Summarization of Contents

User Instructions

Target Audience

Defines the intended users and required qualifications for operating the unit.

Safety Symbols

Explains the meaning of various danger, warning, and caution symbols used.

Guarantee and Liability Terms

Outlines conditions that exclude guarantee and liability claims for damage.

Safety

Designated Application and Limitations

Specifies the intended use of the burner and restrictions for safe operation.

Gas Leakage Safety Procedures

Provides critical steps to take when gas can be smelled.

General Safety Measures

Highlights essential safety practices during normal operation and maintenance.

Electrical Connection Safety

Safety guidelines for working with live electrical components.

Gas Supply Safety Guidelines

Safety requirements for gas supply installation, alterations, and maintenance.

Equipment Modification Restrictions

Rules regarding unauthorized modifications and use of original parts.

Noise Emission Information

Details on noise emissions and protective measures for personnel.

Disposal Guidelines

Instructions for environmentally friendly disposal of the unit's components.

Product Description

Type Key Explanation

Decodes the model designation and its component parts.

Serial Number Identification

Locates the serial number on the name plate for service purposes.

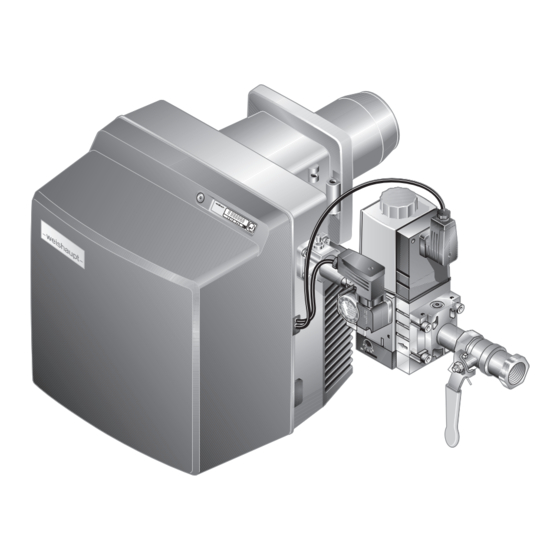

Functionality Overview

Describes the main functional parts: air supply, gas supply, electrical components.

Gas Supply Components

Details components like gas isolating valve, multifunction assembly, and pressure regulators.

Electrical Components Overview

Explains the roles of the combustion manager, operating panel, and ignition unit.

Inputs and Outputs

Lists terminal connections and their respective functions.

Program Sequence Details

Outlines the burner's operating phases from test to standby.

Wiring Diagram

Provides a schematic of electrical connections and component mapping.

Technical Specifications

Covers approval data, electrical specs, ambient conditions, fuels, and emissions.

Burner Rating and Capacity

Details heat ratings and provides a capacity graph for different fuels.

Physical Dimensions and Weight

Provides dimensional drawings and the unit's weight.

Installation

Installation Site and Conditions

Requirements for burner matching, location, and heat exchanger preparation.

Burner Mounting Procedure

Steps for fitting the burner flange and gasket to the heat exchanger.

Optional 180° Burner Rotation

Instructions for rotating the burner for alternative valve train configurations.

Gas Supply Installation

Gas Supply Connection Safety

Critical safety warnings regarding gas leaks and explosion risks.

Installing the Gas Valve Train

Procedures for installing the gas valve train from the right and left.

Soundness Test of Gas Supply Line

Method for performing a leak test on the gas supply line and vent.

Electrical Connection Procedure

Steps and safety precautions for making electrical connections.

Burner Motor Power Connection

Instructions for connecting the separate supply line for the burner motor.

Operation

Operating Panel Interface

Description of buttons and their functions on the burner's operating panel.

Displaying Operating Status

How to view and interpret the combustion manager's current operating status.

Understanding Display Information

Explanation of symbols, status codes, and operating data on the display.

Accessing Info Level Data

Procedure for interrogating burner data via the info level.

Service Level Data Access

Accessing service information such as actuator positions and fault memory.

Parameter Level Configuration

Details on parameters accessible in the parameter level for adjustment.

Access Level Settings

Configuration of burner-specific settings via the access level.

Burner Linearisation Process

Steps for linearising operating points to ensure accurate gas operation.

Commissioning

Commissioning Prerequisites and Checks

Ensuring correct assembly and system readiness before commissioning.

Connecting Measuring Devices

Instructions for connecting devices for ionisation current and mixing pressure.

Checking Gas Connection Pressure

Procedure to verify minimum and maximum gas connection pressures.

Gas Valve Train Soundness Testing

Performing leak tests on the gas valve train in multiple phases.

Purging the Gas Valve Train

Steps to safely purge the gas valve train of air.

Preset Pressure Regulator Adjustment

Determining and setting the pressure regulator based on load and gas type.

Setting Diffuser and Air Damper

Adjusting diffuser and air damper settings for the required heat rating.

Preset Gas and Air Pressure Switches

Initial setting of gas and air pressure switches for commissioning.

Burner Adjustment Procedures

Step-by-step guide for adjusting burner operation without variable speed drive.

Setting Pressure Switches

Checking and adjusting low gas pressure, valve proving, and air pressure switches.

