Summary of Contents for Parker NX8

- Page 1 Servomotors NX Series Technical Manual PVD 3663 1 - PVD 3663_GB_NX_March 2017.Docx...

- Page 2 4 Boulevard Eiffel - CS40090 21604 LONGVIC Cedex - France manufacturer, with brand name Parker, declare under our sole responsibility that the products BRUSHLESS SERVOMOTORS TYPE NX1 / NX2 / NX3 / NX4 / NX6 / NX8 satisfy the arrangements of the directives : Directive 2014/35/EU : “Low Voltage Directive”, LVD...

- Page 3 Compliance with «UL» standards 3 - PVD 3663_GB_NX_March 2017.Docx...

- Page 4 Compliance with «UL» standards 4 - PVD 3663_GB_NX_March 2017.Docx...

-

Page 5: Table Of Contents

Speed ripple ........................ 35 3.2.8. Cogging torque ......................35 3.2.9. Rated data according to rated voltage variation ............36 3.2.10. Voltage withstand characteristics of NX series ............38 3.3. Dimension drawings ......................39 3.3.1. NX1 ..........................39 3.3.2. NX1 UL version ......................42 3.3.3. - Page 6 3.7.2. Temperature measurement with KTY sensors: ............87 3.8. Power Electrical Connections ....................88 3.8.1. Wires sizes ........................88 3.8.2. Conversion Awg/kcmil/mm²: ..................89 3.8.3. Motor cable length ....................... 90 3.8.4. Mains supply connection diagrams ................91 3.9. Feedback system ......................... 98 Resolver 2 poles transformation ratio = 0.5 –...

-

Page 7: Introduction

Reading and understanding the information described in this document is mandatory before carrying out any operation on the motors. If any malfunction or technical problem occurs, that has not been dealt with in this manual, please contact PARKER for technical assistance. In case of missing information or doubts regarding the installation procedures, safety instructions or any other issue tackled in this manual, please contact PARKER as well. -

Page 8: General Safety Rules

1.2.2. General Safety Rules Generality DANGER: The installation, commission and operation must be performed by qualified personnel, in conjunction with this documentation. The qualified personnel must know the safety (C18510 authorization, standard VDE 0105 or IEC 0364) and local regulations. They must be authorized to install, commission and operate in accordance with established practices and standards. -

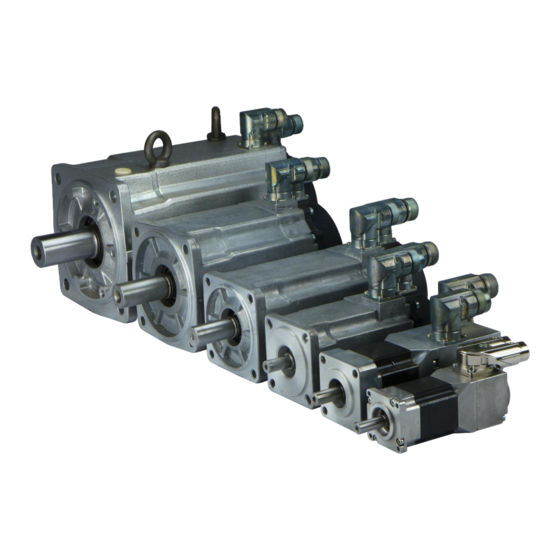

Page 9: Product Description

A large set of torque / speed characteristics, options and customization possibilities are available, making NX Series servomotors the ideal solution for most servosystems applications. Advantages - High precision... -

Page 10: General Technical Data

2.4. General Technical Data NX3, NX4,NX6 Motor type Permanent-magnet synchronous motor Magnets material Neodymium Iron Boron Number of poles IMB5 – IMV1 – IMV3 (EN60034-7) Type of construction IP64, IP64, Degree of protection IP65 in option IP65 in option ... -

Page 11: Product Code

7: with brake and KTY sensor Mechanical Interface 00: plain shaft 10: IP65 with plain shaft 01: key on shaft 11: IP65 with key on shaft Other: custom code Note: All assossiations are not possible – Contact Parker for checking. 11 - PVD 3663_GB_NX_March 2017.Docx... -

Page 12: Technical Data

At high speed, the calculation is more complex, and the derating is much more important. Please refer to PARKER to know the precise data of Torque derating according to ambient temperature at high speed for a specific motor. Illustration:... - Page 13 The following formula gives an indicative of the torque derating at low speed. But in any case refer to PARKER technical department to know the exact values At low speed the torque derating is given by the following formula for an water Inlet temperature >...

