Table of Contents

Advertisement

TopPage

[1] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . . 2-1

[3] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[4] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[5] DISASSEMBLY AND ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Parts marked with "

" are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

SERVICE MANUAL

DIGITAL MULTIFUNCTIONAL

SYSTEM OPTION

FINISHER

PUNCH UNIT

MODEL

CONTENTS

SHARP CORPORATION

CODE: 00ZMXFN27/S2E

MX-FN27

MX-PN14

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Advertisement

Table of Contents

Summarization of Contents

NOTE FOR SERVICING

Precautions for Servicing

Essential safety measures and procedures to follow before performing maintenance or repairs.

Screw Tightening Torque

Recommended torque values for various screws to prevent damage and ensure proper assembly.

[1] SPECIFICATIONS

Finisher Section

Details about the finisher's type, transportation standards, loading method, mode, and power.

Stacker Section

Specifications for offset quantity, stacking capability, and output capacity of the stacker.

Staple Section

Information on staple positions, sheets per staple, and supply method for stapling.

Staple-free Staple Section

Details on staple-free stapling positions and the number of sheets it can handle.

Manual Staple Section

Specifications for manual stapling positions and sheet capacity.

Punch Unit

Technical specifications for the punch unit, including type, paper handling, and dimensions.

Ejectable Paper Size/Weight

Comprehensive table detailing paper sizes and weights compatible with various finisher functions.

Loading Number Per Size

Capacity information for loading different paper sizes and types in the finisher.

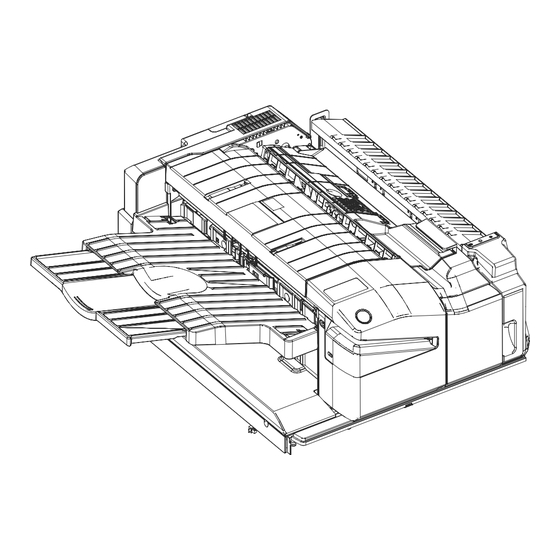

[2] EXTERNAL VIEW AND INTERNAL STRUCTURE

External View

Identification of external parts of the finisher through diagrams and labels.

Cross View

Internal components and their locations shown in a cross-sectional view.

Main Unit

Identification of key components within the main unit of the finisher.

Sensors

Locations and names of various sensors used for detecting paper and unit status.

Solenoid and Switch

Identification of solenoids and switches controlling finisher functions.

Motors

Identification and naming of motors responsible for driving finisher mechanisms.

PWB

Identification of Printed Wiring Boards (PWBs) within the finisher.

Punch Unit

Detailed view of the punch unit, including its sensors, motors, and PWBs.

[3] ADJUSTMENTS

Punch Unit (MX-PN14)

Procedures for adjusting the punch unit and its PWB destination settings.

[4] MAINTENANCE

Finisher

Maintenance tasks for the finisher section, including checks, cleaning, and replacements.

Punch Unit

Maintenance tasks for the punch unit, including checks and replacement cycles.

[5] DISASSEMBLY AND ASSEMBLY

Major Unit and Cover

Step-by-step guide for disassembling and assembling major external units and covers.

Main Unit Components

Details on disassembling key components within the main unit of the finisher.

Disassembly of Specific Units

Procedures for disassembling individual functional units like the punch and stapler.

[6] OPERATIONAL DESCRIPTION

Basic Configuration

Overview of the finisher's functional blocks: feed, processing tray, and stack tray units.

Basic Operation

Explanation of how the finisher receives commands and delivers paper.

Feed Unit

Description of the feed unit's function in delivering paper to the processing tray.

Processing Tray Unit

Details on how the processing tray unit aligns, shifts, and staples paper.

Staple Operation

Explanation of how the stapler unit staples paper based on paper size and mode.

Staple-free Staple Operation

Description of the clinch mechanism for staple-free stapling.

Stack Delivery Operation

How paper stacks are delivered from the processing tray using assist guides.

Paper Retainer Operation

Function of the paper retainer in holding stacks in the delivery tray.

Stack Tray Unit

Operation of the stack tray, including paper height detection and full detection.

Jam Detection

Explanation of sensors and switches used to detect jams and their types.

Power Supply

Information on the finisher's power supply and protective functions.

[7] ELECTRICAL SECTION

Actual Wiring Chart

Detailed wiring diagram illustrating electrical connections within the finisher.

Punch Unit

Wiring diagram specific to the punch unit and its connections.

Need help?

Do you have a question about the MX-PN14 and is the answer not in the manual?

Questions and answers