Table of Contents

Advertisement

Quick Links

Table of Contents

......................................................................................................................

Step 13 - Selector motor removal

Step 2 - Idler versions

........................................................................................

.......................................................................................

.......................................................................................................

................................................................................................

.......................................................................

....................................................................................................

......................................................................................

.............................................................................

..................................................................................................

.........................................................................................

........................................................................................................

....................................................................................

....................................................................................................

..........................................................................

....................................................................................

.....................................................................................

.................................................................................

.........................................................................................

..............................................................................

..........................................................................................

..................................................................................

..................................................................................

........................................................................

......................................................................................................

......................................................................................................

.......................................................................................

........................................................................................................

...................................................................................................

..................................................................................................

.................................................................................

............................................................................

......................................................................................

.........................................................................................

...................................................................................................

......................................................................

.......................................................................

....................................................

................................................................

....................................................................

............................................................

..........................................................

..........................................................

..............................................

.....................................................................

....................................................................

.................................................................

.................................................................

.................................................................

....................................................................

11

12

13

13

14

14

15

15

16

16

17

18

18

19

20

20

21

21

22

22

23

24

24

25

25

26

26

27

27

28

28

29

30

31

31

32

32

33

34

34

35

35

36

36

37

37

38

38

39

39

1

Advertisement

Table of Contents

Summary of Contents for Original Prusa MMU3

-

Page 1: Table Of Contents

..................................Step 1 - MMU History and Printer Compatibility ..................Step 2 - Supported printers ..................Step 3 - MMU3 + Enclosure ....................... Step 4 - Disclaimer ....................Step 5 - Tools required ............... Step 6 - View high resolution images .................... - Page 2 ................... Step 13 - Idler installation ............... Step 14 - Idler center shaft assembly ..................Step 15 - Idler body M3nS nut ..............Step 16 - Idler motor assembly (part 1) ..............Step 17 - Idler motor assembly (part 2) ..............

- Page 3 ..............Step 35 - Rear PTFE parts preparation ................Step 36 - Rear PTFE installation ................Step 37 - Setting the Idler tension 7. Spool holder Assembly ....................................Step 1 - Two Spoolholder types ..........Step 2 - Vacuum formed holder parts preparation .................

- Page 4 ................ Step 12 - Segment assembly (part 1) ............... Step 13 - Segment assembly (part 2) ............... Step 14 - Segment assembly (part 3) ................. Step 15 - Collets: parts preparation ..................Step 16 - Collet installation ................. Step 17 - Cartridge installation ..............

- Page 5 ..............Step 16 - Extruder reassembly (Part 1) ..............Step 17 - Extruder reassembly (Part 2) ..............Step 18 - Extruder reassembly (Part 3) ............Step 19 - Adapter-printer parts preparation ................ Step 20 - Adapter-printer assembly ............. Step 21 - New chimney: parts preparation ..............

- Page 6 ..............Step 12 - Firmware Upgrade: Printer ................. Step 13 - Turning the MMU on ............Step 14 - MMU3 Firmware flashing (part 1) ............Step 15 - MMU3 Firmware flashing (part 2) ..................Step 16 - Gears calibration ..................

- Page 7 Step 20 - MK3S+ Firmware flashing (part 2) ..........Step 21 - MK3S+ Turning the MMU on and reset ............Step 22 - MMU3 Firmware flashing (part 1) ............Step 23 - MMU3 Firmware flashing (part 2) ..........Step 24 - IR filament sensor calibration (Part 1) ...........

- Page 8 Step 15 - MK3.5 Firmware flashing (part 1) ..............Step 16 - MK3.5 Turning the MMU on ............Step 17 - MMU3 Firmware flashing (part 1) ............Step 18 - MMU3 Firmware flashing (part 2) ........... Step 19 - IR filament sensor calibration (Part 1) ..........

- Page 9 ............Step 33 - MMU Filament sensor calibration ..................Step 34 - Footer Status Bar ............. Step 35 - SuperFINDA sensor calibration info ................Step 36 - SuperFINDA calibration ................ Step 37 - Error code details (Part 1) ............... Step 38 - Error code details (Part 2) ........

-

Page 11: Introduction

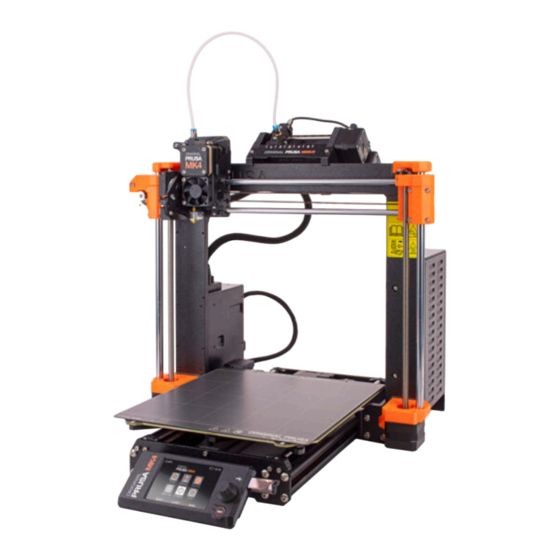

1. Introduction Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 12: Step 1 Mmu History And Printer Compatibility

1. Introduction STEP 1 MMU History and Printer Compatibility Welcome to the MMU3 guide! There were several generations of the Original Prusa Multi-Material printing solution. Verify you are looking at the correct guide for your MMU unit and your printer. -

Page 13: Step 2 Supported Printers

STEP 3 MMU3 + Enclosure The MMU3 is also supported with the Original Prusa Enclosure. If you plan to use this combination, install the MMU3 onto the assembled printer using this guide. Once you’ve completed the MMU3 installation, continue to the Enclosure assembly guide. -

Page 14: Step 4 Disclaimer

Make sure your printer is fully assembled and works perfectly before you proceed to attach the MMU3 onto it. Make a few single material prints. If it has any issues, fix the issues first. Diagnosing printer issues can be harder with the MMU attached. -

Page 15: Step 6 View High Resolution Images

Most of the part drawings on the labels are scaled 1:1 and can be used to identify a part. You can download and 2D print a Prusa Cheatsheet with the 1:1 scaled fastener drawings. help.prusa3d.com/cheatsheet. Print it at 100 %, don't rescale it, otherwise, it won't work. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 16: Step 8 We Are Here For You

STEP 9 Pro tip: inserting the nuts During the MMU3 kit assembly, some screws require tightening with an angled Allen key. Ensure the screw stays perfectly perpendicular to the thread. If it’s difficult to turn, fully release it, realign, and start again to avoid cross-threading. -

Page 17: Step 10 Printed Parts

STEP 10 Printed parts If you ordered the MMU3 Kit without plastic parts, you will need to print them using the pre-sliced G-codes before you can proceed with the assembly. The parts must be printed perfectly in order for the MMU3 to work correctly: no warping or lifted corners, stringing or other irregularities. -

Page 18: Step 11 - Prepare Your Desk

OK, we are ready. Let's start! STEP 12 Continue If you’re building the MMU3 Kit from scratch, continue to the chapter: 4. Idler Body Assembly If you have the Assembled MMU3, continue to the chapter: 7. Spool Holder Assembly For the MMU2S to MMU3 Upgrade, continue to the chapter: 2. -

Page 19: Mmu2S Disassembly (Upg)