-

Page 14: Thermal Equivalent Torque (Rms Torque)

3.1.3. Thermal equivalent torque (rms torque) The selection of the right motor can be made through the calculation of the rms torque (i.e. root mean squared torque) (sometimes called equivalent torque). This calculation does not take into account the thermal time constant. It can be used only if the overload time is much shorter than the copper thermal time constant. - Page 15 Selection of the motor : The motor adapted to the duty cycle has to provide the rms torque M at the rms speed(*) without extra heating. This means that the permanent torque M available at the average speed presents a sufficient margin regarding the rms torque M rms.

-

Page 16: Drive Selection

Please refer to the drive technical documentation for any further information and to select the best motor and drive association. AC890 PARKER drive example: The rated current provided by the AC890 drive depends on its rated power and its mode selection. “Vector mode” is used for induction motors while “Servo mode” is used for brushless AC motors. - Page 17 BRUSHLESS MOTORS NX620EAR ELECTRONIC DRIVE (1) DIGIVEX 7.5/15 et DIGIVEX 8/16 (230V) (400V) (480V) Torque at low speed Permanent current at low speed 5.31 Example n°1 : Peak torque 26.7 Current for the peak torque 21.2 The application needs: Back emf constant at 1000 rpm (25°C)* 95.7 - a rms torque of 7 Nm at the rms speed of 2000 rpm, Nm/A...

- Page 18 Example n°2 : This times; the application needs : - a permanent torque of 5.8 Nm at low speed, - a rms torque of 5.8 Nm at the rms speed of 1890 rpm, - an acceleration torque of 8.8 - a maximal speed of 2800 rpm. Selection of the motor: The selected motor is the type NX620EAR.

-

Page 19: Current Limitation At Stall Conditions (I.e. Speed < 3 Rpm)

3.1.5. Current limitation at stall conditions (i.e. speed < 3 rpm) Recommended reduced current at speed < 3 rpm: reduced Warning: The current must be limited to the prescribed values. If the nominal torque has to be maintained at stop or low speed (< 3 rpm), imperatively limit the current to 70% of I (permanent current at low speed), in order to avoid an excessive overheating of the motor. -

Page 20: Nx Characteristics: Torque, Speed, Current, Power

3.2. NX Characteristics: Torque, speed, current, power… The torque vs speed graph below explains different intrinsic values of the next tables. Torque Peak Torque Permanent Rated Low Speed Power Torque Rated torque Stall torque 3 rpm Rated Speed speed speed 20 - PVD 3663_GB_NX_March 2017.Docx... -

Page 21: Nx Datas - Mains Voltage 230V

NX datas – Mains voltage 3.2.1. 230V Rated Rated Rated Peak Peak Max. speed speed Power Torque Current Torque Current Speed Motor torque Current Mpeak I peak Nmax (kW) (Nm) [Arms] [Nm] [Arms] [rpm] [Nm] [Arms] 230VAC power supply - single or three-phased – natural cooling NX110E_P 0,21 0,33... -

Page 22: Nx Datas - Mains Voltage 400V

NX datas – Mains voltage 3.2.2. 400V Rated Rated Rated Peak Peak Max. speed speed Power Torque Current Torque Current Speed Motor torque Current Mpeak I peak Nmax (kW) (Nm) [Arms] [Nm] [Arms] [rpm] [Nm] [Arms] 400 VAC power supply - three-phased – Natural cooling NX205E_V 0,225 0,287... -

Page 23: Further Data

3.2.3. Further Data Motor Moment of Winding Weight Kt (sine) Inductance Inertia Water Flow Motor Resistance without [Vrms/krpm] [Nm/Arms] [mH] [l/min] [ohms] brake [kgmm²] [kg] NX110A_J 22,4 0,318 12,00 14,9 NX110E_P 29,9 0,455 22,60 26,5 NX205E_S 21,9 0,322 8,89 24,3 NX205E_V 30,2 0,444... -

