Endress+Hauser Proline Promass E 500 Operating Instructions Manual

Coriolis flowmeter profibus pa

Hide thumbs

Also See for Proline Promass E 500:

- Operating instructions manual (290 pages) ,

- Operating instructions manual (302 pages)

Summary of Contents for Endress+Hauser Proline Promass E 500

- Page 1 Products Solutions Services BA01550D/06/EN/04.24-00 71674879 2024-11-01 Valid as of version 01.01.zz (Device firmware) Operating Instructions Proline Promass E 500 Coriolis flowmeter PROFIBUS PA...

- Page 2 • The manufacturer reserves the right to modify technical data without prior notice. Your Endress+Hauser sales organization will supply you with current information and updates to this manual. Endress+Hauser...

- Page 3 Proline Promass E 500 PROFIBUS PA Table of contents Table of contents About this document ....6 Installation ..... . . 22 Document function .

- Page 4 Table of contents Proline Promass E 500 PROFIBUS PA Structure and function of the operating Commissioning ....105 menu ......

- Page 5 13.2 Measuring and test equipment ... 256 13.3 Endress+Hauser services ....256 Repair ......257 14.1 General notes .

- Page 6 About this document Proline Promass E 500 PROFIBUS PA About this document Document function These Operating Instructions contain all the information required in the various life cycle phases of the device: from product identification, incoming acceptance and storage, to installation, connection, operation and commissioning, through to troubleshooting, maintenance and disposal.

- Page 7 Proline Promass E 500 PROFIBUS PA About this document 1.2.4 Tool symbols Symbol Meaning Torx screwdriver Phillips head screwdriver Open-ended wrench 1.2.5 Symbols for certain types of information Symbol Meaning Permitted Procedures, processes or actions that are permitted. Preferred Procedures, processes or actions that are preferred.

- Page 8 • Device Viewer (www.endress.com/deviceviewer): Enter the serial number from the nameplate • Endress+Hauser Operations app: Enter serial number from nameplate or scan matrix code on nameplate. The following documentation may be available depending on the device version ordered: Document type...

- Page 9 Proline Promass E 500 PROFIBUS PA Safety instructions Safety instructions Requirements for the personnel The personnel for installation, commissioning, diagnostics and maintenance must fulfill the following requirements: ‣ Trained, qualified specialists must have a relevant qualification for this specific function and task.

- Page 10 Verification for borderline cases: ‣ For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance in verifying the corrosion resistance of fluid-wetted materials, but does not accept any warranty or liability as minute changes in the temperature, concentration or level of contamination in the process can alter the corrosion resistance properties.

- Page 11 Proline Promass E 500 PROFIBUS PA Safety instructions IT security The manufacturer warranty is valid only if the product is installed and used as described in the Operating Instructions. The product is equipped with security mechanisms to protect it against any inadvertent changes to the settings.

- Page 12 Safety instructions Proline Promass E 500 PROFIBUS PA User-specific access code Write access to the device parameters via the local display, web browser or operating tool (e.g. FieldCare, DeviceCare) can be protected by the modifiable, user-specific access code (→ 159).

- Page 13 Proline Promass E 500 PROFIBUS PA Safety instructions This includes organizational security measures such as the assignment of access authorization as well as technical measures such as network segmentation. Transmitters with an Ex de approval may not be connected via the service interface (CDI-RJ45)! Order code for "Approval transmitter + sensor", options (Ex de): BA, BB, C1, C2, GA,...

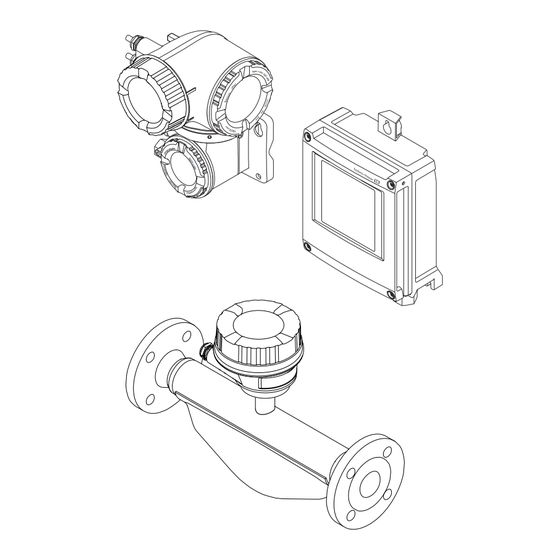

- Page 14 Product description Proline Promass E 500 PROFIBUS PA Product description The measuring system consists of a transmitter and a sensor. The transmitter and sensor are mounted in physically separate locations. They are interconnected by connecting cables. Product design Two versions of the transmitter are available.

- Page 15 Proline Promass E 500 PROFIBUS PA Product description 3.1.2 Proline 500 Signal transmission: analog Order code for "Integrated ISEM electronics", option B "Transmitter" For use in applications required to meet special requirements due to ambient or operating conditions. As the electronics are located in the transmitter, the device is ideal in the event of: •...

- Page 16 • Enter the serial numbers from the nameplates in the Device Viewer (www.endress.com/deviceviewer): all the information about the device is displayed. • Enter the serial numbers from the nameplates into the Endress+Hauser Operations app or scan the DataMatrix code on the nameplate with the Endress+Hauser Operations app: all the information about the device is displayed.

- Page 17 Proline Promass E 500 PROFIBUS PA Incoming acceptance and product identification 4.2.1 Transmitter nameplate Proline 500 – digital Order code: Ser. no.: Ext. ord. cd.: Date: A0029194 3 Example of a transmitter nameplate Name of the transmitter Manufacturer address/certificate holder...

- Page 18 Incoming acceptance and product identification Proline Promass E 500 PROFIBUS PA Proline 500 3 4 5 Order code: Ser. no.: Ext. ord. cd.: Date: A0029192 4 Example of a transmitter nameplate Manufacturer address/certificate holder Name of the transmitter Order code Serial number (Ser.

- Page 19 Proline Promass E 500 PROFIBUS PA Incoming acceptance and product identification 4.2.2 Sensor nameplate Order code: Ser. no.: Ext. ord. cd.: A0029206 5 Example of a sensor nameplate, part 1 Name of the sensor Manufacturer address/certificate holder Nominal diameter of the sensor; flange nominal diameter/nominal pressure; sensor test pressure; medium temperature range;...

- Page 20 Incoming acceptance and product identification Proline Promass E 500 PROFIBUS PA 4.2.3 Symbols on the device Symbol Meaning WARNING! This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in serious or fatal injury. Please consult the documentation for the measuring instrument to discover the type of potential danger and measures to avoid it.

- Page 21 Proline Promass E 500 PROFIBUS PA Storage and transport Storage and transport Storage conditions Observe the following notes for storage: ‣ Store in the original packaging to ensure protection from shock. ‣ Do not remove protective covers or protective caps installed on process connections.

- Page 22 Installation Proline Promass E 500 PROFIBUS PA 5.2.2 Measuring devices with lifting lugs CAUTION Special transportation instructions for devices with lifting lugs ‣ Only use the lifting lugs fitted on the device or flanges to transport the device. ‣ The device must always be secured at two lifting lugs at least.

- Page 23 Proline Promass E 500 PROFIBUS PA Installation Installation in down pipes However, the following installation suggestion allows for installation in an open vertical pipeline. Pipe restrictions or the use of an orifice with a smaller cross-section than the nominal diameter prevent the sensor running empty while measurement is in progress.

- Page 24 Installation Proline Promass E 500 PROFIBUS PA Orientation Recommendation Horizontal orientation, transmitter at bottom Exception: → 8, 24 A0015590 Horizontal orientation, transmitter at side A0015592 This orientation is recommended to ensure self-draining. Applications with low process temperatures may reduce the ambient temperature. To maintain the minimum ambient temperature for the transmitter, this orientation is recommended.

- Page 25 Proline Promass E 500 PROFIBUS PA Installation 6.1.2 Environmental and process requirements Ambient temperature range Measuring device • –40 to +60 °C (–40 to +140 °F) • Order code for "Test, certificate", option JP: –50 to +60 °C (–58 to +140 °F) Readability of the local –20 to +60 °C (–4 to +140 °F)

- Page 26 Installation Proline Promass E 500 PROFIBUS PA A0034391 9 Thermal insulation with exposed extended neck Heating NOTICE Electronics can overheat due to elevated ambient temperature! ‣ Observe maximum permitted ambient temperature for the transmitter. ‣ Depending on the medium temperature, take the device orientation requirements into account.

