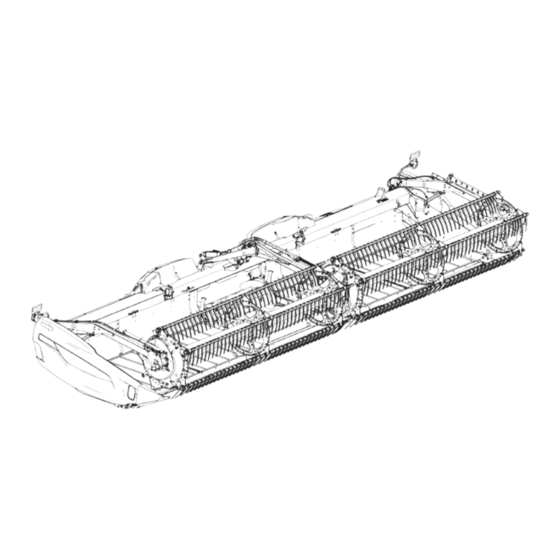

MacDon FlexDraper FD2 Series Operator's Manual

Header with float module

Hide thumbs

Also See for FlexDraper FD2 Series:

- Manual (560 pages) ,

- Installation instructions manual (60 pages) ,

- Quick start manual (2 pages)

Need help?

Do you have a question about the FlexDraper FD2 Series and is the answer not in the manual?

Questions and answers