Page 24: Efficiency Curves

3.2.4. Efficiency curves Caution: The efficiency curves are typical values. They may vary from one motor to an other Caution: The efficiency curves are given for an optimal motor control (no voltage saturation and optimal phase between current and EMF) Caution: The efficiency curves do not include the losses due to the switching frequency. - Page 25 3.2.4.1. Series NX110E Constant efficiency curves of the motor NX110EAP Efficiency [%] 68 70 1000 2000 3000 4000 5000 6000 Speed [rpm] 3.2.4.2. Series NX205E Constant efficiency curves of the motor NX205E Efficiency [%] 1000 2000 3000 4000 5000 6000 7000 Speed [rpm] 25 - PVD 3663_GB_NX_March 2017.Docx...

- Page 26 3.2.4.3. Series NX210E Constant efficiency curves of the motor NX210E Efficiency [%] 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 Speed [rpm] 3.2.4.4. Series NX310E Constant efficiency curves of the motor NX310E Efficiency [%] 72 74 1000 2000 3000 4000 5000...

- Page 27 3.2.4.5. Series NX420E Constant efficiency curves of the motor NX420E Efficiency [%] 1000 2000 3000 4000 5000 6000 7000 Speed [rpm] 3.2.4.6. Series NX430E Constant efficiency curves of the motor NX430E Efficiency [%] 64 66 1000 2000 3000 4000 5000 6000 Speed [rpm] 27 - PVD 3663_GB_NX_March 2017.Docx...

- Page 28 3.2.4.7. Series NX620E Constant efficiency curves of the motor NX620E Efficiency [%] 1000 2000 3000 4000 5000 6000 Speed [rpm] 3.2.4.8. Series NX630E Constant efficiency curves of the motor NX630E Efficiency [%] 1000 2000 3000 4000 5000 6000 Speed [rpm] 28 - PVD 3663_GB_NX_March 2017.Docx...

- Page 29 3.2.4.9. Series NX820E Constant efficiency curves of the motor NX820E Efficiency [%] 76 78 1000 2000 3000 4000 5000 6000 Speed [rpm] 3.2.4.10. Series NX840E Constant efficiency curves of the motor NX840E Efficiency [%] 1000 1500 2000 2500 3000 3500 4000 4500 Speed [rpm]...

- Page 30 3.2.4.11. Series NX860E Constant efficiency curves of the motor NX860E Efficiency [%] 1000 1500 2000 2500 3000 Speed [rpm] 30 - PVD 3663_GB_NX_March 2017.Docx...

- Page 31 3.2.4.12. Series NX860V Constant efficiency curves of the motor NX860V Efficiency [%] 1000 1500 2000 2500 3000 3500 Speed [rpm] 3.2.4.13. Series NX860W Constant efficiency curves of the motor NX860W Efficiency [%] 1000 1500 2000 2500 3000 3500 4000 4500 Speed [rpm] 31 - PVD 3663_GB_NX_March 2017.Docx...

-

Page 32: Electromagnetic Losses

3.2.5. Electromagnetic losses Caution: Following data result from our best estimations but are indicative. They can vary from one motor to another and with temperature. No responsibility will be accepted for direct or indirect losses or damages due to the use of these data. (Following data are indicative) Type Tf [Nm]... -

Page 33: Time Constants Of The Motor

3.2.6. Time constants of the motor 3.2.6.1. Electric time constant: elec With following values given in the motor data sheet inductance of the motor phase to phase [H], ph_ph resistance of the motor phase to phase at 25°C [Ohm]. ph_ph Example: Motor series NX620EAR... - Page 34 Remarks: For a DC motor, the mechanical time constant represents the duration needed mech to reach 63% of the final speed when applying a voltage step without any resistant torque. However this value makes sense only if the electric time constant is much elec ...

-

Page 35: Speed Ripple

(neither external inertia nor resistant torque). 3.2.8. Cogging torque The typical cogging for a NX series below is the maximum value peak to peak in N.cm: Cooging Maxi Motor [N.cm]... -

Page 36: Rated Data According To Rated Voltage Variation

3.2.9. Rated data according to rated voltage variation The nominal characteristics and especially the rated speed, maximal speed, rated power, rated torque, depend on the nominal voltage supplying the motor considered as the rated voltage. The rated data mentioned in the data sheet are given for each association of motor and drive. - Page 37 Maximum speed: The former maximum speed N = 3900 rpm obtained with U =400 V and N =3900 rpm leads to the new maximum speed N given as follows: max2 3476 3900 3476 3900 N.B. If the rated voltage increases (U >...

