Advertisement

Quick Links

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Hyundai 10ELOP

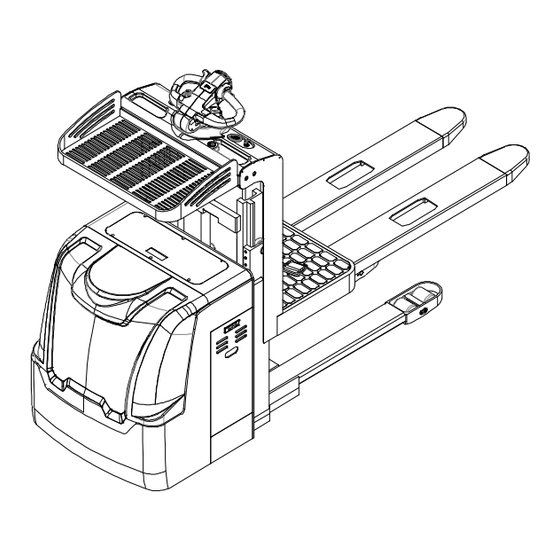

- Page 1 10ELOP Low Order Picker Operation Manual...

- Page 2 According to ISO 3691 “Safety Specification of Motor Industrial Vehicles”, load capacity and lifting height of our 10ELOP Low Order Picker are stipulated as follows: 1.——When the lifting height of 10ELOP is below 750mm (including 750mm), the maximum load capacity is the rated capacity. Overloading is prohibited.

- Page 3 Brief introduction : 10ELOP Low Order Picker adopts storage batteries as the dynamic source and a AC motor as the driving force, traveling through gear transmission. The lifting of the fork relies on the DC motor and the hydraulic transmission system. The up-and-down movement of the oil cylinders lifts the fork and the goods. As the traveling and lifting of the stacker are electrically driven, it possesses the characteristics of energy saving, high efficiency, stable operation, easy operation, safety and reliability, low noise and no pollution, etc.This stacker...

- Page 4 Description: he instruction manual shall be kept by the operator, and shall be read by the operator until he gets a full understanding. The instruction manual is composed of correct operation, convenient and simple maintenance, and routine inspection. The instruction manual shall be carefully read before operation, for purpose of correct drive and suitable maintenance to ensure safe and effective material transportation.

- Page 5 1. Outline drawing outline drawing 10ELOP...

- Page 6 1.2 Main technical parameter Technical parameter of 10ELOP low order picker Manufacturer(abbreviated) HYUNDAI 10ELOP Model Driving model:Electric(Storage battery), Electric (battery) diesel, gasoline, fuel gas Driving model(Manual, Walking, Stand driving, Seat standing driving ,Order picking) Rated load Q(kg) 1000 Load center distance...

- Page 7 2. Brief introduction of structure (See also the structure diagram and the principle diagram of the major parts) The stacker mainly consists of frame, mast, fork, lifting oil cylinder, operation handle, steering device, driving wheel, storage battery pack, hydraulic power unit and control system for electrical equipment, etc. 3.

- Page 8 Notice Even though each electric pallet stacker may have the same technical parameters, there may be differences on features of braking and acceleration as well. Never drive the truck until you get familiar with all those operations. ⑵ Wear of the driver during truck driving: Notice Please put on safety shoes and protective clothes.

- Page 9 maintenance handbooks. Only in the event that the truck manufacturer is no longer in business and there is no successor in the interest to the business, the user may arrange for a modification or alteration to a powered industrial truck, provided, however, that the user shall: a) arrange for the modification or alteration to be designed, tested and implemented by an engineer(s) expert in industrial trucks and their safety;...

- Page 10 Notice If the driver’s view is shielded by the bulky goods carried, please drive backwards or drive under the guidance of other working personnel. Notice Ensure no people around the truck when driving backwards. Notice Driving through the narrow access shall be guided by working personnel. Notice At crossroad or other places impeditive for view, the driver shall not drive until there is no person at both sides.

- Page 11 when travel by other truck or vehicles. Avoid driving in places with bad view. Notice Ensure to provide certain clearance between truck and entrance. Never drive too close to roadside: (3) Notice Ensure to provide enough distance between the truck and roadside or platform edge.

- Page 12 overtaking are forbidden at dangerous places or where view is impeded except accidents. It is forbidden hold body or hands out of the driving cabin. 11) Driver’s view during operation: The driver’s view must keep in the traveling direction of the stacker and pay attention to the condition on driving roads at all times.

- Page 13 4.Initial operation 4.1 Initial operation: 4.1.1 In case of dangerous conditions, the power can be cut off, and the battery plug (not included in the delivery) must be connected to the emergency parking plug of the stacker itself. 4.1.2 The stacker can only be driven by the battery power, but without rectified AC current which may damage the electric parts of the truck.