- Page 27 Proline Promass E 500 PROFIBUS PA Installation Hygienic compatibility When installing in hygienic applications, please refer to the information in the "Certificates and approvals/hygienic compatibility" section → 288 Rupture disk Process-related information: → 279. WARNING Danger from medium escaping! Medium escaping under pressure can cause injury or material damage.

- Page 28 Installation Proline Promass E 500 PROFIBUS PA Verification and adjustment cannot be carried out if the following process conditions are present: • Gas pockets Ensure that the system has been sufficiently flushed with the medium. Repeat flushing can help to eliminate gas pockets •...

- Page 29 Proline Promass E 500 PROFIBUS PA Installation SW 2.5 5 (0.2) min. 15 (0.6) A0029799 Cover borehole for the securing screw Securing screw to lock the cover Installing the measuring instrument 6.2.1 Required tools For transmitter For mounting on a post: •...

- Page 30 Installation Proline Promass E 500 PROFIBUS PA 1. Ensure that the direction of the arrow on the nameplate of the sensor matches the flow direction of the medium. 2. Install the measuring device or turn the transmitter housing so that the cable entries do not point upwards.

- Page 31 Proline Promass E 500 PROFIBUS PA Installation ø TX 25 20…70 ø ( 0.79…2.75) SW 10 A0029051 12 Unit mm (in) Wall mounting Required tools: Drill with drill bit ⌀ 6.0 mm 17 (0.67) 5.8 (0.23) 5.8 (0.23) 149 (5.85) A0029054 ...

- Page 32 Installation Proline Promass E 500 PROFIBUS PA 5. Tighten the fixing screws. 6.2.5 Mounting the transmitter housing: Proline 500 CAUTION Ambient temperature too high! Danger of electronics overheating and housing deformation. ‣ Do not exceed the permitted maximum ambient temperature.

- Page 33 Proline Promass E 500 PROFIBUS PA Installation 20 70 … ( 0.79 to 2.75) SW 13 A0029057 15 Engineering unit mm (in) 6.2.6 Turning the transmitter housing: Proline 500 To provide easier access to the connection compartment or display module, the transmitter housing can be turned.

- Page 34 Installation Proline Promass E 500 PROFIBUS PA – – – 3 mm A0030035 1. Depending on the device version: Loosen the securing clamp of the connection compartment cover. 2. Unscrew the connection compartment cover. 3. Turn the display module to the desired position: max. 8 × 45° in each direction.

- Page 35 Proline Promass E 500 PROFIBUS PA Electrical connection Electrical connection WARNING Live parts! Incorrect work performed on the electrical connections can result in an electric shock. ‣ Set up a disconnecting device (switch or power-circuit breaker) to easily disconnect the device from the supply voltage.

- Page 36 Electrical connection Proline Promass E 500 PROFIBUS PA Ethernet-APL Shielded twisted-pair cable. Cable type A is recommended. https://www.profibus.com Ethernet-APL White Paper " Current output 0 /4 to 20 mA (excluding HART) Standard installation cable is sufficient. Pulse /frequency /switch output Standard installation cable is sufficient.

- Page 37 Proline Promass E 500 PROFIBUS PA Electrical connection A0032476 Proline 500 digital transmitter Proline 500 transmitter Sensor Promass Non-hazardous area Hazardous area: Zone 2; Class I, Division 2 Hazardous area: Zone 1; Class I, Division 1 Standard cable to 500 digital transmitter → 37 Transmitter installed in the non-hazardous area or hazardous area: Zone 2;...

- Page 38 Electrical connection Proline Promass E 500 PROFIBUS PA Cross-section Cable length [max.] 1.00 mm (AWG 17) 240 m (720 ft) 1.50 mm (AWG 15) 300 m (900 ft) Optionally available connecting cable Design 2 × 2 × 0.34 mm (AWG 22) PVC cable with common shield (2 pairs, uninsulated stranded CU wires;...

- Page 39 Proline Promass E 500 PROFIBUS PA Electrical connection Cross-section Cable length [max.] Termination 2 x 2 x 0.50 mm 50 m (150 ft) 2 x 2 x 0.50 mm (AWG 20) (AWG 20) BN WT YE GN • +, – = 0.5 mm •...

- Page 40 Electrical connection Proline Promass E 500 PROFIBUS PA C: Connecting cable between sensor and transmitter: Proline 500 Design 6 × 0.38 mm PVC cable with individual shielded cores and common copper shield Conductor resistance ≤ 50 Ω/km (0.015 Ω/ft) Capacitance: core/shield ≤...

- Page 41 Proline Promass E 500 PROFIBUS PA Electrical connection 7.2.5 device plug pin assignment Assignment Coding Plug/socket PROFIBUS PA + Plug Grounding PROFIBUS PA – Not assigned 7.2.6 Shielding and grounding Optimal electromagnetic compatibility (EMC) of the fieldbus system can be guaranteed only if the system components and, in particular, the lines are shielded and the shield forms as complete a cover as possible.

- Page 42 Electrical connection Proline Promass E 500 PROFIBUS PA A0028768 17 Connection example for PROFIBUS PA Control system (e.g. PLC) PROFIBUS PA segment coupler Cable shield: the cable shield must be grounded at both ends to comply with EMC requirements; observe cable...

- Page 43 Proline Promass E 500 PROFIBUS PA Electrical connection Connecting the measuring instrument: Proline 500 - digital NOTICE An incorrect connection compromises electrical safety! ‣ Only properly trained specialist staff may perform electrical connection work. ‣ Observe applicable federal/national installation codes and regulations.

- Page 44 Electrical connection Proline Promass E 500 PROFIBUS PA Connecting the sensor connection housing via terminals For the device version with the order code for "Sensor connection housing": Option A "Aluminum coated" 10 (0.4) 3 mm TX 20 TX 20 22 mm...

- Page 45 Proline Promass E 500 PROFIBUS PA Electrical connection Connecting the sensor connection housing via terminals For the device version with the order code for "Sensor connection housing": Option B "Stainless" 10 (0.4) 8 mm 22 mm 24 mm A0029613 1. Release the securing screw of the housing cover.

- Page 46 Electrical connection Proline Promass E 500 PROFIBUS PA Connecting the sensor connection housing via the connector For the device version with the order code for "Sensor connection housing": Option C "Ultra-compact hygienic, stainless" A0029615 1. Connect the protective ground. 2. Connect the connector.

- Page 47 Proline Promass E 500 PROFIBUS PA Electrical connection Connecting the connecting cable to the transmitter TX 20 TX 20 10 (0.4) 22 mm 24 mm A0029597 1. Loosen the 4 fixing screws on the housing cover. 2. Open the housing cover.

- Page 48 Electrical connection Proline Promass E 500 PROFIBUS PA 7.3.2 Connecting the signal cable and the supply voltage cable A0028200 Terminal connection for supply voltage Terminal connection for signal transmission, input/output Terminal connection for signal transmission, input/output Terminal connection for connecting cable between sensor and transmitter Terminal connection for signal transmission, input/output;...

- Page 49 Proline Promass E 500 PROFIBUS PA Electrical connection WARNING Housing degree of protection may be voided due to insufficient sealing of the housing. ‣ Screw in the screw without using any lubricant. NOTICE Excessive tightening torque applied to the fixing screws! Risk of damaging the plastic transmitter.

- Page 50 Electrical connection Proline Promass E 500 PROFIBUS PA Connecting the measuring instrument: Proline 500 NOTICE An incorrect connection compromises electrical safety! ‣ Only properly trained specialist staff may perform electrical connection work. ‣ Observe applicable federal/national installation codes and regulations.

- Page 51 Proline Promass E 500 PROFIBUS PA Electrical connection Connecting the sensor connection housing via terminals For the device version with the order code for "Housing": Option A "Aluminum coated" 10 (0.4) 3 mm 22 mm 24 mm A0029612 1. Loosen the securing clamp of the housing cover.

