Table of Contents

Advertisement

Advertisement

Table of Contents

Summarization of Contents

1. X-Line Rigging System

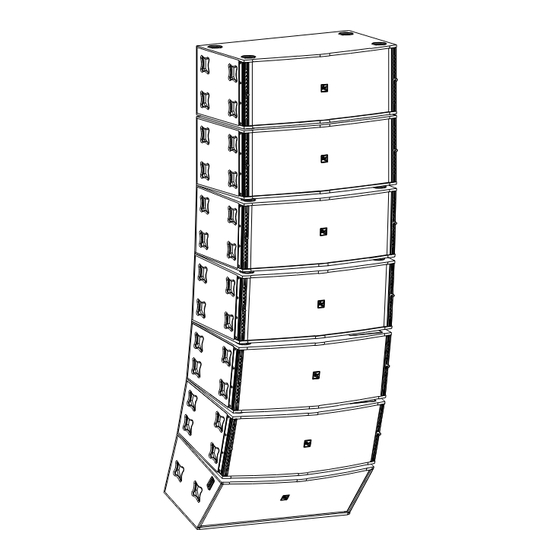

1.1 Overview of the X-Line Flying System

Describes the X-Line system's design for acoustic line arrays, hinged rigging, and track hardware for easy, predictable assembly.

1.2 Enclosure Rigging Hardware Details

Details proprietary high-strength aluminum-alloy track and bracket assemblies used for front and rear rigging on X-Line enclosures.

1.3 Rear Rigging Hinge Details

Explains the Xvhg grid hinge and Xvhl linking hinge, their installation, and safety checks for rear rigging connections.

1.4 Front Rigging Strap Details

Covers Xvsg, Xvsl, and Xvsd chain rigging straps, their triple-stud fittings, and installation procedures for front rigging.

1.5 Xvbp Pull-Up Bar Details

Details the Xvbp pull-up bar used at the bottom of an array to adjust vertical splay angles when gravity is insufficient.

1.6 ATM X-Line Grid Details

Describes the ATM Flyware X-Line Grid, its rigging track compatibility, and attachment of top enclosures using Xvsg straps.

1.7 RS-1B Double-Stud Rigging Fitting

Introduces the RS-1B double-stud fitting for special lightweight applications and pull-up assemblies.

2. X-Line Rigging and Flying Techniques

2.1 Array Considerations

Discusses constructing acoustic line arrays with X-Line systems, stereo configurations, and mirror imaging for optimal coverage.

2.2 Adjusting the Vertical Angles of the Enclosures

Explains how to adjust enclosure vertical angles using front rigging strap attachment locations and chain lengths.

2.3 Deciding Whether to Use an Xvhg or Xvhl at the Grid

Compares Xvhg grid hinges and Xvhl linking hinges for rear attachment to the grid, considering flexibility and rigidity.

2.4 Rigging an Array with Boxes Using X-Line Dollies

Details techniques for rigging arrays using Bottom Stacking Dollies, Downfill Stacking Dollies, and Front Dollies.

2.5 Pull-Up Techniques

Describes using pull-up assemblies like the Xvbp bar for achieving necessary cabinet angles when gravity is insufficient.

3. Rigging-Strength Ratings, Safety Factors, and Special Safety Considerations

3.1 Working-Load Limit and Safety Factor Definitions

Defines working-load limit (WLL) and safety factors, emphasizing a 5:1 ratio and user responsibility for compliance.

3.2 Structural Rating Overview

Outlines the two independent strength ratings: individual rigging point strength and overall enclosure strength.

3.3 Simplified Structural-Rating Guidelines

Presents simplified guidelines for evaluating array safety based on angles, weight, and rigging hardware configurations.

3.4 Complex Structural-Rating Analysis

Explains the need for detailed analysis of forces on rigging hardware and enclosures, recommending consultation with structural engineers.

3.5 Wind Loading

Addresses the system's design to survive winds up to 60 mph and advises against overhead suspension in high winds.

3.6 Electro-Voice Structural-Analysis Procedures

Describes Electro-Voice's structural testing and computer-modeling procedures used in product development and verification.

4. Rigging Inspection and Precautions

Electro-Voice X-Line Loudspeaker Systems

Inspect enclosures for cracks, deformations, or missing components that could reduce strength before each use.

Electro-Voice X-Line Rear Rigging Hinges

Check rear rigging hinges for cracks, corrosion, or damage; ensure they are securely locked before lifting.

Electro-Voice X-Line Front Chain Rigging-Strap Assemblies

Inspect front rigging straps for chain or fitting damage; verify secure locking of fittings before lifting.

Electro-Voice X-Line Pull-Up Bars

Inspect pull-up bar assembly for damage and ensure all rigging hinges are securely locked prior to lifting.

Grid Assemblies

Inspect grid assemblies and associated hardware for damage or deformation, and verify load limitations.

Chain Hoists

Inspect chain hoists for damage and follow manufacturer recommendations for operation and certification.

Building, Tower or Scaffold Supports

Evaluate structural supports for adequacy and certify them with a professional engineer before use.

Miscellaneous Mechanical Components

Inspect mechanical components like chains, slings, shackles for damage or wear, and adhere to manufacturer limits.

Need help?

Do you have a question about the Xsub and is the answer not in the manual?

Questions and answers