Advertisement

Quick Links

Regarding Your Pump Order – Motor Label Explanation

You may notice that the pump you received has a higher horsepower (HP) rating on the

motor label than expected. Rest assured, you have received the correct pump. Here's

why:

● THP (Total Horsepower) reflects the motor's potential power at the shaft, not

the exact operating output.

● HHP (Hydraulic Horsepower) measures the performance of the wet end, the

part that moves water.

● A motor's THP may be higher to ensure optimal performance and efficiency for

the wet end, even if their ratings don't match exactly.

The motor and wet end are appropriately matched to deliver the correct performance for

your system.

If you have any questions, feel free to contact our support team.

Thank you for choosing Pureline!

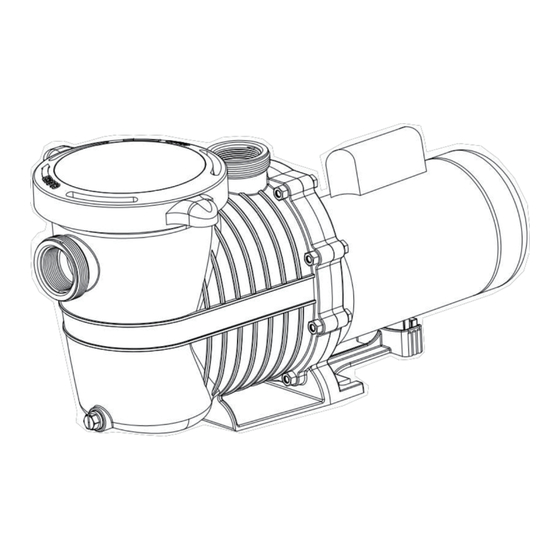

Pure Flow Pump

Notice:

Installation And User Guide

Models: PL1600 Series

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Pureline PL1608

- Page 1 The motor and wet end are appropriately matched to deliver the correct performance for your system. If you have any questions, feel free to contact our support team. Thank you for choosing Pureline! Installation And User Guide Models: PL1600 Series...

- Page 2 READ AND FOLLOW ALL INSTRUCTIONS ATTENTION INSTALLER: This manual contains essential information about the installation, operation, and safe use of this pool pump. Please remember to furnish this manual and all other instructional documents to the end user of this product. Failure to read and follow instructions can result in serious injury.

- Page 3 WARNING- The pump can produce high levels of suction within the suction side of the plumbing system. These high levels of suction can pose a risk if a person comes within close proximity of the suction openings. A person can also be seriously injured by the high level of vacuum or may become trapped and drown.

- Page 4 WARNING- Separation Hazard- Please ensure the strainer cover is properly secured to the pump housing. Do not operate pool and spa circulation system if a system component is not assembled properly, damaged, or missing. All suction and discharge valves must be open when starting the circulation system.

- Page 5 Pump Plumbing There are many different ways a pool pump can be plumbed due to space requirements, existing plumbing, water features, etc... Due to these scenarios, we have listed some general best practices to adhere to when plumbing a pool pump. Pool Plumbing Best Practices ●...

- Page 6 Improper Installation Filter 90° on suction side of pump Pump Pump Discharge Port Filter Ideally no 90° within 12’’ of pump suction port Pump Suction Port 90° 90° 3 Way Valve Piping 1. Larger piping sizes improve pool plumbing. 2. Piping on the suction side of the pump should be the same or larger than the return port. 3.

- Page 7 Electrical Requirements 1. Install all equipment in accordance with the National Electrical Code and all applicable local codes and ordinances. 2. A means for disconnection must be incorporated in the fixed wiring in accordance with the wiring rules. Voltage The voltage at the motor must NOT be more than 10% above or below motor nameplate rated voltage or the motor may overheat, causing the overload tripping.

- Page 8 For Two Speed Pumps If pump comes with a power cord, no wiring needed. If not, wire the pump as below: 1. Ground wire connects to the ground terminal. 2. If your power supply has two hot wires, connect them to each terminal marked with “Line”; If your power supply has one hot wire and one neutral wire, connect either of them to either of the terminal marked with “Line”.

- Page 9 Voltage from the power must be in the range from 90% to 110% of the motor nameplateratedvoltage. Otherwise, the motor may overheat and result in overload tripping and reduced component life. Install, ground, bond, and wire motor in accordance with local or NEC requirements. Motor should be grounded permanently by connecting ground terminal to electrical service ground.

- Page 10 Do NOT add chemicals to the pool/spa system directly in front of pump suction. Adding undiluted chemicals may damage pump and voids the warranty. ATTENTION- Before removing strainer cover: 1. STOP PUMP before proceeding. 2. CLOSE VALVES in suction and outlet pipes 3.

- Page 11 ATTENTION: Wait five seconds before re-starting the pump. Failure to do so may cause ATTENTION: Wait five seconds before re-starting the pump. Failure to do so may cause reverse rotation of motor and seriously damage the pump. reverse rotation of motor and seriously damage the pump. Maintenance Maintenance ●...

- Page 12 Solution: Contact qualified professional to check that the wiring gauge is heavy enough. NOTE: Your pump motor is equipped with an automatic thermal overload protector. The motor automatically shuts off if the power supply drops below a certain point. This prevents damage caused by heat buildup in the motor windings.

- Page 13 Low Flow. Generally check for: 1. Clogged or restricted strainer or suction line. Solution: Contact a qualified professional. 2. Undersized pool piping. Solution: Correct piping size. 3. Plugged, or restricted line of filter, valve partially closed (high gauge reading). Solution: Sand filters- backwash as per the manufacturer’s instructions D.E.

- Page 14 The Pureline Pure Flow pump was inspected before shipment from the warehouse. To original purchasers of this pump, Pureline Products warrants its products free from defects in materials and workmanship for a period of ONE (1) year from the date of purchase.

- Page 15 Description Part Number Pump Cover PL1585 Cover O-ring PL1586 Pump Basket PL1636 Pump Housing PL1632 Diffuser O-ring PL1628 Diffuser PL1627 Impeller 1.0 HP PL1624 Impeller 1.5 HP PL1637 Pump Housing O-ring PL1625 Seal Plate PL1631 Housing Bolts PL1623 Shaft Seal Assembly PL1592 Drain Plug Assembly PL1629...

Need help?

Do you have a question about the PL1608 and is the answer not in the manual?

Questions and answers