Table of Contents

Advertisement

O

PERATOR'S

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning:

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 368022 Cleveland, Ohio 44136-9722.

MTD PRODUCTS INC. P.O. BOX 368022 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A.

M

ANUAL

MODELS

E740

E760

FORM NO. 770-8752A

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

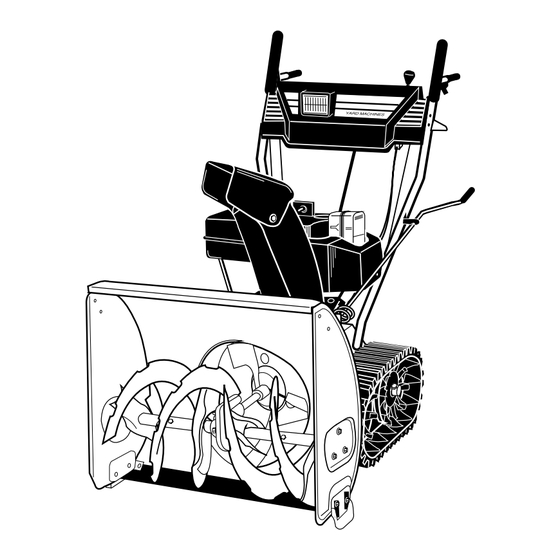

Summary of Contents for MTD E740

- Page 1 Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 368022 Cleveland, Ohio 44136-9722. MTD PRODUCTS INC. P.O. BOX 368022 CLEVELAND, OHIO 44136-9722 PRINTED IN U.S.A.

-

Page 2: Section 1: Important Safe Operation Practices

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES WARNING: THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING TO OPERATE YOUR SNOW THROWER. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. -

Page 3: Maintenance And Storage

• If the snow thrower should start to vibrate abnormally, stop engine immediately for the cause. Vibration is generally a warning of trouble. • Stop engine whenever you leave the operating position, before unclogging the collector/impeller housing or discharge guide, and making any repairs, adjustments, or inspections. -

Page 4: Section 2: Finding Your Model Number

Operators Manual. The information on the model plate is very important if you need help from your dealer or the MTD customer support department. • Every snow thrower has a model plate. You can locate it by standing behind the unit in the operating position and looking down at the dash panel. -

Page 5: Section 4: Contents Of Hardware Pack

SECTION 4: CONTENTS OF HARDWARE PACK Lay out the hardware according to the illustration for identification purposes. Parts are illustrated approximately one-half size. Part numbers are shown in parentheses. (Hardware pack may contain extra items which are not used on your unit.) ATTACHING THE HANDLE ASSEMBLY Hex Bolts 5/16-18 x 1-3/4"... -

Page 6: Section 5: Assembly Instructions

SECTION 5: ASSEMBLY INSTRUCTIONS NOTE: Reference to right or left side of the snow thrower can be determined from behind the unit in the operating position. Left Handle Flat Figure 2 Handle Bolt 1-3/4" Long Figure 3 Handle Panel Carriage Bolt Figure 4 UNPACKING... - Page 7 Chute Assembly Chute Flange Keeper Figure 5 Lock Washer Hex Nut Hex Bolt Upper Chute Crank Bracket Figure 6 Carriage Bolts Hex Lock Nuts Lower Chute Crank Bracket Figure 7 Flat Chute Washers Crank Hairpin Clip Lower Chute Crank Bracket Figure 8 ATTACHING THE CHUTE ASSEMBLY (Hardware B)

- Page 8 IMPORTANT: Attach the shift rod and clutch cables as follows. THEN CHECK THE ADJUSTMENTS AS INSTRUCTED, AND MAKE ANY FINAL ADJUSTMENTS NECESSARY BEFORE OPERATING YOUR SNOW THROWER. Failure to follow the instructions may cause damage to the snow thrower. Traction Shift Lever Drive Clutch...

-

Page 9: Final Adjustments

4. Attach track control cable to track control handle by inserting cable ball into slot on track control handle. Pull cable down and up until it snaps into front of track control handle. Repeat on other side. 5. Secure the track control cables to the inside of the lower handle using the cable ties provided. -

Page 10: Section 6: Controls

SECTION 6: CONTROLS Traction Drive/ Auger Auger Drive Clutch Clutch Lock Shift Left Lever Track Control Chute Crank Figure 14 SHIFT LEVER (See figure 14) The shift lever is located in the center of the handle panel. The shift lever may be moved into one of eight positions. -

Page 11: Section 7: Operation

SECTION 7: OPERATION GAS AND OIL FILL-UP Service the engine with gasoline and oil as instructed in the separate engine manual packed with your snow thrower. carefully. WARNING: Never fill fuel tank indoors, with engine running or while engine is hot. - Page 12 TO STOP ENGINE 1. Run engine for a few minutes before stopping to help dry off any moisture on the engine. 2. To help prevent possible freeze-up of starter, proceed as follows. Connect power cord to switch box on engine, then to 120 volt AC receptacle.