2. MMU2S Disassembly (UPG) Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 20: Step 1 Introduction

Maintain a well-organized workspace to avoid mixing older parts with the new ones. Although some new components might resemble the old ones, they are actually distinct. Note that certain components shouldn't be reused for MMU3, while others are necessary for the upgrade. -

Page 21: Step 3 Disconnecting The Ptfe Tubes

Remove all five PTFE tubes and dispose of them immediately. These tubes will not be used again for MMU3. MMU3 is designed to work with differently-sized PTFE tubes. Reusing MMU2S tubes during the assembly of MMU3 will result in incorrect operation. -

Page 22: Step 5 Disconnecting The Mmu2S (Part 2)

You can set the printer aside for now. We can move onto disassembling the MMU2S unit itself. For the following step, please prepare the MMU-to-Extruder PTFE tube with the Festo fittings QSM-M5 attached. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 23: Step 7 Mmu-To-Extruder Ptfe Tube Disassembly

MK4/S & MK3.9/S owners: Throw the fittings and the PTFE tube away now! Your package includes new ones! Mixing them may lead to issues! MMU3 is designed to work with differently-sized PTFE tubes. Reusing MMU2S tubes during the assembly of MMU3 will result in incorrect operation. -

Page 24: Step 8 Mmu2S Unit Disassembly

Separate the power and data cable bundle from the rest of the cables. Remove the textile wrap off the cables and save the textile wrap for later use. The MMU2S power and data cables won’t be used in MMU3. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 25: Step 10 Idler Motor Removal

Using the shorter side of the 2.5mm Allen key, push the 5x16sh shaft from the inside out. Repeat the same process on the other side. Remove the M3x10 screw and push the 5x16sh shaft outward. Save the 5x16sh shafts for later use. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 26: Step 12 Bearings Removal

Using the 2.5mm Allen key, remove the five M3x10 screws holding the motors. Rotate the motor shaft some more to disengage it from the selector. Pull out the selector motor to remove it from the unit. Save the motor for later use. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 27: Step 14 Selector Removal

Remove the pulley motor from the unit. Save the motor for later use. Using the Allen key, tilt the pulley bearing in order to remove it. Save it for later use too. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 28: Step 16 Selector Disassembly

Handle the board by its sides to avoid damage. Be careful around the electronics, do not touch the individual components on the board. Remember that the board is sensitive to electrostatic discharge (ESD). Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 29: Step 18 Summary

Trapezoid nut (1x) M5-4 Fittings (2x) These fittings are only required for the MK3S+ version. If you are assembling the MK4/S version, use the newly provided fittings instead!! 5x16sh shaft (2x) 5x120sh shaft (2x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 30: Mmu2S Buffer Disassembly (Upg)

3. MMU2S Buffer Disassembly (UPG) Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 31: Step 1 Preparation

Pull all the PTFE tubes out. Dispose of the tubes to prevent them from getting mixed up with the new ones in the future. These tubes will not be used again. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 32: Step 3 Buffer Disassembly

These parts won’t be re-used. STEP 4 Summary That was simple, wasn't it? From the disassembled buffer, please save the buffer plates for later use. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 33: Idler Body Assembly

4. Idler Body Assembly Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 34: Step 1 Tools Necessary For This Chapter

2.5mm Allen key for M3 screws STEP 2 Idler versions There were two versions of the Idler: 1. The MMU3 Idler to be used with the metal Coupler This is the correct part bundled in the MMU3 Kit. 2. The old MMU2S Idler with a printed coupling part. -

Page 35: Step 3 Idler Parts Preparation

Install the second bearing and the shaft in the same way as the first one. Make sure you are inserting the parts into the exact same openings as seen in the picture. Install the third bearing and the shaft into the corresponding opening using the same technique. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 36: Step 5 Idler Bearings Assembly (Part 2)

STEP 6 Idler center bearing assembly Take the remaining bearing and push it into the opening on the side of the idler. Make sure the bearing is flush (aligned) with the surface. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 37: Step 7 Coupler Parts Preparation

Just start the thread so that the grub screw holds in. Make sure none of the two grub screws is protruding into the opening in the center. Otherwise, the coupler will be hard to slide onto the motor shaft later on. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 38: Step 9 Coupler Assembly

The grub screw orientation is important so that the grub screws remain accessible even after the Idler is installed inside the MMU unit. All five bearings are able to rotate. The sixth bearing is flush with the surface. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 39: Step 11 - Idler Body Parts Preparation

If it doesn't engage, try cleaning up the opening with an Allen key and rotating the stopper while inserting. Verify it is seated properly and doesn't fall out. When fully inserted, the bottom part of the stopper should be visible from the side. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 40: Step 13 Idler Installation

The shaft must engage into the bearing in the Idler. Press the shaft all the way in using the 2.5mm Allen key. Secure the shaft in place by attaching an M3x10 screw into the marked position. Tighten it up. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 41: Step 15 Idler Body M3Ns Nut

Orient the coupler so that one of the grub screws is pointing up. Insert the motor shaft into the metal coupler on the Idler. Push the motor towards the Idler body until flush. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 42: Step 18 Idler Motor Assembly (Part 3)

Tighten it up fully using the 2mm Allen key. Rotate the idler so that the second grub screw on the metal coupler is accessible. Tighten the other grub screw fully too. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 43: Selector Assembly

5. Selector Assembly Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 44: Step 1 Tools Necessary For This Chapter

Magnetic steel ball (1x) When upgrading from the MMU2S, ensure you use the new ball provided in the upgrade kit, not the old one. The new ball is made of a ferromagnetic material. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 45: Step 3 Selector Assembly: Magnetic Ball

Trapeze nut (1x) In case you're assembling the unit from scratch, the nut is inside the Motor kit box, attached to the selector motor. M3n nut (1x) M3nS nut (1x) M3x10 screw (2x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 46: Step 6 Selector Assembly: Rods And Cover Parts Preparation

We will tighten them up fully later on. STEP 6 Selector assembly: Rods and Cover parts preparation For the following steps, please prepare: M3nS nuts (2x) Bushing tube 5x6x25bt (2x) M3x10 screws (2x) Selector front plate (1x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 47: Step 7 Selector Assembly: Bronze Bushing Tubes

Add the front plate onto the selector. Make sure the side of it is flush with the flat part of the selector. Attach the front plate with two M3x10 screws. Tighten them up. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 48: Step 9 Selector Assembly: Finda Parts Preparation

Fix the probe in place with M3x10 screw. Tighten the screw up just so that the sensor can no longer be moved. Avoid over-tightening the screw; if SuperFINDA is securely held in place, that's sufficient. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 49: Step 11 - Selector Assembly: Cutter Parts Preparation

Cover the blades with the blade holder. Verify the blades are still seated perfectly in place while attaching the cover. Fix the blade holder in place with M3x10 screw. Tighten it up fully. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 50: Pulley Body Assembly

6. Pulley Body Assembly Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 51: Step 1 Tools Necessary For This Chapter

2.5mm Allen key for M3 screws A measurement tool (optional), a digital caliper would work the best. STEP 2 Pulley-body parts preparation For the following steps, please prepare: Pulley body (1x) 625 bearing (3x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 52: Step 3 Pulley Body: Inserting Bearings

MMU, Make sure you are not re-using the MMU2S PTFE tubes. All the PTFE tubes are supplied pre-cut to the correct size. There is no need to cut the tubes. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 53: Step 5 Front-Ptfe-Holder Assembly

