Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Craftsman 917.292350

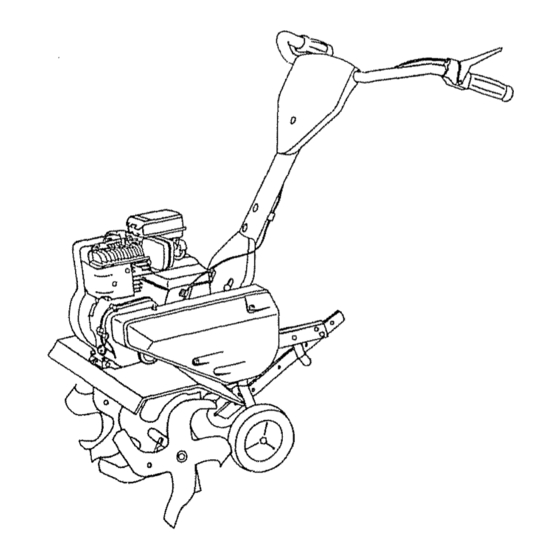

- Page 1 OWNER'S MANUAL 5,0 HP Caution: CH TUNEW_DTH Read and follow all Safety Rules FRONT TiNE T_LLER and instructions Before Operating This Eqmpment o AssembUy Operation Customer Responsibilities Service and Adjustments - Repair Parts Sears, Roebuck and Co., Hoffman Estates, UL 60179 U.S.A.

-

Page 2: Accessories

SAFETY RULES Safe Operation Practices for Walk-Behind PoweCed Rotary Tillers TRAINING • Keep children and pets away.. Read the Owner's Manual carefully. Be thoroughly Do not overload the machine capacity by attempting to familiar with the controls and the proper use of the til! too deep at too fast a rate, equipment, Know how to stop the unit and disengage Never operate the machine at high speeds on slippery... - Page 3 ON CRAFTSMAN TILLER For one (1) year from date of purchase, when this Craftsman Tiller is maintained, lubricated, and tuned up according to the operating and maintenance instructions in the owner's manual, Sears will repair free of charge any defect in material or workmanship.

-

Page 4: Table Of Contents

SAFETY RULES ............MAINTENANCE SCHEDULE ........SERVICE & ADJUSTMEI_JTS ......... 14-17 CUSTOMER RESPONSIBILITIES ..... 3, 12.,14 PRODUCT SPECIFICATIONS ........STORAGE ..............WARRANTY ..............TROUBLESHOOTING ..........ACCESSORIES ............. REPAIR PARTS-TILLER ........20-25 ASSEMBLY ..............REPAIR PARTS-ENGINE ........26-30 OPERATION ............. 8-11 SERVICE/PARTS ORDERING .... - Page 5 i..=,,,,==,,, _L,I._ ill, ACCES$ORUE$ These accessories were available when the tiller was purchased. They are also available at most Sears Retail outlets, Catalog and Service Centers. Most Sears Stores can order repair parts for you when you provide the model number of your tiller.

- Page 6 ..• : ..,,,,=== = ..• ASSEMBLY Your new tiller has been assembled at the factory with exception of those parts left unassembled for shipping purposes,, To ensure safe and proper operation of your tiller all parts and hardware you assemble must be tightened securely° Use the correct tools as necessary to insure proper tightness, TOOLS REQUIRED FOR ASSEMBLY...

-

Page 7: Depth Stake

..=, , i, u ,,,i, i,l_[j_ = ..ASSEMBLY i, = ,i,,=,,,i ....... = ,, ,i, ,=m INSTALL DEPTH STAKE ASSEMBLY UNPACK CARTON & INSTALL HANDLE (See (See Fig. 3) Fig, 2) Insert stake support between engine bracket halves i, =, i,=,= , i,,i,i .. - Page 8 OPERATHO KNOW YOUR TILLER READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TILLER. Compare the illustrations with your tiller to familiarize yourself with the location of various controls and adjustments. Save this manual for future reference. ,....' ..These symbols may appear on your Tiller or in literature supplied...

- Page 9 ,' ,, ...._,r,., OPERATION The operation of any tiller can result in foreign objects thrown into the eyes, which can result in severe eye damage. Always wear safety glasses or eye shields before starting your tiller and while tilling. We recommend a wide vision safety mask over the spectacles or standard safety glasses.