-

Page 13: Section 8: Adjustments

SECTION 8: ADJUSTMENTS WARNING: NEVER attempt to clean chute or make any adjustments while engine is running. CHUTE ASSEMBLY ADJUSTMENT The distance snow is thrown can be adjusted by adjusting the angle of the chute assembly. Refer to the Control section of this manual. SKID SHOE ADJUSTMENT The space between the shave plate and the ground can be adjusted. -

Page 14: Section 9: Lubrication

SECTION 9: LUBRICATION WARNING: Disconnect plug wire and ground against the engine before lubrication or maintenance. ENGINE Refer to engine manual for all engine lubrication instructions. WARNING: When following instruc- tions in separate engine manual for draining oil, be sure to protect frame to avoid oil dripping onto transmission parts. -

Page 15: Section 10: Maintenance

SECTION 10: MAINTENANCE WARNING: Disconnect plug wire and ground against the engine before performing any repairs or maintenance. AUGER BELTS 1. Remove the plastic belt cover on the front of the engine removing screws. See figure 19. Belt Cover Figure 19 2. - Page 16 Friction Wheel Disc Drive Belt Support Bracket Stop Bolt Figure 22 CHANGING THE FRICTION WHEEL RUBBER The rubber on the friction wheel is subject to wear and should be checked after 25 hours of operation, and periodically thereafter. Replace the friction wheel rubber if any signs of wear or cracking are found.

-

Page 17: Section 11: Off-Season Storage

SECTION 11: OFF-SEASON STORAGE WARNING: Never store engine with fuel in tank indoors or in poorly ventilated areas, where fuel fumes may reach an open flame, spark or pilot light as on a furnace, water heater, clothes dryer or other gas appliance. If unit is to be stored over 30 days, prepare for storage as follows: 1. -

Page 18: Section 12: Trouble Shooting Guide

SECTION 12: TROUBLE SHOOTING GUIDE Trouble Possible Cause(s) Engine fails to start Fuel tank empty, or stale fuel. Blocked fuel line. Choke not in ON position Faulty spark plug. Key not in switch on engine. Spark plug wire disconnected. Primer button not depressed. Fuel shut-off valve closed (if so equipped). - Page 19 Gear Assembly Ref. Part No. Description 618-0123 Housing-L.H. 618-0124 Housing-R.H. 710-0642 Screw 711-0909 Spiral Axle 26" 714-0161 Key 715-0143 Pin-Spiral 717-0526 Shaft-Worm 717-0528 Gear-Worm 718-0186 Collar-Thrust 10 721-0325 Plug Ref. Qty. Part No. Description 721-0327 Seal-Oil 721-0328 Locktite 5699 736-0351 Washer-Flat 736-0369 Washer-Flat 736-0445 Washer-Flat 737-0168 Grease...

- Page 20 Handle Assembly...

-

Page 21: Handle Assembly

Handle Assembly Ref. Part No. Description 684-0008 Arm-Shift 684-0103 Panel-Handle 684-0036 Handle-Engagement-R.H. 684-0037 Handle-Engagement-L.H. 710-0276 Screw 710-0451 Bolt-Carriage 710-0599 Screw 10 710-1003 Screw 11 711-0653 Pin-Clevis 12 712-0116 Nut-Hex 13 712-3010 Nut-Hex 14 712-0429 Nut-Lock 15 714-0507 Pin-Cotter 16 715-0138 Pin-Roll 17 720-0201A Knob 18 720-0232... - Page 22 Blower Housing 26’’ Ref. Part No. Description 05931 Housing-Bearing 605-5193 Spiral Assembly-L.H. 26" 605-5192 Spiral Assembly-R.H. 26" 618-0121 Gear Assembly 26" 684-0040A Housing Assembly 26" 710-0459 Arm-Idler Assembly 684-0065 Impeller Assembly 705-5226 Reinforcement-Chute 710-0134 Screw-Carriage 710-0451 Screw-Carriage 710-0604 Screw-Hex 710-0890 Shear Bolt 712-0116 Nut-Hex Lock...

- Page 23 Track and Frame...

- Page 24 Track and Frame...

- Page 25 Track and Frame Ref. Part No. Description 611-0053 Axle Assembly 618-0043 Dog Assembly-R.H. 618-0044 Dog Assembly-L.H. 618-0169 Shaft Assembly 631-0032 Wheel Assembly Idler 656-0012A Disc Assembly 683-0024 Hub Assembly 684-0009 Rod Track Pivot 684-0014B Rod Shift Assembly 684-0021 Bracket Assembly 684-0024 Axle Assembly 684-0031...

- Page 26 Engine and V-Belts Ref. Part No. Description 05896A Bracket-Idler 629-0071 Cord-Extension 110V 710-0627 Screw-Hex 710-1245 Screw-Hex 710-0230 Screw-Hex 710-0342 Screw-Hex 710-0696 Screw-Hex 710-0896 Screw-Hex 10 712-0181 Nut-Hex 11 731-1324 Cover-Belt 12 732-0710 Spring 13 736-0119 Washer-Lock 14 736-0242 Washer-Bell 15 736-0247 Washer-Flat 16 736-0270 Washer-Bell...

- Page 27 George...

- Page 28 For TWO YEARS from the date of retail purchase within the United States of America, its possessions and territories, MTD PRODUCTS INC will, at its option, repair or replace, for the original purchaser, free of charge, any part or parts found to be defective in material or workmanship.

Need help?

Do you have a question about the E740 and is the answer not in the manual?

Questions and answers