Secure the holder with four M3x10 screws from the front. STEP 6 Collet holder parts preparation For the following steps, please prepare: Collet holder (1x) M3n nut (2x) M3x10 screw (2x) Collet (5x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 54: Step 7 Collets Installation

Attach the collet holder into the pulley body. Note the correct part orientation marked by the arrow. The arrow on the collet holder should be pointing towards the pulley body. Secure the collet holder in place by two M3x10 screws. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 55: Step 9 Pulley Motor Parts Preparation

Ensure the grooved part of the pulley is on the motor side. Slide the other pulleys onto the shaft using the same technique. Tighten the grub screws just slightly for now. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 56: Step 12 Pulley Motor Assembly (Part 2)

If it is hard to turn, release the screw fully, re-align it, and start tightening it from the beginning to avoid cross-threading it. Now, turn the unit around again to tighten up the top screw fully too. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 57: Step 13 Pulley Alignment

Check the proper positioning of all of the pullies again. Adjust it if necessary. STEP 14 Selector: parts preparation For the following steps, please prepare: Selector assembly (1x) you prepared earlier. Selector motor (1x) 5x120sh Shaft (2x) M3nS nut (2x) M3x10 screw (3x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 58: Step 15 Selector Installation

Insert the selector motor so that its trapezoidal shaft goes through the pulley body as seen in the picture. Make sure the selector motor cable is pointing up before you proceed to attach the motor. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 59: Step 18 Trapezoid Nut Positioning

Note that you have to excert some force to move it as the motor has physical resistance. Move the selector all the way to the left. Fully tighten the two screws that secure the trapezoid nut. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 60: Step 19 Idler Body Installation Parts Preparation

Insert the 5x16 shaft into the marked opening and push it all the way in until it engages into the bearing in the pulley body. Insert the other 5x16 shaft into the marked opening on the other side. Push it all the way in. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 61: Step 22 Idler Body Installation (Part 3)

Tighten them until the screws are just above the surface. Do not tighten the screws too much. The top of the screw heads shouldn't be below the surface. Later on, we will use these screws to set the Idler tension. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 62: Step 23 Control Board Parts Preparation

Avoid touching the chips, capacitors, and other electronic components. Fix the board in place with three M3x6 screws. Be careful not to damage any of the small components on the board. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 63: Step 25 Pd-Board Parts Preparation

M3x18 screw (2x) M3nS nut (1x) PD-board addon (1x) PD-board-cover (1x) may not be included in some of the earlier MMU3 packages. If your MMU3 package or printed parts does not contain this item, you can proceed without it. STEP 26 Installing the PD-board-cover This step is for those units that have the PD-board-cover in the package. -

Page 64: Step 27 Pd-Board Installation

Don't connect or disconnect the cable if the printer is connected to the power outlet or is powered on. Connect the MMU/printer cable into the PD-board. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 65: Step 28 Connecting The Cables

PD-board, not beneath. Fix the electronics in place by two M3x18 screws. Use the correct type of screws. In case you used longer ones, the unit might not work as expected. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 66: Step 30 Textile Sleeve Parts Preparation

Join the Selector motor cable with the SuperFINDA cable using a zip-tie in the marked position, as seen in the picture. Join the cables together with the Pulley motor cable in the marked position using a zip-tie. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 67: Step 32 Cable Management (Part 2)

Bundle the loose cables together using a zip tie. STEP 33 Stickers parts preparation For the following steps, please prepare: Serial number sticker (1x) Safety sticker (1x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 68: Step 34 Applying The Stickers

Applying the stickers Remove the safety sticker from the protective layer. Apply the safety sticker onto the right side of the MMU3 unit. The correct position is depicted in the second picture. Apply the serial number sticker to the bottom of the MMU3 unit using the same method as before. - Page 69 There are small windows next to each of the pulley positions. Verify the PTFE tube is fully inserted and its end is visible inside the window. If not, push the tube in some more. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

-

Page 70: Step 37 Setting The Idler Tension

With too low idler tension, the MMU unit might struggle with grabbing the filaments properly. With too high idler tension, the idler will struggle with determining its home position and the MMU unit won't work properly. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 71: Spool Holder Assembly

7. Spool holder Assembly Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 72: Step 1 Two Spoolholder Types

For the following steps, please prepare: Spoolholder base (1x) Foam pad (4x) Note, this is a legacy version of the spool holder. If you have the newer injection-molded spool holders, skip these steps. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 73: Step 3 Foam Pads Installation

Attach the four foam pads into the bottom corners of the spoolholder base. STEP 4 Rods, Bearings parts preparation For the following steps, please prepare: PTFE holder (1x) Shaft (2x) Plug (4x) Bearing (4x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 74: Step 5 Rods And Bearings Assembly

There is a notch on the front part of the spoolholder. Attach the PTFE holder onto the notched front part of the spoolholder. Repeat the same steps to build the remaining spool holders until you finish all five. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 75: Step 7 Injection Molded Spoolholder: Parts Preparation

STEP 9 Base assembly (part 1) Take one Base part. Arrange it as seen in the picture. Insert two wheels into the Base. Cover the assembly with another Base part on top. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 76: Step 10 Base Assembly (Part 2)

There is a bending line inside the inner opening on the bottom of the spoolholder side part. Attach an individual foam pad strip onto the middle of the bending line inside the opening, as seen in the picture. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 77: Step 12 Foam Pads Installation (Part 2)

Make sure the longer part of the PTFE holder is located at the narrower side of the Guide part. Push the PTFE holder down onto the Guide until it fully engages and locks in place. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 78: Step 14 Finishing Up The Spoolholders (Inj. Mol.)

Or, if you flip one of the Guides around, they can be joined in an arc pattern. This is handy to form an arc of spool holders around the Buffer so that each filament path is as straight as possible. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 79: Step 16 Buffer Types

If you have the CORE One printer, continue to the 8B. Core One Buffer Assembly If you have the MK4/S, MK3.9/S, MK3.5/S or MK3S/+, continue to the 8A. Cassette Buffer Assembly Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 80: 8A. Cassette Buffer Assembly

8A. Cassette Buffer Assembly Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 81: Step 1 Tools Necessary For This Chapter

2.5mm Allen key for M3 screws STEP 2 Parts preparation For the following steps, please prepare: Buffer plate (6x) Printer holder (1x) Buffer-leg (1x) Segmenter (1x) M3x30 screws (6x) M3nS nuts (6x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 82: Step 3 Peeling The Plates

Insert four M3nS nuts into the small marked openings in the Segmenter. Push them all the way in. Insert the remaining two M3nS nuts into the marked openings on the Printer holder. Push them all the way in. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 83: Step 6 Assembly (Part 3)

Assembly (part 3) Insert the remaining 5 buffer plates into the corresponding openings on the Segmenter and Printer holder. The whole assembly now should look like the one in the second picture. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 84: Step 7 Assembly (Part 4)

Do not overtighten the screw. Otherwise, the buffer plates might deform. Push the screw into the assembly until it reaches the nut. Tighten it up. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 85: Step 9 Parts Preparation: Plate-Holders

8A. Cassette Buffer Assembly STEP 9 Parts preparation: Plate-holders For the following steps, please prepare: Plate-holder (5x) STEP 10 Assembly (part 6) Attach the plate holders to the plates in the marked positions. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 86: Step 11 - Buffer Segment Parts Preparation

There have been several versions of this part available, which might look slightly different. However, the assembly process remains the same. The MMU3 for the MK4 printer necessitates the use of the most recent buffer cartridge design, Version B. Version B has been introduced in April 2024. -

