Table of Contents

Advertisement

ORIGINAL INSTRUCTIONS

Installation, Operation

& Maintenance Manual

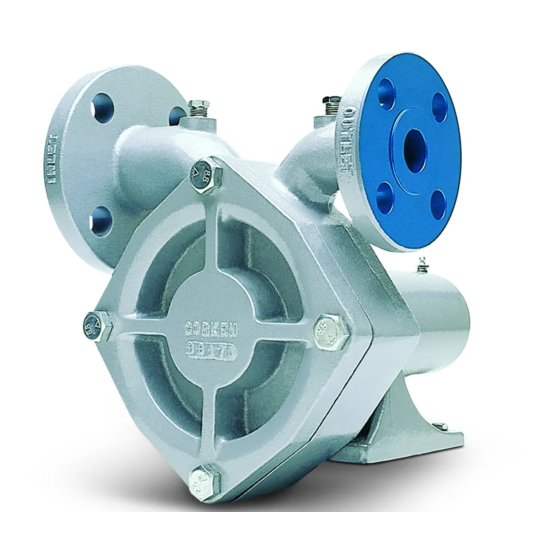

Regenerative Turbine Pumps

for LPG, NH

, and Many Other Liquefied Gases and Thin Liquids

3

All Models 060, 075, and 150

Warning: (1) Periodic inspection and maintenance of Corken products is essential. (2) Inspection, maintenance and installation of

Corken products must be made only by experienced, trained and qualified personnel. (3) Maintenance, use and installation of Corken

products must comply with Corken instructions, applicable laws and safety standards. (4) Transfer of toxic, dangerous, flammable or

explosive substances using Corken products is at user's risk and equipment should be operated only by qualified personnel according

to applicable laws and safety standards.

Scan QR code to view list

of maintenance videos.

Frame Mount

ASME Class 300 RF (ANSI) Flange (FF) and DIN Flange (FD)

Direct Mount

ASME Class 300 RF (ANSI) Flange (DLF) and DIN Flange (DLD)

Solutions beyond products...

IF102H

Advertisement

Table of Contents

Summary of Contents for Corken Coro-Flo FF150

- Page 1 Warning: (1) Periodic inspection and maintenance of Corken products is essential. (2) Inspection, maintenance and installation of Corken products must be made only by experienced, trained and qualified personnel. (3) Maintenance, use and installation of Corken products must comply with Corken instructions, applicable laws and safety standards. (4) Transfer of toxic, dangerous, flammable or explosive substances using Corken products is at user’s risk and equipment should be operated only by qualified personnel according...

- Page 2 Corken One Year Warranty CORKEN, INC. warrants that its products will be free from defects in material and workmanship for a period of one year from date of installation, provided that the warranty shall not extend beyond twenty-four (24) months from the date of shipment from CORKEN.

-

Page 3: Table Of Contents

Table of Contents Principles of the Coro-Flo Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 ®... -

Page 4: Principles Of The Coro-Flo

Coro-Flo pump has several other features ® that make it easier to operate and maintain. The Corken Coro-Flo is a special type of pump known as ® a regenerative turbine. The liquid flows through the inlet • The pump models listed in this manual are mounted... -

Page 5: Chapter 1-Installation

To minimize damage to the paint, web slings this system, the pump has little chance of performing. are preferred over metal slings. 2. A Corken B166 bypass valve allows the pump to vent Pump Weights vapors from the pump and act as a differential relief valve making it ideal for the bypass system. -

Page 6: Pump Foundation For Frame Mounted Models

If misalignment exists, adjust the shims between the pump Laboratories (UL), an external bypass valve must be and baseplate until exact alignment is accomplished. connected in the piping between the pump discharge nozzle and the supply tank for pump recirculation. When Parallel Misalignment bypassing the full output of the pump, the external bypass Coupling faces are parallel but not concentric... -

Page 7: Wire Sizing Chart

Chapter 2—Operation With explosion-proof motor applications in humid climates, the normal breathing and alternating temperatures of the motor (i.e. warm during operation and cold when stopped) The pump operator should be fully informed of the often cause moist air to be drawn into the motor housing. recommended operation procedures... -

Page 8: Pumping From Underground Tanks

• Use vapor eliminator valves and return to the vapor so the incoming liquid enters the vapor section of the space of the tank. A Corken B166 bypass valve has cylinder. If refitting is impossible or impractical, rock the this feature. - Page 9 Item to Check Daily Monthly Three Months Six Months 1. Visual inspection; leaks, hoses, pipes, etc. 2. Clean inlet strainer screen 3. Inspect drive coupling and guard 4. Lubricate pump’s bearing 5. Lubricate motor’s bearing 6. Performance test 7. Re-tighten bolts 8.