- Page 10 OPERATHON .., LI_ ... TO TRANSPORT ADD GASOLINE Fill fuel tank_ Use fresh, clean, regular unleaded gasoline. (Use of leaded gasotine wil_increase carbon ing, allow tiller engine and muffler to and lead oxide deposits and reduce valve tife) CAUTION: Before lifting or transport- cool.

- Page 11 _, , r ..I ..,,,,H=I=, OPERATIO You will find tilling much easier if you leave a row SPARK untilled between passes. Then go back over the entire PLUG area at right angles (See Fig 9)There are two reasons for doing this..

- Page 12 CUSTOMER RESPONS BmL TSES ---- , ....MAINTENANCE SCHEDULE FILL IN DATES AS YOU COMPLETE SERVICE DATES REGULAR SERVICE Check Engine Oil Le,2el Change Engine Oil ..,, i,i O11 Pivot Points inspect Spark Arrester Muffler illU,i n u, ll_ i:_,_ Inspect Air Screen Clean or Replace Air Cleaner Cartridge...

- Page 13 CUSTOME LLmES ......i, H I AL ........,, • ,i,,, Disconnect spark plug wire before performing any maintenance (except carburetor adjustment) to prevent accidental starting of engine° Prevent fires! Keep the engine free of grass, leaves, spilled oil, or fuel. Remove fuel from tank before tipping unit for maintenance.

- Page 14 CUSTOME RESPONSgBBL T ES ...., lu ..,....i ..MUFFLER TRANSIVtlSS_ON Your transmission is sealed and will not require lubrication Do not operate tiller without muffler. Do not tamper with unless serviced. exhaust system. Damaged mufflers or spark arresters CLEANUNG could create a fire hazard.

- Page 15 SERVmCE AN ADJUSTMENTS FINAL CHECK "ON" POSITION MID-WIDTH TILLING - 22" PATH (See Fig. 17) ° Assembte holes "A" in tine hubs to holes "C" in tine • Withtine control"ON" (held down to handle) push down shaft. on handle to raise tines off the ground_ Slowly pull recoil starter handle while observing tines.

-

Page 16: V-Belt

TO REPLACE V-BELT (See Fig. 20) TO REMOVE BELT GUARD (See Fig. 21) Replace V-belt if it has stretched considerably or if it has ° Remove cap nut and washer from side of belt guard,, cracks or frayed edges. ° Loosen (do not remove) tine shield nut on underside of Beit guard must be removed to service belt. - Page 17 SERVICE AND ADJUSTMENTS ENGINE THROTTLE LINKAGE THROTTLE STOP TO ADJUST CARBURETOR (See Fig. 22) The carburetor has a high speed fixed jet and has been preset at the factory and adjustment should not be neces- sary. However, minor adjustments may be required to compensate for differences in fuel, temperature, altitude or Ioad_ If the carburetor does need adjustment, proceed as fotlows_...

- Page 18 ..' ..I ..i,,i ,,, ,..,-i-,_ ....STORAGE ENGINE Immediately prepare your tiller for storage at the end of the season or if the unit will not be used for 30 days or more. Drain oil (with engine warm) and replace with clean oil. (See "ENGINE"...

-

Page 19: Wheels

=FROUBLESHOO=NNG POINTS PROBLEM CAUSE CORRECTION Will not start Out of fuel Fill fuel tank Engine not "CHOKED" properfy See'q_o START ENGINE" in the Operation section Engine flooded. Wait several minutes before attempting to start Dirty air cleaner Clean or replace air cleaner cartridge, Water tn fuel Drain fuel tank and carburetor, and refill tank with fresh... - Page 20 REPAIR PARTS TILLER = - MODEL NUMBER 917;292350 HANDLE ASSEMBLY PART DESCRIPTION PART DESCRIPTION 121145X Clip, Cable Boit 5!16-18 x 2-1/2 72010520 110514X Assembly, Panel and Tube '137118 Panel, Control 98000129 Nut, Flange 152094 Assembly, Handle Column STD533107 Bolt, Carriage 5/16-18 x 3/4 4 9266R Grip, Handle...