- Page 14 5.1.3 Check if the truck brake is normal. Check the lifting, dropping, forward and backward traveling of the truck to see if the actions are normal. Check if the emergency reverse action of the truck is normal with the method indicated in Fig.II: Emergency reverse button Slow button Speed acceleration button...

- Page 15 Notice Please check the following items before operation of the stacker: Ensure no goods falling and goods damaged at loading and unloading area. Ensure no goods or objects impeding for safety. As indicated in Fig. II, pull out the general power supply switch, unlock the electric door lock, and drive the stacker to the goods pile nearby.

- Page 16 to avoid injuring the operator. 5.4 After operation Park the truck in a usual parking space after use and carry out routine maintenance according to the matters specified in Article 6. And charge the truck. 6.Use, maintenance and charge of the storage battery Charging operation methods: This stacker is equipped with a fixed charger.

- Page 17 6. 1. 6 Fully charged basis: When the voltage during the second stage charging reaches 31.2V (12 × 2.6V = 31.2V), the variation of the voltage is no greater than 0.005 (V); the density of the electrolytic solution reaches 1.280 ± 0.005 (25℃), no obvious variation in 2 hours and there are fine air bubbles appear violently, it can be deemed that the batteries are fully charged.

- Page 18 a. No direct sunshine on the batteries and at least 2m away from heat source. b. Avoid contacting with any harmful substances. No metallic matters are allowed to drop into the batteries. c. The batteries should not be placed upright down and should not be impacted mechanically or heavily compressed.

- Page 19 7.1 Check point and check content: Check point Check content When the operation handle is turned, with the Operation handle handle switching between area A and B, there is Braking a noise from the brake. system The clearance between brakes should be kept Brake clearance between 0.2mm and 0.8mm.

- Page 20 Notice All the repair work shall be carried out by professional personnel. Please contact the sales department of our company if you need to adjust or replace the components. 9.1 Precautions during maintenance: Notice The components for replacement shall be produced completely by our company.

- Page 21 pot with storage battery electrolyte inside is raised using plastic funnel, and the electrolyte is poured into the storage battery in a slow way until the liquid level can be seen. After all the storage battery is filled, conduct initial charge to the storage battery timely according to the operation requirements of initial charge 5.1 9.3 Daily inspection Inspection of hydraulic oil level: lower the fork to the lowest position, and oil charge is 12L.

- Page 22 system, The clearance between brakes should be kept Brake clearance hydraulic between 0.2mm and 0.8mm. system and Operation handle Degree of tightness and rotary flexibility. lifting Function ,and check cracks, lubrication and Truck frame system fastener tightness of fasteners. Connecting rod and Function and check the cracks, bending, wheel carrier deformation and lubrication condition.

- Page 23 2. Then adjust the length of the adjustment screws 1 and screw down the tightening screws. After the adjustment, the clearance between brake plate and magnetic steel shall be kept between 0.2-03mm. During the adjustment, make sure that the three tightening screws are adjusted evenly so as to ensure that the clearance between brake plate and magnetic steel are distributed around equally.

- Page 24 Hydraulic oil: HLPISOVG32, in accordance with standard DIN51524T.2, the average sustained temperature is below 60 degrees. D. At the occasion with variable loading, we advise: All the working conditions mentioned above can use the hydraulic oil LHPISOVG46 in accordance with standard DIN51524T.2 for replacement.

- Page 25 timber to lift the driving wheels of truck from the ground. The two front wheels of truck shall be fixed stably by sphenoid wood block. Fasten the truck to transport vehicle with ropes. 10.3 Loading and unloading: Before loading the truck, check out the nameplate for the total weight of truck to choose appropriate hoisting handling equipment.

- Page 26 contact at the wire end. Bad contact. Repair or replace ④ ⑤ There is a trouble at the MOSFET Repair or replace tube type circuit board. ①The contactor is in poor connection The stacker can only Repair or replace or burnt out. move forward ②...

- Page 27 ⑧ Damaged oil pump Repair or replace ⑨ Damaged lifting button Repair or replace ⑩ The electric lock is not unlocked or Repair or replace is damaged. ○ 11Seriously insufficient voltage in the Recharge cell. ① The internal mast is overloaded and Repair or replace deformed ②...

- Page 28 2 Press lifting operation button to measure the system pressure. The stipulated system pressure is 16Mpa for truck with rated load of 1500KG and 16.5 Mpa for truck with rated load of 2000KG. 3 If oil pressure is not in accordance with the specified value, please loosen locknuts of the overflow valves. Turn pressure screw left and right until the pressure reaches the specified value.