-

Page 38: Voltage Withstand Characteristics Of Nx Series

3.2.10. Voltage withstand characteristics of NX series The motors fed by converters are subject to higher stresses than in case of sinusoidal power supply. The combination of fast switching inverters with cables will cause overvoltage due to the transmission line effects. The peak voltage is determined by the voltage supply, the length of the cables and the voltage rise time. -

Page 39: Dimension Drawings

3.3. Dimension drawings 3.3.1. 39 - PVD 3663_GB_NX_March 2017.Docx... - Page 40 40 - PVD 3663_GB_NX_March 2017.Docx...

- Page 41 41 - PVD 3663_GB_NX_March 2017.Docx...

-

Page 42: Nx1 Ul Version

3.3.2. NX1 UL version 42 - PVD 3663_GB_NX_March 2017.Docx... - Page 43 43 - PVD 3663_GB_NX_March 2017.Docx...

- Page 44 44 - PVD 3663_GB_NX_March 2017.Docx...

- Page 45 45 - PVD 3663_GB_NX_March 2017.Docx...

-

Page 46: Nx2

3.3.3. 46 - PVD 3663_GB_NX_March 2017.Docx... - Page 47 47 - PVD 3663_GB_NX_March 2017.Docx...

- Page 48 48 - PVD 3663_GB_NX_March 2017.Docx...

- Page 49 49 - PVD 3663_GB_NX_March 2017.Docx...

-

Page 50: Nx2 Ul Version

3.3.4. NX2 UL version 50 - PVD 3663_GB_NX_March 2017.Docx... - Page 51 51 - PVD 3663_GB_NX_March 2017.Docx...

- Page 52 52 - PVD 3663_GB_NX_March 2017.Docx...

- Page 53 53 - PVD 3663_GB_NX_March 2017.Docx...

-

Page 54: Nx3

3.3.5. 54 - PVD 3663_GB_NX_March 2017.Docx... - Page 55 55 - PVD 3663_GB_NX_March 2017.Docx...

- Page 56 56 - PVD 3663_GB_NX_March 2017.Docx...

-

Page 57: Nx4

3.3.6. 57 - PVD 3663_GB_NX_March 2017.Docx... - Page 58 58 - PVD 3663_GB_NX_March 2017.Docx...

- Page 59 59 - PVD 3663_GB_NX_March 2017.Docx...

- Page 60 60 - PVD 3663_GB_NX_March 2017.Docx...

-

Page 61: Nx6

3.3.7. 61 - PVD 3663_GB_NX_March 2017.Docx... - Page 62 62 - PVD 3663_GB_NX_March 2017.Docx...

- Page 63 63 - PVD 3663_GB_NX_March 2017.Docx...

-

Page 64: Nx8

3.3.8. 64 - PVD 3663_GB_NX_March 2017.Docx... - Page 65 65 - PVD 3663_GB_NX_March 2017.Docx...

- Page 66 66 - PVD 3663_GB_NX_March 2017.Docx...

- Page 67 67 - PVD 3663_GB_NX_March 2017.Docx...

-

Page 68: Nx8 Water Cooled

3.3.9. NX8 water cooled 68 - PVD 3663_GB_NX_March 2017.Docx... -

Page 69: Motor Mounting

3.4. Motor Mounting 3.4.1. Motor mounting By flange in any direction Warning : For NX8 with fan cooling, the air inlet of the fan has to be at 100mm mini from a wall. 100mm Air flow direction 69 - PVD 3663_GB_NX_March 2017.Docx... -

Page 70: Frame Recommendation

3.4.2. Frame recommendation Warning : The user has the entire responsibility to design and prepare the support, the coupling device, shaft line alignment, and shaft line balancing. Foundation must be even, sufficiently rigid and shall be dimensioned in order to avoid vibrations due to resonances. -

Page 71: Shaft Loads

3.5. Shaft Loads 3.5.1. Vibration resistance to shaft end Frequency domain :10 to 55 Hz according to EN 60068 -2-6 Vibration resistance to the shaft end : - radial 3 g - axial 1 g 3.5.2. Motors life time for horizontal mounting The bearing arrangement is made with 2 ball bearings (one on the shaft end + another on the rear). - Page 72 3.5.2.2. NX205 3.5.2.3. NX210 72 - PVD 3663_GB_NX_March 2017.Docx...

