Table of Contents

Advertisement

Quick Links

Operator's Manual

Innershield

Magnum

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10045-F

|

Issue Date Jun - 24

© Lincoln Global, Inc. All Rights Reserved.

PRO Gun,

®

Classic

®

For use with machines having Code Numbers:

K115-1, K115-2, K115-3, K115-4,

K115-8, K115-10, K116-2,

K126-1, K126-2, K126-10,

K126-11, K126-12, K126-13

K126-14, K345-10

IEC 60974-7

GB 15579.7: 22013

Advertisement

Table of Contents

Summarization of Contents

SAFETY DEPENDS ON YOU

EXAMINE CARTON AND EQUIPMENT FOR DAMAGE IMMEDIATELY

Inspect incoming equipment for shipping damage before use.

KEEP YOUR HEAD OUT OF THE FUMES

Position yourself to avoid inhaling welding fumes and gases.

WEAR CORRECT EYE, EAR & BODY PROTECTION

Use appropriate personal protective equipment for welding.

SPECIAL SAFETY SITUATIONS

Special precautions for hazardous materials and conditions.

SECTION A: WARNINGS

CALIFORNIA PROPOSITION 65 HEALTH WARNINGS

Health warnings regarding diesel exhaust and welding fumes.

ARC WELDING SAFETY HAZARDS

Essential safety measures for arc welding operations.

QUALIFIED PERSONNEL REQUIREMENT

Emphasizes that only trained individuals should operate or maintain equipment.

ENGINE POWERED EQUIPMENT SAFETY GUIDELINES

Safety guidelines specific to engine-driven equipment.

ELECTRIC AND MAGNETIC FIELDS (EMF) SAFETY

EMF FIELD INTERFERENCE WITH PACEMAKERS

Warning for individuals with pacemakers regarding EMF exposure.

PROCEDURES TO MINIMIZE EMF EXPOSURE

Steps to reduce exposure to electric and magnetic fields.

ELECTRICAL SHOCK HAZARDS

PRECAUTIONS FOR ELECTRICALLY HAZARDOUS CONDITIONS

Safety measures for welding in damp or conductive environments.

ARC RAY HAZARDS

PROTECTION FROM ARC RAYS

Use of shields and protective gear against arc rays.

FUMES AND GASES HAZARDS

VENTILATION AND EXHAUST REQUIREMENTS

Ensuring adequate ventilation to remove hazardous fumes.

HANDLING TOXIC FUMES AND GASES

Managing risks associated with toxic welding byproducts.

FIRE AND EXPLOSION HAZARDS FROM SPARKS

FIRE PREVENTION MEASURES

Steps to prevent fires caused by welding sparks.

COMPRESSED GAS CYLINDER SAFETY

SAFE HANDLING OF GAS CYLINDERS

Guidelines for safe storage and use of gas cylinders.

ELECTRICAL EQUIPMENT SAFETY GUIDELINES

POWER SOURCE SAFETY PRECAUTIONS

Safety measures for electrically powered welding equipment.

INSTALLATION

PRODUCT TECHNICAL SPECIFICATIONS

Key specifications for the Innershield PRO & Magnum Classic Gun.

PRODUCT COMPONENT DETAILS

Information on essential gun components like tips and liners.

OPTIONAL GUN CONNECTOR KITS

Details on kits for connecting the gun to various feeders.

GUN TUBE GOOSENECKS

Specifications for different gooseneck tube types.

INSTALLATION

SPECIFIC MODEL TECHNICAL DATA

Detailed specifications for specific K115, K116, K345, K126 models.

GUN MODEL OVERVIEW

Comparison of different Innershield PRO & Magnum Classic gun models.

EXPENDABLE PARTS LIST

List of consumable parts for the gun.