- Page 29 KSI,INTERLOCK. 2 Wrong HPD type selected. 3 Accelerator malfunction 4 Key switch and INTERLOCK power-off. 5 Sequencing delay too short. 6 Wrong accelerator type selected. Accelerator voltage is too 2,4 Throttle Wiper Low 1 Accelerator is damaged. low. 2 Wrong accelerator type selected. 3,1 Multiplexer Fault Multiplexer malfunction...

- Page 30 15.Structure diagram (exploded view) and principle diagram of the major parts See attached diagram I for “The principle diagram of hydraulic system” See Electric Instructions for “Instruction of the electric system” 16.Packing list 10ELOP Packing list of low order picker Consignee: Ex-work No.: Contract No.: Ex-work Date:...

- Page 31 Note: 1. The following documents are in the file bag: ①Operation manual of Electric Pallet Stacker 1 volume ②Packing list 1 copy ③Qualification certificate 1 copy 2.Accessories and spare parts Type & Name Use position Q’ty Remarks specification Unlock the Key to the electric lock electric lock Electric...

- Page 32 Hydraulic Schematic Diagram...

- Page 33 Electrical Schematic diagram...

- Page 34 Appendix 1 ISO3691 Powered industrial trucks—Safety code The Second Part Safety Code of motor industrial trucks in service, operation and maintenance Safety rules for the user and driver In order to use the motor industrial truck well, this part set up some rules. The 14.1 is applied to the user, the 14.2 is for the driver.

- Page 35 14.1.4.2 Stability The user should pay attention to section 6 of the code, which is about the stability of the truck in the working conditions. When operating correctly, the high lift truck accord with the section 6 is steady, but the incorrect operating or the wrong maintenance could let the truck working unsteadily.

- Page 36 orientation and fixation correctly. Do not put tools and other metal substance on the lidless battery. Without the special approval (for example the truck factory), the electrical motor truck should not change the battery with different voltage, weight or size. It is obliged to use the battery stated by the factory.

- Page 37 On the both sides of the gangplank or transition board, should mounted the facility to prevent the truck from going over it’s edge. When the gangplank or transition board is fixed its location, should adopt measures to prevent the reverse joint truck from moving suddenly. 14.1.5.3 Lighting When the photometric brightness on the operating field is less than 32LX, the vehicle should equipped auxiliary light.

- Page 38 The driver should pay special attention to the operating circumstance, including the person nearby other staves and fixed or moving substances, and it is necessary to watch out for the passerby at any moment. No matter whether there is load on the lifting part of the truck, it is forbidden anyone passing or standing under the lifting part of the truck.

- Page 39 Or if using reach truck, extense the fork and descend it to unload the goods. After lifting, start the vehicle, no matter with or without load, it is necessary to operate the brake carefully and placidly. It is necessary to ensure that the stacking is firm. After stacking, draw off the fork, and lower the fork to the operating height.

- Page 40 In crossroads and the occasion that would obstruct the driver’s sight or some dangerous occasion, the truck must not exceed other truck moving at the same direction. The driver must avoid the truck rolling over some fluffy object in order to avoid article damages or personnel hurts.

- Page 41 that the floor board can endure all the weight of the industry vehicle, load and the driver. Besides, it is required to check the plank to see if there are crashes, holes or other damages. When the industry truck works on high place or platform, it is forbidden to move other truck by industry truck.

- Page 42 The open flame and smoking is forbidden during refueling. 14.2.4.2.1 Liquid fuel (for example gasoline and diesel fuel) The truck using liquid fuel should add fuel in the appointed places. Before take away the refueling equipment, cover the filler cap and clear up the excessive fuel, the engine could not start up.

- Page 43 Without approval, the battery of different voltage, weight or size could not replace the former one in the vehicle. When reinstalling the battery, the battery should be put on the correct place. Inspecting the liquid surface in the battery using open fire is forbidden. When getting the solvent in the acid carboy, the acid carboy tilting device or siphon pipe could be used.

- Page 44 A) Dent, scuffing, flute; B) Damage of various valves or lever meters; C) Scraps in emergency valve; D) Damage or loss of emergency valve bonnet; E) Leakage at connection of valve and thread; F) Deterioration, damage, or loss of flexible seal at connections of gas filling or gas supply. In case of occurrence of any defective or damage as above mentioned, no container would be allowed to be used before repair.

- Page 45 Customer advisement feedback Occurrence Location of Items Faults causes Trouble-shooting Remarks time faults...

Need help?

Do you have a question about the 10ELOP and is the answer not in the manual?

Questions and answers