Page 87: Step 14 Segment Assembly (Part 2)

Insert three M3n nuts into the marked openings on the Segment and push them all the way in. Add the wheel into the center of the segment. Push the Shaft all the way through the middle of the bearing, until it engages into the segment below. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 88: Step 15 Segment Assembly (Part 3)

Turn the assembly around. Add the fifth M3x6 screw from the other side. Assemble all the remaining segments, using the same technique. STEP 16 Collets: parts preparation For the following steps, please prepare: Collet (10x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 89: Step 17 Collet Installation

Insert the cartridge into the buffer body. Make sure the cartridge is properly inserted. For a later cartridge removal, squish the two handles together and pull it out. Insert all the cartridges into the buffer body. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 90: Step 19 Ptfe Tubes Parts Preparation

Insert the PTFE tubes into the upper collet in each of the cartridges. Push them all the way in. Join the PTFE tubes together using the PTFE clip approximately in the middle. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 91: Step 21 Continue

Continue If you’re installing the MMU3 on an MK4/S printer, move to the chapter: MK4/S Nextruder mod If you’re installing the MMU3 on an MK3S+ or MK3.5/S printer, move to the chapter: MK3S+ / MK3.5 Extruder mod (KIT) In these chapters, we will convert the single-material extruder into the MMU3 version. -

Page 92: 8B. Core One Buffer Assembly

8B. CORE One Buffer Assembly Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 93: Step 1 Tools Necessary For This Chapter

2.5mm Allen key for M3 screws STEP 2 Buffer Plates Preparation For the following steps, prepare: Buffer plate (6x) Segmenter (1x) Plate Holders (4x) M3x30 Screw (4x) M3nS nut (4x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 94: Step 3 Plates Peeling

Lay it on its flat side and rotate it so the larger cutouts face away from you. Insert the four M3nS nuts into the correspoinding pockets in the center. Push them all the way in. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 95: Step 5 Plates Installation

Fix the plates together using the Plate holder in the marked position. Make sure all the plates are seated properly. Install the remaining plate holders so that the assembly is held together in the marked positions. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 96: Step 7 Segmenter Screws

Tighten the remaining two M3x30 screws from the other side. STEP 8 Plate Holder L & R Preparation For the following steps, prepare: Plate holder L (1x) Plate holder R (1x) Magnet 2x5x20 (12x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 97: Step 9 Magnet Installation

The magnets should face away from you, toward position 1. Install the Plate Holder R onto the right side of the assembly. The magnets should face away from you, toward position 1. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) -

Page 98: Step 11 - Buffer Segment Preparation

Segment assembly (part 1) Insert the bearing into the center opening in the wheel. Make sure the bearing is inserted all the way in, until flush with the surface. Repeat for the remaining four wheels. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) - Page 99 Join both parts together using four M3x6 screws. Turn the assembly around. Add the fifth M3x6 screw from the other side. Assemble all the remaining segments, using the same technique. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 100 Otherwise, one of the fins might spread outwards, resulting in a damaged collet. Insert another collet into the other opening. Install collets into the remaining four cartridges too. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 101 For a later cartridge removal, squish the two handles together and pull it out. Insert all the cartridges into the buffer body. STEP 18 PTFE tubes parts preparation For the following steps, prepare: PTFE 650mm (5x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 102 8B. CORE One Buffer Assembly STEP 19 PTFE tubes installation Insert the PTFE tubes into the row of collets on the right of the cartridges. Push them all the way in. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 103 9A. MK4/S, MK3.9/S Nextruder mod Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 104 We recommend setting aside a bag for spare parts to store components that won't be needed anymore. Rest assured, our guide will clearly indicate which parts will be reused and which won't. Let’s begin! Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 105 9A. MK4/S, MK3.9/S Nextruder mod STEP 3 Tools necessary for this chapter For this chapter, please prepare: 2.5mm Allen key 1.5mm Allen key Torx key TX10/8 Needle-nose pliers Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 106 Prusa Nozzle brass (marked PR) The MK4S comes equipped with the Prusa Nozzle CHT by default. However, for optimal performance with the MMU3, we recommend switching to a standard Prusa Nozzle. While high-flow nozzles can be used too, they require specific HF Nozzle Slicer profiles with large purge volumes.

- Page 107 If you own the 4-screw version of the Nextruder, this specific type of set screw is not included. Remove the Idler. Remove the two M3x30 screws with the springs. Remove the idler swivel assembly. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 108 2.5mm Allen key to push the steel ball inside the assembly in. Then, pull the filament sensor assembly out. This filament sensor assembly will not be used with the multi-material Nextruder. It's recommended to store it in a spare parts bag. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 109 Bearing 693 2RS (2x) you removed earlier Pin 2.9x8.5 (2x) you removed earlier M3x6 screw (1x) you removed earlier Spacer tube 13.2x3.8x0.35 (1x) you removed earlier Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 110 Set aside for later use: M3nN nuts and spacer. The printed parts and the screws won’t be re-used. Set them aside so that they don’t mix up with the new parts. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 111 Push the magnet all the way in, until it stops. The polarity / orientation of the magnet isn't important. The printer will automatically adapt to it during the filament sensor calibration process. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 112 Insert the M3x22 screw into the opening near the thick part of the Swivel A. Slide the spacer onto the screw. Insert the second M3x22 screw into the other opening on the side. Slide the Idler nut FS part onto the M3x22 screw. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 113 M3x35 screws (2x) the new, slightly longer ones. This screw is a new type not previously used on a printer! Do not reuse old screws, as they are a different size and would not fit properly! Screw guide (1x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 114 The parts might be greasy. Clean off any excess grease. Set aside for later use: PG-case, PG-ring, PG-assembly, M3x25 screws. The printed main-plate won’t be re-used. Set it aside so that it doesn’t mix up with a new part. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 115 Main plate assembly There is a V-shaped groove on the inside of the large round opening on the new main-plate. Insert the O-ring into the groove. Make sure it is seated properly. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 116 M3x25 screw to temporarily hold the Idler assembly in place. Add the Swivel assembly onto the extruder. The protruding part of the Idler nut FS component should fit inside the filament sensor pocket in the heatsink, as seen in the picture. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 117 A slight wiggling motion can assist with this. Watch out for any deformation or damage to the O-ring. Ensure the O-ring stays properly seated in its groove on the main plate. A slight wiggling motion can assist with this. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 118 Note there is a chamfer on one side of the PG-ring. This side should be facing the gears, while inserting the PG-ring. Gently rotate the adapter while sliding the PG-ring onto the gears to align the gearbox properly. Remove the adapter, while holding the gearbox in place. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 119 MK4 kit. Cover the gearbox using the PG-case. Secure the case using the M3x25 screws. Do not overtighten the screws! Attach the top Loveboard cover back onto the extruder. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 120 9B. MK3S+ / MK3.5 Extruder mod (KIT) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

-

Page 121: Printer Preparation

The printer is properly cooled down and the steel sheet has been removed. The printer is turned off and unplugged. On the MK3.5 printer, ensure you have easy access to the electronics box on the left side. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) - Page 122 STEP 3 MK3S+ Releasing the cable bundle In order to use MMU3 on your MK3S+, a few components on the print head need to be changed. First, we need to release the extruder cable bundle. If you use MK3.5 printer, skip two steps ahead.

