Advertisement

Technische Information

Technical Information

Information Technique

Schutzgeräte

SE-C1 und SE-C2

für Schraubenverdichter

Inhalt

1 SE-C1 und SE-C2

4 Technische Daten

5 Prinzipschaltbilder

1 SE-C1 und SE-C2

Diese optionalen Schutzgeräte über-

wachen mehrere Betriebs-Parameter

und schützen so den Verdichter über

die allgemein üblichen Kontrollfunkti-

onen hinaus.

Zusätzlich zu den Funktionen des

Standard-Schutzgeräts SE-E1 (Über-

wachung von Motor- und Druckgas-

Temperatur, Drehrichtung und Pha-

senausfall vgl. ST-120) überwachen

SE-C1 und SE-C2 noch die Phasen-

symetrie, Schalthäufigkeit und Ölver-

sorgung. Sie ersetzen die Schutzgerä-

te SE-E1, INT389R sowie OFC bei

HS- und OS-Schrauben.

Das SE-C1 ist für die CSH- und die

HS.64/74-Schrauben und das SE-C2

speziell für HS.85-Verdichter konzi-

piert.

Die Schutzgeräte arbeiten über einen

großen Spannungsbereich. Dies er-

laubt den Einsatz in nahezu allen

Stromnetzen (50 und 60 Hz) sowie

eine Überwachung von Verdichtern im

Frequenzumrichter-Betrieb. Ein Vor-

schaltgerät für den Betrieb von Son-

dermotoren für 575 und 690 V ist

nicht erforderlich.

Protection Devices

SE-C1 and SE-C2

for Screw Compressors

Content

1 SE-C1 and SE-C2

2 Monitoring functions

5 Schematic wiring diagrams

1 SE-C1 and SE-C2

These optional protection devices

monitor several operational parame-

ters to protect the compressor beyond

the standard control functions.

SE-C1 and SE-C2 offer all functionali-

ty provided by the standard protection

device SE-E1 (monitoring of motor

and discharge gas temperatures, rota-

tion direction and phase failure, see

ST-120), but also monitor phase sym-

metry, switching frequencies and oil

supply. They replace the protection

devices SE-E1, INT389R and OFC for

HS and OS screws.

The SE-C1 is designed for CSH and

HS.64/74 screws, the SE-C2 especial-

ly for the HS.85 compressors.

The protection devices work over a

large voltage range. This allows the

use in nearly all power supply sys-

tems (50 and 60 Hz), as well as for

monitoring compressors with frequen-

cy inverters. A step down resistor

device for the operation of special

motors for 575 and 690 V is not

required.

Dispositifs de protection

SE-C1 et SE-C2

pour les compresseurs à vis

Sommaire

1 SE-C1 et SE-C2

2 Fonctions de contrôle

3 Fonctions et pannes signalées

1 SE-C1 et SE-C2

Ces dispositifs de protection optionnaux

contrôlent plusieurs paramètres de fonc-

tionnement et protègent aussi le com-

presseur au-delà des fonctions de contrô-

le usuelles.

En plus des fonctions du dispositif de pro-

tection standard SE-E1 (contrôle de la

température moteur et du gaz de refoule-

ment, sens de rotation et défaut de

phase, voir ST-120) sont supplémentés

par des fonctions des SE-C1et SE-C2:

surveillance de la symétrie des phases,

de la fréquence d'enclenchement et d'ali-

mentation en huile. Ils remplacent les dis-

positifs de protection SE-E1, INT389R et

OFC pour des vis HS et OS.

Le SE-C1 a été conçu pour les vis CSH

et HS.64/74, le SE-C2 spécialement pour

les compresseurs HS.85.

Les dispositifs de protection couvrent une

large plage de tensions. Ils sont donc uti-

lisables sur pratiquement tous les

réseaux électriques (50 et 60 Hz) ainsi

que pour le contrôle des compresseurs

avec convertisseur de fréquences. Un

transformateur pour le fonctionnement

des moteurs spéciaux pour 575 et 690 V

n'est pas nécessaire.