Final Commissioning Steps

Concluding checks, documentation, and final settings after commissioning.

Combustion Check and Adjustment

Procedures for checking excess air, flue gas temperature, and emissions.

Calculating Gas Throughput

Formulas and methods for calculating normal and operating gas throughput.

Optimizing Operating Points

Subsequent adjustments to operating points for optimal performance.

Shutdown

Procedure for Operational Breaks

Steps to safely switch off the burner for short or long breaks.

Servicing

Servicing Safety Precautions

Critical safety warnings and preparatory steps before servicing.

Recommended Service Plan

Schedule and procedures for routine maintenance of burner components.

Mixing Head Maintenance

Instructions for removing and refitting the mixing head.

Setting the Mixing Head

Procedure for setting the mixing head and adjusting flame tube.

Ionisation and Ignition Electrode Adjustment

Correct positioning and setting of ionisation and ignition electrodes.

Service Position Guidelines

Steps to achieve a service-friendly position for maintenance.

Fan Wheel Maintenance

Procedure for removing and refitting the fan wheel.

Burner Motor Replacement

Instructions for removing and replacing the burner motor.

Air Damper Actuator Maintenance

Procedure for removing and refitting the air damper actuator.

Angle Drive Maintenance

Guide for removing and refitting the angle drive.

Gas Butterfly Valve Actuator Maintenance

Procedure for removing and refitting the gas butterfly valve actuator.

Double Gas Valve Coil Replacement

Steps for replacing the solenoid coil in the double gas valve.

Breather Plug Replacement

Procedure for replacing the breather plug with an integrated filter.

Multifunction Assembly Filter Replacement

Guide for removing and refitting the filter insert in the multifunction assembly.

Gas Filter Insert Replacement

Procedure for replacing the filter insert in the gas filter.

Combustion Manager Replacement

Steps for replacing the combustion manager unit and initial setup.

Fuse Replacement Procedure

Instructions for safely replacing the internal unit fuse.

Troubleshooting

Fault Condition Procedures

Overview of fault indications and initial troubleshooting steps.

Display Off Faults

Troubleshooting steps when the display is off or shows 'OFF'.

Display Flashes Faults

Interpreting flashing display codes and resetting the burner.

Detailed Fault Code Explanations

Provides detailed fault codes for in-depth error analysis.

Fault Rectification Steps

Lists faults and their rectification procedures, noting qualified personnel requirements.

Common Fault Code Groups

Categorized fault codes (A1h-A6h, A7h-CFh) with rectification guidance.

Operating Problem Diagnosis

Addresses common operating issues like poor start, booming, and display errors.

Technical Documentation

Burner Program Sequence

Detailed list of operating phases, statuses, and functions.

Operating Status Code Reference

Table of operating phases, status codes, and corresponding conditions.

Pressure Unit Conversion Table

Provides conversion factors between various pressure units.

Appliance Category Standards

Explains appliance categories based on EN 676 and gas types.

Appliance Categories for Natural Gas

Table detailing appliance categories by country for Natural Gas.

Appliance Categories for LPG

Table detailing appliance categories by country for Liquid Petroleum Gas.

Appliance Categories for Dual Fuel

Table detailing appliance categories by country for dual fuel burners.

Project Planning

Additional Installation Requirements

Specifies requirements for specific applications and compliance standards.

Spare Parts

Spares Diagram (Main Assembly)

Exploded view diagram of the main burner assembly components.

Spare Parts List (1.01-1.21)

List of spare parts for the main assembly with order numbers.

Spares Diagram (Burner without VSD)

Exploded view diagram for burner components without variable speed drive.

Spare Parts List (2.01-2.30)

List of spare parts for burner without variable speed drive.

Spares Diagram (Burner with VSD)

Exploded view diagram for burner components with variable speed drive.

Spare Parts List (3.01-3.30)

List of spare parts for burner with variable speed drive.

Spares Diagram (Mixing Head)

Exploded view diagram of mixing head components.

Spare Parts List (4.01-4.26)

List of spare parts for mixing head components.

Spares Diagram (Ignition/Sensor)

Exploded view diagram for ignition and sensor components.

Spare Parts List (5.01-5.24)

List of spare parts for ignition and sensor components.

Spares Diagram (Gas Valve Train 1)

Exploded view diagram for gas valve train components.

Spare Parts List (6.01-6.16)

List of spare parts for various gas valve train components.

Spares Diagram (Gas Valve Train 2)

Exploded view diagram for additional gas valve train components.

Spare Parts List (7.01-7.22)

List of spare parts for additional gas valve train components.

Spares Diagram (Gas Valve Train 3)

Exploded view diagram for further gas valve train components.

Spare Parts List (8.01-8.22)

List of spare parts for further gas valve train components.

Notes

User Notes Section

A dedicated section for users to add personal notes and annotations.

Key Word Index

Keyword Index A-K

Alphabetical listing of keywords from A to K for document navigation.

Keyword Index L-W

Alphabetical listing of keywords from L to W for document navigation.

Need help?

Do you have a question about the WG40F/1-A ZM-LN and is the answer not in the manual?

Questions and answers