- Page 123 Remove all four M3x10 screws on the X-carriage-back part. Split the x-carriage about 10 mm (0.4 inch) apart in the back to ensure the cables will be able move through more easily. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 124 Using an Allen key, push the black Adapter-printer part up. Keep in mind there is a steel ball inside, which usually falls out. Remove the part entirely. We will replace Adapter-printer part with a new part. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 125 This way, the cable should slide without a significant resistance. Combine gentle pushing and pulling on the cable to avoid damage. We aim to get 6cm (2.4in) of the cable above the top of the extruder body. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 126 We will use them to hold the extruder parts together. Carefully split the extruder apart by pulling the front out. Create approx. a 1cm (0.5in) gap similar to the one seen in the picture. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 127 PTFE for MK3S+ is 42.3mm long, 1.85mm ID, 4mm OD, inner chamfer on one side, outer chamfer on the other. The bundled PTFE tube is intended for MK3S+ only. The PTFE tubes for MK3S and MK3S+ differ in length. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 128 THIS IS CRUCIAL for the hotend to work properly. After you finish inserting the new PTFE tube, check that the whole hotend is tightened up and nothing got loose during the process. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 129 Take a look from the side of the extruder. The nozzle should be slightly below the printed fan-shroud. If it is significantly lower than in the picture, your hotend isn’t inserted correctly. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 130 Adapter-printer-mmu (1x) The package should include only the orange adapter. If you have printed parts yourself, please don't use the version with the hole for steel ball. (used for single-material printers) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 131 New chimney: parts preparation For the following steps, please prepare: Chimney base (1x) with the Tappex Microbarb 0006-M5 threaded insert Chimney (1x) M3nS nut (1x) M3 washer (1x) M3x30 screw (1x) M3x18 screw (1x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 132 Fix the parts together by M3x18 screw. Tighten it up just so that the parts hold on the extruder. Don't tighten it up fully yet. We will need to move the parts later on. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 133 IR Filament sensor: parts preparation For the following steps, please prepare: Chimney cover (1x) M2x8 screw (1x) you removed from the printer earlier Prusa IR filament sensor (1x) you removed from the printer earlier Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 134 Using a 2.5mm Allen key, push the shaft out. Keep it for later use. Take the Bondtech gear out, BUT BE CAREFUL, there are two bearings inside. Don't lose them!!! Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 135 Add a tiny bit of lubricant into the geared part of the Bondtech gear. Make sure the lubricant doesn’t get into the filament groove. Do not use excessive amount of lubricant. Just a tiny bit will do. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 136 STEP 31 Extruder-idler-mmu assembly (Part 2) Using the 2.5mm Allen key, push the shaft in so that it is inserted evenly on both sides. Ensure the Bondtech gear is able to rotate freely. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 137 Fix the fan using the following screws (depending on the fan version): M3x14 / M3x16b screw (3x) M3x20 / M3x22b screw (1x) in the bottom corner. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 138 Tighten the top screws just lightly. Remember, the top two bearings are secured by the zip-ties - so the top two screws do not have to be overly tight. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 139 Hold it tight while you fix it in place with the zip ties. IMPORTANT: Cut the remaining part of each zip tie using pliers as closest to its head as possible. Note the correct position of each zip ties's head (pointing up) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 140 Tighten up the zip-ties and cut the remaining parts of the zip-ties. STEP 39 Continue If you’re installing the MMU3 on an MK3S+ printer, move to the chapter: MK3S+ Setup and Calibration If you’re installing the MMU3 on an MK3.5 printer, move to the chapter: MK3.5 Setup and Calibration...

- Page 141 9C. MK3S+ Extruder (UPG) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 142 Your MMU unit is now ready. In the following steps, we will work on the extruder. Namely, the filament sensor inside the "chimney". First, make sure the extruder PTFE tube with the fittings is removed from the printer. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 143 Remove the cover. Set it aside so that it won't mix up with the new parts. Disconnect the plug from the IR Filament sensor. Remove the IR Filament sensor and set it aside for later use. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 144 Note the connector orientation on the picture. This way, the connector will pull out of the part easily without a risk of damaging it. Remove the ir-sensor-holder and set it aside so it won't mix up with the new parts. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

-

Page 145: Fan Removal

Remove the fan. We need to split the extruder in order to replace the hotend PTFE tube. Look at the back of the extruder. Remove the M3x40 screw in the top right corner. Original Prusa MMU3 Assembly (includes upgrade from MMU2S) - Page 146 BE EXTRA CAUTIOUS with the hotend cables!!! You can break them! Use a reasonable force to pull the hotend out. Don't bend the cables too much. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 147 If you force the PTFE tube out without the hooks properly disengaged, the PTFE tube can jam inside. Throw the worn-out PTFE tube immediately to the nearest trash bin to avoid installing it back by accident ;) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 148 IT IS CRUCIAL to ensure the hotend is fitted properly in the extruder-body!!! The top of the hotend must fit into the correct recesses in the printed parts. See the second and the third picture for a reference! Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 149 Tighten the two M3x40 screws on the front of the extruder. Now, look at the back of the extruder. Re-insert and tighten up the M3x40 screw on the right. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 150 New chimney: parts preparation For the following steps, please prepare: Chimney base (1x) with the Tappex Microbarb 0006-M5 threaded insert Chimney (1x) M3nS nut (1x) M3 washer (1x) M3x30 screw (1x) M3x18 screw (1x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 151 Fix the parts together by M3x18 screw. Tighten it up just so that the parts hold on the extruder. Don't tighten it up fully yet. We will need to move the parts later on. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 152 For the following steps, please prepare: IR-sensor cover (1x) The new one M2x8 screw (1x) you removed from the printer earlier Prusa IR filament sensor (1x) you removed from the printer earlier Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 153 Look at the back of the extruder. Connect the cable to the filament sensor. Make sure the safety latch on the connector is pointing up and the connector aligns with the pins. If you plug the connector incorrectly, you can damage the eletronics!!! Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 154 If the shape differs, you might need to transfer the Bondtech gear and the nut into the new plastic part. MK3S MMU2S Idler is different than MK3S+ MMU2S / MMU3 Idler and cannot be re-used.

- Page 155 Opening the electronics box Undo the M3x40 screw on the Einsy box to open up the electronics box on the printer. Open up the Einsy-door on the inner side of the electronics box. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 156 9D. CORE One Nextruder mod Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 157 We suggest keeping a spare parts bag for components that will no longer be used. Don't worry, our guide will clearly show which parts to reuse and which to set aside. Let’s begin! Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 158 Regular Prusa Nozzle brass (marked PR) The CORE One comes with the Prusa Nozzle CHT by default. However, for best MMU3 performance, we recommend switching to a standard Prusa Nozzle. High-flow nozzles are also usable, but they need specific HF Nozzle Slicer profiles with large purge volumes.

