Summary of Contents for Berthoud HERMES 1000

- Page 1 HERMES 800 / 1000 / 1200 All regulations 82.526-A ENGLISH © BERTHOUD Agricole 06/2017 Equipment designed for the treatment of cereal and market garden crops To be read carefully and kept for future reference...

- Page 2 ADDITIONAL INFORMATION Additional information is available in the following manuals: Reference Safety and control of sprayers Manual 82.471 Manual 82.525 Boom ALSR (15/16/18 m) Manual 82.467 NOZAL nozzles table Control units Manual 82.528 IMPORTANT: Please read the manuals before using the equipment for the first time, according to its configuration. NOTE: Depending on the configuration of your equipment, some manuals may not be available in your documentation.

-

Page 3: Table Of Contents

CONTENTS 1. General ______________________________________________________________ 5 1.1. Technical characteristics 1.2. Overall dimensions 1.3. Weights table 1.4. Information plate 1.5. Noise measurements 1.6. Position of safety stickers 2. Presentation of the equipment _____________________________________ 9 2.1. Step 2.2. Direct reading float gauge 2.3. Tape gauge (Option) 2.4. - Page 4 5. Sprayer maintenance _____________________________________________ 18 5.1. Practical advice 5.2. Filters 5.3. Blocked nozzles 5.4. External washing option 5.5. Protection against oxidising agents 5.6. Checks prior to the spraying season 5.7. Periodic maintenance table 5.8. Winter Storage 6. Lubrication and greasing _________________________________________ 21 6.1.

-

Page 5: General

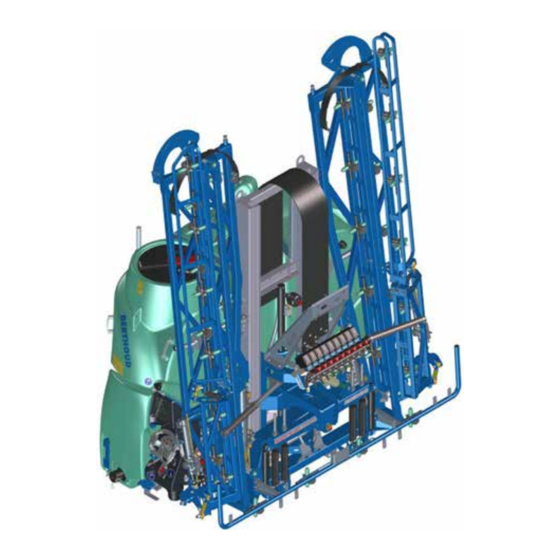

1. GENERAL 1.1 TECHNICAL SPECIFICATIONS HERMES Mounted Sprayer, regulation AUTOREGLEUR Single-piece chassis protected by UHR polyester paint Stainless steel nuts and bolts Chassis Retractable step for access to the manhole. Structure Boom lifting on mast with suspension on nitrogen ball 3-point hitch Hitching Fixed standing feet (with optional handling casters) -

Page 6: Overall Dimensions

1.665 m The height should be understood with the equipment on its support on the ground (without wheels). 1.3 WEIGHTS TABLE The data below relates to France only (see DREAL document). EQUIPMENT HERMES 800 HERMES 1000 HERMES 1200 BOOM ALSR 15... -

Page 7: Information Plate

1.4 INFORMATION PLATE The position of the information plate on your equipment is shown on page 8. The "Type Berthoud " box contains letters and figures. - Example: HER R 12 LR 18 HER = HERMES equipment R = Autoregleur regulation... -

Page 8: Position Of Safety Stickers

1.6 POSITIONS OF SAFETY STICKERS - HERMES - 417.597 417.572 417.593 417.580 455.278 401.362 443.250 418.630 400.382 417.465 401.428 417.587 417.576 417.579 417.590 ATTENTION : Lors de l’accrochage ou du décro- charge de l’appareil assurez-vous que la surface portante du sol est stable et horizontale. ATTENTION : When hitching or dismounting sprayer from tractor linkage make sure that its base is stable and horizontal with the ground. -

Page 9: Presentation Of The Equipment

2. PRESENTATION OF THE EQUIPMENT 2.1 STEP A non-slip step (1), housed in the hopper, provides safe access to the manhole (hopper in closed position). To remove the step from its housing: • Pull the step towards you (1) and pull it out all the way. •... -

Page 10: Tape Gauge (Option)

2.3 TAPE GAUGE (Option) A tape gauge (1), rhighly visible from inside the tractor cab and at control station (BERLOGIC) is positioned on the top of the equipment. It shows the volume contained in the main tank. 2.4 BOOM HEIGHT A working height (H) between 50 and 60cm above the surface to be treated is recommended. -

Page 11: Hand Washtank

HANDWASH TANK For hygiene and convenience: An 18-litre clean water tank (2), separate from the rinse tank is provided for washing your hands and all body parts (face, eyes, etc.) contaminated by the product. The tank is on the left of the main tank; the tap (3) is accessed under the control wheel on the control station. -