- Page 52 Electrical connection Proline Promass E 500 PROFIBUS PA Connecting the sensor connection housing via terminals For the device version with the order code for "Housing": Option B "Stainless" 10 (0.4) 8 mm 22 mm 24 mm A0029613 1. Release the securing screw of the housing cover.

- Page 53 Proline Promass E 500 PROFIBUS PA Electrical connection Attaching the connecting cable to the transmitter 10 (0.4) 3 mm 22 mm 24 mm A0029592 1. Loosen the securing clamp of the connection compartment cover. 2. Unscrew the connection compartment cover.

- Page 54 Electrical connection Proline Promass E 500 PROFIBUS PA 7.4.2 Connecting the signal cable and the supply voltage cable A0026781 Terminal connection for supply voltage Terminal connection for signal transmission, input/output Terminal connection for signal transmission, input/output or terminal connection for network connection via...

- Page 55 Proline Promass E 500 PROFIBUS PA Electrical connection 10 (0.4) mm (in) – A0029815 7. Push the cable through the cable entry. To ensure tight sealing, do not remove the sealing ring from the cable entry. 8. Strip the cable and cable ends. In the case of stranded cables, also fit ferrules.

- Page 56 Electrical connection Proline Promass E 500 PROFIBUS PA 3 (0.12) A0029598 19 Engineering unit mm (in) 1. Use a flat-blade screwdriver to press down on the slot between the two terminal holes. 2. Remove the cable end from the terminal.

- Page 57 Proline Promass E 500 PROFIBUS PA Electrical connection Special connection instructions 7.6.1 Connection examples PROFIBUS PA A0028768 20 Connection example for PROFIBUS PA Control system (e.g. PLC) PROFIBUS PA segment coupler Cable shield provided at one end. The cable shield must be grounded at both ends to comply with EMC requirements;...

- Page 58 Electrical connection Proline Promass E 500 PROFIBUS PA 4...20 mA A0028759 22 Connection example for 4-20 mA current output (passive) Automation system with current input (e.g. PLC) Active barrier for power supply (e.g. RN221N) Analog display unit: observe maximum load...

- Page 59 Proline Promass E 500 PROFIBUS PA Electrical connection Relay output A0028760 25 Connection example for relay output (passive) Automation system with relay input (e.g. PLC) Power supply Transmitter: observe input values → 268 Current input A0028915 26...

- Page 60 Electrical connection Proline Promass E 500 PROFIBUS PA Hardware settings 7.7.1 Setting the device address The address must always be configured for a PROFIBUS DP/PA device. The valid address range is between 1 and 126. In a PROFIBUS DP/PA network, each address can only be assigned once.

- Page 61 Proline Promass E 500 PROFIBUS PA Electrical connection Software addressing ‣ To switch addressing from hardware addressing to software addressing: set DIP switch No. 4 to Off. The device address set in the Device address parameter (→ 112) takes effect after 10 seconds.

- Page 62 Electrical connection Proline Promass E 500 PROFIBUS PA A0034500 1. Loosen the 4 fixing screws on the housing cover. 2. Open the housing cover. 3. Fold open the terminal cover. 4. Set DIP switch no. 2 on the I/O electronics module from OFF → ON.

- Page 63 Proline Promass E 500 PROFIBUS PA Electrical connection Ensuring the degree of protection The measuring instrument fulfills all the requirements for the degree of protection IP66/67, Type 4X enclosure. To guarantee the degree of protection IP66/67, Type 4X enclosure, carry out the following steps after the electrical connection: 1.

- Page 64 Operation options Proline Promass E 500 PROFIBUS PA Operation options Overview of operation options A0034513 Local operation via display module Computer with web browser or operating tool (e.g. FieldCare, DeviceCare, AMS Device Manager, SIMATIC PDM) Field Xpert SFX350 or SFX370...

- Page 65 Proline Promass E 500 PROFIBUS PA Operation options Structure and function of the operating menu 8.2.1 Structure of the operating menu For an overview of the operating menu for experts: see the "Description of Device Parameters" document supplied with the device → 292...

- Page 66 Operation options Proline Promass E 500 PROFIBUS PA 8.2.2 Operating philosophy The individual parts of the operating menu are assigned to certain user roles (e.g. operator, maintenance etc.). Each user role contains typical tasks within the device life cycle. Menu/parameter...

- Page 67 Proline Promass E 500 PROFIBUS PA Operation options Menu/parameter User role and tasks Content/meaning Expert Function- Tasks that require detailed knowledge of Contains all of the device parameters and allows direct access to these by oriented the function of the device: means of an access code.

- Page 68 Operation options Proline Promass E 500 PROFIBUS PA Status area The following symbols appear in the status area of the operational display at the top right: • Status signals→ 189 • F: Failure • C: Function check • S: Out of specification •...

- Page 69 Proline Promass E 500 PROFIBUS PA Operation options Measurement channel numbers Symbol Meaning Measurement channel 1 to 4 The measurement channel number is displayed only if more than one channel is present for the same measured variable type (e.g. totalizer 1 to 3).

- Page 70 Operation options Proline Promass E 500 PROFIBUS PA 8.3.2 Navigation view In the submenu In the wizard /../Operation 0091-1 /../Select medium Access stat.disp Select medium Operator Liquid Locking status Display A0013993-EN A0013995-EN Navigation view Navigation path to current position Status area Display area for navigation Operating elements →...

- Page 71 Proline Promass E 500 PROFIBUS PA Operation options Setup Is displayed: • In the menu next to the "Setup" selection • At the left in the navigation path in the Setup menu Diagnosis Is displayed: • In the menu next to the "Diagnostics" selection •...

- Page 72 Operation options Proline Promass E 500 PROFIBUS PA 8.3.3 Editing view Numeric editor +0.000 Xx – A0034250 29 For entering values in parameters (e.g. limit values) Entry display area Input screen Confirm, delete or reject entry Operating elements Text editor...

- Page 73 Proline Promass E 500 PROFIBUS PA Operation options Operating key Meaning Enter key • Pressing the key briefly confirms your selection. • Pressing the key for 2 s confirms your entry. Escape key combination (press keys simultaneously) Close the editing view without accepting a change.

- Page 74 Operation options Proline Promass E 500 PROFIBUS PA 8.3.4 Operating elements Operating key Meaning Minus key In menu, submenu Moves the selection bar upwards in a picklist In wizards Goes to previous parameter In the text and numeric editor Move the entry position to the left.

- Page 75 Proline Promass E 500 PROFIBUS PA Operation options Calling up and closing the context menu The user is in the operational display. 1. Press the and keys for longer than 3 seconds. The context menu opens. XXXXXXXXXX Setup Conf.backup...

- Page 76 Operation options Proline Promass E 500 PROFIBUS PA 8.3.6 Navigating and selecting from list Different operating elements are used to navigate through the operating menu. The navigation path is displayed on the left in the header. Icons are displayed in front of the individual menus.

- Page 77 Proline Promass E 500 PROFIBUS PA Operation options The direct access code consists of a 5-digit number (at maximum) and the channel number, which identifies the channel of a process variable: e.g. 00914-2. In the navigation view, this appears on the right-hand side in the header of the selected parameter.

- Page 78 Operation options Proline Promass E 500 PROFIBUS PA Ent. access code Invalid or out of range input value Min:0 Max:9999 A0014049-EN For a description of the editing view - consisting of the text editor and numeric editor - with symbols → 72, for a description of the operating elements → 74 8.3.10...

- Page 79 Proline Promass E 500 PROFIBUS PA Operation options 2. Enter the access code. The -symbol in front of the parameters disappears; all previously write- protected parameters are now re-enabled. 8.3.12 Enabling and disabling the keypad lock The keypad lock makes it possible to block access to the entire operating menu via local operation.

- Page 80 Operation options Proline Promass E 500 PROFIBUS PA 8.4.2 Requirements Computer hardware Hardware Interface CDI-RJ45 WLAN Interface The computer must have a RJ45 The operating unit must have a WLAN interface. interface. Connection Standard Ethernet cable Connection via Wireless LAN.

- Page 81 Proline Promass E 500 PROFIBUS PA Operation options Measuring device: Via CDI-RJ45 service interface Device CDI-RJ45 service interface Measuring device The measuring device has an RJ45 interface. Web server Web server must be enabled; factory setting: ON For information on enabling the Web server → 85...