- Page 159 Use a piece of fabric or other material thick enough to cover the heatbed. This will ensure you won't damage (scratch) the surface during the process. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 160 Press and hold the collet on the fitting. While holding it down, push the PTFE tube in, then pull it out. Remove the bowden-bend part and store it as a spare part. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 161 Some older printer versions might have two screws with a T10 head. Remove the cover. Open the Idler swivel. Fully loosen the M3x25 screws holding the gearbox cover. Leave the screws in place. Do not remove them entirely yet. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 162 The parts might be greasy. Clean off any excess grease. STEP 12 Nextruder disassembly (part 3) Using the 1.5mm Allen key, remove the set screw. Remove the Idler. Remove the two M3x30 screws with the springs. Remove the idler swivel assembly. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 163 Split the printed parts to open it up. Set aside for later use: Bearings, pins, spacer and the screw. The printed parts won’t be re-used. Set them aside so that they don’t mix up with the new parts. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 164 Insert the two pins into the corresponding openings. Mount the bearings onto the pins. Cover the assembly with the Idler-lever-b part. Insert the spacer tube into the corresponding opening. Fix the assembly together using the M3x6 screw. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 165 For the following steps, please prepare: Idler nut FS (1x) the new part Magnet 3x1mm (1x) Two tiny magnets are included. Separate them and use only one; the other is a spare. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 166 M3x22 screw (2x) This screw is a new type not previously used on a printer! Do not reuse old screws, as they are a different size and would not fit properly! Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 167 Attach the M3nN nuts onto the screws. Tighten the screws gently while holding the nuts using the neeedle-nose pliers. Do not overtighten the nuts. The Swivel must be able to move freely. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 168 The old shorter M3x30 screws won’t be re-used. Push the M3x35 screws through the screw guide. Attach the springs onto the end of both the screws. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 169 The new main plate is 3D printed using MJF technology. It cannot be replicated with the same quality using FDM printing. O-ring 24,5x1,5 (1x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 170 If you own the 4-screw version of the Nextruder, this specific type of set screw is not included. MMU Tension screws assembly (1x) MMU Swivel assembly (1x) MMU Idler assembly (1x) Main plate assembly (1x) PG-assembly (1x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 171 Insert the tension screw assembly through the heatsink and guide it towards the Swivel assembly. Gradually tighten the tension screws one at a time until their ends are flush with the surface of the Idler nut part on the other side, as shown. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 172 A slight wiggling motion, while inserting, can assist. STEP 32 Gearbox Assembly Preparation For the following steps, prepare: PG-case assembly (1x) PG-ring (1x) M3x25 screws (3x) PG-assembly adapter (1x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 173 Remove the adapter, while maintaining the gearbox assembly in place. Check the PG ring for adequate lubrication. If necessary, apply a slight amount of grease, as explained in the Nextruder Assembly guide. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 174 Close the Idler and secure it using the Swiwel. STEP 36 Nextruder Side Cover Preparation For the following steps, prepare: Nextruder Side Cover (1x) you removed earlier M3x10 screw (1x) you removed earlier Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 175 Re-install the side cover. First, hook it on the bottom, then push the top towards the Nextruder. Fix it in place using the M3x10 screw. Congratulations. Your Nextruder has been successfully reworked into the MMU version. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 176 10A. MK4/S, MK3.9/S Setup and Calibration Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 177 Fix the frame holders to the unit with four M3x10 screws. If the bolt doesn't easily go in, use the 1.5mm Allen key to adjust the nut position inside the Pulley body. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 178 Fix the label plate in place using the two M3x10 screws. STEP 4 Attaching the MMU unit (part 1) The MMU3 unit should be placed onto the top part of the printer's frame. Place the MMU3 unit onto the frame. Attach it just by the top hooks.

- Page 179 Then, take off the cover. Loosen the two M3x18 screws holding the ext-cable-holder. Raise the cable holder. Use needle-nose pliers to remove the indicated part of the cable holder, creating space for the MMU cable. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 180 Tighten the two M3x18 screws on top of the ext-cable-holder. Align the xBuddy box cover with the xBuddy box and secure it with four M3x6 screws. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

-

Page 181: Software Download

Visit the MMU3 page on Help.Prusa3D.com We will need to install the latest Prusa Slicer. Download the latest Drivers & Apps package. MMU3 on MK4 requires Drivers & Apps (PrusaSlicer) version 2.7.3 or newer. Leave this page open for the upcoming steps! Install the downloaded package on your computer and open the PrusaSlicer app. - Page 182 Please be aware that the MMU3 on MK4 IS NOT COMPATIBLE with older PrusaSlicer profiles or G-codes for MMU2, MMU2S, or even MMU3 + MK3S+ or MK3.5. Using an incompatible G-code file on the MMU3 + MK4 could lead to a failed print or potentially damage the printer! STEP 11...

- Page 183 Firmware Upgrade: Printer IMPORTANT!!! Before you proceed further; There are two firmware files. One is for the printer. The other one is for the MMU3 unit. Both needs to be flashed to the respective device. Printer’s firmware - .bbf file for the MK4 control board: (e.g.

- Page 184 LED lights on the MMU unit) Wait until it boots up properly, before issuing any commands to the printer. Since you've converted the extruder to the MMU version, when prompted to reconfigure the filament sensor's behavior, which will appear immediately, choose 'Continue'. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 185 STEP 14 MMU3 Firmware flashing (part 1) The MMU3 firmware file needs to be flashed into the MMU unit itself. Find the microUSB connector on the right side of the MMU3 unit. Connect the unit to your computer using the bundled microUSB cable.

- Page 186 Loosen the three screws on the front of the gearbox by 1.5 turns. The printer will go through the automatic gearbox alignment. This process can’t be seen from the outside. Once prompted, tighten the screws in the pattern indicated on the screen. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 187 Make sure there is SuperFINDA sensor (Finda) selected in any of the fields. You will see the respective symbols and sensor values displayed on the bottom of the screen. The sensor values are also shown in the Info > Sensor Info menu. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 188 10A. MK4/S, MK3.9/S Setup and Calibration STEP 20 SuperFINDA sensor calibration info If you built the MMU3, the SuperFINDA sensor inside the selector must be calibrated. For factory-assembled MMU3 units, the SuperFINDA is pre-calibrated, so you can skip the calibration steps.

- Page 189 Watch the sensor readings on the LCD (Info > Sensor Info -> FINDA ) Note, there is a slight lag in the sensor's readings on the LCD; proceed slowly. Repeat the test, adjusting SuperFINDA height until consistent readings occur when inserting and removing filament. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 190 Note, if the MMU unit is in IDLE state, the buttons have a different functions; For example; If there is no filament loaded, the side buttons can be used to move the selector right and left. But more on that later. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 191 Various versions of the blue fittings were included with Prusa products shipped before April 2024. The MMU3 on the MK4 printer requires either the black fitting or the latest evolution of the blue fitting, which has an internal diameter of 2.6mm.

- Page 192 For the following steps, please prepare: 360x2.5mm PTFE tube (1x) The PTFE tube bundled with the MMU3 for MK4 has an internal diameter of 2.5mm. In case you are upgrading from the 2mm ID MMU2S tube, and you have trouble distinguishing between the old and the new one, try comparing the internal diameter of the two.

- Page 193 PTFE tubes should not be bent too much. Otherwise, the filaments will jam. There were multiple versions of the spool holder available with the MMU3. Refer to one of the pictures, depending on your spool holder version.

- Page 194 There have been several versions of buffer parts available, which might look slightly different. However, the assembly process remains the same. The MMU3 for MK4 necessitates the use of the latest version of the buffer components. If you're using an older version, it's essential to rebuild the device using the most recent version available.

- Page 195 10B. MK3S+ Setup and Calibration Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 196 1.5mm Allen key for Filament sensor calibration 2.5mm Allen key for M3 screws Phillips screwdriver for power cable terminals STEP 2 Frame holders parts preparation Frame holder (2x) Label-plate (1x) M3x10 screws (6x) M3nS nut (2x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 197 Pulley body. STEP 4 Label plate installation Insert the label plate into the recess on the front of the frame holders. Fix the label plate in place using the two M3x10 screws. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 198 10B. MK3S+ Setup and Calibration STEP 5 Attaching the MMU unit (part 1) The MMU3 unit should be placed in the middle of the top part of the printer's aluminum frame. Place the MMU3 unit onto the frame. Attach it just by the top hooks.