- Page 73 3.5.2.4. NX310 3.5.2.5. NX420 73 - PVD 3663_GB_NX_March 2017.Docx...

- Page 74 3.5.2.6. NX430 3.5.2.7. NX620 74 - PVD 3663_GB_NX_March 2017.Docx...

- Page 75 3.5.2.8. NX630 3.5.2.9. NX820 75 - PVD 3663_GB_NX_March 2017.Docx...

- Page 76 3.5.2.10. NX840 3.5.2.11. NX860 76 - PVD 3663_GB_NX_March 2017.Docx...

-

Page 77: Cooling

3.6. Cooling In compliance with the IEC 60034-1 standards: 3.6.1. Natural and fan cooled motor The ambient air temperature shall not be less than -15°C and more than 40°C. It is possible to use the motors in an higher ambient temperature but with an associated derating to the motor performances. -

Page 78: Fan Cooled Motor

3.6.2. Fan cooled motor The ambient air temperature shall not be less than -15°C and more than 40°C. It is possible to use the motors in an higher ambient temperature but with an associated derating to the motor performances. Warning: To reach the motor performances calculated, the motor must be thermally well connected to a aluminium flange with a dimension of 400 mm x 400 mm and with a thickness of 12 mm. -

Page 79: Water Cooled Motor

3.6.3. Water cooled motor Danger: The cooling system has to be operational when the motor is running or energized. Danger: The Inlet temperature and the water flow have to be monitored to avoid any exceeding values. Caution: When motor is not running, the cooling system has to be stopped 10 minutes after motor shut down. -

Page 80: Additives For Water As Cooling Media

3.6.4. Additives for water as cooling media Please refer to motor technical data for coolant flow rates. The water inlet temperature must not exceed 25°C without torque derating. The water inlet temperature must not be below 5°C. The inner pressure of the cooling liquid must not exceed 5 bars. Caution: To avoid the appearance of corrosion of the motor cooling system, the water must have anti-corrosion additive. -

Page 81: Motor Cooling Circuit Drop Pressure

3.6.5. Motor cooling circuit drop pressure The tab below describes the drop pressure at the water flow rate from the motor data: Motor type Drop pressure @ nominal water flow NX860W 0.3 bar @ 5 l/min Note : all motors drop pressure are checked before shipping. 3.6.6. -

Page 82: Flow Derating According To Glycol Concentration

3.6.7. Flow derating according to glycol concentration Glycol concentration [% ] 10.2 10.6 11.1 11.8 12.4 15.3 15.9 16.7 17.6 18.7 20.4 21.2 22.2 23.5 24.9 25.5 26.5 27.8 29.4 31.1 30.6 31.8 33.4 35.3 37.3 35.7 37.1 38.9 41.1 43.6 40.8 42.4... - Page 83 Main formulas Power dissipatio Flow rate With: Flow rate [l/min] Power_dissipation [W] ° Gradient inlet-outlet [°C] Cp thermal specific capacity of the water as coolant [J/kg°K] (Cp depends on the % glycol concentration please see below) Thermal specific capacity Cp according to % glycol concentration and temperature We have considered an average temperature of the coolant of 30°C.

-

Page 84: Water Cooling Diagram

3.6.8. Water cooling diagram Recommendation: The use of a filter allows to reduce the presence of impurities or chips in the water circuit in order to prevent its obstruction. We recommend 0.1mm filter. This section shows typical water cooling diagram : There is no recommendation on water inlet and... - Page 85 No Parallel Circuit Chiller or Exchanger without flow control Pump Servomotor To other(s) device(s) No Serial Circuit Pump Servomotors 85 - PVD 3663_GB_NX_March 2017.Docx...