INSTALLATION

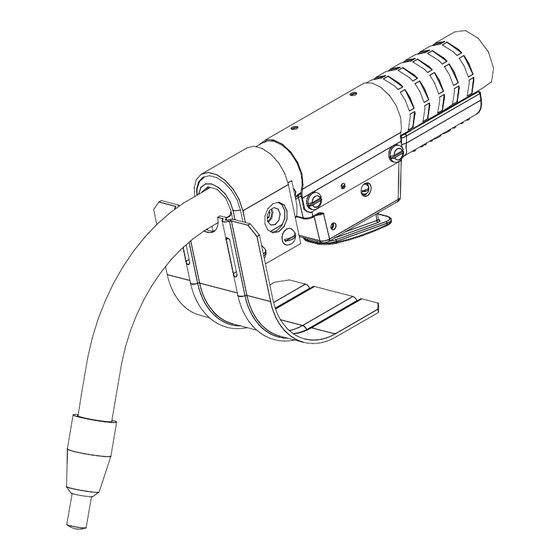

GENERAL PRODUCT DESCRIPTION

Overview of the Innershield PRO & Magnum Classic Gun design and features.

RECOMMENDED WELDING PROCESSES

Guidance on suitable welding processes for the gun.

PROCESS AND EQUIPMENT LIMITATIONS

Constraints on usage with specific processes or equipment.

INSTALLATION

CONNECTING TO LINCOLN FEEDERS

Step-by-step guide for connecting to Lincoln wire feeders.

CONVERTING GUNS FOR OTHER FEEDERS

Procedures for adapting the gun for non-Lincoln feeders.

K466/K613 INSTALLATION PROCEDURES

Specific installation steps for K466/K613 connector kits.

INSTALLATION

K466-5 FEEDER CONNECTION

Installation for L-Tec feeders using K466-5 kit.

K466-6/K466-7/K466-9 FEEDER CONNECTION

Installation for Wirematic/Hobart/SP100T feeders.

K613-2/K613-7 FEEDER CONNECTION

Installation for Tweco #5 compatible feeders.

K613-6 FEEDER CONNECTION

Installation for Lincoln 3/32" feeders.

INSTALLATION

INSTALL AND TRIM CABLE LINER

Instructions for installing and trimming the cable liner.

MILLER FEEDER CONNECTION

Connecting the gun to Miller wire feeders.

HOBART FEEDER CONNECTION

Connecting the gun to Hobart wire feeders.

L-TEC FEEDER CONNECTION

Connecting the gun to L-Tec wire feeders.

INSTALLATION

LINCOLN WIREMATIC/POWER MIG FEEDER CONNECTION

Connecting to specific Lincoln feeders.

TWECO ADAPTED FEEDER CONNECTION

Connecting to Tweco feeders.

LINCOLN 3/32" DIAMETER WIRE FEEDER CONNECTION

Connecting for 3/32" wire to Lincoln feeders.

OPERATION

ELECTRODES AND EQUIPMENT SELECTION

Choosing the correct electrodes and equipment for the gun.

MAKING A WELD PROCEDURE

Step-by-step guide for performing a weld.

AVOIDING WIRE FEEDING PROBLEMS

Tips for preventing common wire feeding issues.

ACCESSORIES

WIRE FEEDER CONNECTION KITS

List and specifications of wire feeder connection kits.

MAINTENANCE

MAGNUM LINER REMOVAL AND INSTALLATION

Detailed instructions for Magnum liner servicing.

MAINTENANCE

GUN TUBE AND NOZZLE MAINTENANCE

Procedures for maintaining gun tubes and nozzles.

CABLE LINER CLEANING

How to clean the cable liner for optimal performance.

TROUBLESHOOTING

GUIDE TO USING TROUBLESHOOTING

Instructions on how to effectively use the troubleshooting guide.

TROUBLESHOOTING

NO WIRE FEED ON TRIGGER PULL

Troubleshooting steps for when the wire feed fails.

SLUGGISH WIRE FEED ON TRIGGER PULL

Diagnosing and resolving slow wire feeding issues.

TROUBLESHOOTING

INTERMITTENT WIRE FEED

Addressing inconsistent wire feeding during operation.

FREQUENT BIRDNesting/KINKING

Solutions for wire birdnesting and kinking problems.

CONTACT TIP BURNBACK ISSUES

Troubleshooting contact tip burnback.

POOR WELD BEAD APPEARANCE

Identifying causes for unsatisfactory weld bead quality.

UNEXPECTED WIRE FEED (NO TRIGGER)

Resolving wire feeding without trigger activation.

Need help?

Do you have a question about the Innershield PRO Magnum Classic K126-12 and is the answer not in the manual?

Questions and answers