- Page 199 Extruder-cable-clip. Make sure no cable is getting pinched! For easier cable-management inside the electronics box, attach the extruder cable bundle to the hooks on the inside of the Einsy-base with two zip-ties in the marked positions. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 200 You can fix the cable to the MMU3 holder using a zip-tie in marked location. Make sure it points to the side - not down. Otherwise, it might interfere with the extruder cable while printing.

- Page 201 Attach the top hinge to the printers frame using the M3x10 screw. Make sure there is enough clearance for the MMU3 cable when you close the door. The cable should be held by the door but must not be squished too much.

- Page 202 Verify the IR Filament sensor connector is installed correctly. Make sure it is plugged in correctly as there are several ways for it to go wrong! Make sure the signal cable is properly connected to all pins! Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 203 MK3S+ Closing the electronics box Close the door. Make sure no wire is being pinched while you close the door. Tighten up the M3x40 screw from the other side to lock the door. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

-

Page 204: Software Download

Open the PrusaSlicer Assistant / Wizard. (Configuration > Configuration Assistant > Prusa FFF) Scroll down to MK3 Family and make sure that the corresponding printer + MMU3 option is selected, depending on which printer model you have. The default nozzle is 0.4mm from factory. - Page 205 Visit the MMU3 Downloads page on Help.Prusa3D.com Find the ORIGINAL PRUSA MMU3 on the list. Download the latest FIRMWARE file bundle. STEP 18 Selecting a Printer firmware file Open up the firmware bundle you have downloaded earlier. Open one of the folders depending on the printer model you have (select "MK3S"...

- Page 206 Hit Rescan to make sure your printer appears in the Serial port: column Hit the Flash button. Wait until you see the Flashing succeeded message. In case of any issues with flashing the firmware please visit our troubleshooting article. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 207 STEP 22 MMU3 Firmware flashing (part 1) The MMU3 firmware file needs to be flashed into the MMU unit itself. Find the microUSB connector on the right side of the MMU3 unit. Connect the unit to your computer using the bundled microUSB cable.

- Page 208 MMU3 Firmware flashing (part 2) Open PrusaSlicer and select Configuration ->Flash Printer Firmware from the top menu. Hit Browse and select the MMU3 firmware image file on your computer. (e.g. MMU3_3.0.0.hex) Serial port should be auto-detected. Hit the Flash button.

- Page 209 Insert a 1.5mm Allen key into the extruder. Don't push it all the way in yet. Make sure you are using the thinnest of the bundled Allen keys; 1.5mm. Do not use the 2mm one!! Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 210 By rotating the calibration screw, we need to fine-tune the chimney position so that the number on the LCD reliably changes when inserting and removing the Allen key or filament from the Bontech gears. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 211 10B. MK3S+ Setup and Calibration STEP 26 IR filament sensor calibration (Part 3) Calibrating the IR filament sensor is super-crucial in order for MMU3 unit to work properly! Please, repeat this check several times. Confirm the sensor works correctly: See the LCD again if the Fil. sensor number displays 1 when Allen key (/filament) is inserted all the way or 0 when it´s not inserted all the way in.

- Page 212 10B. MK3S+ Setup and Calibration STEP 27 SuperFINDA sensor calibration info If you built the MMU3, the SuperFINDA sensor inside the selector must be calibrated. For factory-assembled MMU3 units, the SuperFINDA is pre-calibrated, so you can skip the calibration steps.

- Page 213 Sensor Info) Note, there is a slight lag in the sensor's readings on the LCD; proceed slowly. Repeat the test, adjusting SuperFINDA height until consistent readings occur when inserting and removing filament. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 214 F1 is the expected filament position. It means, the selector is in the first position. 1>3 would mean, the selector is changing from the first to the third. F? = position not yet set. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 215 If there is no filament loaded, the side buttons can be used to move the selector right and left. But more on that later. While in an error state, the printer might be beeping. You can change the Sound setting in the Tune or Settings menu. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 216 See the second picture. The tube on the left is the new one. A 2.5mm ID PTFE tube is required for the MMU3. M5-4 fittings (2x) The fittings may have either a blue or a black collet.

- Page 217 PTFE tubes should not be bent too much. Otherwise, the filaments will jam. Note that due to the decreased filament friction in the MMU3 compared to the MMU2S, some of the 3rd-party MMU2S re-winding spool holders might no longer work with the MMU3.

- Page 218 10C. MK3.5 Setup and Calibration Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 219 1.5mm Allen key for Filament sensor calibration 2.5mm Allen key for M3 screws Phillips screwdriver for power cable terminals STEP 2 Frame holders parts preparation Frame holder (2x) Label-plate (1x) M3x10 screws (6x) M3nS nut (2x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 220 Pulley body. STEP 4 Label plate installation Insert the label plate into the recess on the front of the frame holders. Fix the label plate in place using the two M3x10 screws. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 221 10C. MK3.5 Setup and Calibration STEP 5 Attaching the MMU unit (part 1) The MMU3 unit should be placed in the middle of the top part of the printer's aluminum frame. Place the MMU3 unit onto the frame. Attach it just by the top hooks.

- Page 222 Similarly, remove the break-off part on the Ext-cable-holder-b. Loosen the two M3x10 screws on top of the cable cover. Guide the MMU/Printer cable through the corresponding opening into the xBuddy box. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 223 Secure the zip-ties snugly but not too tight to avoid the risk of accidentally disconnecting or damaging the cables. Align the xBuddy box cover with the xBuddy box and secure it with four M3x6 screws. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

-

Page 224: Software Download

Click Finish to close the Wizard. In Printer: menu, select the MMU3 printer profile for future slicing. Note, the MMU3 on MK3.5 is reverse-compatible with the older MK3S+ MMU3 or MMU2S Slicer profile and G-codes - but not with the MMU2 profiles! - Page 225 MK3.5 printer (marked by MK35) There are two firmware files in the folder. One for the printer, the other one for the MMU unit. As a firmware file for the MK3.5, select the MK35 .bbf file Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 226 Since you've converted the extruder to the MMU version, when prompted to reconfigure the filament sensor's behavior, which will appear immediately, choose 'Continue'. Extruder type can be changed in Settings > Hardware > Extruder Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 227 STEP 17 MMU3 Firmware flashing (part 1) The MMU3 firmware file needs to be flashed into the MMU unit itself. Find the microUSB connector on the right side of the MMU3 unit. Connect the unit to your computer using the bundled microUSB cable.

- Page 228 Insert a 1.5mm Allen key into the extruder. Don't push it all the way in yet. Make sure you are using the thinnest of the bundled Allen keys; 1.5mm. Do not use the 2mm one!! Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 229 By rotating the calibration screw, we need to fine-tune the chimney position so that the number on the LCD reliably changes when inserting and removing the Allen key or filament from the Bontech gears. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 230 10C. MK3.5 Setup and Calibration STEP 21 IR filament sensor calibration (Part 3) Calibrating the IR filament sensor is super-crucial in order for MMU3 unit to work properly! Please, repeat this check several times. Confirm the sensor works correctly: See the LCD again if the Filament sensor...