-

Page 86: Thermal Protection

3.7. Thermal Protection Different protections against thermal overloading of the motor are proposed as an option: Thermoswitch, PTC thermistors or KTY temperature built into the stator winding. No thermal protection are available for the NX1 motor The thermal sensors, due to their thermal inertia, are unable to follow very fast winding temperature variations. -

Page 87: Temperature Measurement With Kty Sensors

3.7.2. Temperature measurement with KTY sensors: Motor temperature can also be continuously monitored by the drive using a KTY 84- 130 thermal sensor built in to the stator winding. KTY sensors are semiconductor sensors that change their resistance according to an approximately linear characteristic. -

Page 88: Power Electrical Connections

3.8. Power Electrical Connections 3.8.1. Wires sizes In every country, you must respect all the local electrical installation regulations and standards. Not limiting example in France: NFC 15-100 or IEC 60364 as well in Europe. Cable selection depends on the cable construction, so refer to the cable technical documentation to choose wire sizes Some drives have cable limitations or recommendations;... -

Page 89: Conversion Awg/Kcmil/Mm²

Example of sizes for H07 RN-F cable : Conditions of use: Case of 3 conductors type H07 RN-F: 60°C maximum Ambient temperature: 30°C Cable runs on dedicated cables ways Current limited to 80%*I at low speed or at motor stall. Example: Io=100 Arms Permanent current at standstill : 80 Arms... -

Page 90: Motor Cable Length

For motors windings which present low inductance values or low resistance values, the own cable inductance, respectively own resistance, in case of large cable length can greatly reduce the maximum speed of the motor. Please contact PARKER for further information. -

Page 91: Mains Supply Connection Diagrams

3.8.4. Mains supply connection diagrams 91 - PVD 3663_GB_NX_March 2017.Docx... - Page 92 92 - PVD 3663_GB_NX_March 2017.Docx...

- Page 93 93 - PVD 3663_GB_NX_March 2017.Docx...

- Page 94 94 - PVD 3663_GB_NX_March 2017.Docx...

- Page 95 95 - PVD 3663_GB_NX_March 2017.Docx...

- Page 96 96 - PVD 3663_GB_NX_March 2017.Docx...

- Page 97 97 - PVD 3663_GB_NX_March 2017.Docx...

-

Page 98: Feedback System

3.9. Feedback system Resolver 2 poles transformation ratio = 0.5 – code A 3.9.1. NX2 & NX3 NX4, NX6 & NX8 Parker part number 220005P1000 220005P1001 220005P1002 Electrical specification Values @ 8 kHz Polarity 2 poles Input voltage 7 Vrms... -

Page 99: Hiperface Encoder Multiturn Ekm36 Dsl Sil2 - Code Q

Hiperface encoder multiturn EKM36 DSL SIL2 – code Q 3.9.3. NX2, NX3, NX4, NX6 & NX8 Model EKM36 SIL2 (Sick) Type Absolute multi turn encoder Parker part number 220174P0012 Electrical interface Hiperface DSL Revolutions 4 096 Integral non-linearity ± 80’’... -

Page 100: Hiperface Encoder Multiturn Skm36 (128Pulses) - Code S

Hiperface encoder multiturn SKM36 (128pulses) – code S 3.9.5. NX2, NX3, NX4, NX6 & NX8 Model SKM36 (Sick) Type Absolute multi turn encoder Parker part number 220174P0004 128 sine/cosine periods per Line count revolution Electrical interface Hiperface Position values per... -

Page 101: Hiperface Encoder Multiturn Srm50 (1024Pulses) - Code U

Hiperface encoder multiturn SRM50 (1024pulses) – code U 3.9.7. NX1 & NX2 NX3, NX4, NX6 & NX8 Model SRM50 (Sick) Type Absolute multi turn encoder Parker part number 220174P0001 1024 sine/cosine periods per Line count revolution Electrical interface Hiperface Position values per... -

Page 102: Endat Encoder Multiturn Ecn1125 - Code W

Operating temperature -40°C to +115 °C range With unregulated power supply (AC890 PARKER drive for instance), the max cable length is 65m with 0.25mm² power supply wire due to the voltage drop into the cable itself. 102 - PVD 3663_GB_NX_March 2017.Docx... - Page 103 Maximum Endat cable length Please refer to the following curve to calculate the max cable length depending on the clock frequency AC890 PARKER Wiring – EnDat encoder From Heidenhain 103 - PVD 3663_GB_NX_March 2017.Docx...

