Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Slayer STEAM SINGLE

- Page 1 STEAM SINGLE User and maintenance manual...

- Page 3 Translation of the original instruction...

-

Page 4: Table Of Contents

CONTENTS 1. Important safety measures......2 7. Cleaning and maintenance ......17 7.1 Overview of cleaning and maintenance inter 2. Introduction ............3 vals ............17 2.1 Aim of this manual........3 7.2 Coffee circuit washing .......18 2.2 How to read this manual ......4 7.2.1 Quick Clean .........18 2.3 General rules for using the machine ...4 7.2.2 Full Clean ..........18 3. -

Page 5: Important Safety Measures

IMPORTANT SAFETY • The use of the machine by minors, with or without adult MEASURES labor relations. • The cleaning and maintenance of the machine is the using your machine. dren. • Do not leave the machine unattended while it is in use. thorised to use the machine. -

Page 6: Cleaning The Machine

INTRODUCTION AIM OF THIS MANUAL • For more information about the cleaning of the ma chine, refer to ch.7. manual is the Steam Single IN THE EVENT OF A LONG PERIOD OF NON- chine. The manufacturer of the machine is: If the machine is to be left unused for a long time (e.g. -

Page 7: How To Read This Manual

HOW TO READ THIS MANUAL GENERAL RULES FOR USING THE MACHINE Before using the machine, read the warnings and instruc formation concerning its safety and correct hygienic use. WARNING: The service boiler water must be changed at least once a day. WARNING: Keep this manual for future consul- are indicated with the abbreviation Fig., followed by the tation. -

Page 8: Safety Labels And Symbols

Replace worn, illegible ATTENTION: hot surface labels with identical new ones in the same po- sitions. 707 Lind Ave SW, Renton, 98057 Washington, USA STEAM SINGLE+ 220-240 V 50-60 Hz 2,1-2,4 kW Date: 202407 Steam: 0.2MPa / 140 °C Code:ST1PX9WL1001A Group: 1.2MPa / 120 °C... -

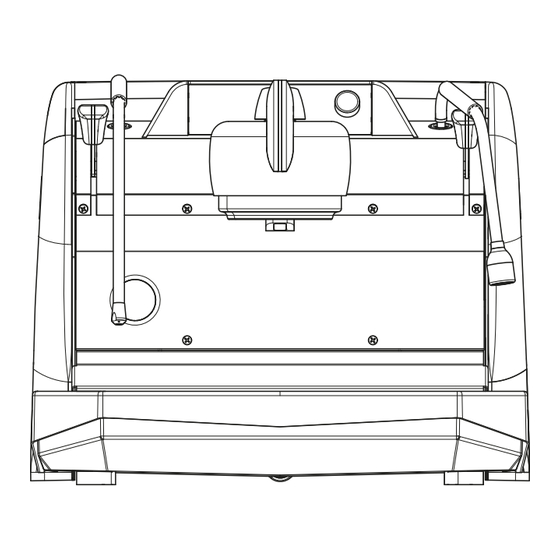

Page 9: Parts Of Your Machine

PARTS OF YOUR MACHINE below, see Fig. 4.1. 2. Barista Dashboard™ 5. Steam wand 7. Hot Water Actuator 9. Steam Actuator 13. Encoder Knob Fig. 4.1 - Parts of the machine... -

Page 10: Use

WARNING: When using the machine, do not bring your hands or other body parts close to the brew group, hot water tap, or steam wand. DAILY OPERATION WARNING: Before operating the machine, check that the main power switch is on. Fig. -

Page 11: Coffee Brewing

Hot water and steam cannot be dispensed at this stage. Using the respective actua- tors will display the following message: 12:34a Machine Cold Machine Cold Brewings will be available only when the pro- grammed working pressure is reached. • Turn the Encoder knob to activate the heating element •... -

Page 12: Brewing Modes

• 5.2.1 BREWING MODES • of the basket. 5.2.1.1 AUTOMATIC MODE • Move the actuator from the right to the center or left to • • The Barista Dashboard shows the main screen, where Time Temp: Stm: 19.7 45.6 88.9 1.2b 5.2.1.2 MANUAL MODE •... -

Page 13: Dispensing Hot Water

STEAM DISPENSING Time Temp Stm M 22.5 89.2 1.2b insulating devices to move the water tap and steam wand. NOTE. When the machine is switched on, it is WARNING: After each use, clean the steam wand always in manual mode. (see par. -

Page 14: Checking The Water Level In The Reservoir

5.4.2 CHECKING THE WATER LEVEL IN SETTINGS THE RESERVOIR NAVIGATION COMMANDS No water in the reservoir is indicated on the Ba rista Dashboard via an error code and messages: To navigate through the menus and settings screens, use the commands described below. •... - Page 15 PROGRAMMING FLOWS Time Temp: Stm: Time Temp Stm M 12.3 45.6 88.9 1.2b 12.3s 88.9°C 1.2b Brew Parameters Save Last Shot Position Enter Shot Weight <Shot..> < xx.x > g Brew Post Position <xx.x>s xxx.xg xx.xg < Shot 1 > Brew Post xx.xs <xxx.x>g xx.xg...