ST-121-2

Advertisement

Summarization of Contents

Introduction to Bitzer SE-C1 and SE-C2 Protection Devices

SE-C1 and SE-C2 Overview

Optional protection devices monitor parameters beyond standard functions for compressors.

Key Monitoring Functions

Overview of the various monitoring functions provided by SE-C1 and SE-C2.

Functional and Failure Messages

Details on functional and failure messages indicated by the protection devices.

Technical Data and Schematics Summary

Summary of technical data and principle wiring diagrams for the protection devices.

Detailed Monitoring Functions

Temperature Monitoring

Monitoring of motor, oil, and discharge gas temperatures via PTC sensors.

PTC Measuring Circuit Integrity

Monitoring of the PTC measuring circuit for short circuits or cable failures.

Advanced Compressor Monitoring

Phase Failure, Asymmetry, and Rotation Checks

Monitoring phase failure, asymmetry, and rotation direction for compressor protection.

Maximum Switching Frequency Control

Monitoring and limiting the maximum switching frequency of the compressor.

Oil Level and Supply Monitoring

Monitoring of oil level in CSH compressors and the oil supply.

Oil Management and Reset Procedures

Oil Supply Flow Monitoring

Monitoring the oil supply for HS screws via oil flow switch.

Oil Stop Valve Functionality

Monitoring the oil stop valve function for SE-C2 on HS.85 compressors.

Manual Resetting Protection Devices

Procedure for manual reset of the protection devices after fault clearance.

SE-C1 Electrical Wiring Diagrams

CSH Compressor Wiring

Electrical connection diagram for SE-C1 in CSH compressor terminal box.

HS.64/HS.74 Compressor Wiring

Electrical connection diagram for SE-C1 in HS.64/HS.74 compressor terminal box.

SE-C2 Electrical Wiring Diagrams

HS.85 Compressor Wiring

Electrical connection diagram for SE-C2 in HS.85 compressor terminal box.

Protection Device Signal Lamp Functions

H1/H2: Pause Time Indication

H1 off, H2 on: Indicates pause time restriction.

H1/H2: Phase Issue Alerts

H1 on, H2 on: Indicates phase issues like wrong direction or failure.

H1/H2: Temperature/PTC Faults

H1 flashing, H2 on: Indicates temperature or PTC circuit faults.

Signal Output Terminals H1/H2

Signal outputs for H1 and H2 lamps on the protection device.

SE-C1 LED Fault Diagnosis

Operational Status LED Indicators

LEDs indicating compressor operating status: running or at standstill.

SE-C1 Fault Message LED Combinations

LED combinations indicating specific fault conditions for SE-C1.

SE-C2 LED Fault Diagnosis

SE-C2 Fault Message LED Combinations

LED combinations indicating specific fault conditions for SE-C2.

Technical Specifications

Operating and Motor Voltage Specifications

Operating voltage range and motor voltage specs for various power sources.

Relay and PTC Circuit Specifications

Specifications for relay contacts and the PTC measuring circuit.

Connection Terminals and Safety Warnings

Terminal details, wire capacity, and critical safety warnings for connections.

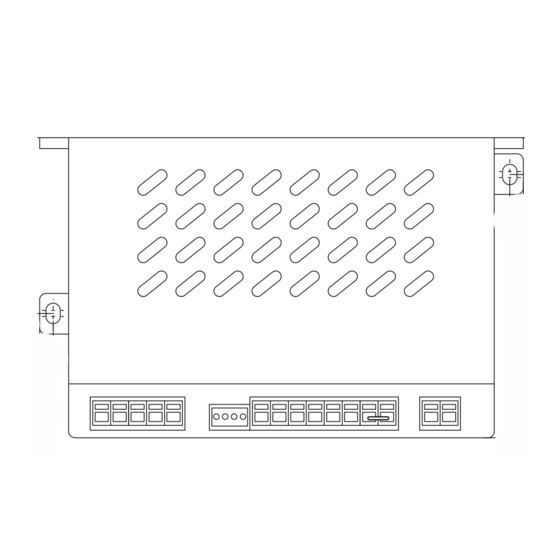

Dimensional Drawings and Layout

Device Dimensions and Component Layout

Mechanical dimensions and component layout of the protection devices.

