Table of Contents

Advertisement

Quick Start Guide

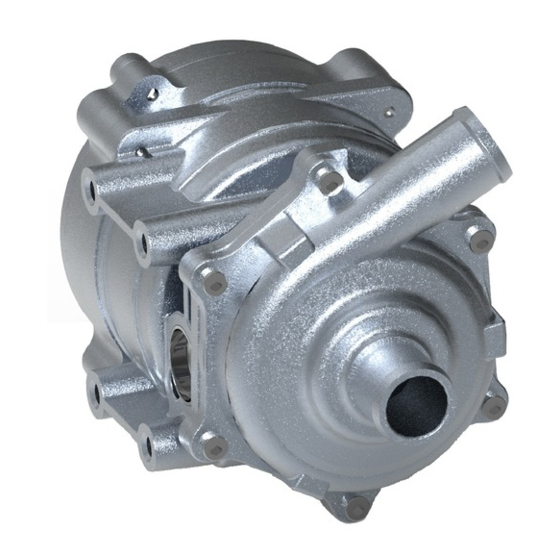

WP120 Electric Water Pump

This manual is effective for consumer installations

of EMP WP120 water pumps. OEM installers must

contact EMP for production requirements.

Rev

Rev By

Date

Description of Change

Approved By

A

ME

5/17/21

New Release

ECN6212

9970137016 Rev. A – 05/17/2021

© 2021 EMP Inc.

1

Advertisement

Table of Contents

Summarization of Contents

Introduction

Purpose

Presents information related to the pump's dimensions, electrical specifications, coolant guidelines, plumbing, orientation, and maintenance.

Service Technician Responsibilities

Ensures all safety and information messages are read and understood before performing service.

Liability Disclaimer

States EMP cannot anticipate all potential hazards and users must ensure their methods are safe.

Additional Information

Provides access to service software, bulletins, manuals, and drawings via the EMP website.

Technical Help

Contact EMP Customer Service for technical assistance via phone or email.

Warnings, Cautions and Notes

Explains the styling of WARNING, CAUTION, and NOTE headings for safety and information.

Definition of Terms

Defines technical terms like CAN, EMPower Connect, Ignition Enable, and RPM.

Specifications

Performance Specifications

Details maximum/minimum operating temperatures and motor speeds for the pump.

Mechanical Specifications

Covers component construction material and weight.

Electrical Specifications

Lists input voltage, operating current draw, and thermal protection.

Dimensions and Hole Locations

Provides diagrams with physical dimensions and mounting hole spacing.

Material Listing

Lists major external and fluid contacting parts with their materials.

Operating Limits

Details temperature limitations for operation and storage.

Identification

Model Codes

Explains the structure and meaning of EMP water pump model codes.

Installation

Environment

Emphasizes environment cleanliness for pump life and submersible capability.

Orientation

Details the standard orientation and pump specific installation requirements.

Plumbing

Specifies hose diameter for pump inlet and potential issues with trapped air.

Hose Clamps

Recommends SAE20CT worm drive hose clamps and specifies torque.

System Fill Procedure

Provides step-by-step instructions for filling the system and purging air.

Approved Fluids

Lists recommended fluid types and precautions for coolants and additives.

Wiring

Recommended Wiring Practices

Outlines best practices for routing and securing electrical harnesses.

Electrical Connections

Describes power input and ignition enable connections.

10-way Component Connector

Details the pinout and wire colors for the male 10-way connector.

10-way Mating Connector

Provides part numbers and notes for the female 10-way mating connector.

10-way On/Off Single Speed Control

Details the pinout and purpose for the 10-way single speed control connector.

Pump Operation

Describes how the component operates in on/off single speed mode and 'Power Hold' option.

7-way Component Connector

Details the pinout and wire colors for the male 7-way connector.

7-way Mating Connector

Provides part numbers and notes for the female 7-way mating connector.

7-way Connector Greasing

Specifies applying dielectric grease to electrical connectors for protection.

7-way On/Off Single Speed Control

Details the pinout and purpose for the 7-way single speed control connector.

Routine Maintenance

Maintenance Schedule

Outlines checks for fluid levels, coolant quality, and wiring integrity.

Physical Inspection

Instructs to check the weep hole for clogs and ensure electrical connections are tight.

EMPower Connect Service Tool

Diagnostic Outputs (WP120)

Details gathering operational and diagnostic info via CAN using EMPower Connect.

Diagnostic Outputs (WP120L)

Details viewing performance via PWM using EMP-Link communication protocol.

Troubleshooting

Pump Not Running

Checks for electrical connections, ignition enable status, and wiring.

Pump Running But Not Pumping

Checks system fluid level, tubing restrictions, priming, and inlet hose.

No CAN Communication

Verifies communication harness, CAN message formats, and component address.

Suspected Water Pump Seal Leak

References service bulletin for inspection and diagnostic procedures.

Pump Producing Excessive Noise

Checks for cavitation, low inlet pressure, trapped debris, or plumbing issues.

Need help?

Do you have a question about the WP120 24V and is the answer not in the manual?

Questions and answers