Advertisement

Table of Contents

O

PERATOR'S

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning:

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 368022 Cleveland, Ohio 44136-9722.

MTD PRODUCTS INC. P.O. BOX 368022 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A.

M

ANUAL

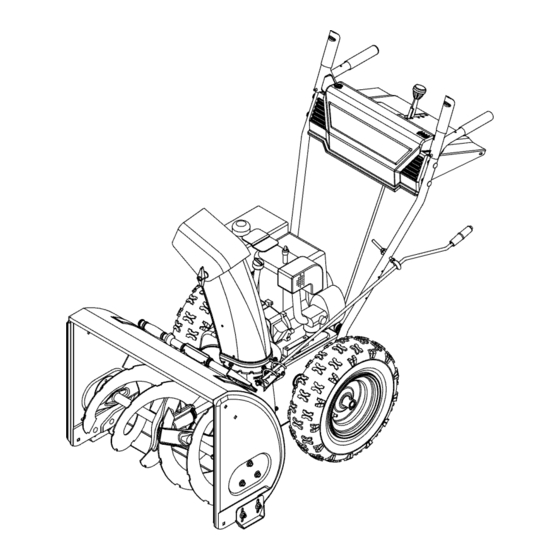

SNOW THROWER

MODELS

E600E, E610E

E640F, E660G

FORM NO

. 770-10002E.fm

(5/2001)

Advertisement

Table of Contents

Summarization of Contents

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

Training and Safety Rules

Read and follow all instructions. Be familiar with controls and never allow children to operate.

Preparation for Operation

Inspect the area, wear safety glasses, use adequate winter garments, and avoid loose clothing.

Operation Safety Guidelines

Exercise caution, keep bystanders away, and avoid slippery surfaces or falling.

Maintenance and Storage

Maintenance Procedures

Check bolts, screws, safety devices, and adjust controls. Maintain or replace safety labels.

Storage Guidelines

Clean machine, lubricate parts, and store in a well-ventilated area away from ignition sources.

Contents Of Hardware Pack

Hardware Identification for Assembly

Lay out hardware for identification. Part numbers are shown in parentheses for assembly steps.

SECTION 2: ASSEMBLING YOUR SNOW THROWER

Unpacking and Loose Parts

Remove staples, lay carton flat, remove packing material, and check for loose parts before discarding.

Attaching the Handles and Panel

Secure handles to the snow thrower and attach the handle panel using provided hardware.

Attaching Control Cables and Chute Assembly

Connect control cables and attach the chute assembly using flange keepers and hex bolts.

Attaching Chute Directional Control

Install the chute directional control, ensuring proper engagement with the chute assembly.

Attaching the Shift Rod

Connect the shift rod to the shift arm assembly and shift lever, ensuring correct alignment.

Lamp Wiring

Route the lamp wire and connect it to the alternator lead wire under the fuel tank.

SECTION 3: KNOW YOUR SNOW THROWER

Operating Controls Overview

Familiarize yourself with all controls: Shift Lever, Auger Control, Traction Control, Chute Controls.

Starting and Fuel Systems

Understand ignition key operation, choke control, and fuel shut-off valve (if equipped).

SECTION 4: OPERATING YOUR SNOW THROWER

Before Starting Checks

Read warnings, connect spark plug wire, and ensure proper fuel and oil levels.

Starting the Engine

Use recoil or electric starter. Follow choke and primer instructions for cold or warm engines.

Stopping the Engine and Drive Engagement

Remove ignition key to stop. Engage drive by selecting speed and squeezing traction control.

Engaging Augers and Operating Tips

Squeeze auger control to engage. Discharge snow downwind and adjust skid shoes as needed.

SECTION 5: MAKING ADJUSTMENTS

Traction Control and Shift Rod Adjustment

Adjust traction control and shift rod for proper engagement and smooth operation.

Drive Wheels Configuration

Configure drive wheels for one-wheel or both-wheel drive by inserting click pins.

SECTION 6: MAINTAINING YOUR SNOW THROWER

Lubrication Guide

Lubricate chute directional control, wheels, gear shaft, and drive/shifting mechanism.

Gear Case, Engine, and Auger Shaft Maintenance

Check gear case grease, refer to engine manual, and lubricate auger shaft bearings.

SECTION 7: SERVICE

Auger Shear Bolt and Shave Plate Service

Check auger shear bolts if augers won't turn. Service shave plate and skid shoes for wear.

Belt Replacement

Disconnect spark plug wire. Remove belt cover, unhook spring, and remove belts from pulleys.

Drive Belt and Friction Wheel Service

Replace drive belts and friction wheel rubber as needed, following reverse order of disassembly.

SECTION 8: OFF-SEASON STORAGE

Storage Precautions

Never store with fuel indoors. Clean and lubricate machine before storing.

SECTION 9: TROUBLE SHOOTING GUIDE

Engine Start and Running Issues

Troubleshoot engine failure to start or erratic running by checking fuel, choke, plug, and carburetor.

Power, Discharge, and Vibration Issues

Address loss of power, overheats, unit not propelling, or discharge chute issues.

MANUFACTURER'S LIMITED WARRANTY

Warranty Coverage and Exclusions

Covers defects for 2 years; wear parts for 90 days. Excludes misuse, accidents, and unauthorized parts.

Obtaining Warranty Service

Contact authorized dealer with proof of purchase or call MTD Customer Service.

Need help?

Do you have a question about the E640F and is the answer not in the manual?

Questions and answers