Table of Contents

Advertisement

ORIGINAL INSTRUCTIONS

ID105K

Installation, Operation

& Maintenance Manual

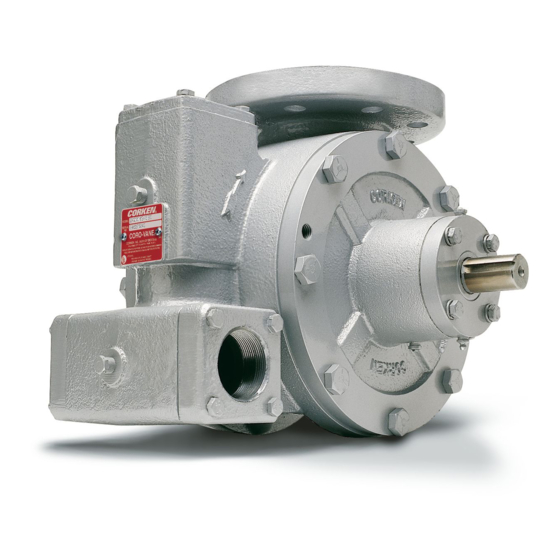

Z-Series Sliding Vane Pumps

Truck and Stationary

Model Z2000 Truck Pump

Model Z3200 Truck Pump

Model Z3500 Truck and

Stationary Pump

Model Z4200 Truck Pump

Model Z4500 Stationary Pump

Warning: (1) Periodic inspection and maintenance of Corken products is essential. (2) Inspection, maintenance and installation of Corken products

must be made only by experienced, trained and qualified personnel. (3) Maintenance, use and installation of Corken products must comply with

Corken instructions, applicable laws and safety standards (such as NFPA Pamphlet 58 for LP-Gas and ANSI K61.1-1972 for Anhydrous Ammonia).

(4) Transfer of toxic, dangerous, flammable or explosive substances using Corken products is at user's risk and equipment should be operated

only by qualified personnel according to applicable laws and safety standards.

Solutions beyond products...

Advertisement

Table of Contents

Summary of Contents for Corken Z Series

- Page 1 Warning: (1) Periodic inspection and maintenance of Corken products is essential. (2) Inspection, maintenance and installation of Corken products must be made only by experienced, trained and qualified personnel. (3) Maintenance, use and installation of Corken products must comply with Corken instructions, applicable laws and safety standards (such as NFPA Pamphlet 58 for LP-Gas and ANSI K61.1-1972 for Anhydrous Ammonia).

- Page 2 Corken One Year Warranty CORKEN, INC. warrants that its products will be free from defects in material and workmanship for a period of one year from date of installation, provided that the warranty shall not extend beyond twenty-four (24) months from the date of shipment from CORKEN.

-

Page 3: Table Of Contents

Table of Contents APPLICABLE NOTICES FOR ATEX 94/9/EC CONFORMITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 PRINCIPLES OF THE Z-SERIES SLIDING VANE PUMP (CORO-VANE ) . -

Page 4: Applicable Notices For Atex 94/9/Ec Conformity

Applicable Notices for Training Instructions: Instructions for the safe application and use of this ATEX 94/9/EC Conformity product are provided in this manual. Read this manual completely prior to installation and use of this product. Product Type: Only qualified and properly trained personnel should be Sliding Vane Pump (Coro-Vane ®... -

Page 5: Principles Of The Z-Series Sliding Vane Pump

Principles of the Z-Series Sliding Chapter 1—Installation of the Vane Pump (Coro-Vane Z-Series Coro-Vane Truck Pump ® ® The Z-Series truck pump is a special type of rotary positive Before installing of your pump, remove all temporary displacement pump, known as a sliding vane pump. plastic plugs. -

Page 6: The Outlet Piping Should Include The Following

Figure 1.1: Shaft Alignment 1 . 1 The Outlet Piping Should Correct assembly Include the Following 1. A liquid filled pressure gauge should be installed in the Incorrect assembly pump outlet or near it. A pressure gauge is necessary to determine the efficiency of your pumping system. 2. -

