedso much that the bit is nolonger cutting, {t is scraping, .... -

Page 14: Edge Routing

OPERATION EDGE ROUTING Place routeron workpieca,making sure Ihe router bitdoes ROUTER notcontactworkplace Turnrouter on and letmotor build to its futlspeed Beginyour cut, gradually feeding cutterInto workpfeceo -_LOT Uponcompletionof cut,tam motor off and let it coma to a TOP EDGE SHAPING completestopbefore removingrouter from work surface. - Page 15 OPERATION ROUTING GROOVES See Figure22._ When routing acrossthe face ofboards,set muterat desired depthofcut,placetheedgeof routerbaseagainstwod_piece, and turn on your muter. Slowly feed the cutterinto the workplacealongdesired cutlino. When muting straight cuts across stock, clamp a straight- edge to the workplace to USe as a guide_ Positionthe straightedgepsmtlel to the cutllne and offsetthe distsnca UNCUTEDGE betweenthe cuttingedge of the cutterand the edge of the...

- Page 16 OPERATION ROUTING WITH A ROLLER GUIDE See Figures26 and27. A roiterguide has been suppfledwithyourrouter,it is useful for routing uneven edges and trimming laminates The miler guide attachesto the guide holder as shown In figure26. Itcanbe adjustedin andoutaswellas upand down, Therotlerguide ridesagalnsttheuncutedge oftt_ workpiece When routingadecorative groove alongan unevenedge,the distance from roiter guide to cutletshouldbe the same as the distance from the desired cut and ihe edge of the...

-

Page 17: Routing With Guide Bushings

OPERATION ROUTING WITH GUIDE BUSHINGS (Cont'd) secure templatelethe workplace Set routertodesireddepth of cut and turnIf on- Place routerbase on the _mptate with the co]lar of tl_e guide bushing against Ihe edge of the template. Lower cutter into the workplace and proceed around template, keepingguide bushing pressed againsl templateedge, When routingwithiemplate guidebushings It isnecessary to... -

Page 18: Maintenance

MAINTENANCE GENERAL Onlythe partsshownon pads list,page 23, are Intendedto When electdc Iools are used on fiberglass boats, sports be repatred or replaced by the customer AI! other parts cars, wallboard, spackling compounds,or plaster, it has represent an important p art of the doubleinsulation sy.stem been foundthat they are subject to acceleratedwear and and Shouldbe servicedonly by a qualified Seam _ervice possiblepremature failure, as the fiberglass chips and... - Page 19 MAINTENANCE PLUNGE LOCK ACTUATOR ADJUSTMENTS COMPRESSION SeeFigure32 SPRING The plunge tack actuator has been properly set at the factory and no initial adjustments should be required, However, after extended use slight readjustment mlty,be required, If this situation occurs, make adjul_tments as follows: RELEASE _1..

- Page 20 MAINTENANCE DEPTH CONTROL KNOB ADJUSTMENTS SeeFigure 34. The depth control knob ts apdng loaded against hex nut to prevent router motor from acddently separating from router base,, ff depth control knob is turned too far up depth adjustment rod, the spring wllf cause depth control knob to pop off before hex nut., Do not remove hex not.

- Page 23 CRAFTSMAN ROUTER - MODEL NUMBER 315.275062 ....| The model number will be found on a plate _hed to the motor housing. AJways men_,on the model number m at! correspondence regard_j your ] 'e r PAGe. FO. m ORDe.l I,S O.S...

-

Page 24: How To Order Repair Parts

Industrial Electror c OWNER'S Plunge Router MANUAL Double Insulated SERVICE Nov,,that you have purchased your router, should e need ever exist for repair paris or so.ice, simply contact any Seam Service Center and most Sears, Roebuck and Co stores. Be sure to provide all pertinent facts when you cat{ or visit.

Need help?

Do you have a question about the 315.275062 and is the answer not in the manual?

Questions and answers