Table of Contents

Advertisement

ORIGINAL INSTRUCTIONS

Installation, Operation

& Maintenance Manual

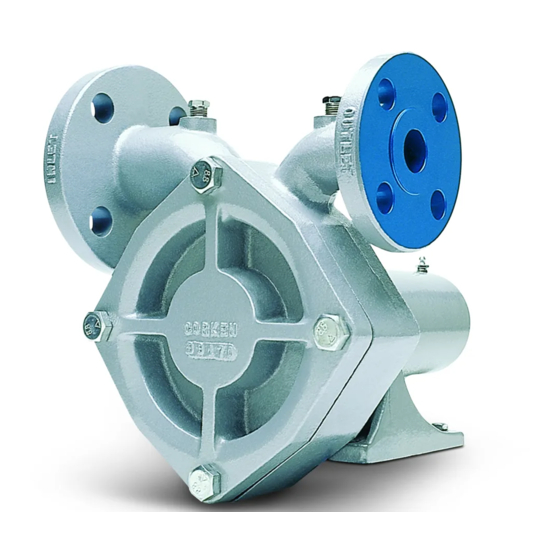

Regenerative Turbine Pumps

for LPG, NH

, and Many Other Liquefied Gases and Thin Liquids

3

All Models 060, 075, and 150

Warning: (1) Periodic inspection and maintenance of Corken products is essential. (2) Inspection, maintenance and installation of

Corken products must be made only by experienced, trained and qualified personnel. (3) Maintenance, use and installation of Corken

products must comply with Corken instructions, applicable laws and safety standards. (4) Transfer of toxic, dangerous, flammable or

explosive substances using Corken products is at user's risk and equipment should be operated only by qualified personnel according

to applicable laws and safety standards.

Scan QR code to view list

of maintenance videos.

Frame Mount

ASME Class 300 RF (ANSI) Flange (FF) and DIN Flange (FD)

Direct Mount

ASME Class 300 RF (ANSI) Flange (DLF) and DIN Flange (DLD)

Solutions beyond products...

IF102H

Advertisement

Table of Contents

Summarization of Contents

Chapter 1-Installation

1.1 Location Requirements

Specifies requirements for pump installation location and ventilation.

1.2 Inlet Piping Requirements

Details essential components for the pump inlet piping system.

1.3 Outlet Piping Requirements

Lists required components for the pump outlet piping.

1.4 Bypass System Requirements

Outlines mandatory components for the pump bypass system.

1.5 Pump Foundation for Frame Mounted Models

Provides guidance on constructing a foundation for frame-mounted pumps.

1.6 Level Base Installation

Describes how to ensure the pump mounting base is level.

1.7 Coupling Alignment

Explains the importance and method for aligning pump and driver couplings.

1.8 Driver Installation and Wiring

Covers critical aspects of correctly wiring and installing the electric motor driver.

1.9 Wire Sizing Chart

Provides a chart for selecting appropriate wire sizes based on motor HP and distance.

Chapter 2-Operation

2.1 Filling New Cylinders and Tanks

Details the procedure for filling new tanks and cylinders with gas.

2.2 Pumping From Underground Tanks

Discusses challenges and considerations for pumping liquefied gases from underground tanks.

Chapter 3-Preventative Maintenance

Purpose, Scope, and Procedures

Combines explanations of maintenance purpose, scope, and general safe procedures.

Visual Inspection and Strainer Cleaning

Details visual checks for leaks/damage and the process for cleaning the inlet strainer.

Component Inspection and Lubrication

Covers inspection of couplings, bearings, and starter points, plus lubrication tasks.

Performance Testing and Bolt Tightening

Explains pump performance testing and the importance of checking hold-down bolts.

Chapter 4-Repair Service

Impeller and Mechanical Seal Repairs

Covers common repairs involving the pump's impeller and mechanical seal.

Chapter 5-Seal Replacement Instructions

Disassembly and Component Removal

Details steps for disassembling the pump and removing its components.

Seal Cleanliness and Workmanship

Emphasizes the importance of cleanliness and careful handling during seal replacement.

Seal Housing and Seat Procedures

Covers removal of the seal housing O-ring, inspection of bearings, and seal seat removal.

Seal Assembly and Installation

Guides on verifying new seals and installing the seal housing and O-ring.

Shaft Components and Final Assembly

Details installation of seal sleeve O-ring, seal, and retainer ring.

Impeller, Key, and Cover Installation

Explains the installation of the impeller, key, and pump cover.

Appendix A-Model Number Identification Code

Model 060 Coro-Flo

Pump Options

Breaks down model number codes and available options for the Model 060.

Model 075 Coro-Flo

Pump Options

Breaks down model number codes and available options for the Model 075.

Model 150 Coro-Flo

Pump Options

Breaks down model number codes and available options for the Model 150.

Appendix B-Material and Mechanical Specifications

Equipment Type and Options Overview

Categorizes pump types and available options for models 060, 075, 150.

Features and Benefits Summary

Highlights key advantages and characteristics of the Coro-Flo pumps.

Operating Specifications and Limits

Provides operational parameters like pressure, flow, and temperature limits.

Pump Component Material Specifications

Details the materials used for various pump components.

Appendix C-Performance Curves

Model 060 Coro-Flo

Performance Curves

Shows performance curves specific to the Model 060 pump.

Model 075 Coro-Flo

Performance Curves

Displays performance curves for the Model 075 pump.

Model 150 Coro-Flo

Performance Curves

Provides performance curves for the Model 150 pump.

Appendix D-Outline Dimensions

Frame Mount Dimensions

Presents dimensional drawings and specifications for frame mount pump configurations.

Direct Mount Dimensions

Shows dimensional drawings and specifications for direct mount pump configurations.

Frame Mount Dimensions with

–101 Mounting

Details dimensions for frame mount models with a specific mounting type.

Appendix E-Parts Details

Frame Mount Parts List

Lists and illustrates pump components with part numbers for frame mount models.

Direct Mount Parts List

Lists and illustrates pump components with part numbers for direct mount models.

Appendix F-Troubleshooting Guide

Low Capacity Issues

Addresses issues related to reduced pump output and probable causes.

No Flow or Locked Pump

Provides causes and remedies for pumps with no flow or that are locked.

Pump Pressure Issues

Offers solutions for pumps failing to generate sufficient pressure.

Noise and Vibration Causes

Explains common causes of noise and vibration and their fixes.

Motor Overheating and Leaks

Troubleshoots motor overheating, overload protection, and leaks.

Appendix H-Installation and Piping Instructions

Aboveground Inlet Piping and Reducer Guidelines

Covers inlet piping, reducer types, and avoiding restrictions for aboveground pumps.

Aboveground Bypass Line Configuration and Routing

Details correct configuration and routing for bypass lines in aboveground systems.

Aboveground Pump Location Relative to Tank Level

Provides guidance on optimal pump placement relative to the tank level.

Aboveground Back Check Valve and Bypass Valve Usage

Explains the use of back check valves and bypass valve types for aboveground systems.

Aboveground Upstream Straight Pipe Requirement

Specifies the recommended length of straight pipe upstream of the pump.

Aboveground Bypass Valve Configuration for Vaporizers

Details bypass valve configurations for vaporizer feed systems.

Underground Installation Overview

Introduces considerations for installing pumps in underground tank systems.

Underground Submersible Manifold Use

Discusses the use of submersible manifolds in underground pump installations.

Need help?

Do you have a question about the Coro-Flo DLD150 and is the answer not in the manual?

Questions and answers