Page 7: Hydraulic Drive Systems

4. If your system has a Corken bypass valve, adjust the valve For proper installation of pump drives, follow the rules by turning the adjusting screw counter clockwise until the... -

Page 8: Chapter 3-Installation Of The Z-Series Coro-Vane

You can detect this “pull down” in pressure by observing your 1/2" x 8" anchor bolt NOTE: Z4500 truck tank pressure gauge as the pump is operating. baseplate should be filled with grout. To prevent this violent liquid boiling, pressure in some form Pump base Metal shim must be introduced into the truck tank. -

Page 9: The Bypass System Must Include The Following

(pumping through the bypass system). In this period the motor will heat up and vaporize the 2. Always install a Corken ZV200 or B177 external condensed moisture, and drive it out of the motor. No motor bypass valve in the discharge line of pump. -

Page 10: Chapter 4-Operation Of The Z-Series Stationary Coro-Vane

Maintenance (IOM) Manual (IH106) for more details emergency procedures in event of a malfunction. on the use of the Corken bypass valves. 6. Close all hose valves. 12. Your pump has an internal relief valve, it must be set higher than the external bypass setting. -

Page 11: Chapter 5-Maintenance Of The Z-Series Coro-Vane

All of these parts, plus O-rings that all propane, anhydrous ammonia, or whatever product and grease seals, are offered in the Corken “repair kit” being pumped is bled from the pump and connecting listed in this manual directly after the Seal Replacement piping. - Page 12 bearing cap. Always clean each grease zerk and relief b. While transferring liquid with the pump, close the fitting before lubricating the bearings. This practice discharge valve(s) so the full flow will be directed helps prevent foreign material from reaching the back to the storage tank through the bypass valve.

-

Page 13: Chapter 6-Z-Series Coro-Vane

PUMP AND PIPING BEFORE STARTING TO Workmanship INSTALL YOUR SEAL ASSEMBLY. Your Corken pump is a precision piece of equipment with very close clearances. Treat it as such. Never use force during assembly or disassembly (see steps 1 through 10). - Page 14 Sideplate Carbon seal Head Seal seat Grease seal NOTE ORIENTATION: The grease seal is inserted with smooth side up, flush with the shoulder of the head, and directly beneath the seal seat as shown in this illustration. Roller bearings Retainer ring Thrust bearing mounting ring Thrust bearings Bearing cap...

- Page 15 Step 6 Step 8 Completing installation Install the new seal assembly (retainer and carbon) Torque the head bolts in a crossing pattern. There is no need to disassemble or re-shim the bearing caps. Repeat Clean the pump shaft and apply a generous amount of light all of the above steps when replacing the seal assembly oil to the shaft and seal assembly.

-

Page 16: Repair/Rebuild Kits With Iron Seal Seat

6 . 1 Repair/Rebuild Kits with Iron Seal Seat Repair Kit 3193-X1 (Z2000, ZH2000, ZX2000, ZXH2000) Rebuild Kit 3194-X1 (Z2000, ZH2000, ZX2000, ZXH2000) Includes all items in the Repair Kit plus the following: 2-224A O-ring, Buna-N 2-231A O-ring, Buna-N 4414 2754-X Roller bearing 4427... -

Page 17: Repair/Rebuild Kits With Silicon Carbide Seal Seat

6 .2 Repair/Rebuild Kits with Silicon Carbide Seal Seat Repair Kit 3193-X16 (Z2000, ZH2000, ZX2000, ZXH2000) Rebuild Kit 3194-X16 (Z2000, ZH2000, ZX2000, ZXH2000) Includes all items in the Repair Kit plus the following: 2-224A O-ring, Buna-N 2-231A O-ring, Buna-N 4414 2754-X Roller bearing 4427... -

Page 18: Assembly Instructions For All Z-Series Repair And Rebuild Kits

6 .3 Assembly Instructions For All Z-Series Repair and Rebuild Kits 1. Place the pump head on a clean work surface with the 14. Carefully install the head over the pump shaft and seal bolting flange down. assembly and torque the bolts in accordance with the appropriate bolt torque pattern drawing. -