-

Page 21: Belt Guard

REPAIR PARTS TILLER - - MODEL NUMBER 917:292350 BELT GUARD AND PULLEY ASSEMBLY PART DESCRIPTION PART DESCRIPTION 121313X 110528X Bolt, BeltGuard Assembly, Bracket, Belt Guard 9484R CNp, CabIe 12000036 Ring, Klip 86777 Screw, Hex Washer Head, Slotted, STD541237 Nut, Hex, Jam 3/8-16 Thread Cutting #10-24 x 1/2 Type D 9178R Pulley, Idler... - Page 22 REPAIR PARTS "TILLER - - MODEL NUMBER 917_292350 WHEEL AND DEPTH STAKE ASSEMBLY PART DESCRIPTION PART DESCRIPTION 9194R Pin, Clevis 120958X Washer 74780520 Bolt, Hex Head 5/18-18 x I-I/4 5388J Spring, Stake STD523107 Bott, HexHead 5/16-18x3/4 121t17X Bolt, Shoulder STD541031 Nut, Hex 5/16-18 9188R Wheel...

- Page 23 REPAIR PARTS TILLER- - MODEL NUMBER 917_292350 TINE ASSEMBLY " DESCRIPTION PART PART DESCRIPTION 674A63 Tine, Inner, LH_ 674A66 Tine, Outer, R.t4.. 674A65 Tine, Outer, LH° STD624008 Clip, Hairpin 4929H Pin, Clevis 674A64 Tine, Inner, R.H.

- Page 24 REPAIR PARTS TILLER - = MODEL NUMBER 917:292350 TRANSMISSION PART DESCRIPTION PART DESCRIPTION 9173R 74760524 Bolt, Hex 5/t6-18 x 1-1/2 Grade 2 Spacer, Split STD54143I 74780652 Bolt, Fin, Hex 3/8-16 x 3-1/4 Nut, Hex, Keps 5/16-18 UNC 19091412 Washer 13/32 x '13/16 x 11 STD551037 Washer 9/32 x 7/8 x 12 Gauge 19092016...

- Page 25 REPAIR PARTS TILLER - - MODEL NUMBER 917.292350 DECALS PART DESCRIPTION 158094 Decal, Logo 158093 Decal, Logo 1580O5 Decal, Logo 158006 Decal, 5HP/24 Sears 137539 Decal, Caution, Tine Control 120431X Decal, Hand Placement t10719X Decal, Operation and Lubrication 120075X Decal, Warning, Rotating Tines 272931 Decal, Engine 272630...

- Page 26 REPABRPARTS TILLER - - MODEL NUMBER 917.292350 BRIGGS & STRATTON ENGtNE - - MODEL NUMBER 137202,TYPE NO. 0116-01...

- Page 27 REPAUR PARTS TILLER - - MODEL NUMBER 917,292350 BRIGGS & STRATTON ENGINE -- MODEL NUMBER 137202,TYPE NO. 0116-01 127A i,iii1,, iiii _;¢_ 124 611 I , u,, 190A...

- Page 28 REPAHF_PARTS TILLER - o MODEL NUMBER 917.292350 BRIGGS & STRATTON ENGINE - - MODEL NUMBER 137202, TYPE NO. 01 !6-01 REQUIRES SPECIAL TOOLS TO INSTALL. SEE REPAIR INSTRUCTION MANUAL. 332_ 59 _ 459 _:_ 689 O...

-

Page 29: Throttle

REPAIR PARTS TILLER - - MODEL NUMBER 917;292350 BRIGGS & STRATTON ENGINE - - MODEL NUMBER 137202, TYPE NO. 0116-01 KEY PART KEY PART NO, NO. DESCRIPTION NO. NO. DESCRIPTION 497144 CyfinderAssembly 93312 Retainer, intake Valve and Exhaust 399268 Bushing, Cylinder Spring 299819 * Seal, Oil... - Page 30 REPAIR PARTS TILLER - o MODEL NUMBER 917.292350 BRIGGS & STRATTON ENGmNE -- MODEL NUMBER 137202,TYPE NO. 0116-01 KEY PART KEY PART NOo NO. DESCRIPTION NO. NO. DESCRIPTION 203 280720 Bell Crank 528 231550 Tube, Breather 231520 Screw, Shoulder 529 67838 Grommet, Breather Tube Filter, Air 262279...

- Page 31 SERVICE NOTES...

-

Page 32: Tines

® CH TINE WIDTH FRONT TgNE TroLLER MODEL NO. Each tiller has its own model number, Each engine has its own model number. 917.292350 The model number for your filler will be found on a plate attached to the right hand engine bracket. The model number for your engine will be found on the blower housing of the engine, All parts listed herein may be ordered from any Sears, Roebuck and COr.

Need help?

Do you have a question about the 917.292350 and is the answer not in the manual?

Questions and answers