- Page 82 Operation options Proline Promass E 500 PROFIBUS PA IP address 192.168.1.XXX; for XXX all numerical sequences except: 0, 212 and 255 → e.g. 192.168.1.213 Subnet mask 255.255.255.0 Default gateway 192.168.1.212 or leave cells empty Via WLAN interface Configuring the Internet protocol of the mobile terminal NOTICE If the WLAN connection is lost during the configuration, settings made may be lost.

- Page 83 Proline Promass E 500 PROFIBUS PA Operation options 2. Enter the IP address of the web server in the address line of the web browser: 192.168.1.212 The login page appears. 2 3 4 Device name: Device tag: Signal Status:...

- Page 84 Operation options Proline Promass E 500 PROFIBUS PA 8.4.5 User interface A0029418 Function row Local display language Navigation area Header The following information appears in the header: • Device name • Device tag • Device status with status signal → 192 •...

- Page 85 Proline Promass E 500 PROFIBUS PA Operation options Navigation area The menus, the associated submenus and parameters can be selected in the navigation area. Working area Depending on the selected function and the related submenus, various actions can be performed in this area: •...

- Page 86 Operation options Proline Promass E 500 PROFIBUS PA 3. If no longer needed: Reset the modified properties of the Internet protocol (TCP/IP) → 81. Access to the operating menu via the operating tool The structure of the operating menu in the operating tools is the same as for operation via the local display.

- Page 87 Proline Promass E 500 PROFIBUS PA Operation options Proline 500 – digital transmitter open press A0029163 33 Connection via service interface (CDI-RJ45) Computer with web browser (e.g. Microsoft Internet Explorer, Microsoft Edge) for accessing the integrated web server or with "FieldCare" operating tool, "DeviceCare" with COM DTM "CDI Communication TCP/IP"...

- Page 88 Operation options Proline Promass E 500 PROFIBUS PA A0034569 Transmitter with integrated WLAN antenna Transmitter with external WLAN antenna LED lit constantly: WLAN reception is enabled on measuring device LED flashing: WLAN connection established between operating unit and measuring device Computer with WLAN interface and web browser (e.g.

- Page 89 FieldCare Function range FDT-based (Field Device Technology) plant asset management tool from Endress+Hauser. It can configure all smart field units in a system and helps you manage them. By using the status information, it is also a simple but effective way of checking their status and condition.

- Page 90 Operation options Proline Promass E 500 PROFIBUS PA Establishing a connection 1. Start FieldCare and launch the project. 2. In the network: Add a device. The Add device window opens. 3. Select the CDI Communication TCP/IP option from the list and press OK to confirm.

- Page 91 DeviceCare Function range Tool for connecting and configuring Endress+Hauser field devices. The fastest way to configure Endress+Hauser field devices is with the dedicated "DeviceCare" tool. Together with the device type managers (DTMs) it presents a convenient, comprehensive solution. Innovation brochure IN01047S Source for device description files →...

- Page 92 System integration Proline Promass E 500 PROFIBUS PA System integration Overview of device description files 9.1.1 Current version data for the device Firmware version 01.01.zz • On the title page of the manual • On the transmitter nameplate • Firmware version Diagnostics →...

- Page 93 Proline Promass E 500 PROFIBUS PA System integration 9.2.1 Manufacturer-specific GSD This GSD guarantees the unrestricted functionality of the measuring device. Device-specific process parameters and functions are therefore available. Manufacturer-specific GSD ID number File name PROFIBUS PA 0x156D EH3x156D.gsd Use manufacturer-specific GSD Assignment is performed in the Ident number selector parameter via the Manufacturer option.

- Page 94 System integration Proline Promass E 500 PROFIBUS PA Compatibility with earlier model If the device is replaced, the measuring device Promass 500 supports the compatibility of the cyclic data with previous models. It is not necessary to adjust the engineering parameters of the PROFIBUS network with the Promass 500 GSD file.

- Page 95 Proline Promass E 500 PROFIBUS PA System integration 2. Set the device address: The same device address that was set for the Promass 80 or Promass 83 PROFIBUS PA must be used. 3. Connect the measuring device Promass 500 PROFIBUS PA.

- Page 96 System integration Proline Promass E 500 PROFIBUS PA Previous model: Promass 83 PROFIBUS PA Control variable Function Support 0 → 2 Positive zero return: ON 0 → 3 Positive zero return: OFF 0 → 4 Zero point adjustment: START 0 → 8...

- Page 97 Proline Promass E 500 PROFIBUS PA System integration Cyclic data transmission Cyclic data transmission when using the device master file (GSD). 9.5.1 Block model The block model shows which input and output data the measuring device makes available for cyclic data exchange. Cyclic data exchange takes place with a PROFIBUS master (Class 1), e.g.

- Page 98 System integration Proline Promass E 500 PROFIBUS PA AI module (Analog Input) Transmit an input variable from the measuring device to the PROFIBUS master (Class 1). The selected input variable including its status is cyclically transmitted to the PROFIBUS master (Class 1) via the AI module. The input variable is depicted in the first four bytes in the form of a floating point number as per the IEEE 754 standard.

- Page 99 Proline Promass E 500 PROFIBUS PA System integration Input variable Alternative GSV flow NSV flow Alternative NSV flow S&W volume flow Water cut percentage Oil density Water density Oil mass flow Water mass flow Oil volume flow Water volume flow...

- Page 100 System integration Proline Promass E 500 PROFIBUS PA Selection: totalizer value Input variable Mass flow Volume flow Corrected volume flow Target fluid mass flow Carrier mass flow Only available with the "Concentration" application package Factory setting Function block Factory setting: TOTAL...

- Page 101 Proline Promass E 500 PROFIBUS PA System integration Input data of TOTAL Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Measured value: floating point number (IEEE 754) Status SETTOT_MODETOT_TOTAL module The module combination consists of the SETTOT, MODETOT and TOTAL functions: •...

- Page 102 System integration Proline Promass E 500 PROFIBUS PA Assigned compensation values A compensation value is permanently assigned to the individual Analog Output blocks. Function block Compensation value AO 1 External pressure AO 2 External temperature AO 3 External reference density AO 4 External S&W percentage...

- Page 103 Proline Promass E 500 PROFIBUS PA System integration Factory setting Function block Factory setting DI 1 Empty pipe detection DI 2 Low flow cut off Data structure Input data of Discrete Input Byte 1 Byte 2 Discrete Status DO module (Discrete Output) Transmit discrete output values from the PROFIBUS master (class 1) to the measuring device.

- Page 104 System integration Proline Promass E 500 PROFIBUS PA Assignment of medium type: function block DO 5 Methanol in water Ammonium nitrate in water Iron(III) chloride in water HFCS42 HFCS55 HFCS90 Original wort % mass / % volume Coef Set No. 1 Coef Set No.

- Page 105 Proline Promass E 500 PROFIBUS PA Commissioning Commissioning 10.1 Post-mounting and post-connection check Before commissioning the device: ‣ Make sure that the post-installation and post-connection checks have been performed successfully. • Checklist for "Post-installation" check→ 34 • Checklist for "Post-connection" check→ 63 10.2...

- Page 106 Commissioning Proline Promass E 500 PROFIBUS PA X X X X X X X 20.50 Main menu 0104-1 Display language English Operation Setup Display language 0104-1 English à Deutsch Español Français Display language 0104-1 à English Deutsch Español Français Hauptmenü...

- Page 107 Proline Promass E 500 PROFIBUS PA Commissioning Navigation "Setup" menu Setup Device tag → 108 ‣ System units → 108 ‣ → 111 Medium selection ‣ Communication → 112 ‣ Analog inputs → 113 ‣...

- Page 108 Commissioning Proline Promass E 500 PROFIBUS PA XXXXXXXXX A0029422 37 Header of the operational display with tag name Tag name Enter the tag name in the "FieldCare" operating tool → 90 Navigation "Setup" menu → Device tag Parameter overview with brief description...

- Page 109 Proline Promass E 500 PROFIBUS PA Commissioning Temperature unit → 110 Pressure unit → 110 Parameter overview with brief description Parameter Description Selection Factory setting Mass flow unit Select mass flow unit. Unit choose list Country-specific: • kg/h Effect •...