Page 19: Model Number Identification Code And Available Options

Appendix A—Z-Series Truck Pumps Model Number and Identification Code Base Model Z2000/ZH2000 ZX2000/ZXH2000 Z/ZH3200 Z/ZH4200 Model Number Base X X X X X X X Inlet 2" NPT 2" NPT 3" ANSI 4" ANSI Outlet 2" NPT 2" NPT 2" ell Dual 2"... - Page 20 Appendix A—Z-Series Stationary Pump Model Number and Identification Code Base Model Z3500 Z4500 Model Number Inlet 3" NPT (Standard) 4" 300# ANSI Base X X X X X X Outlet 3" NPT Elongated (Standard) 3" 300# ANSI Weight—bare pump lb (kg) (73) (120) Vane...

-

Page 21: Specifications

Appendix B—Specifications Equipment Type & Options Applications Truck sliding vane pump Propane bulk transfer Auto-fuel pumping Multiple connection options nurse tanks Carousel cylinder filling Optional auxiliary inlet LPG cylinders Features & Benefits Sliding vane: Positive displacement Heavy duty bearings: Long bearing life Single mechanical seal: Very easy seal replacement and maintenance Built in relief valve (NPT models only): Factory pre-set—added protection... -

Page 22: Performance Curves

3. Temperatures below 70°F (21°C) This loss of delivery is not caused by the pump but is a result of the natural thermodynamic properties of liquefied petroleum gases. See the “GUIDE TO CORKEN LIQUEFIED GAS TRANSFER EQUIPMENT” (CP226) for additional information. - Page 23 3. Temperatures below 70°F (21°C) This loss of delivery is not caused by the pump but is a result of the natural thermodynamic properties of liquefied petroleum gases. See the “GUIDE TO CORKEN LIQUEFIED GAS TRANSFER EQUIPMENT” (CP226) for additional information.

- Page 24 3. Temperatures below 70°F (21°C) This loss of delivery is not caused by the pump but is a result of the natural thermodynamic properties of liquefied petroleum gases. See the “GUIDE TO CORKEN LIQUEFIED GAS TRANSFER EQUIPMENT” (CP226) for additional information.

- Page 25 Appendix C—Performance Charts Z2000, ZH2000, ZX2000, and ZXH2000 Coro-Vane Truck Pumps ® Pump Differential Approximate Delivery of Brake hp Pump Torque Speed Pressure Propane Required Required psid (kPa) gpm (L/min) bhp (kW) ft•lb (N•M) 50 (345) 82 (309) 2.9 (2.2) 20.4 (27.7) 100 (689) 77 (291)

- Page 26 Appendix C—Performance Curves Z3500...

- Page 27 Appendix C—Performance Curves Z4500...

-

Page 28: Outline Dimensions

1/4" x 1-9/16" square key INTERNAL RELIEF VALVE SET AT 150 P.S.I. NOT FOR RECIRCULATING INSTALLER TO PROVIDE SEPARATE BY-PASS VALVE SET AT 125 P.S.I. MAXIMUM 2-1/8 CORKEN, INC. 2-1/8 A Unit Of IDEX Corp. (5.40) (5.40) 1-1/8 (2.85) 3-1/4 (8.25) - Page 29 (37.94) (12.70) INTERNAL RELIEF VALVE SET AT 150 P.S.I. NOT FOR RECIRCULATING INSTALLER TO PROVIDE SEPARATE BY-PASS VALVE SET AT 125 P.S.I. MAXIMUM CORKEN, INC. A Unit Of IDEX Corp. 1/4" NPT Internal 1-5/8 (4.13) relief 2" NPT valve discharge...

- Page 30 Appendix D—Outline Dimensions for Model Z3500 3.25 (8.18) 7.688 (19.5) 1.125 (2.9) 3" NPT outlet 6.813 6.046 (17.3) (15.4) 7.188 1/4" (18.3) keyway 1.758 5.500 (4.5) (14.0) 3" NPT inlet 1.250 1.250 3.000 3.000 (3.2) (3.2) (7.6) (7.6) 1.750 1.750 4.125 4.125 (4.4)

- Page 31 Appendix D—Outline Dimensions for Model Z4200 1-3/16 (3.01) Internal relief valve INLET 1/4" NPT 2" NPT auxillary inlet (20.32) 2-5/8 (6.67) 13-13/16 (35.08) OUTLET 3-1/4 (8.26) 1/4" NPT 7-3/4 (17.78) (19.69) 16-31/32 (43.08) 19-1/2 (49.53) 7-7/8 BC 10-1/8 D (20.00) (25.72) Inlet: 2-1/8...

