Summarization of Contents

General Information

Safety

Explains safety designations, general guidelines, personnel qualifications, and specific safety actions.

Electrical Safety

Covers electrical hazards like sudden start-up, shock, and overload protection.

High Temperature Safety

Addresses hazards related to hot surfaces and spraying water.

High Pressure Safety

Details risks associated with exceeding maximum working pressure and thermal expansion.

Transport and Storage

Transport and Handling Requirements

Guidelines for safe transport and handling to prevent damage during transit.

Uncrating and Lifting

Procedures for safely removing the pump from its crate and lifting it.

Receipt, Inspection, and Damage Reporting

Steps for checking received pumps for shortages or damages and reporting them.

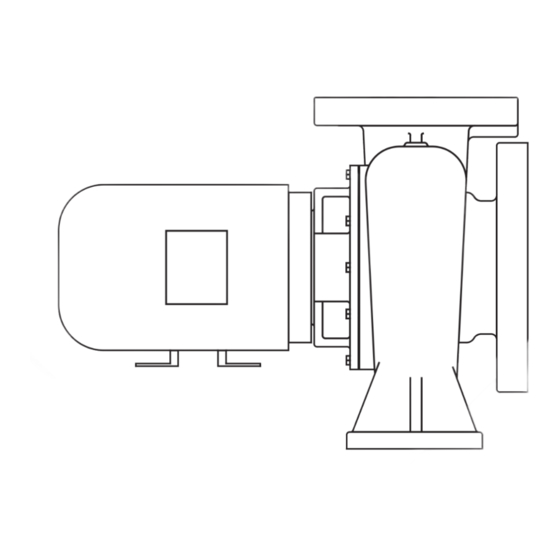

Product Description

Unpacking

Instructions for safely unpacking the pump unit and its components.

Storage

Guidelines for short-term and long-term storage of the pump unit.

Configuration

Details the available pump models and optional features.

NSF Certifications Available

Information on NSF certifications for pumps, including specific requirements.

Pump Installation

Pump Location

Recommendations for the optimal placement of the pump unit for accessibility and performance.

Foundation

Requirements for creating a stable and rigid foundation for the pump unit.

Setting the Pump

Procedures for placing the pump unit on the foundation and initial checks.

Leveling The Pump

Techniques for accurately leveling the pump unit using spirit levels.

Piping and Connections

Guidelines for anchoring, supporting, and aligning piping to the pump.

Suction Piping

Recommendations for short, direct suction piping to minimize head loss.

Reducers

Proper installation of eccentric and straight taper reducers on suction nozzles.

Discharge Piping

Recommendations for short, direct discharge piping to reduce friction loss.

Valves

Importance of discharge and foot valves for priming and control.

Flooded Suction

Specific requirements for flooded suction installations and gate valve placement.

Expansion Joints

Use of expansion joints to prevent piping strain and transmit forces.

Strainers and Screens

Importance of strainers and screens for preventing pump clogging.

Alignment

General Alignment

Importance of checking and maintaining alignment after installation and grouting.

Initial Alignment of Flexible Coupling

Procedures for aligning the pump and driver shafts using flexible couplings.

For Fine Alignment, 3500 RPM Operation, For All Other Coupler Types

Using dial indicators for precise alignment with specific tolerances.

Pipe Alignment

Ensuring proper piping alignment before connection to avoid strain.

Pump Operation

Lubrication

Recommendations for bearing lubrication frequency and type.

Rotation

How to check motor rotation direction before connecting the coupling.

Guarding

Ensuring all guards are in place and secure before start-up.

Priming and Filling

Steps to ensure the pump is completely filled with liquid before starting.

Foot Valve Priming

Using a foot valve for priming on suction lift applications.

Vacuum Priming

Methods for removing air using vacuum equipment.

Inductor Priming

Method of priming using a priming inductor and high-pressure liquid.

Shaft Sealing Settings and Adjustments

Mechanical Seals

Information on the construction, function, and maintenance of mechanical seals.

Start-up, Operation, and Shutdown

Valve Setting at Start-up

Proper setting of discharge and suction valves during pump start-up.

Pump Maintenance and Service

Operation

Key points to ensure before starting the pump.

Starting Up

Step-by-step procedure for safely starting the pump.

Shut Down

Recommended sequence for safely stopping the pump.

Mechanical Seal Maintenance

Procedures for maintaining mechanical seals, including break-in period.

Recommended Spare Part List

List of essential spare parts to keep on hand for maintenance.

Fastener Torque and Sequence

Importance of correct fastener torque values for assembly and maintenance.

Repairs

Complete Pump Disassembly - Model 1620/1650

Detailed steps for completely disassembling the pump models.

Inspection of Components

Guidance on inspecting disassembled pump components for wear or damage.

Reassembly Procedures

Steps for reassembling the power frame, mechanical seal, and complete pump.

Troubleshooting Guide

Insufficient Pressure or Flow

Identifies causes and remedies for low or no pressure and flow.

Excessive Power Consumption

Lists potential causes and solutions for high power usage.

Abnormal Noise and Vibration

Troubleshoots causes of unusual noise and vibration issues.

Motor Fails to Start

Addresses common issues when the motor does not start.

Motor Runs Hot

Diagnoses and resolves problems related to an overheating motor.

Assembly Exploded View

Model 1650 Close Coupled Configuration

Exploded view showing components of the Model 1650 close coupled pump.

Model 1620 Frame Mounted Configuration

Exploded view showing components of the Model 1620 frame mounted pump.

Need help?

Do you have a question about the 1620 and is the answer not in the manual?

Questions and answers