-

Page 10: Chapter 4-Repair Service

Chapter 4—Repair Service If visual inspection indicates the impeller is in good condition, remove the shim and reinstall the cover and make sure the pump spins freely. Many times this CAUTION: Relieve system pressure before procedure adjusts for slight impeller wear. If the pump performing any maintenance to the pump . -

Page 11: Chapter 5-Seal Replacement Instructions (Note: Models Beginning With Serial Number Prefix Yu)

Chapter 5—Seal Replacement Cleanliness The smallest amount of dirt on a new seal can cause Instructions (NOTE: Models premature seal failure. Keep all parts, tools, and hands clean while handling the seal. Avoid touching the smooth Beginning with Serial Number lapped faces of the carbon rotor or seal seat. - Page 12 STEP 4 Remove seal sub assembly: Slide O-ring the seal sub assembly (seal and seal removal sleeve) off the shaft and remove the seal sleeve O-ring from the shaft. STEP 5 Remove seal housing: Using a 90° pick or hook tool inserted behind the face of the seal housing, slowly pull out around the circumference of the seal housing until it can...

- Page 13 ASSEMBLY STEP 8 Verify the contents of the new 3189-1X_6 seal assembly and clean pump shaft before installation . NOTE: Install the two locator pins before proceeding to STEP 9. One goes into the seal sleeve and one goes into the seal housing. Use the old seal assembly for reference.

- Page 14 STEP 11 O-ring O-ring Install the seal sleeve O-ring: Clean placement the pump shaft and install the new seal sleeve O-ring. Make sure it is seated on the shoulder of pump shaft. STEP 12 Align locator pin Assemble the seal and seal sleeve: and hole Apply a thin coat of oil to the face of the rotating carbon and the O-ring that...

- Page 15 Install the cover: Install the O-ring, and pump cover. Torque each cover bolt to 60 ft•lbs. Be certain the Corken label on the cover is horizontal and right side up. Rotate the pump shaft and ensure the impeller turns freely. NOTE: On older...

-

Page 16: Model Number Identification Code And Available Options

Appendix A—Model Number Identification Code and Available Options Model 060 Coro-Flo Pumps ® Model Number Frame Mount Direct Mount Base Model Number Base X X X X FF060 FD060 DLF060 DLD060 Inlet 1½" ASME 40 mm DIN 1½" ASME 40 mm DIN Outlet 1"... - Page 17 Appendix A—Model Number Identification Code and Available Options Model 075 Coro-Flo Pumps ® Model Number Frame Mount Direct Mount Base Model Number Base X X X X FF075 FD075 DLF075 DLD075 Inlet 1½" ASME 40 mm DIN 1½" ASME 40 mm DIN Outlet 1"...

- Page 18 Appendix A—Model Number Identification Code and Available Options Model 150 Coro-Flo Pumps ® Model Number Frame Mount Direct Mount Base Model Number Base X X X X FF150 FD150 DLF150 DLD150 Inlet 1½" ASME 40 mm DIN 1½" ASME 40 mm DIN Outlet 1"...

-

Page 19: Specifications

Appendix B—Material and Mechanical Specifications for Models 060, 075, and 150 Coro-Flo Pumps ® Equipment Type and Options Applications Regenerative turbine pump Under and aboveground autogas dispensing Foot mounted (FF060, FF075, FF150, FD060, FD075, or FD150) Multiple cylinder filling stations Direct mounted (DLF060, DLF075, DLF150, DLD060, DLD075, Vaporizer feed—high pressure or DLD150) -

Page 20: Performance

Appendix C—Performance Curves Model 060 Coro-Flo Pumps ® 6.00 3450 RPM @ 60 Hz 5.25 Differential pressure: 4.50 10.0 bar 145.0 psi 3.75 Flow: 32.2 L/min 3.00 8.5 gpm 2.25 Power required: 3.8 kW 1.50 5.15 hp 0.75 L/min Flow Rate The performance curves are based on aboveground LPG installations. - Page 21 Appendix C—Performance Curves Model 075 Coro-Flo Pumps ® 4.47 12.5 2880 RPM @ 50 Hz 3.73 10.0 Differential pressure: 10.0 bar 2.98 145.0 psi Flow: 2.24 42 L/min 11 gpm 1.49 Power required: 3.65 kW 0.75 4.9 hp L/min Flow Rate 6.71 3450 RPM @ 60 Hz 5.97...

