Summarization of Contents

INTRODUCTION

GENERAL SAFETY TIPS

Provides essential safety guidelines and warnings for operating and maintaining the MEC aerial work platform.

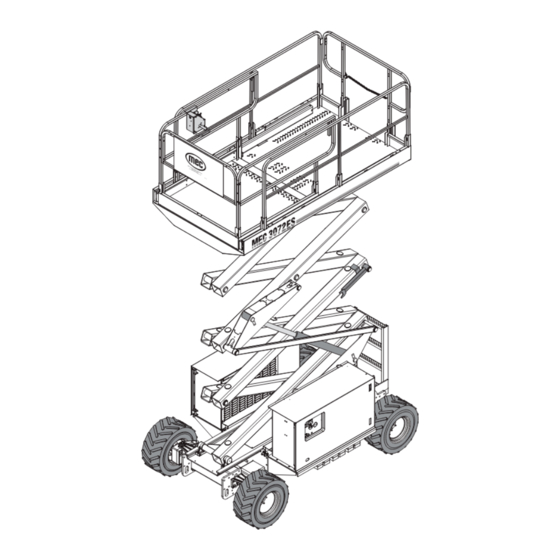

PRIMARY MACHINE COMPONENTS

Identifies and illustrates the main components of the MEC aerial work platform.

PRIMARY MACHINE COMPONENTS: COMPARTMENTS

Details the components located within the control and power modules of the machine.

PRIMARY MACHINE COMPONENTS LOCATOR

Maps major components to their respective sections in the manual for easy reference.

SPECIFICATIONS: ANSI MODELS

Lists technical specifications for ANSI compliant models of the aerial work platform.

SPECIFICATIONS: CE MODELS

Lists technical specifications for CE compliant models of the aerial work platform.

LUBRICATION

Provides a chart detailing lubrication points, specifications, and recommended frequencies.

SECTION 1 HYDRAULICS

Hydraulic Fluid

Details handling precautions and recommendations for hydraulic fluid used in the system.

Hydraulic System components

Describes the key components of the hydraulic system, including reservoir, filter, and pump.

Wheel Drive

Explains the hydraulic wheel motors that power the machine's drive system.

Parking Brake and Towing Circuit

Details the operation and resetting procedure for the parking brake and towing mechanism.

Emergency Systems And Procedures

Outlines procedures for emergency lowering of the platform in case of power failure.

Steering Circuit

Illustrates and describes the hydraulic steering system components and operation.

Platform Lift Circuit

Explains the hydraulic system responsible for lifting and lowering the platform.

Lift Cylinder Components

Details the components and diagrams for the lift cylinders used in the platform system.

Optional Outriggers

Describes the hydraulic manifold and cylinders used for the optional outrigger system.

Cylinder Repair

Provides instructions for the removal, preparation, and disassembly of hydraulic cylinders.

Hydraulic Manifold

Details the removal, disassembly, cleaning, assembly, and installation of the hydraulic manifold.

SECTION 2 ELECTRICAL SYSTEM

Electrical System - General

Provides an overview of the electrical control system, including upper and lower controls.

Deutsch Connectors

Explains the procedure for connecting, disconnecting, and servicing Deutsch brand electrical connectors.

Batteries

Covers battery maintenance, recommended intervals, and specifications for the machine's power source.

Battery Charger

Details electrical requirements and specifications for the battery charging system.

Controls

Describes the function and operation of various controls, including emergency stops and platform/base selectors.

Upper Controls

Explains the operation of the machine using the upper control panel, including joystick and switches.

Alarms and Switches

Details the function of various alarms and switches, such as Master Disconnect and Limit Switches.

Continuity Checks

Provides instructions for performing continuity checks on various types of electrical switches.

Motor Controller

Identifies the location and function of motor control modules used in the system.

SECTION 3 MECHANICAL COMPONENTS

Torque Specifications

Provides torque values for various fasteners and hydraulic components for proper assembly.

Base / Undercarriage

Details maintenance precautions and inspection points for the machine's base and undercarriage.

Hoses and Cables

Provides guidance on inspecting and checking hydraulic hoses and electrical cables for damage or leaks.

Raising the Machine

Outlines the safe procedures for raising and supporting the machine using jacks and stands.

Tires/Wheels

Provides instructions for inspecting tires and the procedure for changing wheels on the machine.

Drive Motors

Describes the hydraulic drive motors on the front and rear axles and their associated brakes.

Steer Cylinder

Explains the replacement procedure for the hydraulic cylinders used in the steering system.