- Page 16 when enabled Next Service : Brewing Shot Counter xxx Days yyyyy Cycles Shot1: xxxx Brewing Shot Counter Reset ALL Shot CNT? Hot Water < YES > Shot2: xxxx Program Dose Hot Water Dose 1:< xx.x > s Brewing Shot Counter Manual: xxxx Hot Water Dose 2:<...

-

Page 17: Parameter Description

PARAMETER DESCRIPTION • Calibrate Weight - AUTOMATIC mode) • Main screen Calibrate Time Temp: Stm: Weight 12.3 45.6 88.9 1.2b • Position - Choice for which brew settings are • valid: Shot1 (actuator in center), Shot2 (actua Time- tor to left) or Both Wt - Expected wt..Shot wt.. - Page 18 • Time and Date Hot Water Program Dose Time and Date hh:mm:ss dd mmm yy • Hot Water Dose 1 - time setting for dose 1. From 0.5 to 30.0 seconds • at 0.5 second intervals). • Manager Menu • Hot Water Dose 2 - time setting for dose 2.

- Page 19 The modes are: Power Save Man - Manual: when this mode is selected, the Settings --- ator is quickly moved away and then returned to • selecting from three modes: 5d - Auto- Mon - Fri (Monday to Friday) and Sat - Sun set time when the actuator is returned to the initial (Saturday and Sunday), for each of which it is Wake Up time (on) and...

-

Page 20: Cleaning And Maintenance

CLEANING AND MAINTENANCE WARNING: The machine must undergo the cleaning and maintenance tasks explained in this chapter, at the indicated intervals. OVERVIEW OF CLEANING AND MAINTENANCE INTERVALS After 8 On request After each Activities hours of Daily Weekly on Barista Tools inactivity Dashboard... -

Page 21: Coffee Circuit Washing

COFFEE CIRCUIT WASHING WARNING: Failure to run the coffee circuit wash Quick Clean cycle causes grease and limescale deposits and leads to a deterioration in the performance of the machine. or other body parts close to the grouphead dur- ing the cleaning cycle. •... - Page 22 • Turn the Encoder knob until Full Clean • on the Barista Dashboard: Remove Portafilter Click for Flush Full Clean • The Barista Dashboard shows the following message: • Push the Encoder knob to start the cleaning cycle. Full Clean Final Flush XXs, where XXs The Barista Dashboard shows the following message, indicates the time remaining until the end of the clean where XXs indicates the time left until the end of this...

-

Page 23: Tank Water Change

PORTAFILTER CLEANING Time Temp Stm M • 22.5s 89.2°C 1.2b aluminium or iron. Moving the brew actuator from the right, will Barista Dashboard the following message: Group Locked - Execute Washing When the message Group Locked - Exe- cute Washing TANK WATER CHANGE •... -

Page 24: Cleaning The Steam Wand

CLEANING THE STEAM WAND • oughly. insulating devices to move the water spout and • steam wand. steam for at least 10 seconds. 7.5.1 AFTER EACH USE • rinse thoroughly. • 7.5.2 AT THE END OF THE DAY • • •... -

Page 25: Cleaning The Drip Tray

CLEANING THE DRIP TRAY BODY PANEL CLEANING WARNING: Do not use products with ammonia, NOTE: The following operations can also be abrasives or degreasers. performed with the machine switched off. WARNING: Do not spray liquids into the cavities • of the body panels. •... -

Page 26: Cleaning The Water Reservoir

CLEANING THE WATER 7.10 SERVICE MAINTENANCE RESERVOIR WARNING: The operations described in this sec- • Pull out the water reservoir. nical staff. dicated on the Barista Dashboard. For service maintenance, contact the technical assistan ce service. DISPOSING OF THE Fig. 7.4 - Reservoir extraction MACHINE •... -

Page 27: Malfunctions And Faults

MALFUNCTIONS AND FAULTS PROBLEM CAUSE SOLUTION The machine does not work Fig. 4.1) is off. Water leakage from the Clean gasket. Coffee brewing time too short. Coffee ground too coarsely. The coffee is too old. hole. Increase the coarseness of the coffee grind. -

Page 28: Status Indications

STATUS INDICATIONS messages in the form of error and/or warning codes. as shown below and require the intervention of technical staff: Error Temp Stm M 89.2°C 1.2b Warning messages are shown in the center of the Ba centre. The most common ones are listed below: INDICATION CAUSE SOLUTION... - Page 29 INDICATION CAUSE SOLUTION out by technical staff. Upgrading + Remove loaded, the machine's buzzer USB + progress bar [nn%] the USB memory stick and “Low Water Level!” No water in the tank is indicated on the Barista Insert the water tank in the + “->...

-

Page 30: 10. Technical Data

10. TECHNICAL DATA NOTE: The manufacturer reserves the right to make changes or improvements without prior notice. STEAM SINGLE 330 (13) 315 (12.4) 560 (22.05) 447 (17.6) mm (inches) Weight pounds... - Page 31 STEAM SINGLE tipo di macchina 1 gruppo Type of machine 1 group type de machine 1 groupe Maschinentypen 1 Einheit modelo de la 1 grupo máquina 1 grupo tipo de la màquina Capacità [ bar ] [ °C ] Fluido...

- Page 32 Cimbali Group S.p.A. Via A. Manzoni, 17 20082 Binasco (MI), Italia...

Need help?

Do you have a question about the STEAM SINGLE and is the answer not in the manual?

Questions and answers