- Page 110 Commissioning Proline Promass E 500 PROFIBUS PA Parameter Description Selection Factory setting Temperature unit Select temperature unit. Unit choose list Country-specific: • °C Effect • °F The selected unit applies to: • Electronic temperature parameter (6053) • Maximum value parameter (6051) •...

- Page 111 Proline Promass E 500 PROFIBUS PA Commissioning 10.6.3 Selecting and setting the medium The Select medium wizard submenu contains parameters that must be configured in order to select and set the medium. Navigation "Setup" menu → Medium selection ‣ Medium selection Select medium →...

- Page 112 Commissioning Proline Promass E 500 PROFIBUS PA Parameter Prerequisite Description Selection / User entry / User interface Reference sound velocity In the Select gas type parameter, the Enter sound velocity of gas at 0 °C (32 1 to 99 999.9999 m/s Others option is selected.

- Page 113 Proline Promass E 500 PROFIBUS PA Commissioning 10.6.5 Configuration of the Analog Inputs The Analog inputs submenu guides the user systematically to the individual Analog input 1 to n submenu. From here you get to the parameters of the individual analog input.

- Page 114 Commissioning Proline Promass E 500 PROFIBUS PA Parameter overview with brief description Parameter Prerequisite Description Selection / User entry Channel – Select the process variable. • Mass flow • Volume flow • Corrected volume flow • Density • Reference density • Target mass flow •...

- Page 115 Proline Promass E 500 PROFIBUS PA Commissioning Navigation "Setup" menu → I/O configuration ‣ I/O configuration I/O module 1 to n terminal numbers → 115 I/O module 1 to n information → 115 → 115 I/O module 1 to n type Apply I/O configuration →...

- Page 116 Commissioning Proline Promass E 500 PROFIBUS PA 0/4 mA value → 116 20 mA value → 116 → 116 Current span Failure mode → 116 Failure value → 116 Parameter overview with brief description Parameter...

- Page 117 Proline Promass E 500 PROFIBUS PA Commissioning Active level → 117 Terminal number → 117 → 117 Response time status input Terminal number → 117 Parameter overview with brief description Parameter Description Selection / User interface / User entry Assign status input Select function for the status input.

- Page 118 Commissioning Proline Promass E 500 PROFIBUS PA Damping output 1 to n → 120 Failure mode → 120 → 120 Failure current Parameter overview with brief description Parameter Prerequisite Description User interface / Factory setting Selection / User entry Terminal number –...

- Page 119 Proline Promass E 500 PROFIBUS PA Commissioning Parameter Prerequisite Description User interface / Factory setting Selection / User entry Assign current output 1 to n – Select process variable for • Off – current output. • Mass flow • Volume flow • Corrected volume flow •...

- Page 120 Commissioning Proline Promass E 500 PROFIBUS PA Parameter Prerequisite Description User interface / Factory setting Selection / User entry 0/4 mA value In Current span parameter Enter 4 mA value. Signed floating-point Depends on country: (→ 119), one of the number • 0 kg/h following options is selected: •...

- Page 121 Proline Promass E 500 PROFIBUS PA Commissioning 10.6.10 Configuring the pulse/frequency/switch output The Pulse/frequency/switch output wizard guides you systematically through all the parameters that can be set for configuring the selected output type. Navigation "Setup" menu → Advanced setup → Pulse/frequency/switch output ‣...

- Page 122 Commissioning Proline Promass E 500 PROFIBUS PA Parameter overview with brief description Parameter Prerequisite Description Selection / User Factory setting interface / User entry Operating mode – Define the output as a pulse, • Pulse – frequency or switch output. • Frequency • Switch Terminal number –...

- Page 123 Proline Promass E 500 PROFIBUS PA Commissioning Parameter Prerequisite Description Selection / User Factory setting interface / User entry Failure mode The Pulse option is selected in Define output behavior in • Actual value – the Operating mode alarm condition. • No pulses parameter (→ 121) and a...

- Page 124 Commissioning Proline Promass E 500 PROFIBUS PA Parameter overview with brief description Parameter Prerequisite Description Selection / User Factory setting interface / User entry Operating mode – Define the output as a pulse, • Pulse – frequency or switch output. • Frequency • Switch Terminal number –...

- Page 125 Proline Promass E 500 PROFIBUS PA Commissioning Parameter Prerequisite Description Selection / User Factory setting interface / User entry Assign frequency output The Frequency option is Select process variable for • Off – selected in Operating mode frequency output. • Mass flow parameter (→ 121).

- Page 126 Commissioning Proline Promass E 500 PROFIBUS PA Parameter Prerequisite Description Selection / User Factory setting interface / User entry Maximum frequency value The Frequency option is Enter maximum frequency. 0.0 to 10 000.0 Hz – selected in the Operating mode parameter (→ 121)

- Page 127 Proline Promass E 500 PROFIBUS PA Commissioning Configuring the switch output Navigation "Setup" menu → Pulse/frequency/switch output ‣ Pulse/frequency/switch output 1 to n Operating mode → 127 Terminal number → 127 Signal mode → 127 Switch output function →...

- Page 128 Commissioning Proline Promass E 500 PROFIBUS PA Parameter Prerequisite Description Selection / User Factory setting interface / User entry Switch output function The Switch option is selected Select function for switch • Off – in the Operating mode output. • On parameter. • Diagnostic behavior •...

- Page 129 Proline Promass E 500 PROFIBUS PA Commissioning Parameter Prerequisite Description Selection / User Factory setting interface / User entry Assign flow direction check • The Switch option is Select process variable for flow – selected in the Operating direction monitoring. mode parameter. • The Flow direction check...

- Page 130 Commissioning Proline Promass E 500 PROFIBUS PA Relay output function → 130 Assign flow direction check → 130 → 131 Assign limit Assign diagnostic behavior → 131 Assign status → 131 Switch-off value → 131 →...

- Page 131 Proline Promass E 500 PROFIBUS PA Commissioning Parameter Prerequisite Description User interface / Factory setting Selection / User entry Assign limit The Limit option is selected in Select process variable for limit • Mass flow – Relay output function function. • Volume flow parameter.

- Page 132 Commissioning Proline Promass E 500 PROFIBUS PA Parameter Prerequisite Description User interface / Factory setting Selection / User entry Switch-on delay In the Relay output function Define delay for the switch-on 0.0 to 100.0 s – parameter, the Limit option is of status output.

- Page 133 Proline Promass E 500 PROFIBUS PA Commissioning Parameter overview with brief description Parameter Prerequisite Description Selection / User Factory setting entry Format display A local display is provided. Select how measured values • 1 value, max. size – are shown on the display.

- Page 134 Commissioning Proline Promass E 500 PROFIBUS PA Parameter Prerequisite Description Selection / User Factory setting entry Value 1 display A local display is provided. Select the measured value that • Mass flow – is shown on the local display. • Volume flow •...

- Page 135 Proline Promass E 500 PROFIBUS PA Commissioning Parameter Prerequisite Description Selection / User Factory setting entry • Current output 2 • Current output 3 0% bargraph value 1 A local display is provided. Enter 0% value for bar graph Signed floating-point Country-specific: display.

- Page 136 Commissioning Proline Promass E 500 PROFIBUS PA 10.6.13 Configuring the low flow cut off The Low flow cut off wizard systematically guides the user through all the parameters that must be set to configure low flow cut off. Navigation "Setup" menu → Low flow cut off ‣...

- Page 137 Proline Promass E 500 PROFIBUS PA Commissioning 10.6.14 Configuring partially filled pipe detection The Partial filled pipe detection wizard guides you systematically through all parameters that have to be set for configuring the monitoring of the pipe filling. Navigation "Setup" menu → Partially filled pipe detection ‣...

- Page 138 Commissioning Proline Promass E 500 PROFIBUS PA 10.7 Advanced settings The Advanced setup submenu with its submenus contains parameters for specific settings. Navigation to the "Advanced setup" submenu X X X X X X X 20.50 0104-1 Main menu Display language English Display/operat.

- Page 139 Proline Promass E 500 PROFIBUS PA Commissioning ‣ Totalizer 1 to n → 146 ‣ → 148 Display ‣ WLAN settings ‣ Concentration ‣ Heartbeat setup ‣ Configuration backup → 153 ‣ Administration → 155 10.7.1...