Platform Removal

Details the step-by-step procedure for safely removing the platform assembly from the machine.

Lift Cylinder Removal and Installation

Provides instructions for the removal and installation of the machine's lift cylinders.

Scissor Beam Assembly

Describes the maintenance and inspection of the scissor beam assembly, including component removal.

Outrigger Function

Explains the operational characteristics and system logic for the optional outrigger deployment.

SECTION 4 TROUBLESHOOTING

General Troubleshooting Tips

Offers general guidance for diagnosing common electrical and hydraulic system malfunctions.

Electrical System Troubleshooting

Details troubleshooting steps for the electronic control system, modules, and communication links.

EZ-Cal Scan Tool

Explains how to use the EZ-Cal interface tool for troubleshooting and making adjustments to the machine.

Using the EZ-Cal with the Flow Charts

Guides on using EZ-Cal flow charts to locate diagnostic information and adjust machine personalities.

EZ-Cal ADJUSTMENT

Provides a table detailing adjustable parameters, their IDs, personalities, factory settings, and explanations.

EZ-CAL SETUP

Details the procedures for configuring machine settings using the EZ-Cal tool, requiring specific access levels.

EZ-Cal DIAGNOSTICS Menu

Explains how to use the EZ-Cal diagnostics menu to view and test individual circuits for irregularities.

RETRIEVE MODE AND HELP MESSAGES FROM THE EZ-CAL

Describes how to access and interpret MODE and HELP messages provided by the EZ-Cal tool.

EZ-CAL HELP MESSAGES

Lists and explains various information-only and function-active messages displayed by the EZ-Cal system.

FUNCTION ACTIVE Messages

Details messages indicating normal operation of specific machine functions.

CALIBRATION Messages

Lists messages related to calibration requirements for sensors and system functions.

SHUTDOWN Help Messages

Lists messages that indicate the system has shut down functions to prevent issues.

WIRING Messages

Identifies common HELP messages related to potential problems with the machine's wiring.

P600 TEMPERATURE Messages

Lists HELP messages indicating issues related to excessive duty cycling or poor heatsinking of the P600 module.

SUPPLY Messages

Highlights HELP messages related to internal supply issues within the control modules.

SENSOR Messages CE MODELS

Lists HELP messages indicating problems detected with sensors, specifically for CE models.

CANBUS Messages

Identifies HELP messages related to communication issues between modules via the CAN bus.

POWER WIRING Messages

Lists HELP messages indicating problems likely caused by errors in the machine's power wiring.

OTHER Messages

Covers miscellaneous HELP messages, including 'SOME BIG BAD PROBLEM!' and 'FACTORY OVERRIDE'.

TROUBLE TABLE

A guide to help technicians diagnose problems by matching symptoms to possible causes and remedies.

HYDRAULIC PRESSURE ADJUSTMENT PROCEDURES

Provides instructions and a table for checking and adjusting hydraulic pressure relief valves.

TROUBLESHOOTING BATTERY CHARGER

Offers guidance on diagnosing and resolving issues related to the machine's battery charger performance.

SECTION 5 SCHEMATICS

Hydraulic Schematic

Provides a detailed diagram of the machine's hydraulic system with component callouts.

Electric System

Presents schematics for the machine's electrical system, detailing upper controls for early and current models.

Electric Schematics: Base

Illustrates the electrical wiring diagram for the base of the machine, showing connections to modules.

P600 Motor Control Module

Shows the P600 Motor Control Module, its location, and pinout details for system connections.

GP400 Matrix Module

Details the GP400 Matrix Module, its location, pinouts, and connections within the control system.

Matrix Module Controller

Illustrates the Matrix Module Controller, its location, and pin assignments for system integration.

SECTION A CONTROLS

Upper Controls, ANSI Models

Details the components and wiring diagram for the upper control panel on ANSI models.

Upper Controls, CE Models

Details the components and wiring diagram for the upper control panel on CE models.

Upper Control Box Cover Assembly

Provides an exploded view and part list for the upper control box cover assembly.

Upper Control Joystick

Illustrates the components of the upper control joystick assembly, including switches and grips.

Lower Controls

Details the components and wiring diagram for the lower control panel of the machine.

SECTION B PLATFORM AND RAILS

Platform Assembly

Provides an exploded view of the platform assembly, showing all constituent parts.

Rollout Deck Lock Pin Assembly

Illustrates the components of the rollout deck lock pin assembly for securing the platform extension.

Roller Assembly

Details the components that make up the roller assembly for the platform's movement.