- Page 32 Appendix D—Outline Dimensions for Model Z4500 8-Ø .875 (2.2) on a 6-5/8" B.C. Outlet 3" R.F. 300# ANSI flange 8.469 1.875 (21.5) (4.8) Inlet 4" R.F. 300# 10.75 ANSI flange (27.3) 5/16" square key (2.5) (16.5) 8-Ø .875 (2.2) 2.875 2.875 4.688 4.688...

- Page 33 Hydraulic drive adapter assembly 2-1/8 INTERNAL RELIEF VALVE SET AT 150 P.S.I. NOT FOR RECIRCULATING INSTALLER TO PROVIDE SEPARATE BY-PASS VALVE (5.40) SET AT 125 P.S.I. MAXIMUM CORKEN, INC. A Unit Of IDEX Corp. 4248 1-1/8 D (2.85) Hydraulic motor 3-1/4 (8.25) 13/16 (2.06)

- Page 34 10-15/16 (27.75) INTERNAL RELIEF VALVE SET AT 150 P.S.I. NOT FOR RECIRCULATING INSTALLER TO PROVIDE SEPARATE BY-PASS VALVE SET AT 125 P.S.I. MAXIMUM CORKEN, INC. A Unit Of IDEX Corp. Hydraulic motor Hydraulic drive adapter assembly 6-5/8 D B.C. 3-7/8 (16.83)

- Page 35 (24.77) 12-3/8 (31.43) MODEL SERIAL CORO-VANE CORKEN,INC. A Unit Of IDEX Corp. OKLAHOMA CITY,OKLAHOMA MADE IN U.S.A. POWER OPERATED PUMP FOR LPG OR ANHYDROUS NH READ CORKEN INSTRUCTION MANUAL BEFORE OPERATING LISTED 656L PAT. NOS. 3,072,066 AND 3,392,677 Hydraulic motor...

- Page 36 Appendix D—Outline Dimensions for Z3500–103 Mounting 3" NPT outlet 3" NPT inlet 18-1/8 (46) (7.62) 4-1/2 1-1/2 (3.8) (11.4) 12 (30.5) 5-3/16 15 (38.1) (13.2) 7-3/16 (18) 1/4" pipe plug Electric motor 7-3/16 (18) 8-1/2 (22) 1-1/4 (3) Adjustable motor slidebase Use four 1/2"...

- Page 37 Appendix D—Outline Dimensions for Z4500–103 Mounting Inlet 4" - 300# ANSI 4 (10.16) 1-1/2 Baseplate web (3.81) 12-1/4 (31.12) 17 (43.18) 5-5/8 20 (50.80) (14.30) Beltguard 8-1/2 1-7/8 Discharge Electric motor (21.59) (4.76) 3" - 300# ANSI 10-3/4 (27.31) 10-1/2 (26.67) 9-1/2 (24.13)

-

Page 38: Parts Details

Appendix E—Parts Details for Models Z/ZH/ZX/ZXH2000 37 (45 ft•lb) 36 (25 ft•lb) 36 (25 ft•lb) 35 (15 ft•lb) 37 (45 ft•lb) 36 (25 ft•lb) Inlet O-ring Code Note: Hydraulic motor is not shown. A Buna-N B Neoprene ®a See pages 16 and 17 for repair/rebuild kits. D Viton ®a CAUTION: Always relieve pressure in the unit before attempting... - Page 39 Appendix E—Parts Details for Models Z/ZH3200 28 (60 ft•lb) 25 (25 ft•lb) Inlet 29 (15 ft•lb) 28 (60 ft•lb) O-ring Code Outlet A Buna-N (25 ft•lb) Note: Hydraulic motor is not shown. B Neoprene ®a See pages 16 and 17 for repair/rebuild kits. D Viton ®a CAUTION: Always relieve pressure in the unit before attempting...