- Page 140 Commissioning Proline Promass E 500 PROFIBUS PA Linear expansion coefficient (1817) → 140 Square expansion coefficient (1818) → 140 Parameter overview with brief description Parameter Prerequisite Description Selection / User Factory setting interface / User entry Corrected volume flow calculation – Select reference density for •...

- Page 141 Proline Promass E 500 PROFIBUS PA Commissioning ‣ Zero verification → 144 ‣ Zero adjustment → 145 Parameter overview with brief description Parameter Description Selection Installation direction Set sign of flow direction to match the direction of the arrow on •...

- Page 142 Commissioning Proline Promass E 500 PROFIBUS PA If the adjustment was completed successfully, the Density adjustment factor parameter and the Density adjustment offset parameter and the values calculated for them are shown on the display. "2 point adjustment" option 1. In the Density adjustment mode parameter, select the 2 point adjustment option and confirm.

- Page 143 Proline Promass E 500 PROFIBUS PA Commissioning Density adjustment factor → 143 Density adjustment offset → 143 Parameter overview with brief description Parameter Prerequisite Description Selection / User Factory setting entry / User interface Density adjustment mode – • 1 point adjustment –...

- Page 144 Commissioning Proline Promass E 500 PROFIBUS PA Zero verification and zero adjustment cannot be performed if the following process conditions are present: • Gas pockets Ensure that the system has been sufficiently flushed with the medium. Repeat flushing can help to eliminate gas pockets •...

- Page 145 Proline Promass E 500 PROFIBUS PA Commissioning Parameter Description Selection / User interface Factory setting Zero point adjustment status • Busy – • Zero point adjust failure • Ok Additional information Indicate whether to display additional • Hide – information. • Show...

- Page 146 Commissioning Proline Promass E 500 PROFIBUS PA Zero point measured → 146 Zero point standard deviation → 146 → 146 Select action Parameter overview with brief description Parameter Description Selection / User interface Factory setting Process conditions Ensure process conditions as follows.

- Page 147 Proline Promass E 500 PROFIBUS PA Commissioning Unit totalizer → 147 Totalizer operation mode → 147 → 147 Control Totalizer 1 to n Failure mode → 147 Parameter overview with brief description Parameter Description Selection Factory setting Assign process variable Select process variable for totalizer.

- Page 148 Commissioning Proline Promass E 500 PROFIBUS PA 10.7.4 Carrying out additional display configurations In the Display submenu you can set all the parameters associated with the configuration of the local display. Navigation "Setup" menu → Advanced setup → Display ‣...

- Page 149 Proline Promass E 500 PROFIBUS PA Commissioning Parameter overview with brief description Parameter Prerequisite Description Selection / User Factory setting entry Format display A local display is provided. Select how measured values • 1 value, max. size – are shown on the display.

- Page 150 Commissioning Proline Promass E 500 PROFIBUS PA Parameter Prerequisite Description Selection / User Factory setting entry Value 1 display A local display is provided. Select the measured value that • Mass flow – is shown on the local display. • Volume flow •...

- Page 151 Proline Promass E 500 PROFIBUS PA Commissioning Parameter Prerequisite Description Selection / User Factory setting entry • Current output 2 • Current output 3 0% bargraph value 1 A local display is provided. Enter 0% value for bar graph Signed floating-point Country-specific: display.

- Page 152 Commissioning Proline Promass E 500 PROFIBUS PA Parameter Prerequisite Description Selection / User Factory setting entry Display language A local display is provided. Set display language. • English English • Deutsch (alternatively, the • Français ordered language is • Español preset in the device) •...

- Page 153 Proline Promass E 500 PROFIBUS PA Commissioning Security type → 153 WLAN passphrase → 153 → 153 Assign SSID name SSID name → 153 Apply changes → 153 Parameter overview with brief description Parameter Prerequisite Description User entry / ...

- Page 154 Commissioning Proline Promass E 500 PROFIBUS PA Navigation "Setup" menu → Advanced setup → Configuration backup ‣ Configuration backup Operating time → 154 Last backup → 154 → 154 Configuration management Backup state → 154 Comparison result →...

- Page 155 Proline Promass E 500 PROFIBUS PA Commissioning Options Description Compare The device configuration saved in the device memory is compared with the current device configuration of the HistoROM backup. Clear backup data The backup copy of the device configuration is deleted from the memory of the device.

- Page 156 Reset access code to factory settings. Character string comprising numbers, letters and special characters For a reset code, contact your Endress+Hauser service organization. The reset code can only be entered via: • Web browser • DeviceCare, FieldCare (via CDI-RJ45 service interface) •...

- Page 157 Proline Promass E 500 PROFIBUS PA Commissioning Navigation "Diagnostics" menu → Simulation ‣ Simulation Assign simulation process variable → 158 Process variable value → 158 → 159 Status input simulation Input signal level → 159 Current input 1 to n simulation →...

- Page 158 Commissioning Proline Promass E 500 PROFIBUS PA Parameter overview with brief description Parameter Prerequisite Description Selection / User entry Assign simulation process variable – Select a process variable for the • Off simulation process that is activated. • Mass flow • Volume flow •...

- Page 159 Proline Promass E 500 PROFIBUS PA Commissioning Parameter Prerequisite Description Selection / User entry Switch output simulation 1 to n In the Operating mode parameter, the Switch the simulation of the switch • Off Switch option is selected. output on and off.

- Page 160 Commissioning Proline Promass E 500 PROFIBUS PA 3. Enter the access code again in the Confirm access code parameter (→ 155) to confirm. The symbol appears in front of all write-protected parameters. • Disabling parameter write protection via access code → 78.

- Page 161 Commissioning Via Web browser, FieldCare, DeviceCare (via CDI-RJ45 service interface), fieldbus You can only obtain a reset code from your local Endress+Hauser service organization. The code must be calculated explicitly for every device. 1. Note down the serial number of the device.

- Page 162 Commissioning Proline Promass E 500 PROFIBUS PA 4. Enable or disable write protection: Setting the write protection (WP) switch on the main electronics module to the ON position enables hardware write protection/setting to OFF (factory setting) disables hardware write protection.

- Page 163 Proline Promass E 500 PROFIBUS PA Operation Operation 11.1 Reading off the device locking status Device active write protection: Locking status parameter Operation → Locking status Function scope of the "Locking status" parameter Options Description None The access authorization displayed in the Access status parameter applies →...

- Page 164 Operation Proline Promass E 500 PROFIBUS PA 11.4.1 "Measured variables" submenu The Measured variables submenu contains all the parameters needed to display the current measured values for each process variable. Navigation "Diagnostics" menu → Measured values → Measured variables ‣...

- Page 165 Proline Promass E 500 PROFIBUS PA Operation GSV flow → 169 → 169 GSV flow alternative NSV flow → 170 NSV flow alternative → 170 Oil CTL → 170 Oil CPL → 170 Oil CTPL →...

- Page 166 Operation Proline Promass E 500 PROFIBUS PA Parameter overview with brief description Parameter Prerequisite Description User interface Factory setting Mass flow – Displays the mass flow that is Signed floating-point – currently measured. number Dependency The unit is taken from: Mass flow unit parameter (→...

- Page 167 Proline Promass E 500 PROFIBUS PA Operation Parameter Prerequisite Description User interface Factory setting Target mass flow With the following conditions: Displays the mass flow that is Signed floating-point – Order code for "Application currently measured for the number package", option ED target medium.

- Page 168 Operation Proline Promass E 500 PROFIBUS PA Parameter Prerequisite Description User interface Factory setting Carrier volume flow With the following conditions: Displays the volume flow Signed floating-point – • Order code for "Application currently measured for the number package", option ED carrier medium.

- Page 169 Proline Promass E 500 PROFIBUS PA Operation Parameter Prerequisite Description User interface Factory setting S&W volume flow For the following order code: Displays the S&W volume flow Signed floating-point – • "Application package", option which is calculated from the number EJ "Petroleum"...

- Page 170 Operation Proline Promass E 500 PROFIBUS PA Parameter Prerequisite Description User interface Factory setting NSV flow For the following order code: Displays the net volume flow Signed floating-point – • "Application package", option which is calculated from the number EJ "Petroleum"...