- Page 22 Appendix C—Performance Curves Model 150 Coro-Flo Pumps ® 20.0 15.0 15.0 2880 RPM @ 50 Hz 12.5 12.5 Differential pressure: 15.0 10.0 bar 10.0 10.0 145.0 psi Flow: 10.0 85 L/min 22.5 gpm Power required: 5.1 kW 6.8 hp L/min Flow Rate 17.5 17.5...

-

Page 23: Outline Dimensions

Appendix D—Outline Dimensions for Models 060, 075, and 150 Coro-Flo Pumps ® Frame Mount ASME Class 300 RF (ANSI) Flange (FF) and DIN Flange (FD) square keyway (bolts) Direct Mount ASME Class 300 RF (ANSI) Flange (DLF) and DIN Flange (DLD) Note: Mounting is designed for NEMA C-face and IEC B14 face frame motors . - Page 24 Pumps ® Frame Mount ASME Class 300 RF (ANSI) Flange (FF) and DIN Flange (FD) with –101 Mounting Electric motor driver Inlet Inlet Coupling guard CORKEN Use four 1/2" anchor bolts Flange Dimensions C Dimensions All Models Model A (inlet) B (outlet) 182T–215T Frame...

-

Page 25: Parts Details

Impeller, stainless steel—model 075 prior to serial number prefix YU. For a complete Neoprene ®d 5240-1 Impeller, stainless steel—model 150 explanation of Corken’s serial number prefix Viton ®d codes, see page A400 (latest version) located in 5240-062 Impeller, steel—model 060 the “Policy and Prices”... - Page 26 Impeller, stainless steel—model 075 prior to serial number prefix YU. For a complete Neoprene ®d 5240-1 Impeller, stainless steel—model 150 explanation of Corken’s serial number prefix Viton ®d codes, see page A400 (latest version) located in 5240-062 Impeller, steel—model 060 the “Policy and Prices”...

-

Page 27: Troubleshooting Guide

Appendix F—Troubleshooting Guide In diagnosing pump and “system” troubles, the following information is essential: 1. Pump model and serial number 6. Pressure at pump’s discharge port 2. Electric motor: hp and RPM 7. Pressure in the storage tank 3. Product specific gravity 8. -

Page 28: Extended Storage

Symptom Probable Cause Remedy Noise or Defective or wrong size Confirm the size of the bypass valve required for the application. vibration in bypass valve Inspect, repair, or replace the valve. the pump Loose anchor bolts Tighten all pump’s anchor bolts. (continued) Electric motor High differential pressure... -

Page 29: Installation And Piping Instructions

Appendix H—Aboveground Installation and Piping Instructions Yes! CORKEN CORKEN CORKEN CORKEN Do not use restricted inlet line! Use inlet line larger than pump suction nozzle. Same size nozzle OK on short runs. Pressure drop caused by restriction in suction line will cause vaporization and cavitation. - Page 30 Never locate pump above Yes! level of liquid feeding pump. Product must be able to flow by gravity into pump. CORKEN CORKEN CORKEN Always locate pump below tank level ...the lower the better! Since liquefied gases boil when drawn into a pump by its own suction, the pump must be fed by gravity flow to give stable, trouble-free operation.

- Page 31 A differential On vaporizer feed pumps, a back check valve bypass valve like the Corken B166, T166, or B177 controls should be installed between the pump and to a fixed difference in pressure between the pump discharge and the tank.

- Page 32 In-line excess flow valve (37–57 L/min) 5. Transfer of toxic, dangerous, flammable or explosive substances Back pressure check valve using Corken equipment is at the user’s risk. Only qualified Bypass return line’s valve Existing personnel should operate Corken equipment according to the Eccentric reducer, applicable laws and safety standards.

- Page 33 In-line excess flow valve (37–57 L/min) 5. Transfer of toxic, dangerous, flammable or explosive substances Back pressure check valve using Corken equipment is at the user’s risk. Only qualified Ball valve, 2" Existing personnel should operate Corken equipment according to the Eccentric reducer, 2"...

- Page 36 Solutions beyond products... CORKEN, INC. • A Unit of IDEX Corporation 9201 North I-35 Service Road, Oklahoma City, OK. 73131 Phone (405) 946-5576 • Fax (405) 948-7343 Website: www.corken.com E-mail: cocsalesdept@idexcorp.com @CorkenInc Printed in the U.S.A. March 2020...

Need help?

Do you have a question about the Coro-Flo FF150 and is the answer not in the manual?

Questions and answers