-

Page 104: Incremental Encoder-Commuted Lines 10 Poles-2048Pulses-Code X (On Request)

X ( On request) NX1, NX2, NX3, NX4, NX6 & NX8 Model F10 (Hengstler) Type Incremental encoder with 10 pole commutation signals Parker part number 220167P0003 Line count 2048 pulses per revolution Electrical interface Line driver 26LS31 Incremental signals ± 2.5' System accuracy commutation signals ±... -

Page 105: Cables

3.9.11. Cables To connect NX motor in connector version to PARKER drive : AC890, COMPAX3 or SLVD, you can use complete cable with part number on the tabs below. The "xxx" in the part number must be replaced by the length in meter. - Page 106 3.9.11.2. Power cable with or without brake Cable reference Cable reference Cable reference Cable reference Motor size for AC890 for COMPAX3 for SLVD for 637/638 CS4UP0F4R0xxx CC3UP0F4R0xxx CS5UP0F4R0xxx CS2UP0F4R0xxx for NX2 to NX8 CS4UP1F1R0xxx CC3UP1F1R0xxx CS5UP1F1R0xxx CS2UP1F1R0xxx Current ≤ 12Amps for NX2 to NX8 CS4UP2F1R0xxx CC3UP2F1R0xxx CS5UP2F1R0xxx CS2UP2F1R0xxx Current ≤...

- Page 107 3.9.11.4. Power cable with or without brake and Hiperface DSL encoder Cable reference Motor size for PSD / SLVD Current ≤ 12Amps CP1UD1F1R0xxx Current ≤ 24Amps CP1UD2F1R0xxx For other drive, you can assembly cable and plug by soldering with part number on the tab below: Feedback Sensor Cable reference...

-

Page 108: Brake Option

3.10. Brake option Caution: The holding brake is used to completely immobilize the servomotor under load. It is not designed to be used for repeated dynamic braking ; dynamic braking must only be used in the case of an emergency stop and with a limited occurance depending on the load inertia and speed. -

Page 109: Commissioning, Use And Maintenance

4. COMMISSIONING, USE AND MAINTENANCE 4.1. Instructions for commissioning, use and maintenance 4.1.1. Equipment delivery All servomotors are strictly controlled during manufacturing, before shipping. While receiving it, it is necessary to verify motor condition and if it has not been damaged in transit. -

Page 110: Storage

4.1.3. Storage Before being mounted, the motor has to be stored in a dry place, without rapid or important temperature variations in order to avoid condensation. During storage, the ambient temperature must be kept between -20 and +60°C. If the torque motor has to be stored for a long time, verify that the shaft end, feet and the flange are coated with corrosion proof product. -

Page 111: Preparation

4.2.2. Preparation Once the motor is installed, it must be possible to access the wiring, and read the manufacturer’s plate. Air must be able to circulate around the motor for cooling purposes. Clean the shaft using a cloth soaked in white spirit or alcohol. Pay attention that the cleaning solution does not get on to the bearings. -

Page 112: Electrical Connections

Warning : a misalignment of the coupling device makes stress and load on the motor shaft depending the rigidity of the installation. The variations of the temperature makes stress and load due to the dilatation. These loads (axials and radiale) do not exceed the load written (§... -

Page 113: Cable Connection

4.3.1. Cable connection Please, read §3.7 "Electrical connection" to have information about cable connection Many useful information are already available in the drive documentations. 4.3.2. Encoder cable handling Danger: before any intervention the drive must be stopped in accordance with the procedure. Caution: It is forbidden to disconnect the Encoder cable under voltage (high risk of damage and sensor destruction). -

Page 114: Maintenance Operations

VDE 0105 or IEC 0364) and local regulations. They must be authorized to install, commission and operate in accordance with established practices and standards. Please contact PARKER for technical assistance. Danger: before any intervention the motor must be disconnected from te power supply. -

Page 115: Troubleshooting

Whenever an operating incident occurs, consult the relevant servo drive installation instructions (the troubleshooting display indications will help you in your investigation) or contact us at: http://www.parker.com/eme/repairservice. Check there is no mechanical blockage or if the motor You note that the motor does not turn by hand terminals are not short-circuited. - Page 116 It may be overloaded or the rotation speed is too low : You think the motor is becoming unusually hot check the current and the operating cycle of the motor. Check if the mounting surface is enough or if this surface is not a heat source –...

Need help?

Do you have a question about the NX8 and is the answer not in the manual?

Questions and answers