Diagram Legend

Legend identifying components shown in the dimensional drawings.

Component Identification for Schematics (Part 1)

Thermostats, Fuses, and Control Units

Identification of thermostats, fuses, and control units (B1-B2, F1-F21).

Signal Lamps, Contactors, and Relays

Identification of signal lamps, contactors, and relays (H1-H8, K1-K9).

Time and Pulse Relays Identification

Identification of time and pulse relays (K3T, K4T, K5T, K7T).

Compressor, Inverter, Switch, Sensor Identification

Identification of compressor, inverter, switch, and sensor components (M1, N1, Q1, R1-R9).

Component Identification for Schematics (Part 2)

Switches and EMC Screening Units

Identification of switches (S1, S2, S4) and EMC screening units (U).

CSH Compressor Solenoid Valves

List of solenoid valves specific to CSH compressors (Y1-Y5).

HS.64/HS.74 Compressor Solenoid Valves

List of solenoid valves specific to HS.64/HS.74 compressors (Y1-Y3, Y6-Y8).

HS.85 Compressor Solenoid Valves

List of solenoid valves specific to HS.85 compressors (Y2-Y8).

Control and Protection Device Identification

Identification of the SE-B2 oil filter control and SE-C1/SE-C2 protection devices.

CSH Part Winding Start Wiring Diagram

Infinite Capacity Control

Infinite capacity control for CSH compressors.

Wiring Diagram Options

Options for ECO operation, liquid injection, and oil level monitoring.

CSH Part Winding Start: 4-Step Capacity Control

4-Step Capacity Control Details

4-step capacity control for CSH compressors.

Wiring Diagram Options

Options for ECO operation, liquid injection, and oil level monitoring.

CSH Star-Delta Start Wiring Diagram

Infinite Capacity Control

Infinite capacity control for CSH compressors.

Y/A Switching Time Relay Requirement

Time relay needed if Y/A switching time exceeds 2 s.

CSH Star-Delta Start: 4-Step Capacity Control

4-Step Capacity Control Details

4-step capacity control for CSH compressors.

Wiring Diagram Options

Options for ECO operation, liquid injection, and oil level monitoring.

HS.64/HS.74 Wiring Diagrams

Control Sequence Notes

Note on control sequences Y6/Y7 and manual SH-100.

ECO Operation Option (Path 21)

Option for ECO operation, specifying path 21.

Terminal Box Heating Element Option (Path 23)

Optional heating element for terminal box, specifying path 23.

HS.85 Part Winding Start Wiring Diagram

Infinite Capacity Control

Infinite capacity control for HS.85 compressors.

ECO Operation Option (Path 27)

Option for ECO operation, specifying path 27.

Terminal Box Heating Element Option (Path 28)

Optional heating element for terminal box, specifying path 28.

HS.85 Part Winding Start: 4-Step Capacity Control

4-Step Capacity Control Details

4-step capacity control for HS.85 compressors, dependent on conditions.

Operating Condition Limitation for CR50%

Limitation to minimum CR50% based on operating conditions.

Frequency Inverter Operation: SE-C1 and CSH

Legend Reference for Diagrams

References to legend pages for component identification.

K7T Delay vs. Inverter Ramp-Up Time

K7T delay time must match frequency inverter ramp-up time (max 5 s).

ECO and Liquid Injection Options

Options for ECO operation and liquid injection.

Frequency Inverter Operation: SE-C1 and HS.64/HS.74

Legend Reference for Diagrams

References to legend pages for component identification.

ECO Operation Option (Path 22)

Option for ECO operation, specifying path 22.

Terminal Box Heating Element Option (Path 24)

Optional heating element for terminal box, specifying path 24.

Frequency Inverter Operation: SE-C2 and HS.85

Legend Reference for Diagrams

References to legend pages for component identification.

ECO Operation Option (Path 28)

Option for ECO operation, specifying path 28.

Terminal Box Heating Element Option (Path 29)

Optional heating element for terminal box, specifying path 29.

Need help?

Do you have a question about the SE-C2 and is the answer not in the manual?

Questions and answers