Entry Chain, ANSI Models

Illustrates the components of the entry chain system used on ANSI models.

Entry Chain, ANSI Models

Lists the part numbers and quantities for the entry chain assembly on ANSI models.

Swing Gate

Provides an illustration of the swing gate assembly, likely for CE Standard / ANSI Option.

Swing Gate, CE Standard / ANSI Option

Lists the parts and quantities for the swing gate assembly, applicable to CE and ANSI models.

Control Cable Installation

Illustrates the installation process for control cables within the machine's structure.

Control Cable / Horn Installation

Lists parts for control cable and horn installation, noting serial number applicability.

Power to Platform

Illustrates the components for delivering power to the platform, including receptacle and conduit.

Power to Platform – Airline to Platform

Lists parts for the power to platform system and details airline components for platform connection.

Lanyard Anchorage Points

Illustrates the location and components of certified lanyard anchorage points on the platform.

Lanyard Attachment: CE Standard – ANSI Option

Lists parts for the lanyard attachment kit, applicable to CE Standard and ANSI Option configurations.

SECTION C SCISSORS

Scissor Assembly, 3072

Provides an exploded view of the 3072 scissor assembly, detailing beam and component installation.

Scissor Assembly, 3072RT: Up to Serial #11211099

Lists parts for the 3072RT scissor assembly up to a specified serial number.

Scissor Assembly, 3772

Illustrates the 3772 scissor assembly, showing beam and cylinder installation details.

Scissor Assembly, 3772RT: Up to Serial #11211099

Lists parts for the 3772RT scissor assembly up to a specified serial number.

Scissor Assembly, Beams Install

Provides a diagram showing the installation of beams within the scissor assembly.

Scissor Assembly, 3072RT: Serial #11211100 - UP

Lists parts for the 3072RT scissor assembly from serial number 11211100 onwards.

Scissor Assembly, Cylinder Install

Illustrates the installation of the cylinder within the scissor assembly structure.

Scissor Assembly, 3072RT: Serial #11211100 - UP (continued)

Lists parts for the 3072RT scissor assembly, continuing from a previous serial number range.

Scissor Assembly, Cylinder Install

Illustrates the installation of the cylinder within the scissor assembly structure for 3772 models.

Scissor Assembly, 3772RT: Serial #11211100 - UP

Lists parts for the 3772RT scissor assembly from serial number 11211100 onwards.

Scissor Assembly, Cylinder Install

Illustrates the cylinder installation within the scissor assembly for 3772 models, continuing from previous sheets.

Scissor Assembly, 3772RT: Serial #11211100 - UP (continued)

Lists parts for the 3772RT scissor assembly, continuing from a previous serial number range.

Limit Switch Installation

Illustrates the installation of the limit switch, including its mounting bracket and associated hardware.

Limit Switch Installation

Lists parts required for the installation and mounting of the limit switch.

Scissor Guards

Provides an illustration of the scissor guards, showing their placement and components.

Scissor Guards - 3072ES, CE Models

Lists parts for scissor guards specifically for the 3072ES model with CE configuration.

Scissor Guards

Illustrates the scissor guards for 3772CE models.

Scissor Guards - 3772ES, CE Models

Lists parts for scissor guards specifically for the 3772ES model with CE configuration.

SECTION D AXLES

Rear Axle Assembly

Illustrates the rear axle assembly, including the hydraulic wheel motor with brake.

Rear Axle Assembly

Lists parts for the rear axle assembly, including the motor, mount, and wheel/tire components.

Front Axle Assembly

Illustrates the front axle assembly, showing the hydraulic wheel motor and associated hardware.

Front Axle Assembly

Lists parts for the front axle assembly, including the wheel motor, mount, and steering components.

X72 Wheel Motor, Rear

Provides an exploded view of the DT710 brake motor components used in the rear axle.

Wheel Motor, Rear

Lists parts for the rear wheel motor, including seals and disk kits.

X72 Wheel Motor, Front

Illustrates the DT701 Series motor components for the front wheel motor.

Wheel Motor, Front

Lists parts for the front wheel motor, including seals and seal kits.

SECTION E HYDRAULICS

Main Manifold Assembly

Provides an illustration of the X72ES manifold assembly, showing component placement.

Main Manifold Assembly

Lists parts for the main manifold assembly, including valves, coils, and fittings.

Main Relief Manifold

Illustrates the main relief manifold assembly with its components.

Main Relief Manifold Assembly

Lists parts for the main relief manifold, including the relief valve and fittings.

Outrigger Manifold Installation

Illustrates the installation of the outrigger manifold and its connection to the main manifold.