Page 12: Starting-Up The Sprayer

3. READYING THE SPRAYER FOR USE 3.1 ADAPTING THE TRANSMISSION SHAFT IMPORTANT: This operation must be carried out with the aim of achieving the shortest possible length. The length of the transmission shaft can mean shafts 20 mm longer than their guards when in that an adjustment is necessary, depending on the their position ready for use. -

Page 13: Rinsingbefore Using For The First Time

3.4 RINSING THE EQUIPMENT BEFORE USING IT FOR THE FIRST TIME WARNING: Before using your sprayer with phytosanitary products for the first time (herbicide, insecticide or other), the equipment must be flushed completely. • Remove the nozzles if they are fitted. NOTE: •... -

Page 14: Main Sprayer Functions With Gama 101 Or Gama 130 Pump

4. MAIN SPRAYER FUNCTIONS WITH A GAMA 101 OR GAMA 130 PUMP 4.1 ADJUSTING THE VALVES The main functions are shown on the BERLOGIC (list (1), figure 12). To obtain the desired position, pull the indexing palette (6) towards you and turn the wheel (4) to position the index (3) opposite the desired function on the disc (2) and then release the indexing palette (6). -

Page 15: Induction Hopper

4.3 INDUCTION HOPPER The Induction hopper is used to mix phytosanitary • Being able to clean the induction hopper circuit powders and liquids while the main tank is being filled. immediately after use. This feature ensures that the product is mixed NOTE: perfectly with the water and makes the work easier at the same time. -

Page 16: Spraying Functions Positions

4.4 SPRAYING FUNCTIONS: POSITIONS 1-10 NOTE: The rinsing functions allow partial rinsing if there is no change of products but not a complete rinsing of the circuit (for that, 4.5). Position of the valves Position of the State of the Power FUNCTIONS index on the... -

Page 17: Complete Rinsing Functions: Positions

4.5 COMPLETE RINSING FUNCTIONS: POSITIONS 11-15 The rinsing cycle provides thorough rinsing at the end of the day or when there is a change of product. Position of the valves Position of State Power FUNCTIONS the wheel of the Time take-off index sections... -

Page 18: Sprayer Maintenance

5. SPRAYER MAINTENANCE 5.1 PRACTICAL ADVICE The whole of the equipment should be rinsed internally egular maintenance (including tanks, booms and nozzles) by following the By cleaning your sprayer regularly during and at the procedures ( 4.5, page 17). end of spraying programs: •... -

Page 19: Blocked Nozzles

Pump, reduction gear, angle transmission: Check the oil levels. Nozzles: Change the nozzles once per year or if their flow rate is 10% to 15% greater than their initial flow rate. For this use FLOW TEST, BERTHOUD reference 765.241 or FLOW COMPARATOR, BERTHOUD reference 778.887. -

Page 20: Periodic Maintenance Table

• When adding anti-freeze, take into consideration 5.4, page 19), re-paint any bare mechanical the residual volume in the circuit pipework. parts (BERTHOUD reference 769.077 for the blue paint aerosol or 778.890 for the green paint • Run the pump at idling speed. -

Page 21: Lubrication And Greasing

(1). NOTE: Gama pump capacities: IMPORTANT: Gama 101 and 130 = 1.40 litres We recommend SAE 30 oil, BERTHOUD Drain the pump before each spraying reference 769.286, 2-litre can. program. 6.2 GREASING We recommend you to pay attention to the... -

Page 22: Spraying Circuit

7. SPRAYING CIRCUIT 82.526 - HERMES... -

Page 23: Reminder Of Your Parameters

8. REMINDER OF YOUR PARAMETERS To remind you of the programmed values, the nozzles brand and their colours, fill in the boxes below. NOZZLE 1 Nozzle NOZZLE 2 Nozzle NOZZLE 3 Nozzle NOZZLE 4 Nozzle NOZZLE 5 Nozzle NOTE: At the start of every spraying season, check the actual flow rate from the nozzles. Wheel perimeter: Number of pulses: 82.526 - HERMES... -

Page 24: Notes On Treatments Applied During The Season

9. NOTES ON THE TREATMENTS CARRIED OUT DURING THE SEASON Volume Speed Date Field Treatment Product Dose Nozzle Pressure l/ha km/h 82.526 - HERMES... - Page 25 82.526 - HERMES...

- Page 26 Agricole S.A.S. Z.I. de Bois Baron - 1 rue de l’Industrie 69220 BELLEVILLE S/SAÔNE - FRANCE Tel.: 04 74 06 50 50 - Fax : 04 74 06 50 77 RCS Villefranche-Tarare B 515 720 829 www.berthoud.com 82.526 - HERMES...

Need help?

Do you have a question about the HERMES 1000 and is the answer not in the manual?

Questions and answers