Summarization of Contents

Introduction

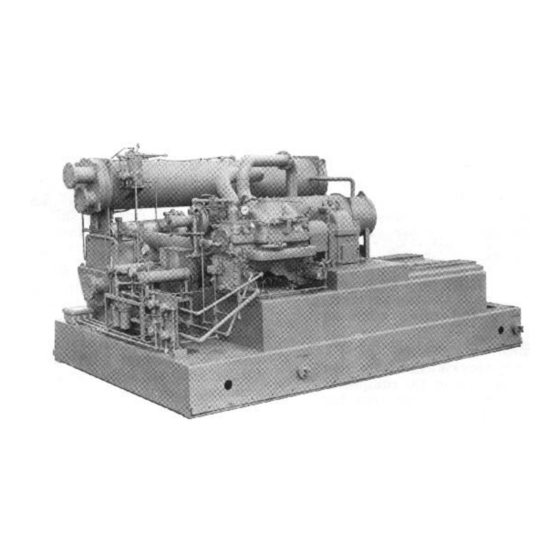

General

General overview and initial considerations before starting machine operations.

Job Data Required

List of essential job specifications, drawings, and data needed for preparation.

Initial Preparations

Key checks and tasks to perform before beginning machine start-up.

Charge Machine with Refrigerant

Check Coupling Separation and Alignment

Verifying compressor, gear, and drive alignment and coupling separation.

Grouting

Information on grouting materials and placement procedures.

Check Safety Control Settings

Adjusting and verifying safety control settings before operating the machine.

START-UP PROCEDURE

Compressor Oil Preparation

Procedures to prevent oil foaming and loss during start-up.

Before Starting Machine Check

Final checklist before starting the machine.

To Start Machine

Detailed steps for starting the refrigeration machine.

Adjusting the Refrigerant Charge

Adjusting Refrigerant Levels

Adjusting liquid level controllers for proper vessel liquid levels.

Purge Operation

Check Running System

Checking operating sounds, temperatures, pressures, and levels.

Hot Alignment Check

Doweling

Procedure for doweling components to maintain coupling alignment.

PUMPOUT PROCEDURES

General

General information on the use of the pumpout unit.

Pumpout Adjustments

Adjustments for pumpout compressors and controls.

Machine Evacuation (No Refrigerant)

Steps to evacuate the machine when no refrigerant is present.

Remove Air After Opening Machine

Procedure to remove air after opening the machine with refrigerant in storage.

Transfer Refrigerant from Storage Tank

Transferring refrigerant from a storage tank to the machine.

Transfer Refrigerant to Storage Tank (Below Machine)

Transferring refrigerant from the machine to a lower storage tank.

Pressurize Machine (No Refrigerant)

Pressurizing the machine when it has no refrigerant.

Distill Refrigerant Charge

Removing water and impurities from refrigerant by distillation.

Pumpout Procedures, Later Model 5F Units

Pumpout procedures for later model 5F units with specific valves.

Transfer Refrigerant to Storage Tank (Above/Level)

Transferring refrigerant to storage tanks located above or level with the machine.

Pressurize Machine (No Refrigerant, cont.)

Pressurizing the machine when it has no refrigerant.

Distill Refrigerant Charge (cont.)

Distilling refrigerant to remove water and impurities.

Charge Refrigerant

Using the pumpout unit to charge refrigerant into a dehydrated machine.

6D Pumpout Procedures

Evacuate Refrigeration Machine (No Refrigerant)

Evacuating the refrigeration machine for 6D units.

Evacuate Storage Tank

Evacuating the storage tank for 6D units.

Transfer Refrigerant from Storage Tank

Transferring refrigerant from storage to a 6D machine.

Transfer Refrigerant from Machine to Storage Tank

Transferring refrigerant from a 6D machine to storage.

Remove Entrapped Refrigerant

Removing any entrapped refrigerant from the 6D unit.

Establish Vacuum for Service

Establishing vacuum for service on 6D units.

INSTRUCTING THE OPERATOR

Cooler-Condenser-Economizer

Explaining the function of the cooler, condenser, and economizer.

Key Machine Components

Explaining major machine components and their functions to the operator.

Need help?

Do you have a question about the 19EB and is the answer not in the manual?

Questions and answers