Manifold - Outrigger (HD Models)

Lists parts for the outrigger manifold assembly on HD models, including coils and valves.

Hose Kit - Axles

Illustrates the routing of hydraulic hoses connected to the machine's axles.

Hydraulic Hoses - Axles

Lists part numbers and specifications for hydraulic hoses used with the machine's axles.

Hose Kit - Steering, Motor Case Drain, Brake

Illustrates the routing of hydraulic hoses for steering, motor case drain, and brake systems.

Hydraulic Hoses - Steering, Brake Release and Axle Return

Lists part numbers and specifications for hydraulic hoses related to steering, brake release, and axle return.

Hose Kit - Pump and Lift

Illustrates the routing of hydraulic hoses connecting the pump to the lift cylinders.

Hydraulic Hoses - Pump and Return

Lists part numbers and specifications for hydraulic hoses used for the pump and return lines.

Hose Kit - Outriggers

Illustrates the hydraulic hose routing for the outrigger system on HD models.

Hydraulic Hoses - Outrigger (HD Models)

Lists part numbers and specifications for hydraulic hoses used with the outrigger system on HD models.

3072 Lift Cylinder

Provides an exploded view of the 3072 lift cylinder with bearings, showing all components.

Lift Cylinder, 3072

Lists parts for the 3072 lift cylinder, including the cylinder itself, hoses, fittings, and seals.

3772 Lower Lift Cylinder

Illustrates the components of the 3772 lower lift cylinder, showing seals and barrel assembly.

Lift Cylinder, Lower, 3772

Lists parts for the lower lift cylinder of the 3772 model, including cylinder, hoses, and valve components.

3772 Upper Lift Cylinder

Provides an exploded view of the 3772 upper lift cylinder, showing seals and barrel assembly.

Lift Cylinder, Upper, 3772

Lists parts for the upper lift cylinder of the 3772 model, including cylinder, hoses, and coil components.

X72 Steering Cylinder

Illustrates the components of the X72 steering cylinder, showing seals and rod assembly.

Steering Cylinder

Lists parts for the steering cylinder, including adapters, jamnuts, and rod ends.

Outrigger Cylinder

Provides an illustration of the outrigger cylinder, showing seals and piston assembly.

Outrigger Cylinder

Lists parts for the outrigger cylinder, including the cylinder, switches, coils, and fittings.

SECTION F BASE

Base Assembly

Illustrates the base assembly of the machine, showing the main frame and structural weldments.

Base Assembly

Lists parts for the base assembly, including weldments, covers, and support modules.

Ballast

Illustrates the ballast or counterweight installation for both 3072 and 3772 models.

Ballast (Counterweight) Installation

Lists parts for the ballast and counterweight installation, including bars, retainers, and plates.

Modules Installation

Illustrates the installation of control and power modules onto the machine's chassis.

Modules Installation

Lists parts required for installing control and power modules, including weldments, covers, and bolts.

Control Module

Provides an illustration of the control module, showing the placement of internal components.

Control Module

Lists parts for the control module, including panels, brackets, controllers, and hydraulic components.

Control Module

Illustrates the control module layout, showing the placement of various electronic and hydraulic components.

Control Module (continued)

Lists additional parts for the control module, including screws, nuts, pump, and covers.

Power Module

Illustrates the power module, showing the battery arrangement and battery disconnect switch.

Power Module

Lists parts for the power module, including weldments, panels, battery holddowns, and batteries.

Wire Harness

Illustrates the routing of wire harnesses connecting various modules and components of the machine.

Wire Harness

Lists part numbers for various wire harnesses connecting the main control module to other system components.

Outrigger Installation

Illustrates the installation process for the outrigger system on HD models.

Outrigger Installation (3772ES HD)

Lists parts for the outrigger installation specific to the 3772ES HD model.

SECTION G DECALS

Decals, ANSI Models

Illustrates various safety, warning, and identification decals applied to ANSI models of the machine.

Decals, ANSI Models (continued)

Lists additional decals for ANSI models, including warnings, capacities, and model identifiers.

Decals, CE Models

Illustrates safety, warning, and capacity decals specific to CE models of the aerial work platform.

Decals, CE Models

Lists decals for CE models, including warnings, battery information, and control labels.

Decals, Front and Control Side

Illustrates decals located on the front and control side of the machine for CE models.

Decals, Rear and Power Side

Illustrates decals located on the rear and power side of the machine for CE models.

Need help?

Do you have a question about the 3772ES and is the answer not in the manual?

Questions and answers