- Page 171 Proline Promass E 500 PROFIBUS PA Operation Parameter Prerequisite Description User interface Factory setting Water CTL For the following order code: Displays the correction factor Positive floating- – • "Application package", option which represents the effect of point number EJ "Petroleum"...

- Page 172 Operation Proline Promass E 500 PROFIBUS PA Parameter Prerequisite Description User interface Factory setting Water reference density For the following order code: Signed floating-point – • "Application package", option number EJ "Petroleum" • In the Petroleum mode parameter, the Net oil &...

- Page 173 Proline Promass E 500 PROFIBUS PA Operation Parameter Prerequisite Description User interface Factory setting Oil corrected volume flow For the following order code: Displays the currently Signed floating-point – • "Application package", option calculated volume flow of the number EJ "Petroleum"...

- Page 174 Operation Proline Promass E 500 PROFIBUS PA Parameter Prerequisite Description User interface Factory setting Weighted density average For the following order code: Displays the weighted average Signed floating-point – • "Application package", option for the density since the last number EJ "Petroleum"...

- Page 175 Proline Promass E 500 PROFIBUS PA Operation Parameter overview with brief description Parameter Prerequisite Description Selection / User entry / User interface Assign process variable – Select process variable for totalizer. • Mass flow • Volume flow • Corrected volume flow • Target mass flow •...

- Page 176 Operation Proline Promass E 500 PROFIBUS PA Input values of current input The Current input 1 to n submenu contains all the parameters needed to display the current measured values for every current input. Navigation "Diagnostics" menu → Measured values → Input values → Current input 1 to n ‣...

- Page 177 Proline Promass E 500 PROFIBUS PA Operation ‣ Pulse/frequency/switch output → 177 1 to n ‣ Relay output 1 to n → 178 Output values of current output The Value current output submenu contains all the parameters needed to display the current measured values for every current output.

- Page 178 Operation Proline Promass E 500 PROFIBUS PA Parameter overview with brief description Parameter Prerequisite Description User interface Output frequency 1 to n In the Operating mode parameter, the Displays the value currently measured 0.0 to 12 500.0 Hz Frequency option is selected.

- Page 179 Proline Promass E 500 PROFIBUS PA Operation Function range of "Control Totalizer " parameter Options Description Totalize The totalizer is started. Reset + hold The totaling process is stopped and the totalizer is reset to 0. Preset + hold The totaling process is stopped and the totalizer is set to its defined start value from the Preset value 1 to n parameter.

- Page 180 Operation Proline Promass E 500 PROFIBUS PA / ../XXXXXXXX 175.77 40.69 kg/h -100s A0016357 38 Chart of a measured value trend • x-axis: depending on the number of channels selected displays 250 to 1000 measured values of a process variable.

- Page 181 Proline Promass E 500 PROFIBUS PA Operation Parameter overview with brief description Parameter Prerequisite Description Selection / User entry / User interface Assign channel 1 The Extended HistoROM application Assign process variable to logging • Off package is available. channel. • Mass flow •...

- Page 182 Operation Proline Promass E 500 PROFIBUS PA Parameter Prerequisite Description Selection / User entry / User interface Assign channel 3 The Extended HistoROM application Assign a process variable to logging For the picklist, see Assign package is available. channel. channel 1 parameter (→ 181) ...

- Page 183 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostics and troubleshooting 12.1 General troubleshooting For local display Error Possible causes Remedial action Local display is dark, but signal output is within The cable of the display module is not plugged in...

- Page 184 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA For access Fault Possible causes Remedial action Write access to parameters is not possible. Hardware write protection is enabled. Set the write protection switch on the main electronics module to the OFF position →...

- Page 185 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Fault Possible causes Remedial action Operation with FieldCare or DeviceCare via Firewall of the PC or network is blocking Depending on the settings of the firewall used service interface CDI-RJ45 (port 8000) is not communication.

- Page 186 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA 12.2 Diagnostic information via light emitting diodes 12.2.1 Transmitter Proline 500 – digital Different LEDs in the transmitter provide information on the device status. A0029689 Supply voltage Device status Not used...

- Page 187 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Color Meaning Communication Device does not receive any Profibus data. White Device receives Profibus data. Service interface (CDI), Not connected or no connection established. Ethernet Link/Activity Yellow Connected and connection established.

- Page 188 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA 12.2.2 Sensor connection housing Proline 500 – digital Various light emitting diodes (LED) on the ISEM electronics unit (intelligent sensor electronics module) in the sensor connection housing provide information about the device status.

- Page 189 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting 12.3 Diagnostic information on local display 12.3.1 Diagnostic message Faults detected by the self-monitoring system of the measuring device are displayed as a diagnostic message in alternation with the operational display.

- Page 190 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic behavior Symbol Meaning Alarm • Measurement is interrupted. • Signal outputs and totalizers assume the defined alarm condition. • A diagnostic message is generated. Warning • Measurement is resumed. • The signal outputs and totalizers are not affected.

- Page 191 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting 12.3.2 Calling up remedial measures X X X X X X X X X X X X X X 20.50 S801 Supply voltage Menu Diagnostic list Diagnostics 1 S801 Supply voltage...

- Page 192 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA A0031056 Status area with status signal Diagnostic information Remedial measures with service ID In addition, diagnostic events which have occurred can be shown in the Diagnostics menu: • Via parameter → 249 •...

- Page 193 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Xxxxxx/…/…/ Device name: Xxxxxxx Mass flow: kg/h 12.34 Device tag: Xxxxxxx Volume flow: 12.34 m /h ³ Status signal: Function check (C) Xxxxxx Diagnostics 1: C485 Simu... Remedy information: Deactivate... Failure (F)

- Page 194 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA The user is in the Diagnostics menu. 1. Call up the desired parameter. 2. On the right in the working area, mouse over the parameter. A tool tip with remedy information for the diagnostic event appears.

- Page 195 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Coding Measuring value (hex) Byte 5 Quality Quality Substatus Limits A0032228-EN 40 Structure of the coding byte The content of the coding byte depends on the configured failure mode in the individual function block.

- Page 196 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information pertaining to the electronics: diagnostic number 200 to 399 Diagnostic number 200 to 301, 303 to 399 Measured value status (fixed assignment) Diagnostic behavior Device diagnostics Quality Coding Category...

- Page 197 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Measured value status (fixed assignment) Diagnostic behavior Device diagnosis Quality Coding Category (configurable) (fixed assignment) Quality Substatus (hex) (NE107) Logbook entry only GOOD 0x80 to 0x8E – – 12.7 Overview of diagnostic information •...

- Page 198 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 046 Sensor limit exceeded 1. Inspect sensor 2. Check process condition Measured variable status [from the factory] Quality Good Quality substatus Maintenance demanded Coding (hex)

- Page 199 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 062 Sensor connection faulty 1. Check or replace sensor electronic module (ISEM) 2. If available: Check connection cable between sensor and transmitter Measured variable status 3.

- Page 200 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 063 Exciter current faulty 1. Check or replace sensor electronic module (ISEM) 2. If available: Check connection cable between sensor and transmitter Measured variable status 3.

- Page 201 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 082 Data storage 1. Check module connections 2. Contact service Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal...

- Page 202 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 083 Memory content 1. Restart device 2. Restore HistoROM S-DAT backup (' D evice reset' parameter) Measured variable status 3. Replace HistoROM S-DAT Quality Quality substatus...

- Page 203 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 140 Sensor signal asymmetrical 1. Check or replace sensor electronic module (ISEM) 2. If available: Check connection cable between sensor and transmitter Measured variable status [from the factory] 3.

- Page 204 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 144 Measuring error too high 1. Check or change sensor 2. Check process conditions Measured variable status [from the factory] Quality Quality substatus Maintenance alarm...

- Page 205 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting 12.7.2 Diagnostic of electronic Diagnostic information Remedy instructions Short text 201 Device failure 1. Restart device 2. Contact service Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27...

- Page 206 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 242 Software incompatible 1. Check software 2. Flash or change main electronics module Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27...

- Page 207 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 252 Modules incompatible 1. Check electronic modules 2. Check if correct modules are available (e.g. NEx, Ex) Measured variable status 3. Replace electronic modules Quality...