- Page 231 10C. MK3.5 Setup and Calibration STEP 22 SuperFINDA sensor calibration info If you built the MMU3, the SuperFINDA sensor inside the selector must be calibrated. For factory-assembled MMU3 units, the SuperFINDA is pre-calibrated, so you can skip the calibration steps.

- Page 232 Watch the sensor readings on the LCD (Info > Sensor Info -> FINDA ) Note, there is a slight lag in the sensor's readings on the LCD; proceed slowly. Repeat the test, adjusting SuperFINDA height until consistent readings occur when inserting and removing filament. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 233 Note, if the MMU unit is in IDLE state, the buttons have a different functions; For example; If there is no filament loaded, the side buttons can be used to move the selector right and left. But more on that later. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 234 See the second picture. The tube on the left is the new one. A 2.5mm ID PTFE tube is required for the MMU3. M5-4 fittings (2x) The fittings may have either a blue or a black collet.

- Page 235 PTFE tubes should not be bent too much. Otherwise, the filaments will jam. Note that due to the decreased filament friction in the MMU3 compared to the MMU2S, some of the 3rd-party MMU2S re-winding spool holders might no longer work with the MMU3.

- Page 236 10D. CORE One Setup and Calibration Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 237 Enclosed with the Blob on top. If you have this version, continue to the Blob Preparation. There are also several community versions we won't be covering in this guide. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 238 Ensure the holder marked R is on the unit's right side (sides are reversed when the unit is upside down). Ensure the part with the M3nN nuts faces the back. Watch out! the nuts might keep falling out. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 239 Now, we will place the MMU assembly onto the top back part of the printer. Hook the notch on the MMU holders to the front part of the metal profile. Lean the MMU against the profile. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 240 Lite. For the following steps, prepare: Blob (1x) Vent (1x) CORE ONE ASSEMBLY MULTI TOOL (1x) version E2 or newer Vent Nut (2x) BlobLock (2x) M3x10rT (4x) O-ring (2x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 241 Use the Assembly Multi Tool to hold the nuts while tightening. Tighten the screws just so that the vent holds in place when moved to a side. Make sure vent is still easy to slide. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 242 Tighten the locks just until snug. It should be able to move the locks using a reasonable force. STEP 12 (ENC) MMU Holder Preparation For the following steps, prepare: CO_MMU_Holder (2x) M3x10 screw (4x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 243 Align the flat front of the holders with the unit. Attach the holders using four M3x10 screws. STEP 14 (ENC) Blob Holder Preparation For the following steps, prepare: Blob Sheet Metal (1x) Blob_Holder (2x) M3x10rT screws (8x) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 244 Attach the MMU unit to the sheet metal with two M3x10rT screws at the front. Tighten the screws with reasonable force to avoid stripping the self-tapped plastic thread. Fix the unit using the other two M3x10rT screws at the bottom. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 245 MMU faces the front of the printer. Fix it to the metal profiles in the back using two M3x10rT screws. Tighten two M3x10rT screws on sides against the M3nN nuts held with needle- nose pliers. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 246 This will unhook it from the cable bundle behind. Remove the cover. STEP 20 Back Cover Removal 2 Remove the six screws holding the xBuddy cover. Remove the cover by sliding it out. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 247 Attach the xBuddy box cover using the 6 M3x4rT screws. Make sure no cable is getting pinched. Re-install the back cover, making sure the MMU cable fits through the mousehole opening on top. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 248 Software Download Visit Prusa3D.com Download the latest Drivers & Apps package from the Software tab. MMU3 on CORE One requires PrusaSlicer version 2.9.2 or newer. Install the latest PrusaSlicer and open it. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 249 Open the Prusa Research printer list and select MMU version of your printer. Select the nozzle type and size in the list below. Click Finish to save the settings. In Printer: menu, select the MMU3 printer profile for future slicing. STEP 26 Firmware files download You will need to update the firmware for both the printer and the MMU unit.

- Page 250 First, transfer the firmware file onto a USB drive. Turn on the printer and connect the USB drive into it. Press the RESET button to restart it. Then, select the FLASH option on the screen to begin the update. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 251 MMU unit. Since you've converted the extruder to the MMU version, when prompted to reconfigure the filament sensor's behavior, which should appear immediately, choose 'Continue'. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 252 STEP 29 MMU3 Firmware flashing (part 1) The MMU3 firmware file needs to be flashed into the MMU unit itself. Find the microUSB connector on the right side of the MMU3 unit. Connect the unit to your computer using the bundled microUSB cable.

- Page 253 Loosen the three screws on the front of the gearbox by 1.5 turns. The printer will go through the automatic gearbox alignment. This process can’t be seen from the outside. Once prompted, tighten the screws in the pattern indicated on the screen. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 254 To change the settings, visit Settings > User Interface > Footer menu. The sensor values are also shown in the Info > Sensor Info menu. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 255 10D. CORE One Setup and Calibration STEP 35 SuperFINDA sensor calibration info If you built the MMU3, the SuperFINDA sensor inside the selector must be calibrated. For factory-assembled MMU3 units, you can skip the calibration steps. In the next step, we'll calibrate the sensor's position.

- Page 256 Watch the sensor readings on the LCD (Info > Sensor Info -> FINDA ) Note, there is a slight lag in the sensor's readings on the LCD; proceed slowly. Repeat the test, adjusting SuperFINDA height until consistent readings occur when inserting and removing filament. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 257 The status of the filament sensor is always displayed in the Footer section of the error screen to assist in diagnosis. Adjacent to it, you will find the status of the Finda sensor. (Note the FINDA status reading on the LCD has a slight delay.) Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 258 Note, if the MMU unit is in IDLE state, the buttons have a different functions; For example; If there is no filament loaded, the side buttons can be used to move the selector right and left. But more on that later. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 259 Quick tip: If you need to remove the PTFE tube from the fitting, press the collet in. While the collet is pressed, first press the PTFE tube in, then pull it out entirely. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 260 STEP 42 PTFE Length Calibration The MMU-to-Extruder PTFE tube length needs to be set in the firmware. Visit the menu Settings>Hardware>MMU Set the length: Enclosed version: 390mm. Lite version: 450mm. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 261 First, hook it at the back, then lean it onto the printer. STEP 44 Buffer Attachment Attach the buffer assembly onto the right side of the printer. Make sure the magnets are attached properly into the recessed side panel on the printer. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 262 Note the spool holder positioning. It is important that filament has as straight path as possible and that nothing interferes. PTFE tubes should not be bent too much. Otherwise, the filaments will jam. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

-

Page 263: First Flight

11. First Flight Original Prusa MMU3 Assembly (includes upgrade from MMU2S) - Page 264 Verify the spool is able to rotate freely and nothing interferes. Keep in mind that the MMU3 works with several printer models, so the parts in the pictures might look slightly different from yours. However, the general steps are the same.

- Page 265 Keep pushing the corresponding filament end into the PTFE tube from the buffer into the MMU, until you feel the filament being pulled in. Remember, the filament tip must be straight and sharp in order to load it properly. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 266 After a given filament is successfully loaded into the MMU, return its cassette back into the buffer. Repeat the same process for the other filament positions, until you successfully load all five filaments into the MMU. Original Prusa MMU3 Assembly (includes upgrade from MMU2S)

- Page 267 Note, after you issue a command to the MMU unit, wait and let it finish the operation. Don't rush. Don't play around with the printer in the meanwhile. Let it finish first if the MMU unit does something (homing, loading, unloading). Original Prusa MMU3 Assembly (includes upgrade from MMU2S)