- Page 40 Appendix E—Parts Details for Models Z3500 35 (45 ft•lb) 34 (25 ft•lb) 34 (25 ft•lb) 33 (25 ft•lb) O-ring Code 34 (25 ft•lb) A Buna-N B Neoprene ®a Note: Hydraulic motor is not shown. D Viton ®a See pages 16 and 17 for repair/rebuild kits. Teflon ®a CAUTION: Always relieve pressure in the unit before attempting any repairs.

- Page 41 Appendix E—Parts Details for Models Z/ZH4200 (25 ft•lb) (25 ft•lb) (25 ft•lb) (75 ft•lb) O-ring Code A Buna-N B Neoprene ®a D Viton ®a Note: Hydraulic motor is not shown. (25 ft•lb) Teflon ®a See pages 16 and 17 for repair/rebuild kits. CAUTION: Always relieve pressure in the unit before attempting any repairs.

- Page 42 Appendix E—Parts Details for Model Z4500 O-ring Code A Buna-N B Neoprene ®a D Viton ®a Teflon ®a (25 ft•lb) Note: Hydraulic motor is not shown. (75 ft•lb) See pages 16 and 17 for repair/rebuild kits. CAUTION: Always relieve pressure in the unit before attempting any repairs.

- Page 43 Appendix E—Parts Details for Hydraulic Adapter (4496-X1) Fits Models Z2000, Z3200, and Z3500 Only Ref. Part No. Description 1343 Grease relief fitting 1359 Lubrication plate 2158 Grease zerk 2159 Lubricap 2270 Shaft key 4439 Bearing cap shim—0.002" 4439-1 Bearing cap shim—0.010" 4439-2 Bearing cap shim—0.020"...

- Page 44 Appendix E—Parts Details for Hydraulic Adapter (4496-1X1) Fits Models Z4200 and Z4500 Only Ref. Part No. Description 1343 Grease relief fitting 1359 Lubrication plate 2158 Grease zerk 2159 Lubricap 2270 Shaft key 4439 Bearing cap shim—0.002" 4439-1 Bearing cap shim—0.010" 4439-2 Bearing cap shim—0.020"...

-

Page 45: V-Belt Selection

Appendix F—V-Belt Selection for Stationary Coro-Vane Pumps ® 1,450 RPM Motor 1,750 RPM Motor Motor Nominal Sheave Pitch Diameter Sheave Pitch Diameter Belt Belt Pump RPM Number Number Pump Motor Pump Motor B15.4 B7.4 1-3V14.0 1-3V3.35 3V600 B13.6 B4.2 1-3V10.6 1-3V2.80 3V530 B12.4... -

Page 46: Troubleshooting Guide

Appendix F—V-Belt Selection for the Z4500 1,450 RPM Motor 1,750 RPM Motor Motor Nominal Sheave Pitch Diameter Sheave Pitch Diameter Belt Belt Pump RPM Number Pump Motor Pump Motor Number 3VX690 QD3/3V14.00 QD3/3V4.12 QD3/3V19.00 QD3/3V4.75 3/3V800 3VX710 QD3/3V14.00 QD3/3V4.50 QD2/3V19.00 QD2/3V5.30 3VX800 3VX710... - Page 47 Appendix G—Troubleshooting Guide (continued) Problem Cause Solution Low capacity Suction pipe too small or Indicated by pump inlet pressure dropping several pounds (continued) restricted when pump is started. Remove restriction or modify piping. Worn vanes Replace. Pump without vapor return Without vapor equalization, a pump can remove only about 3% of the truck tank capacity per minute without severe cavitation and capacity loss.

-

Page 48: Extended Storage

Pump Specifications ® Operating Specifications for Char-Lynn Hydraulic Motor If your Corken Z-Series pump is to be removed from service for some time, the pump must be protected Mounting flange 2 bolt SAE A as propane, butane and anhydrous ammonia all leave 1 in.

Need help?

Do you have a question about the Z Series and is the answer not in the manual?

Questions and answers