- Page 208 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 262 Sensor electronic connection faulty 1. Check or replace connection cable between sensor electronic module (ISEM) and main electronics Measured variable status 2. Check or replace ISEM or main electronics...

- Page 209 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 270 Main electronic failure Change main electronic module Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal Diagnostic behavior...

- Page 210 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 271 Main electronic failure 1. Restart device 2. Change main electronic module Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27...

- Page 211 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 272 Main electronic failure 1. Restart device 2. Contact service Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal...

- Page 212 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 273 Main electronic failure Change electronic Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal Diagnostic behavior Alarm Influenced measured variables •...

- Page 213 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 276 I/O module 1 to n faulty 1. Restart device 2. Change I/O module Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27...

- Page 214 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 302 Device verification active Device verification active, please wait. Measured variable status [from the factory] Quality Good Quality substatus Function check Coding (hex) 0xBC to 0xBF...

- Page 215 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 311 Electronic failure 1. Do not reset device 2. Contact service Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal...

- Page 216 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 332 Writing in HistoROM backup failed Replace user interface board Ex d/XP: replace transmitter Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27...

- Page 217 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 372 Sensor electronic (ISEM) faulty 1. Restart device 2. Check if failure recurs Measured variable status 3. Replace sensor electronic module (ISEM) Quality Quality substatus...

- Page 218 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 373 Sensor electronic (ISEM) faulty 1. Transfer data or reset device 2. Contact service Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27...

- Page 219 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 375 I/O- 1 to n communication failed 1. Restart device 2. Check if failure recurs Measured variable status 3. Replace module rack inclusive electronic modules...

- Page 220 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 382 Data storage 1. Insert T-DAT 2. Replace T-DAT Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal Diagnostic behavior...

- Page 221 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 383 Memory content 1. Restart device 2. Delete T-DAT via ' R eset device' parameter Measured variable status 3. Replace T-DAT Quality Quality substatus Maintenance alarm...

- Page 222 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 387 HistoROM backup failed Contact service organization Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal Diagnostic behavior Alarm Influenced measured variables •...

- Page 223 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 331 Firmware update failed 1. Update firmware of device 2. Restart device Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27...

- Page 224 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 410 Data transfer 1. Check connection 2. Retry data transfer Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal...

- Page 225 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 412 Processing download Download active, please wait Measured variable status Quality Uncertain Quality substatus Initial value Coding (hex) 0x4C to 0x4F Status signal Diagnostic behavior...

- Page 226 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 437 Configuration incompatible 1. Restart device 2. Contact service Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal Diagnostic behavior...

- Page 227 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 438 Dataset 1. Check data set file 2. Check device configuration Measured variable status 3. Up- and download new configuration Quality Uncertain Quality substatus Maintenance demanded...

- Page 228 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 442 Frequency output 1 to n 1. Check process 2. Check frequency output settings Measured variable status [from the factory] Quality Good Quality substatus Function check...

- Page 229 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 453 Flow override Deactivate flow override Measured variable status Quality Good Quality substatus Function check Coding (hex) 0xBC to 0xBF Status signal Diagnostic behavior Warning Influenced measured variables •...

- Page 230 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 482 FB not Auto/Cas Set Block in AUTO mode Measured variable status Quality Good Quality substatus Coding (hex) 0x80 to 0x83 Status signal Diagnostic behavior...

- Page 231 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 485 Measured variable simulation Deactivate simulation Measured variable status Quality Good Quality substatus Function check Coding (hex) 0xBC to 0xBF Status signal Diagnostic behavior Warning Influenced measured variables •...

- Page 232 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 491 Current output 1 to n simulation Deactivate simulation Measured variable status Quality Good Quality substatus Function check Coding (hex) 0xBC to 0xBF Status signal...

- Page 233 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 494 Switch output simulation 1 to n Deactivate simulation switch output Measured variable status Quality Good Quality substatus Function check Coding (hex) 0xBC to 0xBF...

- Page 234 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 497 Simulation block output Deactivate simulation Measured variable status Quality Good Quality substatus Coding (hex) 0x80 to 0x83 Status signal Diagnostic behavior Warning Influenced measured variables –...

- Page 235 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 529 Concentration settings faulty 1. Check concentration settings 2. Check input values e.g. pressure, temperature Measured variable status Quality Quality substatus Function check Coding (hex)

- Page 236 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA 12.7.4 Diagnostic of process Diagnostic information Remedy instructions Short text 803 Current loop 1. Check wiring 2. Change I/O module Measured variable status Quality Quality substatus Process related Coding (hex) 0x28 to 0x2B...

- Page 237 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 831 Sensor temperature too low Increase ambient temp. around the sensor housing Measured variable status [from the factory] Quality Uncertain Quality substatus Process related Coding (hex)

- Page 238 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 832 Electronic temperature too high Reduce ambient temperature Measured variable status [from the factory] Quality Quality substatus Process related Coding (hex) 0x28 to 0x2B Status signal...

- Page 239 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 833 Electronic temperature too low Increase ambient temperature Measured variable status [from the factory] Quality Quality substatus Process related Coding (hex) 0x28 to 0x2B Status signal...

- Page 240 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 834 Process temperature too high Reduce process temperature Measured variable status [from the factory] Quality Uncertain Quality substatus Process related Coding (hex) 0x78 to 0x7B...

- Page 241 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 835 Process temperature too low Increase process temperature Measured variable status [from the factory] Quality Uncertain Quality substatus Process related Coding (hex) 0x78 to 0x7B...

- Page 242 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 842 Process limit Low flow cut off active! 1. Check low flow cut off configuration Measured variable status [from the factory] Quality Uncertain Quality substatus...

- Page 243 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 882 Input signal 1. Check input configuration 2. Check external device or process conditions Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27...

- Page 244 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 910 Tubes not oscillating 1. Check electronic 2. Inspect sensor Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal...

- Page 245 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 912 Medium inhomogeneous 1. Check process cond. 2. Increase system pressure Measured variable status [from the factory] Quality Uncertain Quality substatus Process related Coding (hex)

- Page 246 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 913 Medium unsuitable 1. Check process conditions 2. Check electronic modules or sensor Measured variable status [from the factory] Quality Uncertain Quality substatus Process related...

- Page 247 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 942 API density out of specification 1. Check process density with selected API commodity group 2. Check API related parameters Measured variable status Quality Quality substatus...

- Page 248 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Diagnostic information Remedy instructions Short text 944 Monitoring failed Check process conditions for Heartbeat Monitoring Measured variable status [from the factory] Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27...

- Page 249 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting 12.8 Pending diagnostic events The Diagnostics menu allows the user to view the current diagnostic event and the previous diagnostic event separately. To call up the measures to rectify a diagnostic event: •...

- Page 250 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA / ../Diagnose list Diagnostics F273 Main electronic Diagnostics 2 Diagnostics 3 A0014006-EN 41 Using the example of the local display To call up the measures to rectify a diagnostic event: •...

- Page 251 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting 12.10.2 Filtering the event logbook Using the Filter options parameter you can define which category of event message is displayed in the Events list submenu. Navigation path Diagnostics → Event logbook → Filter options Filter categories •...

- Page 252 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Info number Info name I1451 Monitoring on I1457 Measured error verification failed I1459 I/O module verification failed I1460 HBSI verification failed I1461 Sensor verification failed I1462 Sensor electronic module verific. failed...

- Page 253 Proline Promass E 500 PROFIBUS PA Diagnostics and troubleshooting Options Description Restart device The restart resets every parameter with data stored in volatile memory (RAM) to the factory setting (e.g. measured value data). The device configuration remains unchanged. Restore S-DAT backup Restores the data that is saved on the S-DAT.

- Page 254 Diagnostics and troubleshooting Proline Promass E 500 PROFIBUS PA Parameter Description User interface Factory setting Firmware version Shows the device firmware version installed. Character string in the format – xx.yy.zz Device name Shows the name of the transmitter. Promass 300/500 –...

- Page 255 "Manufacturer' s information" document. The manufacturer' s information is available: • In the Download Area of the Endress+Hauser web site: www.endress.com → Downloads • Specify the following details: •...

- Page 256 • Observe the maximum permitted medium temperature for the measuring device . 13.2 Measuring and test equipment Endress+Hauser offers a variety of measuring and testing equipment, such as Netilion or device tests. Your Endress+Hauser Sales Center can provide detailed information on the services.